[POM-TQM] Finals - (3) Product and Service Design

1/49

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

50 Terms

Manufacturability

The capability of an organization to produce an item at an acceptable profit

Serviceability

The capability of an organization to provide a service at an acceptable cost or profit

Reverse Engineering

Dismantling and inspecting a competitor’s product to discover product improvements

Research and Development (R&D)

Organized efforts to increase scientific knowledge or product innovation

Basic Research

Has the objective of advancing the state of knowledge about a subject without any near-term expectations of commercial applications

Applied Research

Has the objective of achieving commercial applications

Development

Converts the results of applied research into useful commercial applications

Product Liability

The responsibility of a manufacturer has for any injuries or damages caused by a faculty product

Uniform Commercial Code (UCC)

Under this, products carry an implication of merchantability and fitness

Key Aspects of Designing for Sustainability

Cradle-to-grave assessment

End-of-life programs

The three Rs

Three Rs

Reduction of costs and materials used

Reusing parts of returned products

Recycling

Cradle-to-Grace Assessment

The assessment of the environmental impact of a product or service throughout its useful life. It is also known as life cyle analysis (LCA)

Value Analysis

Examination of the function of parts and materials in an effort to reduce the cost and/or improve the performance of a product

Remanufacturing

Refurbishing used products by replacing worn-out or defective components. It can be performed by the original manufacturer or another company

Design for Disassembly (DFD)

Designing a product to that used products can be easily taken apart

Recycling

Recovering materials for future use and applies to manufacturing parts

Design for Recycling (DFR)

Product design that takes into account the ability to disassemble a used product to recover the recyclable parts

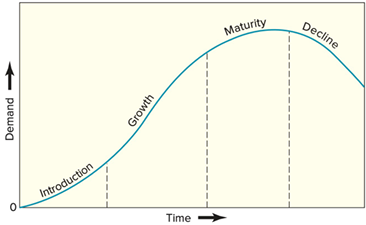

Product or Service Life Stages

Standardization

• Extent to which there is an absence of variety in a product, service, or process

• Products are made in large quantities of identical items

• Every customer or item processed receives essentially the same service

Advantages of Standardization

• Fewer parts to deal with

• Reduced training costs and time

• More routine purchasing, handling, and inspection

• Orders fillable from inventory

• Opportunities for long production runs and automation

Disadvantages of Standardization

• Designs may be frozen too early

• High cost of design changes

• Decreased product variety

Mass Customization

A strategy of producing basically standardized goods or services, but incorporating some degree of customization in the final product or service

Delayed Differentiation

The process of producing a product or service but not quite completing production until customer preferences are known. It is a postponement tactic.

Modular Design

A form of standardization in which component parts are grouped into modules that are easily replaced or interchanged

Advantages of Modular Design

• Easier diagnosis and remedy of failures

• Easier repair and replacement

• Simplification of manufacturing and assembly

• Training costs are relatively low

Disadvantages of Modular Design

• Limited number of possible product configurations

• Limited ability to repair a faulty module; if it cannot be disassembled, the entire module

must often be scrapped

Reliability

The ability of a product, part, or system to perform its intended function under a prescribed set of conditions. This is always specified with respect to certain conditions.

Failure

Situation in which a product, part, or system does not perform as intended

Normal Operating Conditions

The set of conditions under which an item’s reliability is specified

Potential Ways to Improve Reliability

• Improve component design

• Improve production and/or assembly techniques

• Improve testing

• Use backups

• Improve preventive maintenance procedures

• Improve user education

• Improve system design

Robust Design

A design that results in products or services that can function over a broad range of conditions. The more robust a product or service, the less likely it will fail due to a change in the environment in which it is used or in which it is performed.

Degree of Newness

The degree of change affects the newness of the product or service to the market and to the organization

Product or Service Design Changes

1. Modification of an existing product or service

2. Expansion of an existing product line or service offering

3. Clone of a competitor’s product or service

4. New product or service

Quality Function Deployment (QFD)

An approach that integrates the “voice of the customer” into both product and service development

• The purpose is to ensure that customer requirements are factored into every aspect of the process

• Listening to and understanding the customer is the central feature of this

Basic Quality of Kano Model

Refers to customer requirements that have only limited effect on customer satisfaction if present, but lead to dissatisfaction if absent

Performance Quality of Kano Model

Refers to customer requirements that generate satisfaction or dissatisfaction in proportion to their level of functionality and appeal

Excitement Quality of Kano Model

Refers to a feature or attribute that was unexpected by the customer and causes excitement

Phases in Product Design and Development

1. Feasibility analysis

2. Product specifications

3. Process specifications

4. Prototype development

5. Design review

6. Market test

7. Product introduction

8. Follow-up evaluation

Concurrent Engineering

Bringing engineering design and manufacturing personnel together early in the design phase. It also may involve manufacturing, marketing and purchasing personnel in loosely integrated cross-functional teams

Concurrent Engineering

The purpose is to achieve product designs that reflect customer wants as well as manufacturing capabilities

Computer-aided Design (CAD)

Product design using computer graphics

Advantages of Computer-aided Design (CAD)

• Increases productivity of designers, 3 to 10 times

• Creates a database for manufacturing information and product specifications

• Provides possibility of engineering and cost analysis on proposed designs

• CAD that includes finite element analysis (FEA) can significantly reduce time to market

• Enables developers to perform simulations that aid in the design, analysis, and commercialization of new products

Production Requirements

Designers must take into account production capabilities

• Equipment

• Skills

• Types of materials

• Schedules

• Technologies

• Special abilities

Manufacturability

• Ease of fabrication and/or assembly

• It has important implications for

Cost

Productivity

Quality

Component Commonality

When products have a high degree of similarity in features and components, a part can be used in multiple products

Benefits of Component Commonality

• Savings in design time

• Standard training for assembly and installation

• Opportunities to buy in bulk from suppliers

• Commonality of parts for repair

• Fewer inventory items must be handled

Service Design

Begins with a choice of service strategy, which determines the nature and focus of the service, and the target market

Key Issues in Service Design

• Degree of variation in service requirements

• Degree of customer contact and involvement

Differences between Service and Product Design

1. Products are generally tangible; services are intangible

2. Services are created and delivered at the same time

3. Services cannot be inventoried

4. Services are highly visible to consumers

5. Some services have low barriers to entry and exit

6. Location is often important to service design, with convenience as a major factor

7. Service systems range from those with little or no customer contact to those that have a very high degree of customer contact

8. Demand variability alternately creates waiting lines or idle service resource

Phases in Service Design Process

1. Conceptualize

• Idea generation

• Assessment of customer wants/needs

• Assessment of demand potential

2. Identify service package components needed

3. Determine performance specifications

4. Translate performance specifications into design specifications

5. Translate design specifications into delivery specifications