DCE review

1/58

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

59 Terms

What are bubble caps used for?

To prevent flooding, when low vapour flowrates are desired.

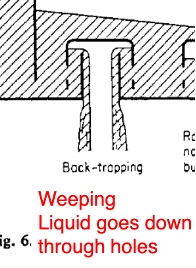

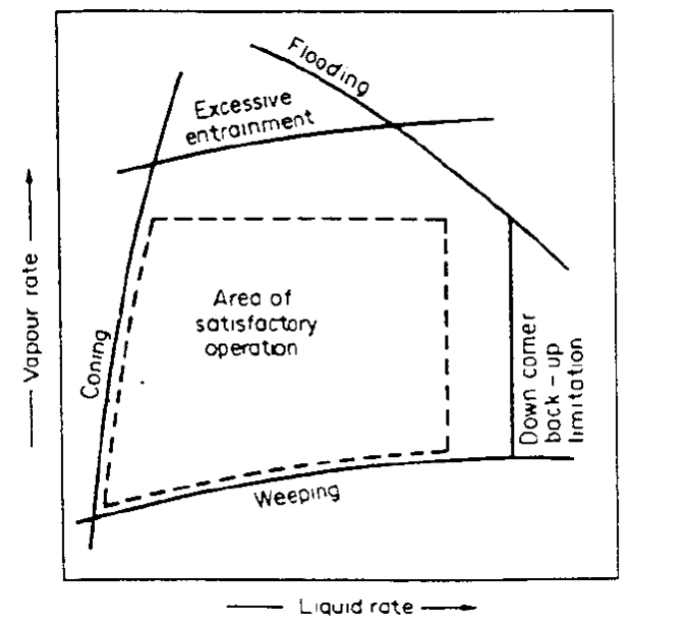

What is weeping? What causes it?

Weeping is when liquid drips through plate holes

Caused by too low vapour flowrate (+low liquid surface tension)

What is flooding? What causes it?

Flooding is when liquid backs up in downcomers and fills up the column.

It is caused by too high a pressure drop resulting from liquid and/or vapour flowrates which are high-very high.

What is entrainment? What causes it?

Entrainment is when droplets of liquid are transported in the vapour stream exiting at the top of the column

It occurs when vapour flowrates are too high. Including extra space for vapour-liquid disengagement helps prevent entrainment.

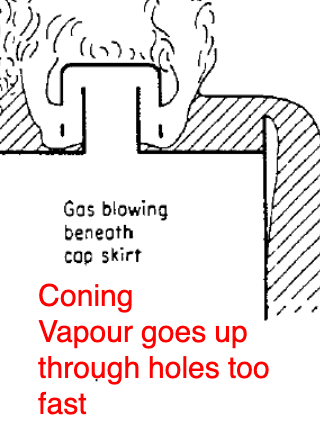

What is coning? What causes it?

Coning is when vapour pushes through the liquid without bubbling through it, preventing sufficient vapour-liquid contact

It is caused by low liquid flowrates.

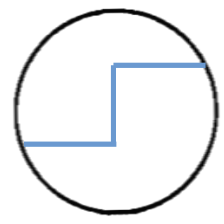

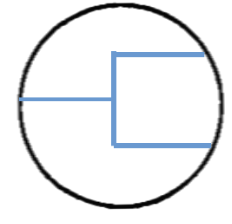

Sketch the ideal operation zone of distillation column based on liquid rate and vapour rate

What are valve trays used for?

To prevent flooding when low vapour flowrates / high turn down ratios are desired. Similar to bubble caps, but with moving pieces.

Researching it, it seems like valve trays are just better at everything.

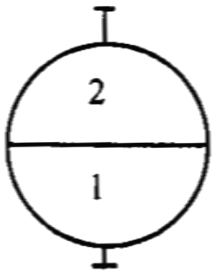

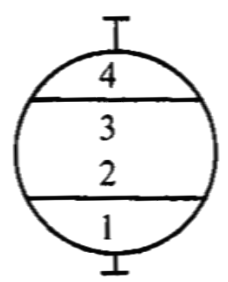

Single pass plate

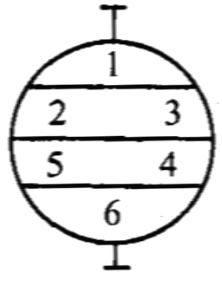

Reverse flow plate

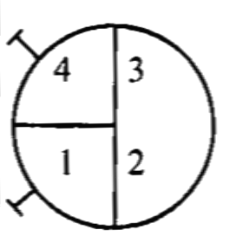

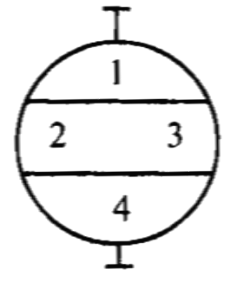

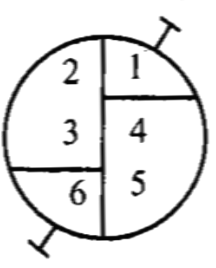

Double pass plate

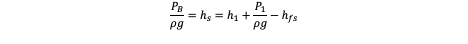

Available Net Positive Suction Head formula

Apparent pressure at pump entry point (PB)

What is the point of NPSHr?

To account for the fact that pressure drop within the pump may occur before pressure is increased

How to use Bernoulli equation to create system curve

Treat Q as a variable

Evaluate all terms in the EBE as constants or functions of Q

Eventually you will get hp=aQ²+bQ+c

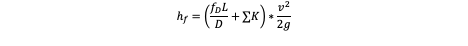

Friction head equation

Friction factor equation

Procedure for when a question says that the amount of component a in the gas stream drops by b%

(100-a)/100 * b in = b out

(100-a)/100 * G (mol/t) * y1(molfrac) = Gs(mol/t) * Y2 (mol ratio)

Gs (mol/t) = G (mol/t) * (1-y1)

(100-a)/100 * Gs (mol/t) * Y1(mol ratio) = Gs(mol/t) * Y2 (mol ratio)

