2.) ERGO - Foodservice Design

1/61

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

62 Terms

Overview

Introduces the roles & responsibilities of each member of the foodservice design project team.

Describes the sequence of steps involved in the design of a foodservice facility.

Introduces the work typically performed by a foodservice consultant in the design process.

Discusses how the costs of a new or renovated foodservice facility are estimated.

The Project Team

The Owner’s Representative.

The Architect.

The Engineers.

The Foodservice Facilities Design Consultant.

The Interior Designer.

The General Contractor.

The Foodservice Equipment Contractor.

The Owner’s Representative – Typical Roles & Responsibilities

Selecting team members (architect, foodservice consultant, etc.).

Determining operational goals for the project.

Setting the budget & obtaining funds for the project.

Evaluating the design for the project.

Accepting or rejecting recommendations of equipment, furniture, etc.

The Architect: Typical Project Roles & Responsibilities

Coordinating the work of the design team (engineers, consultants, interior designer).

Preparing & submitting design drawings & specifications for the project.

Managing the bidding & contract negotiation process.

Coordinates & inspects the construction process.

Potential Architectural Team Members

Principal in Charge: markets the firm & negotiates the contract with the Owner; the individual ultimately in charge.

Project Manager: responsible for the design process on a day-to-day basis; coordinates the work of the other team members.

Design Architect: works closely in the planning & schematic design phases to set the overall direction of the design.

Site Architect: has a temporary office at the job site & coordinates & supervises the construction progress.

Principal in Charge:

markets the firm & negotiates the contract with the Owner; the individual ultimately in charge.

Project Manager:

responsible for the design process on a day-to-day basis; coordinates the work of the other team members.

Design Architect:

works closely in the planning & schematic design phases to set the overall direction of the design.

Site Architect:

has a temporary office at the job site & coordinates & supervises the construction progress.

Criteria for Selecting an Architect

Successful experience with similar projects, including foodservice facilities.

Relevant experience of the proposed team (engineers, consultants, etc.).

“Chemistry” – the expectation of a positive & productive working relationship.

The Engineers: Roles & Responsibilities

Electrical engineers: design the systems that supply electricity as needed in the facility.

Mechanical engineers: design the plumbing, heating, ventilation, & air-conditioning systems within the facility.

Structural engineers: design systems to support the structure of the building & to protect its integrity.

Civil engineers: design site improvements necessary for a facility.

Electrical engineers:

design the systems that supply electricity as needed in the facility.

Mechanical engineers:

design the plumbing, heating, ventilation, & air-conditioning systems within the facility.

Structural engineers:

design systems to support the structure of the building & to protect its integrity.

Civil engineers:

design site improvements necessary for a facility.

The Foodservice Consultant: Typical Roles & Responsibilities

Assists the owner in identifying operational goals & objectives.

Works closely with the architect to determine space requirements.

Designs the foodservice areas & lays out equipment within them.

Recommends equipment to the owner.

The Foodservice Consultant: Typical Roles & Responsibilities

Prepares drawings & specifications for the foodservice-related parts of the project.

Coordinates construction of the foodservice areas, including an inspection of the completed facility.

Common Foodservice Consulting Services

Market & Financial Feasibility Studies.

Master Planning & Programming to determine what approaches, systems, & design concepts will best meet the Owner’s objectives.

Facility Evaluation to pinpoint strengths & weaknesses of existing foodservices & recommend improvements.

Foodservice Facilities Design.

Operations Analysis to identify inefficiencies & recommend improvements.

The Interior Designer: Typical Roles & Responsibilities

Gives the foodservice operation its distinctive visual character & theme through the design of interior spaces, the selection of colors, & the specification of furniture & finishes.

Focuses on the public or customer parts of the facility, rather than on the kitchen or storage areas.

The General Contractor: Typical Roles & Responsibilities

Overall responsibility for the construction of the facility in accordance with the plans & specifications prepared by the design team.

Selects sub-contractors to perform specific parts of the construction work, coordinates their progress, & monitors their performance.

Works with the architect & owner to resolve problems encountered in the construction process.

