1. Food preservation

1/16

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

17 Terms

Preservation methods

Traditional methods

Thermal methods

Concentrating

Packaging

Combinations/other

Process concepts

Fluid flow

Reactions-Reactors

Heat transfer

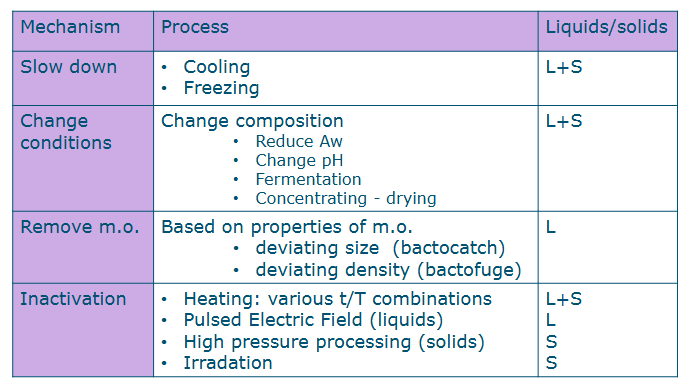

How to control microorganisms and enzymes

Slow down deterioration reactions

Change conditions for undesired m.o.

Remove m.o.

Inactivate m.o. and enzymes

Food Preservation mechanisms

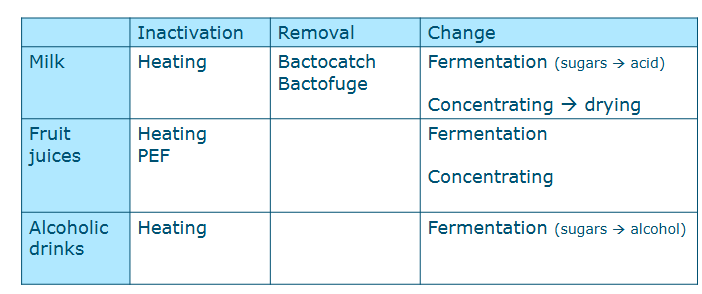

Food preservation mechanisms for milk, fruit juices & alcholic drinks

PEF = pulse electric field

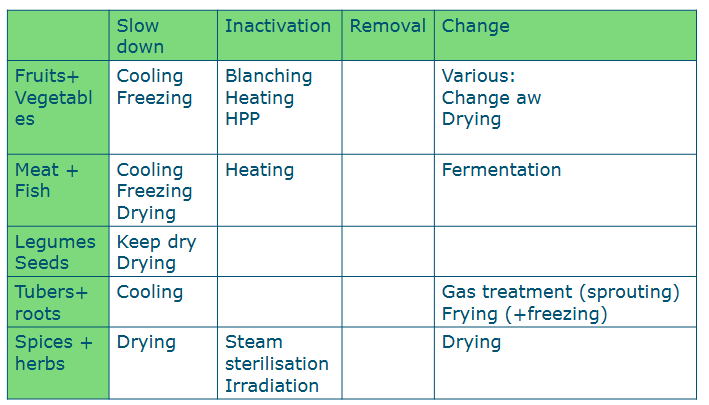

Food preservation mechanisms for semi-solid foods

(Heat treatments) Thermisation

Gets rid of psychrotrophic bacteria

65-72 C, 15-22 seconds

(Heat treatments) LTLT, low temperature; long time

62-65 C, for at least 30 min

(Heat treatments) Pasteurization

72-75 C, for 15-40 seconds

(Heat treatments) Flash pasteurization

85 C

1-2 seconds

(Heat treatments) UHT, ultra-high temperature

Sterilization

135-140 C, for 1-2 seconds

Aim of bactofugation & bactocatch

Used for milk/dairy

Aim:

prolonged shelf life

Preserve taste and nutritional value

Remove Clostridia sporeformers from milk for cheesemaking

Can be achieved by doing this instead of heat treatments

Process of bactofugation

Increase temp for fat removal

Centrifugation: separation of fat fraction

Bactofugation: separate stream with bacteria

Sterilization of stream with bacteria

Recombining + mild pasteurization of recombined stream

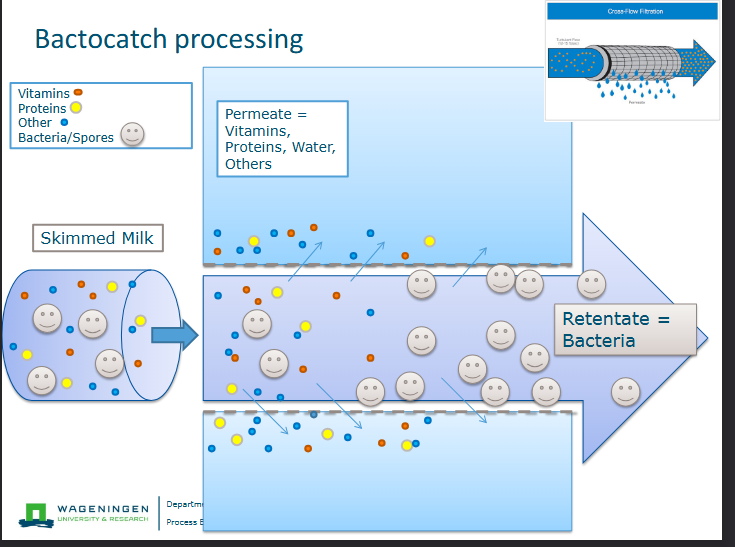

Process of bactocatch

used for ESL milk-milk with extended shelf life

Membrane process; Microfiltration (membrane 1.4 micrometer)

Separation based on size

Effect of treatment on product

The effect can be tested, for example the protein nativity is an indicator for heat treatment

Or measure beta lactoglobulin nativity

Packaging for preservation

Post package treatment (cans)

You have to heat the can

Aseptic packaging

Product is sterilized first, followed by filling disinfected containers under sterile, enclosed conditions

Three categories of operations

Separations: including cleaning, fractionation and purification

Conversions and structuring: such as fermentation, enzymatic/microbial inactivation, and changing ingredient positioning

Stabilizations: involving a preservation treatment to reduce deterioration risk and packaging