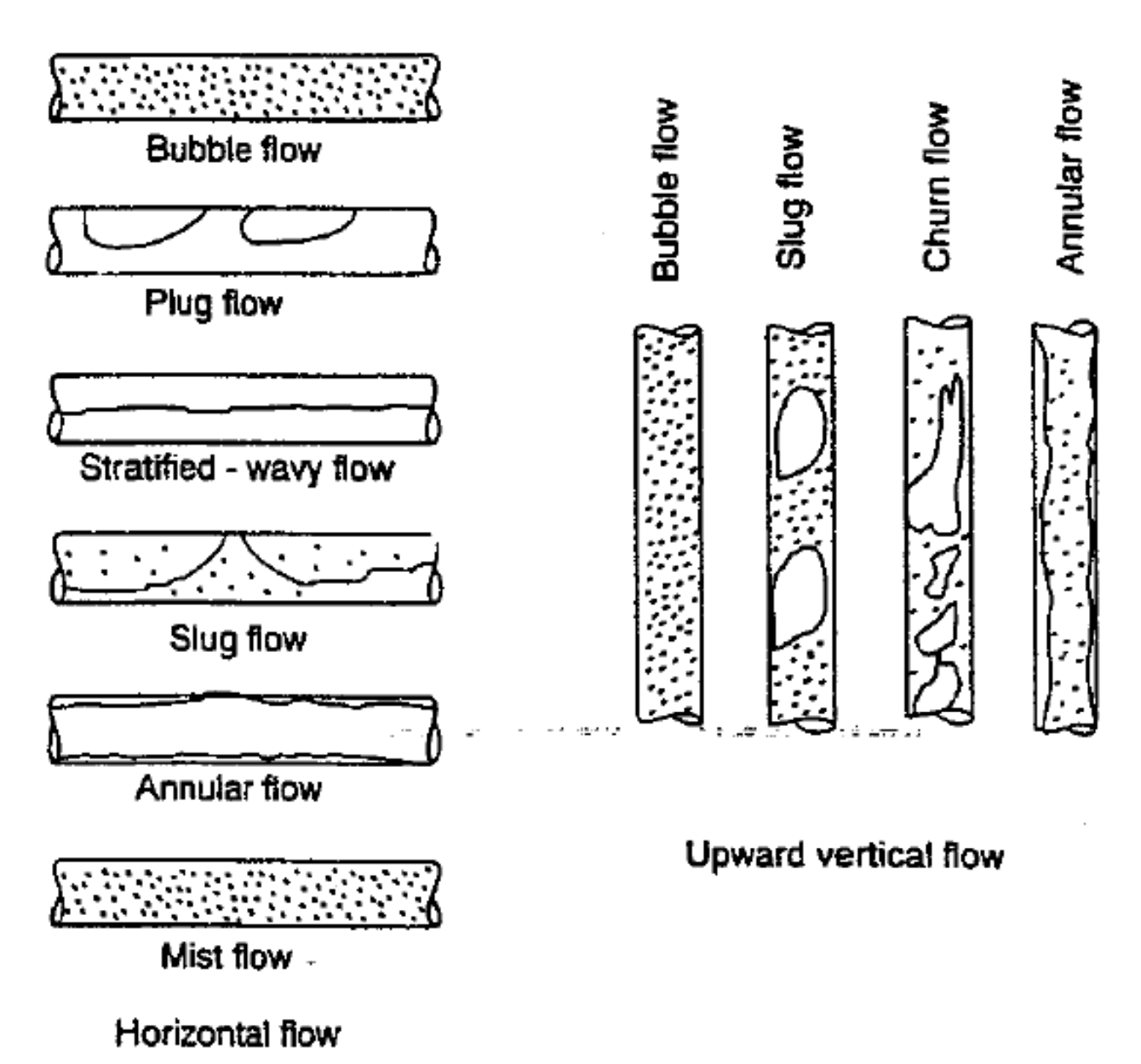

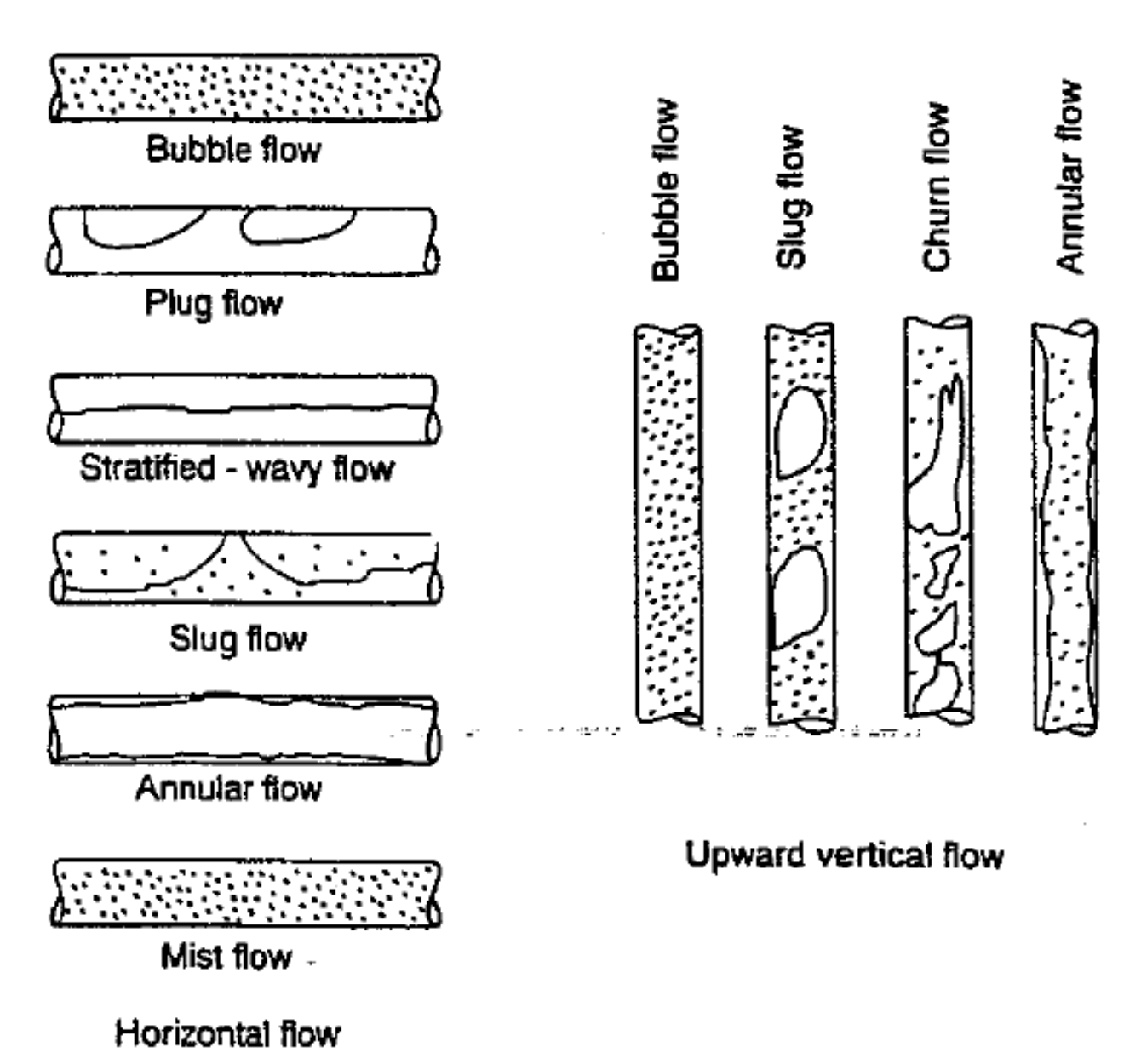

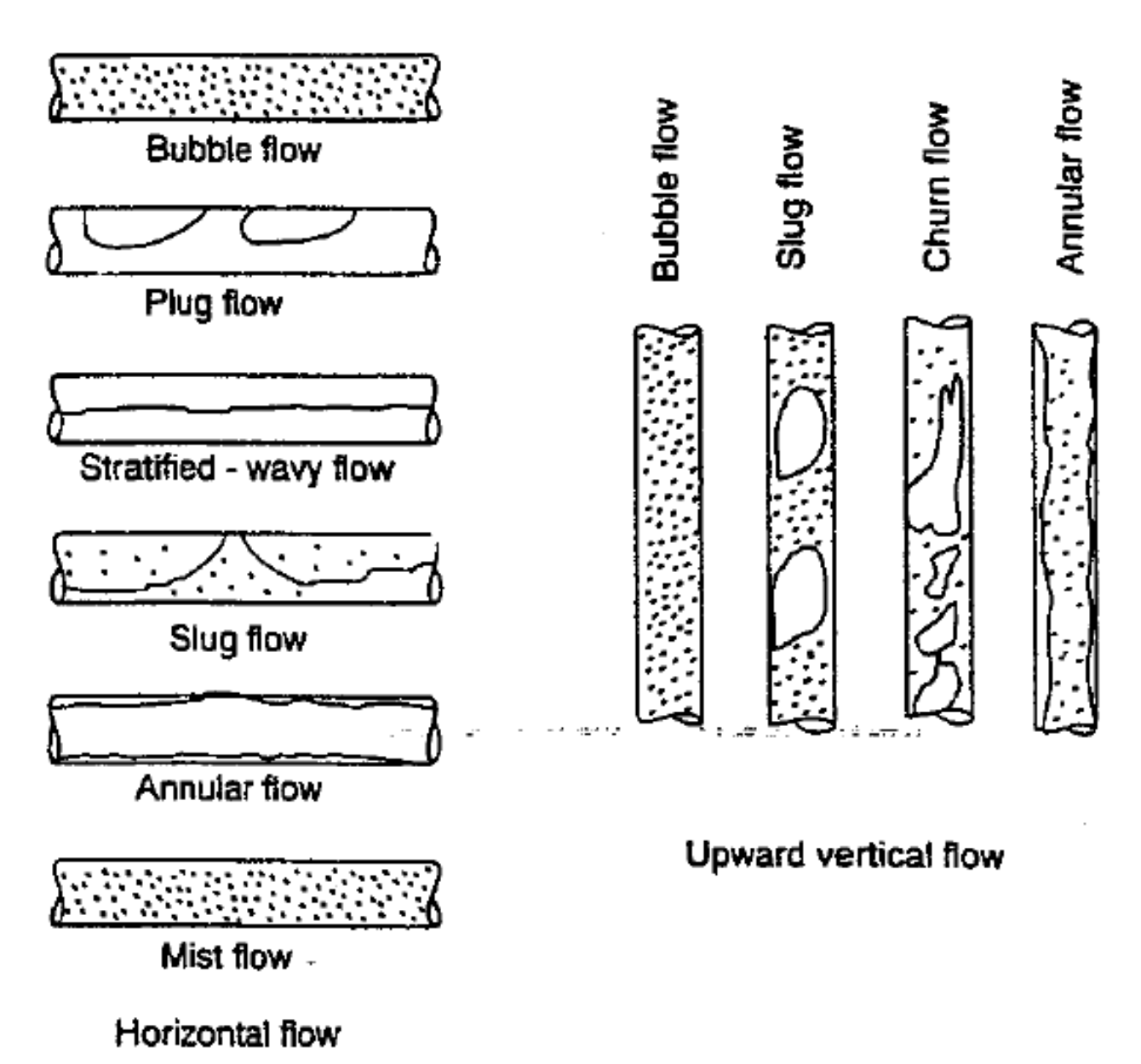

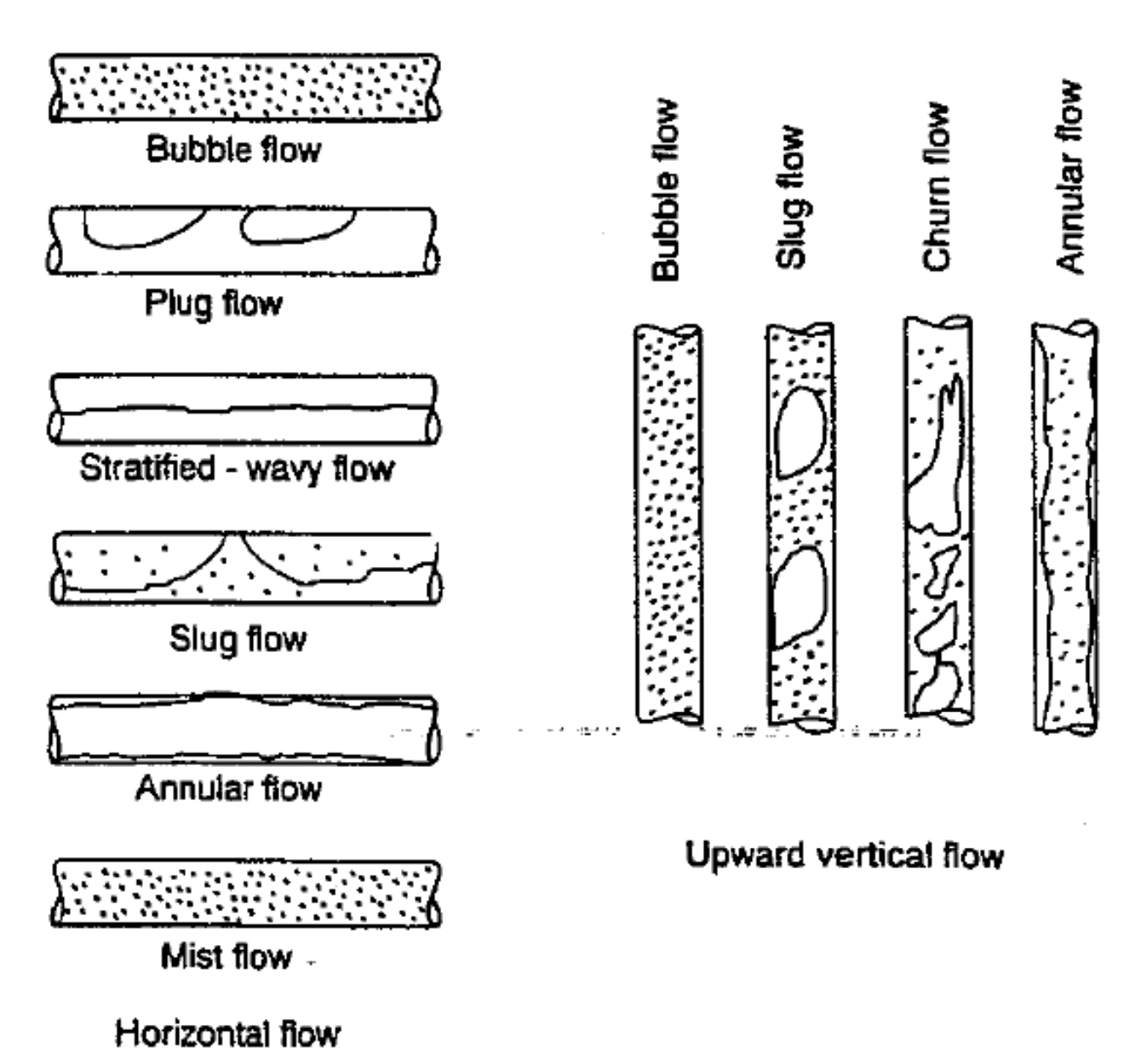

What type of flow in compressors should be avoided and why

Slug flow, because it is not energy efficient

What type of multi-phase flow involves a continuous liquid phase and small dispersed pockets of gas

Bubble flow

What type of flow involves separate liquid and gas flows

Stratified flow

What type of flow involves a ring of liquid with a central flow of gas

Annular flow

What type of flow involves small pockets of gas forming at the top of the pipe?

Plug flow

What type of flow involves large pockets of gas forming at the top of the pipe?

Slug flow

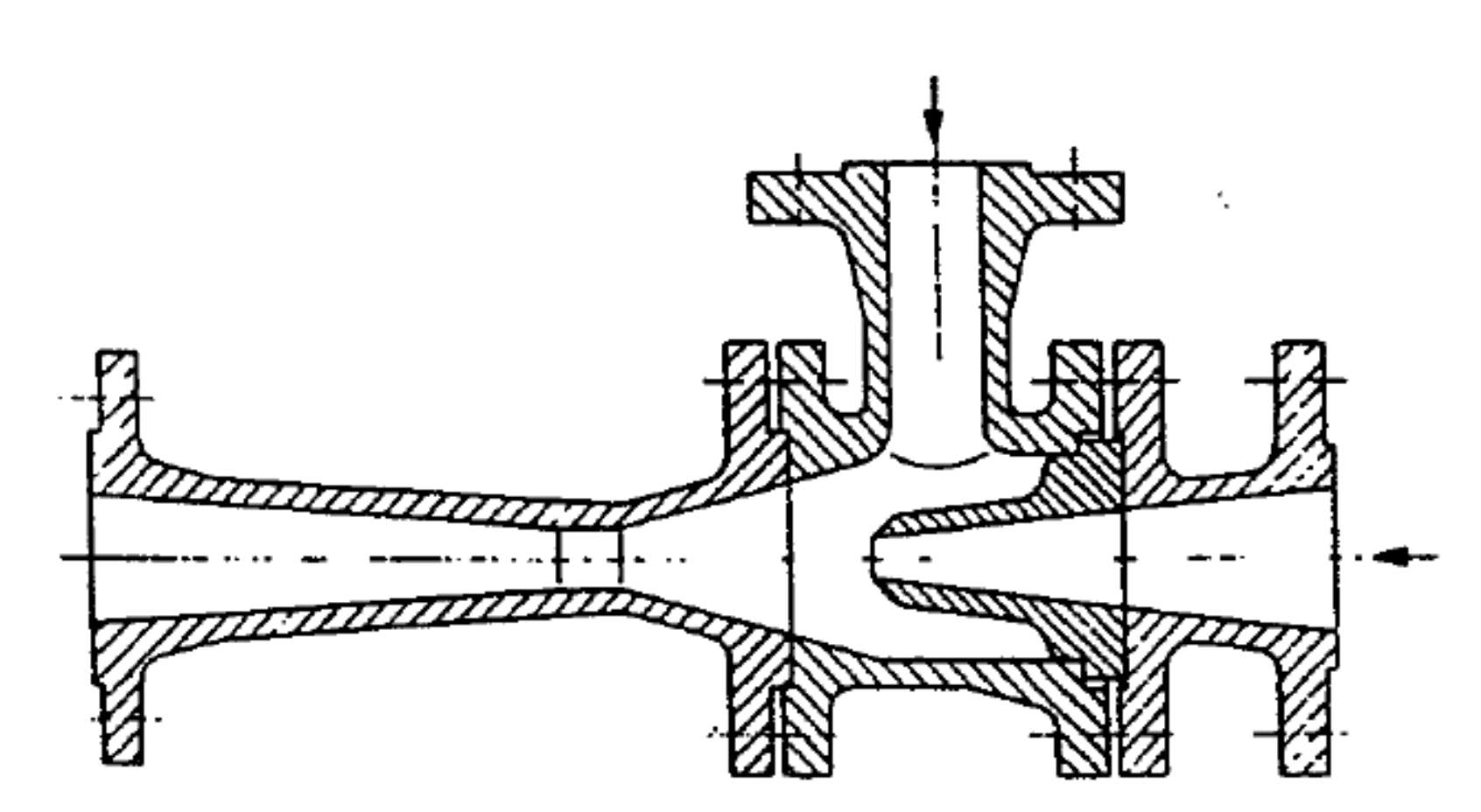

Ejector

nozzle combined with diffuser. Benefit of no moving parts.

A utility fluid is pushed through the nozzle, dropping its pressure and increasing its velocity. The drop in pressure sucks a process fluid into the ejector, where the fluids mix. They exit through a diffuser which decreases the velocity and increases the pressure of the mixture.

Vacuum pumps

Rotary type

Take in low pressure gas, discharge at atmospheric pressure

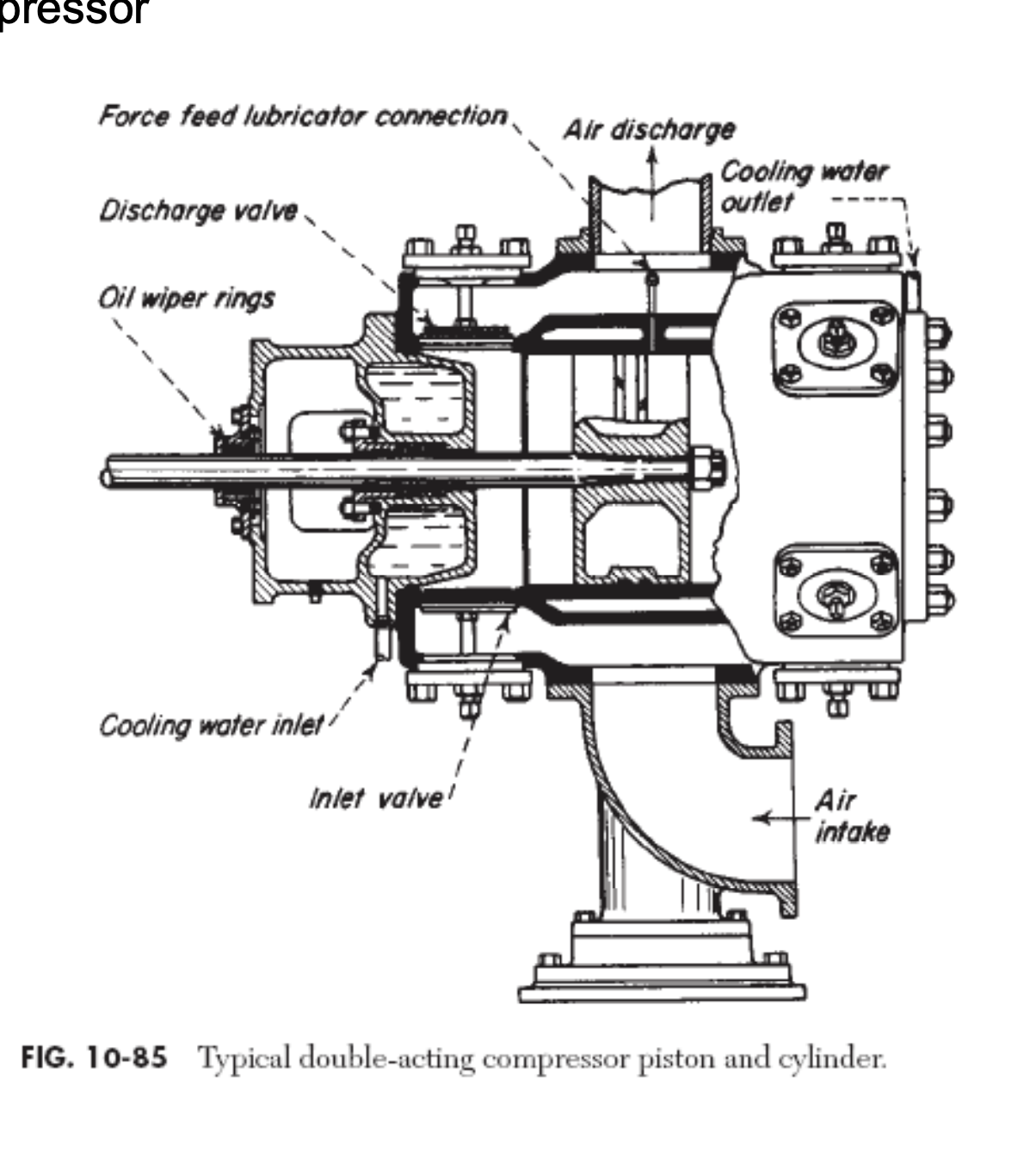

Reciprocating piston compressor

Not as reliable as other compressors

Large power consumption

Delivers the highest discharge pressure

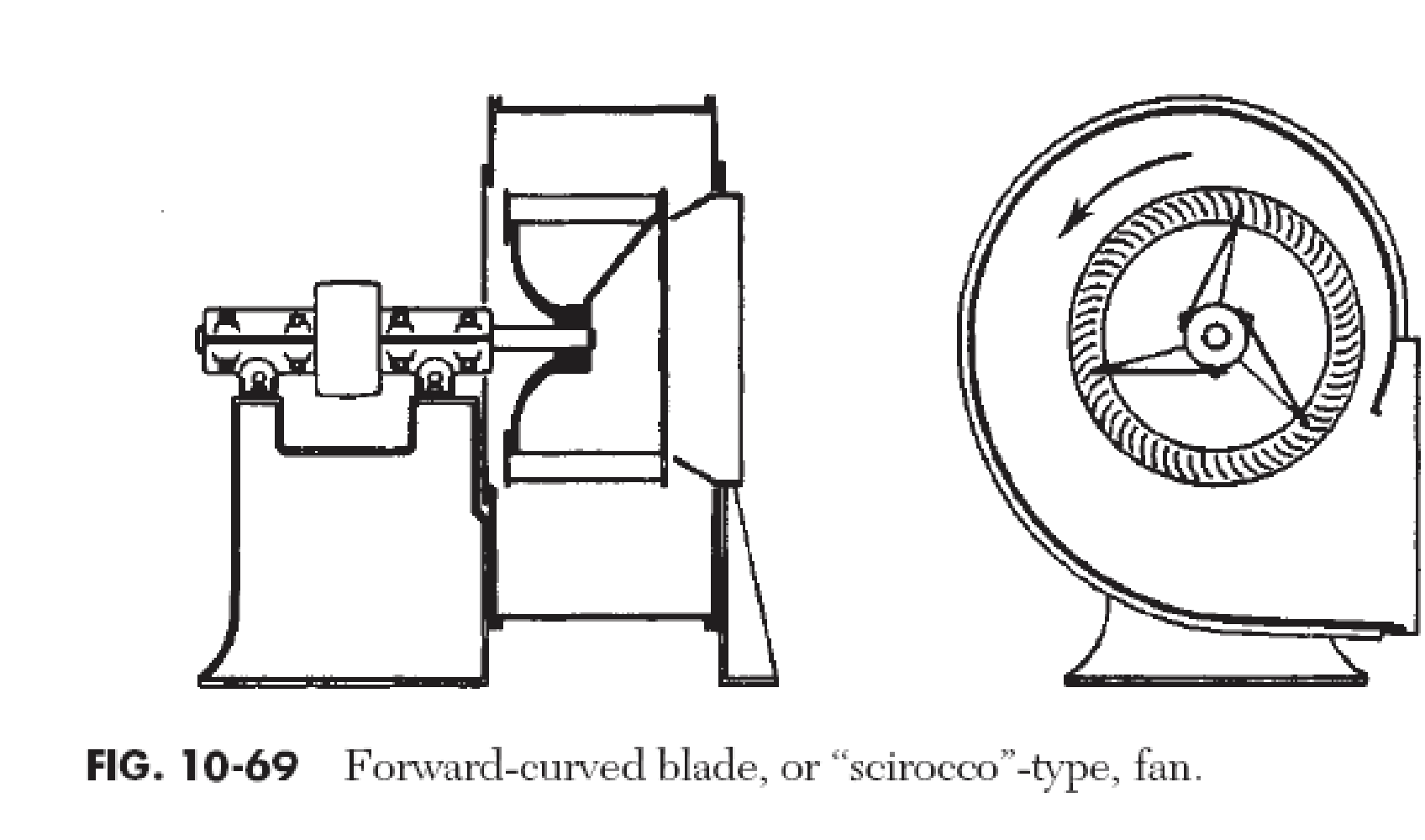

Centrifugal blowers and compressor

Include fans and compression stages

This enables fairly flexible operation

High reliability

Can service wide range of pressures and of flow rates

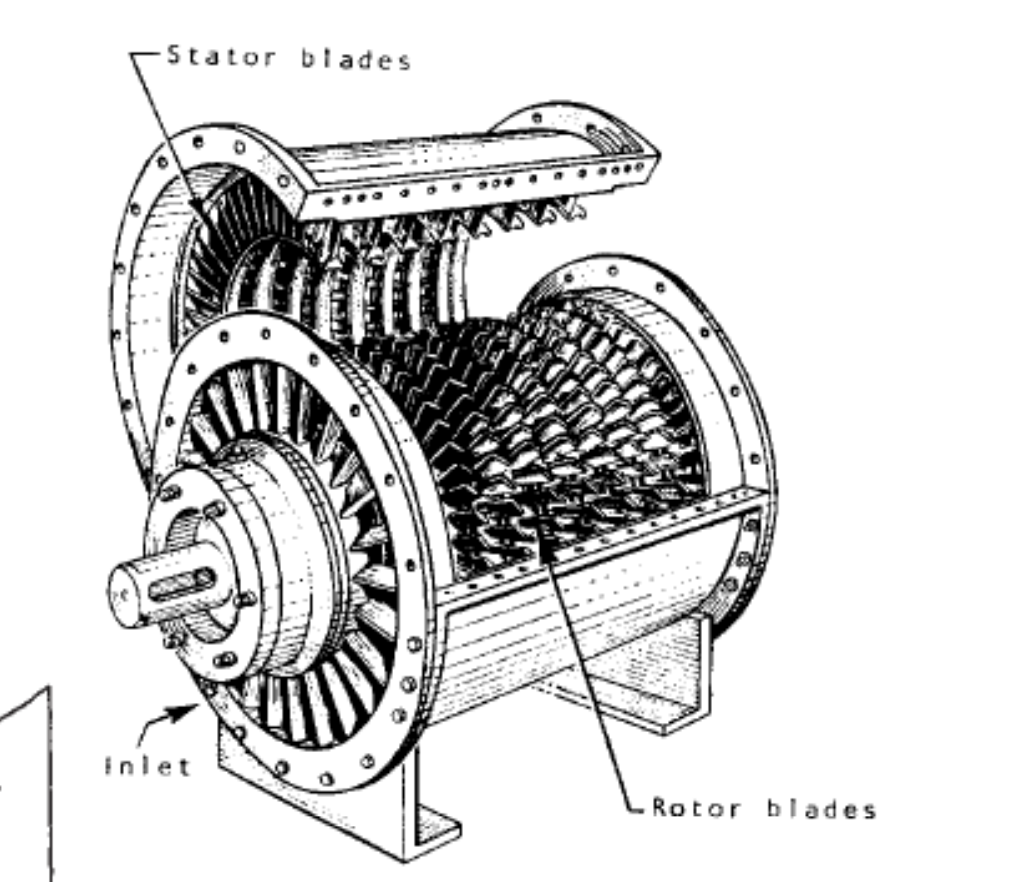

Axial flow blowers

Provide the highest flowrates

Cannot deliver high discharge pressure

High reliability

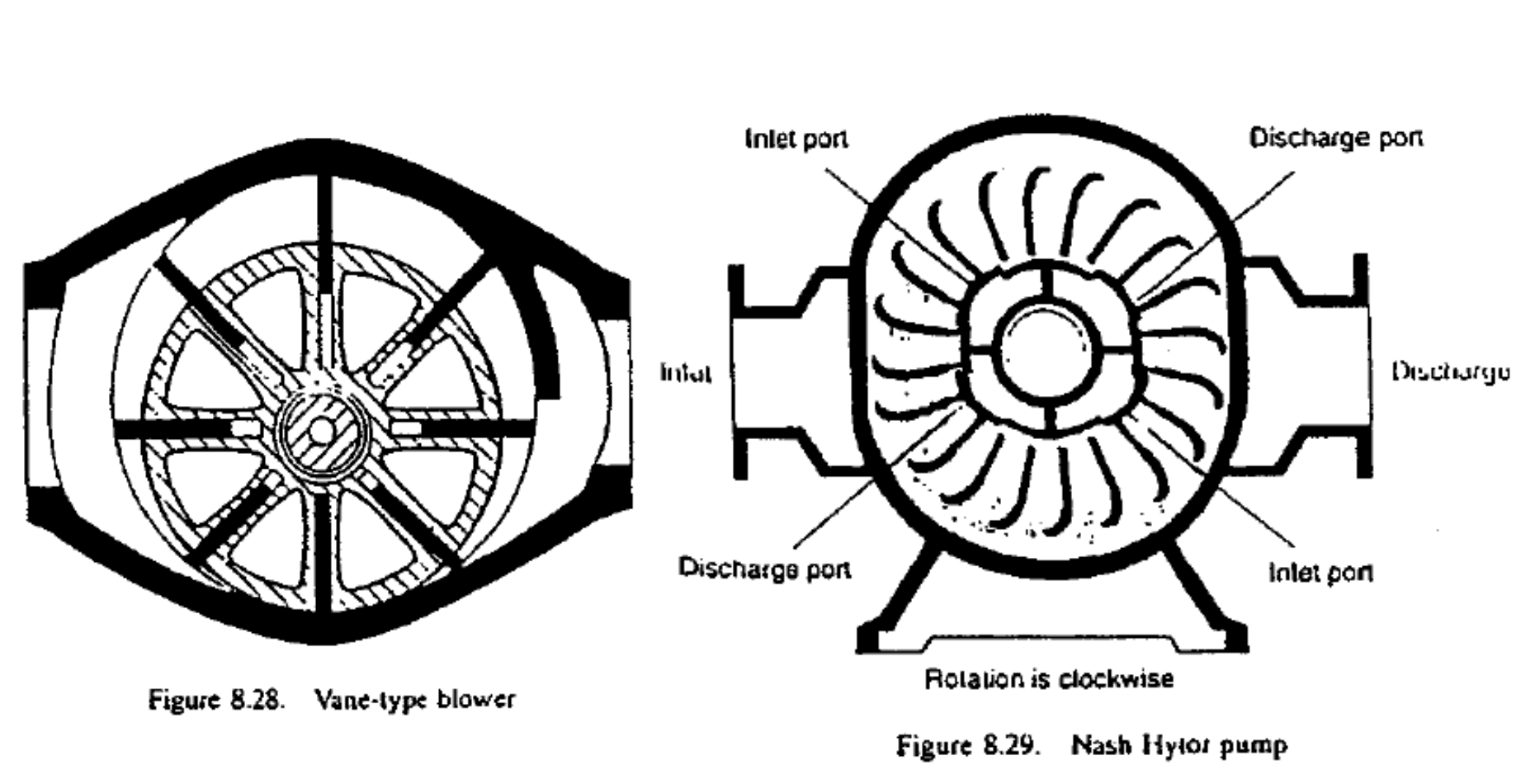

Rotary blowers and compressors

Sliding vane type: Blades move out and in as the rotor spins. Low power, low pressure, low noise

Liquid ring: liquid seal rotates with impeller

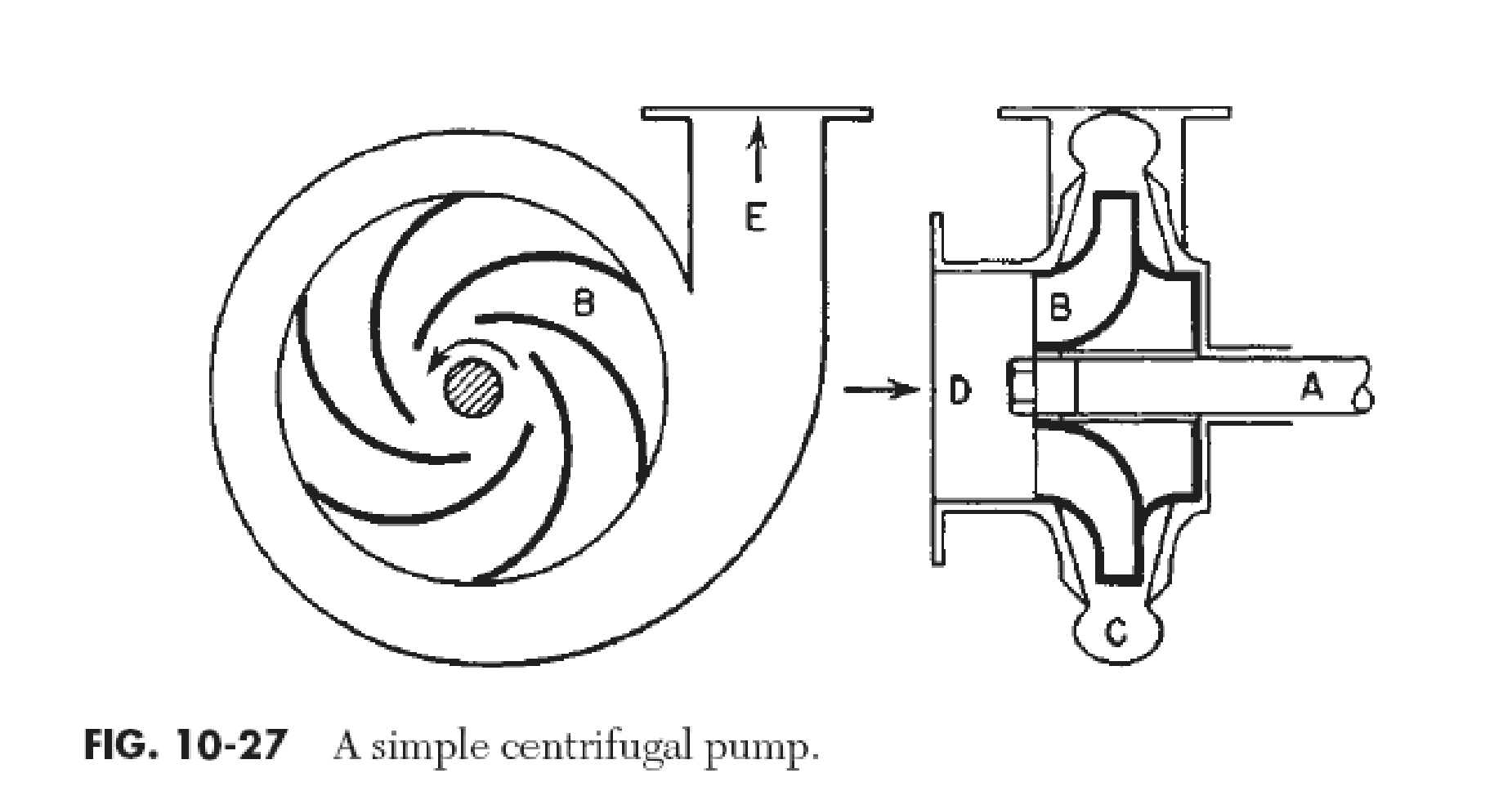

Centrifugal pump

Commonly used because simple and low cost

Low maintenance

Versatile: available for vast range of volumetric flowrates and discharge pressure requirements

Radial, axial and mixed flows

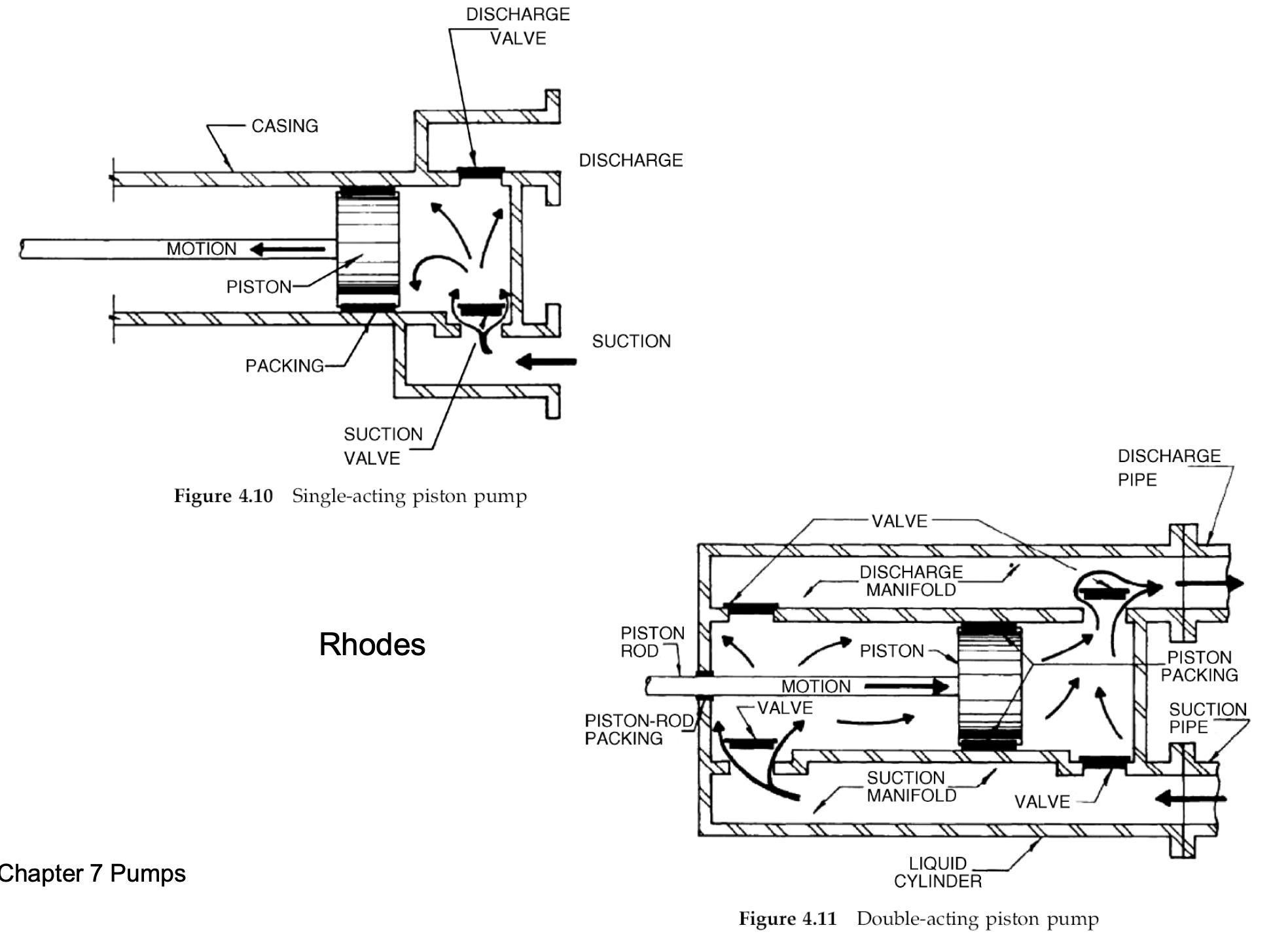

Reciprocating pump

Pistons/plungers used to push liquid through a delivery valve. As piston/plunger retracts liquid is pulled in through a suction valve. Double acting allows constant movement of fluid.

Low-medium vol. flows, with high pump head

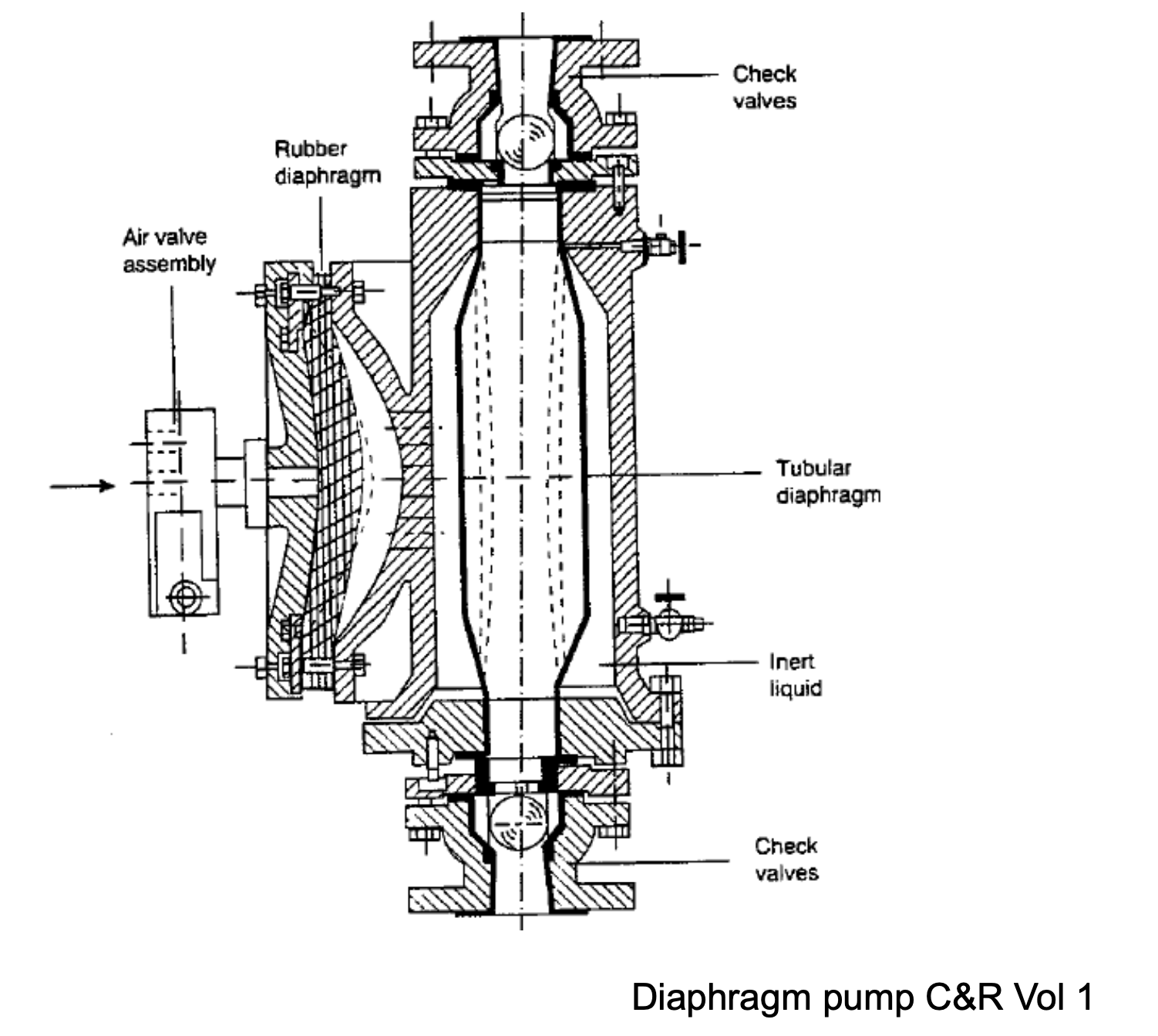

Diaphragm pump (reciprocating)

Corrosive liquids or suspended abrasive solids

Diaphragm flexes back and forth drawing in and then pushing out liquids

Diaphragms are made form rubber, teflon, plastic

Low vol flows and medium pump head

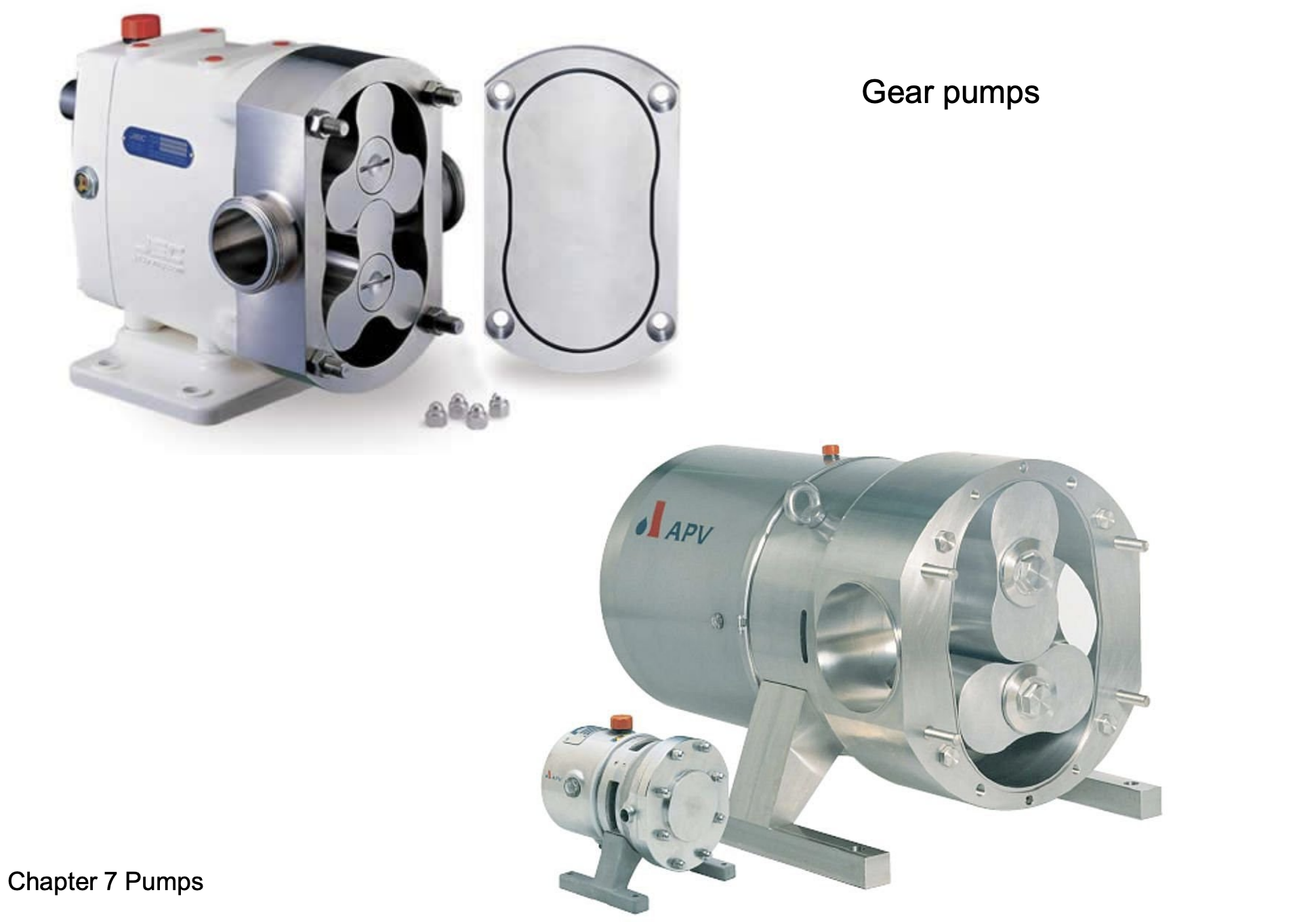

Rotary pumps

Liquid displaced by rotating gear or screw.

No valves → more even flowrate than reciprocating pumps

Low-medium vol. flows, with high pump head

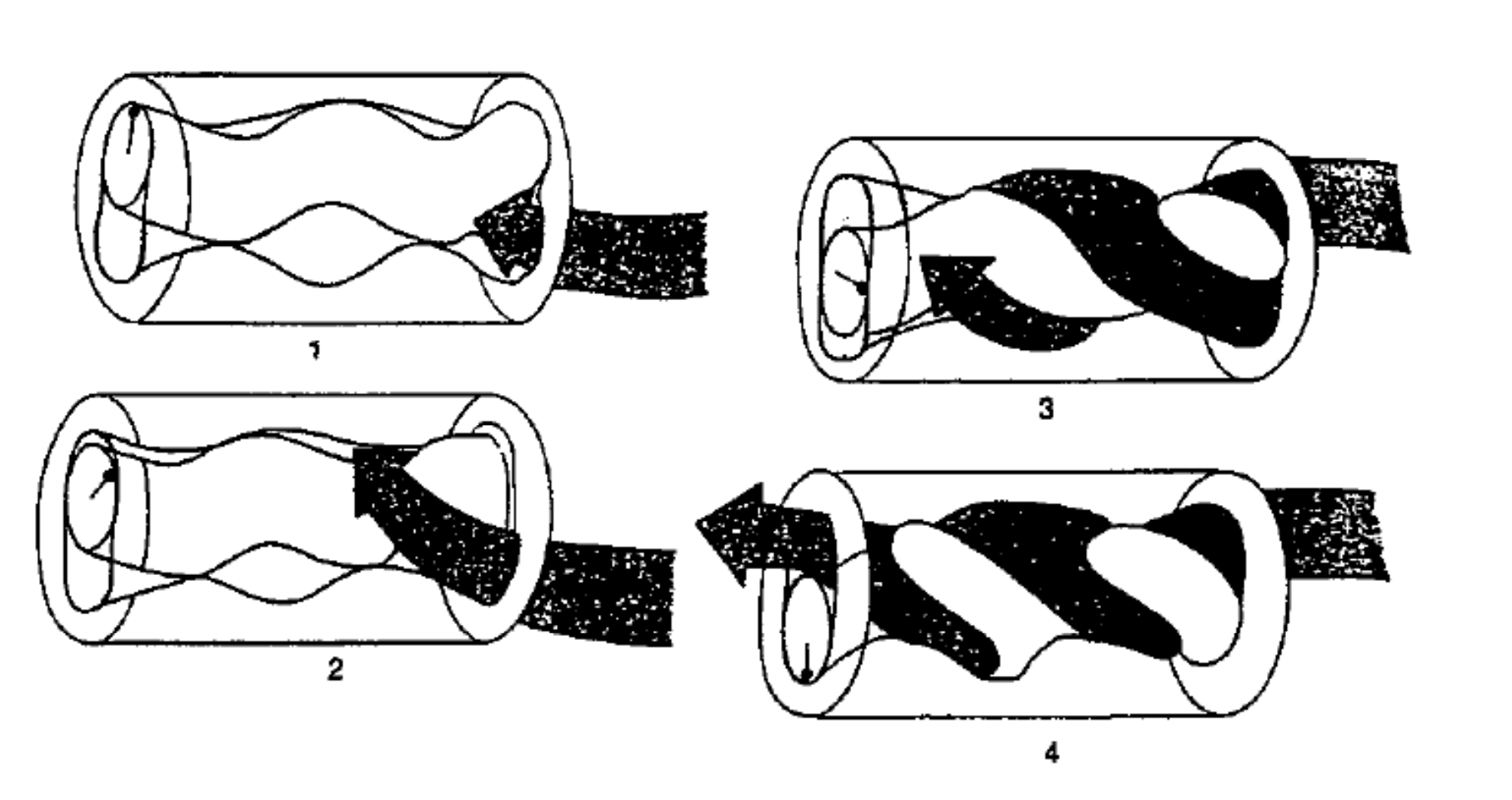

Mono pump

Handles corrosive and gritty liquids e.g. slurry

Pumps against high pressure

Rotating helical cavity

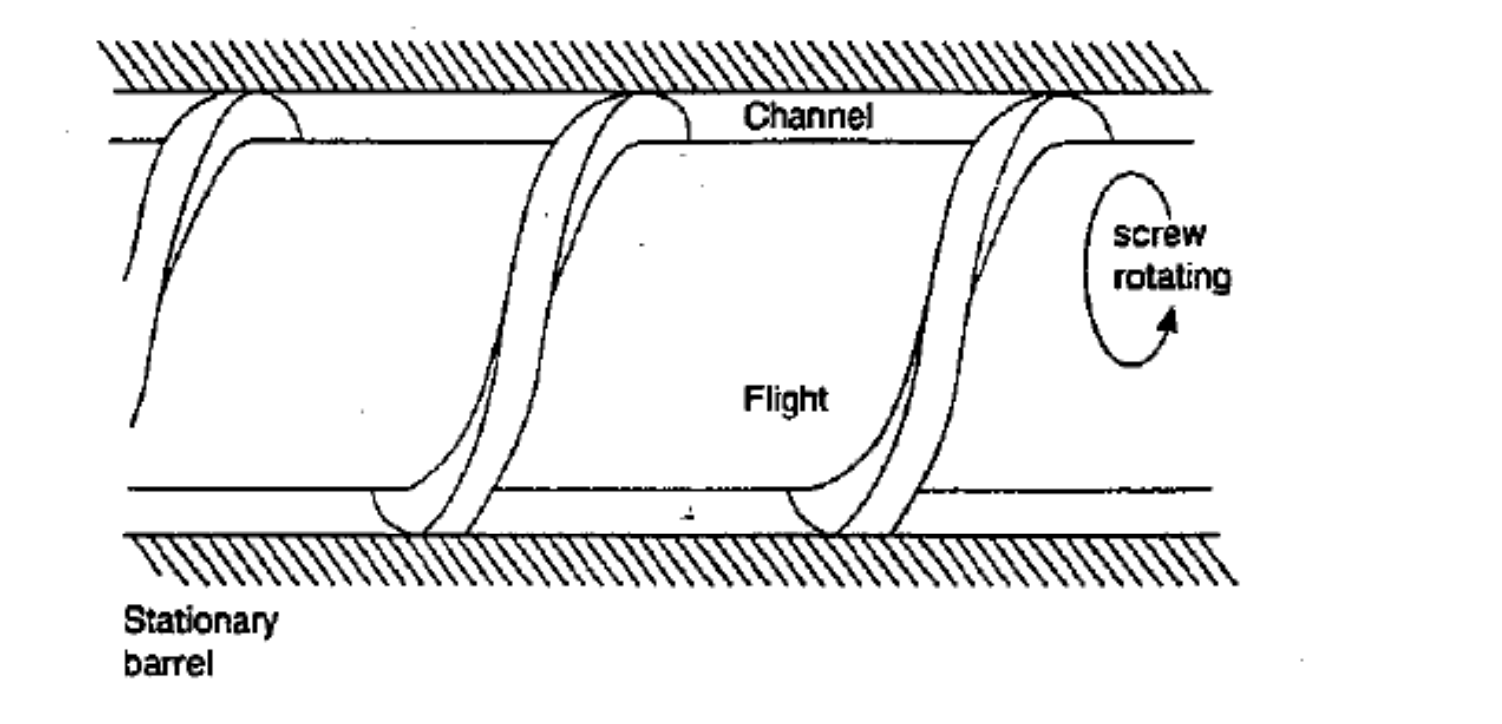

Screw pump

High viscous material

Screw revolves in a barrel

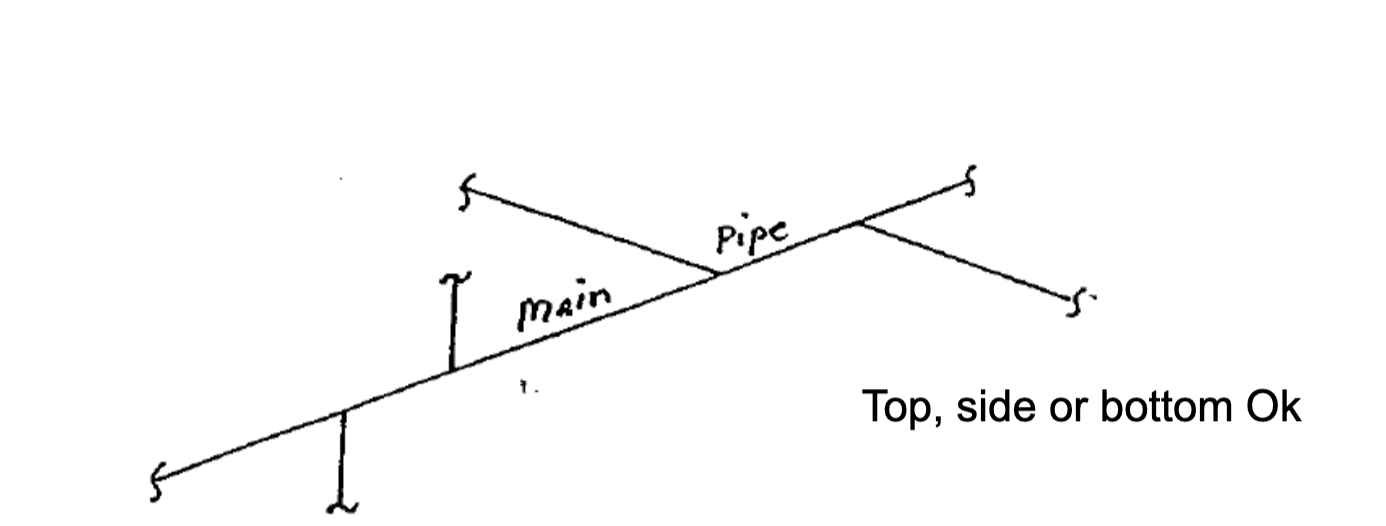

Branches off main pipe for clean fluids

Top, side, bottom

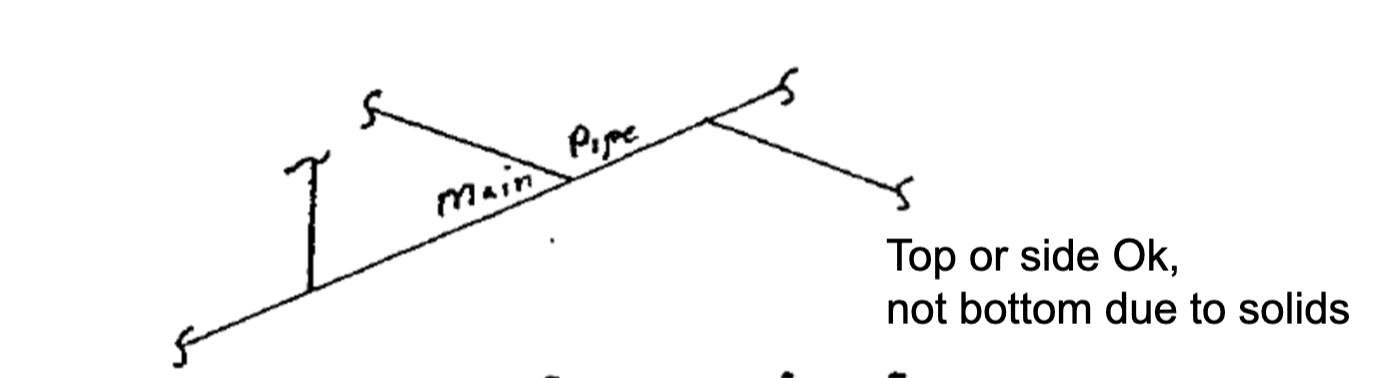

Branches off main pipe for dirty fluids

Top, side

Bottom not allowed because of solids settling

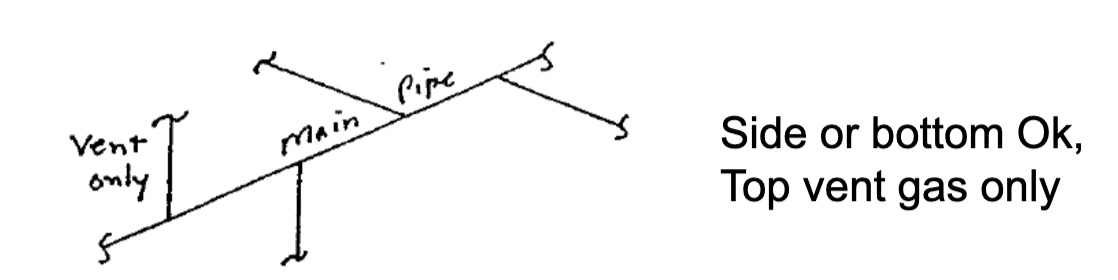

Clean liquids with gas bubbles

Side, bottom

Top to vent gas only

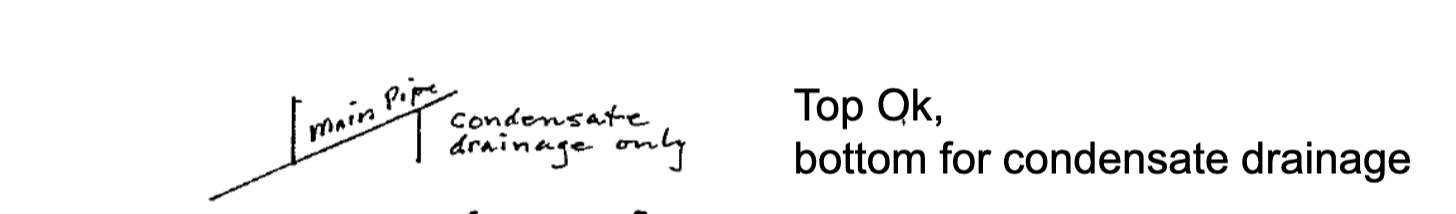

Steam out of main pipe

Top ok

Bottom only to drain condensate

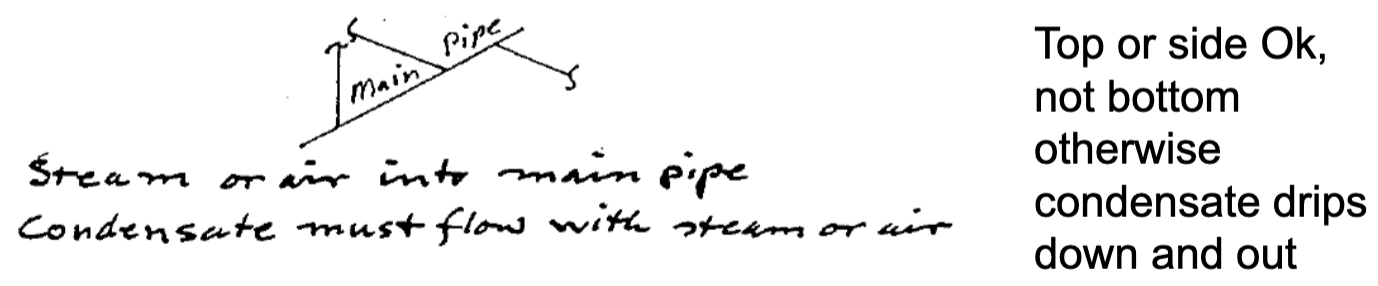

Steam into main pipe

Top and side.

Bottom not ok because condensate will travel backwards

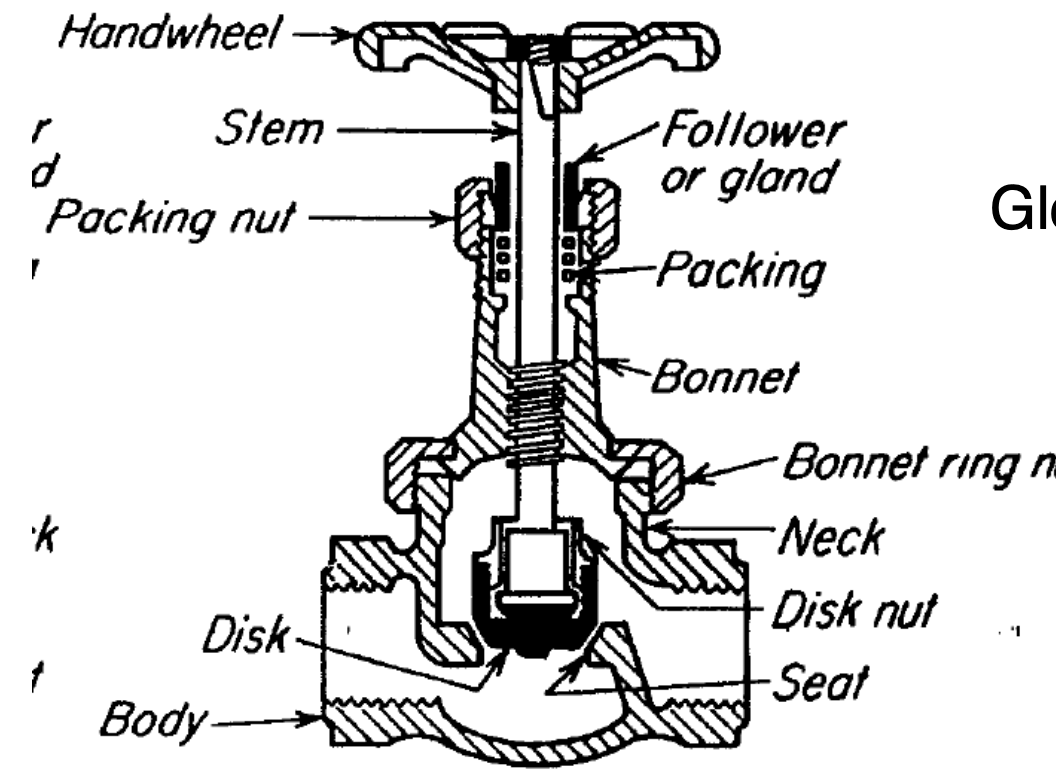

Close down valves

E.g. globe valve

Manual valve

Disc pushed into place to control circular orifice

Great for flow rate control

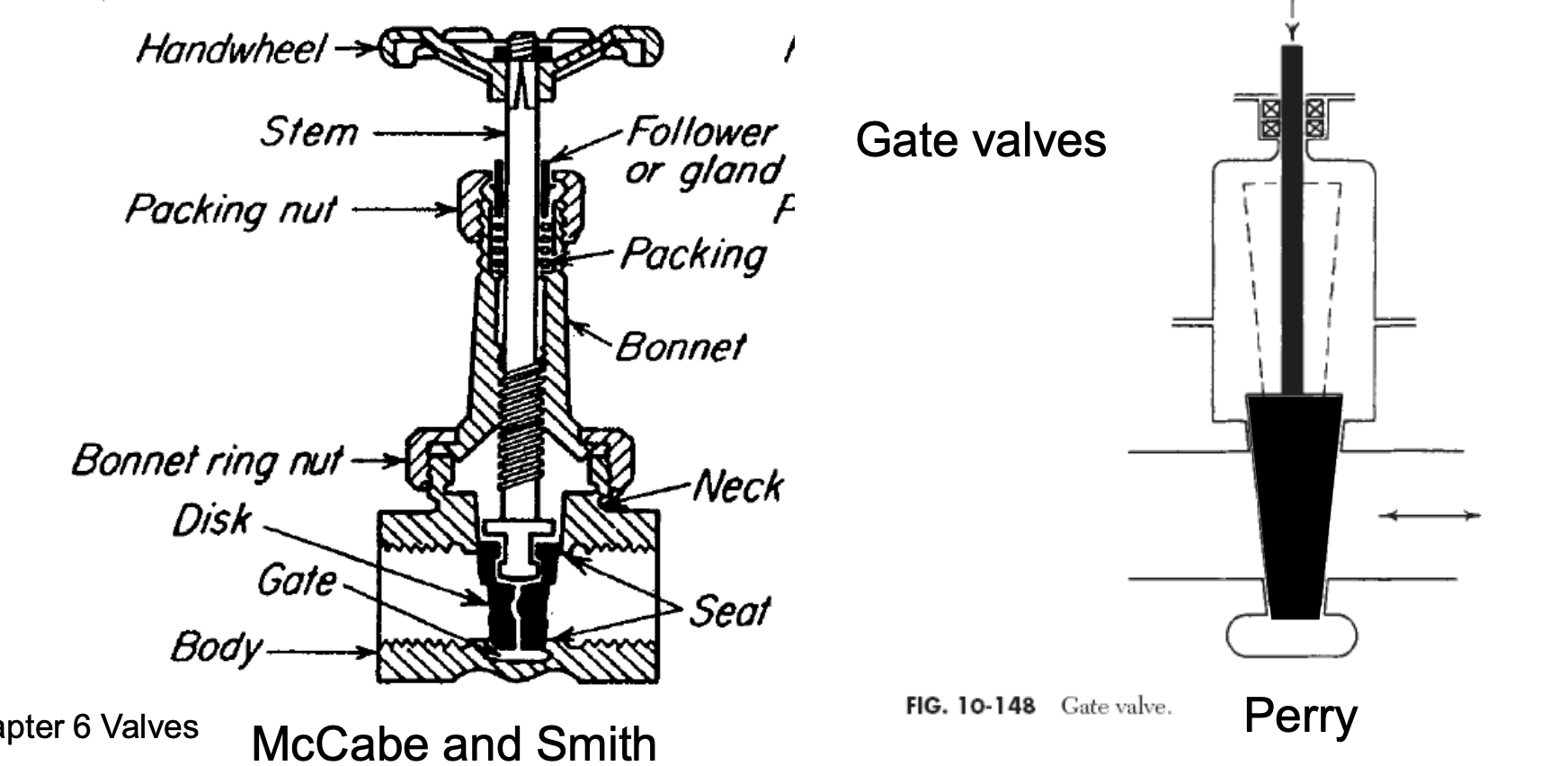

Slide valves

e.g. gate valve

Manual valve

vertical closure slides down and blocks path of flow

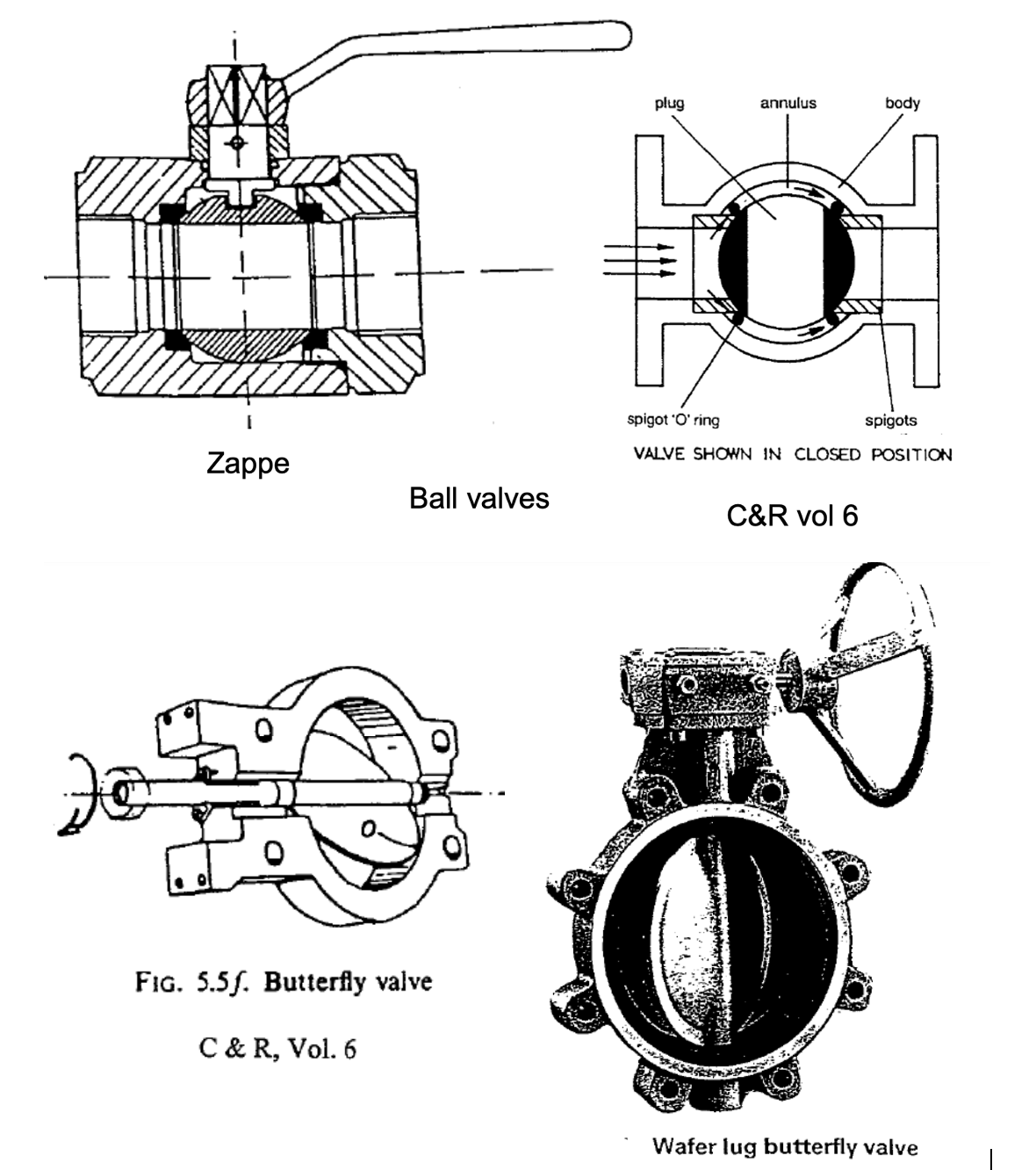

Rotary valves

e.g. ball valves, butterfly valves

Manual valve

A closure member / plug rotates to create an opening. In the case of ball valves this can be a piece with an orifice or it can be a plate in the case of butterfly valves

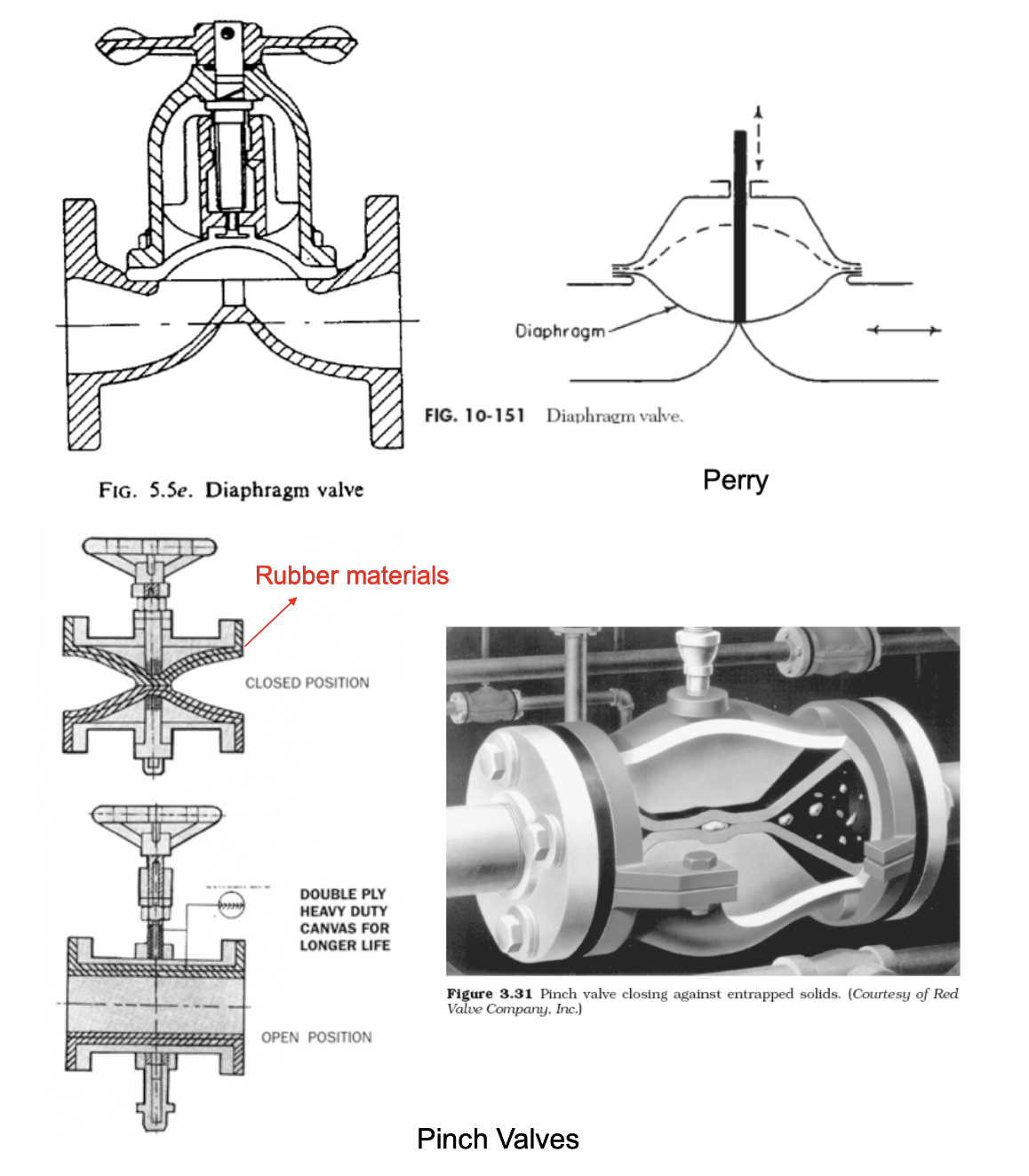

Flex-body valves

e.g. diaphragm valves, pinch valves

Manual valve

Used to handle abrasive, sticky solids

Used in food and pharma processing

Useful for flow control

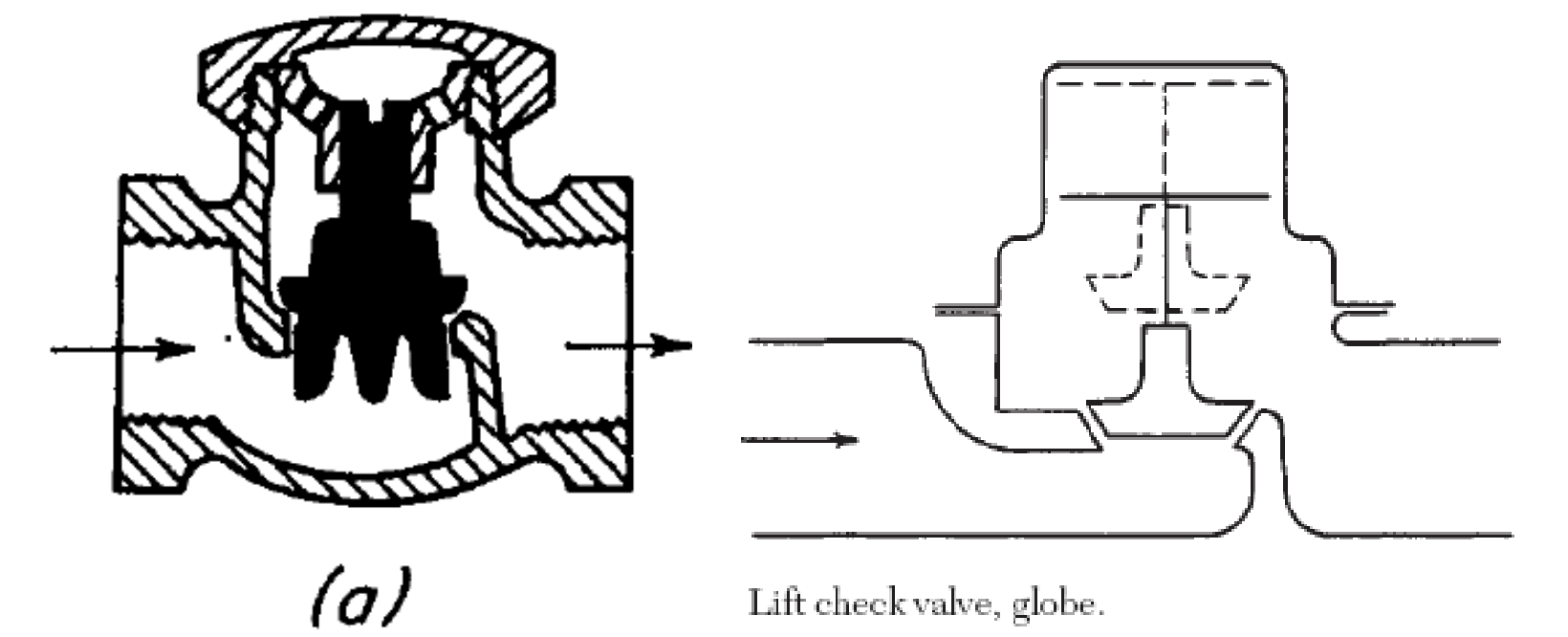

Lift check valves

Check valve

Valve which opens for forward flow, closes for reverse flow

NOT FOR SAFETY APPLICATIONS

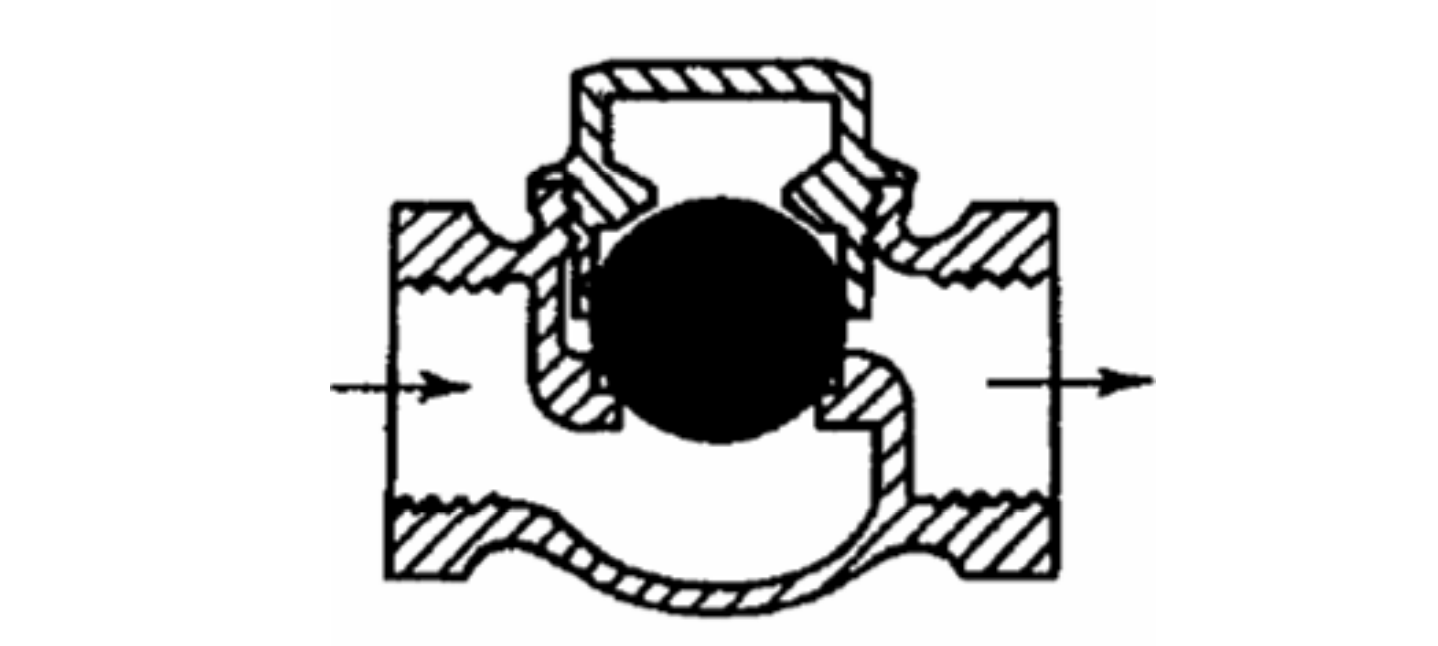

Ball check valve

Check valve

Valve which opens for forward flow, closes for reverse flow

NOT FOR SAFETY APPLICATIONS

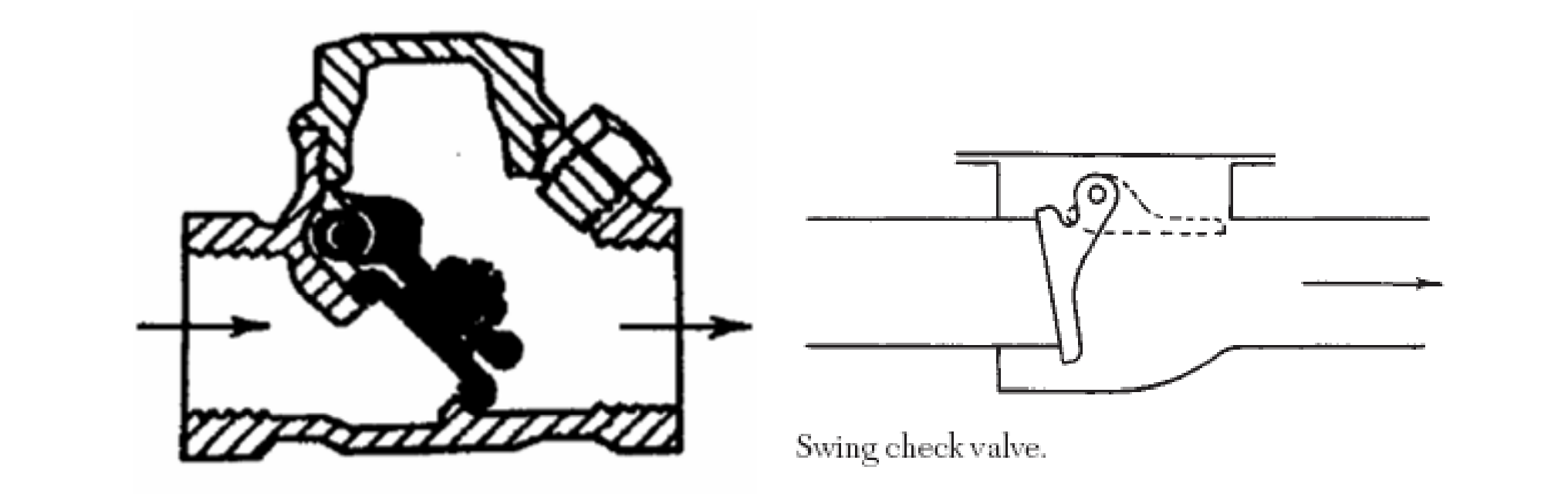

Swing check valve

Check valve

Valve which opens for forward flow, closes for reverse flow

NOT FOR SAFETY APPLICATIONS

Diaphagm check valve

Check valve

Valve which opens for forward flow, closes for reverse flow

NOT FOR SAFETY APPLICATIONS

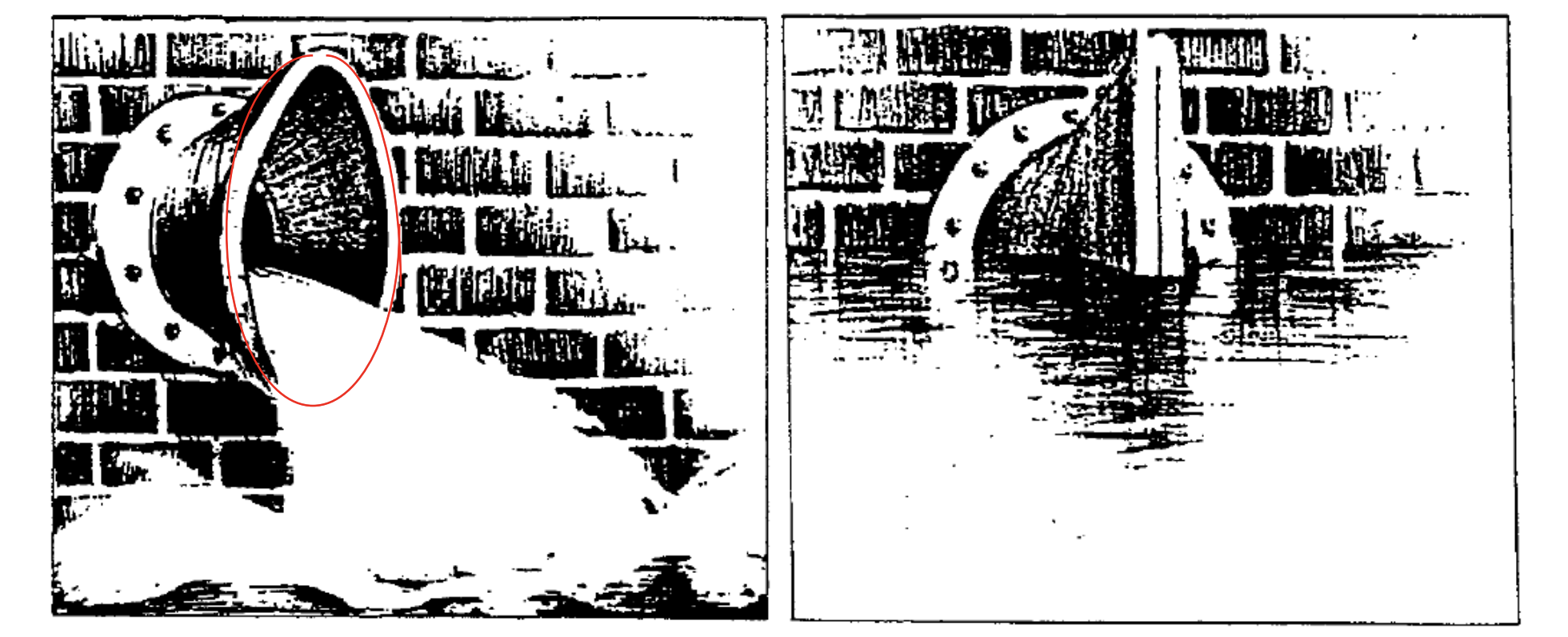

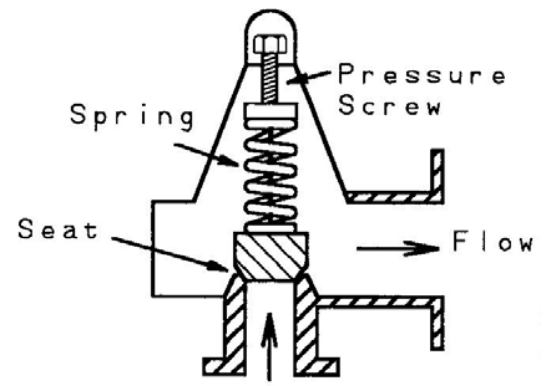

Spring Operated Relief Valve

Set pressure adjusted by spring tension. Shuts off when vessel pressure reduces. May shut off early due to back pressure.

Some leakage

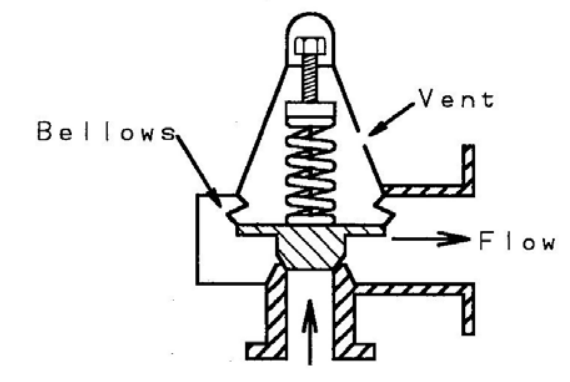

Balanced Bellows Spring Relief valve

Bellows means back pressure does not force the valve shut.

Some leakage

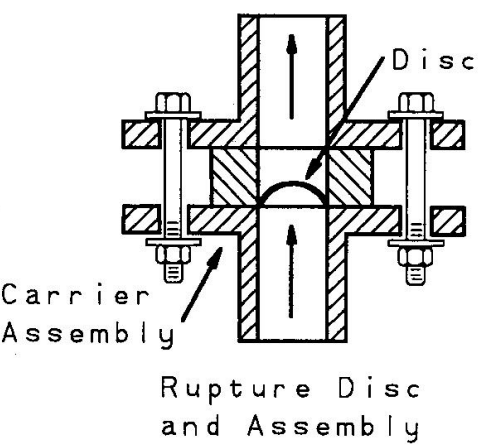

Bursting disc/rupture disc

Thin sheet of metal designed to break at certain pressure. Will not leak, must be replaced after being “blown”