Alternatives to a General Contractor

Construction Manager: involved as part of the design team, advising on construction costs of design alternatives; coordinates the actual construction.

Is involved in the preparation of the contract documents.

Design-Build Firm: employs its own architects, engineers, & consultants.

Handles all aspects of the project from inception through design to opening day.

Construction Manager:

involved as part of the design team, advising on construction costs of design alternatives; coordinates the actual construction.

Is involved in the preparation of the contract documents.

Design-Build Firm:

employs its own architects, engineers, & consultants.

Handles all aspects of the project from inception through design to opening day.

The Foodservice Equipment Contractor

A dealer who markets foodservice equipment.

May be a sub-contractor hired by the general contractor or may be a ‘prime’ contractor hired by the owner.

Furnishes & installs the equipment as designed & specified by the foodservice design consultant.

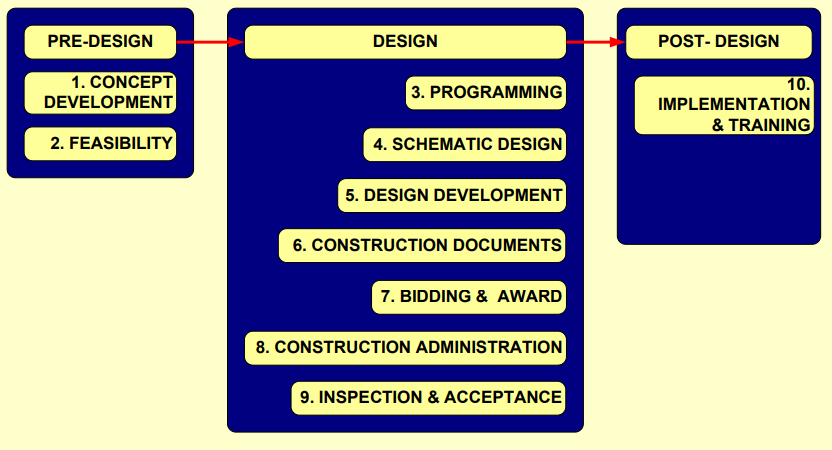

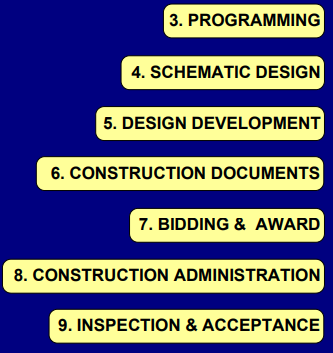

The Design Sequence

The Design Sequence

The Design Sequence

The Design Sequence

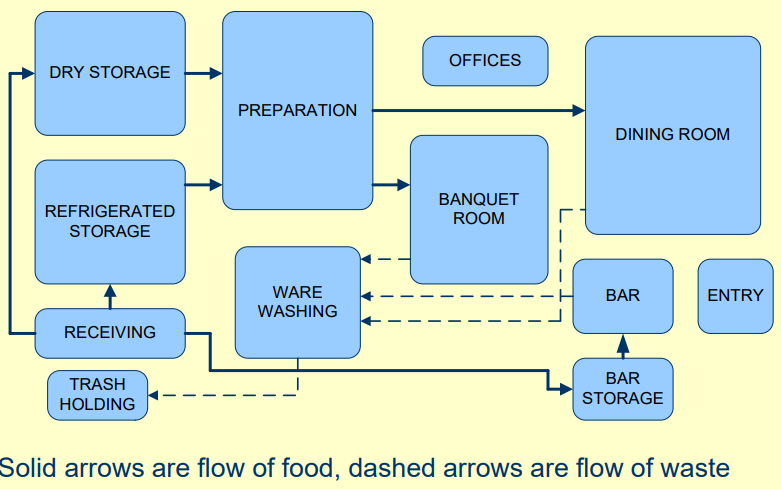

Space Analysis & Programming

Space analysis: determines the amount of area required for each of the functional areas of the foodservice operation.

Determination of adjacency: what functional areas need to be located next to each other?

Foodservice program statement: narrative description of the requirements for each functional area, used by the design team.

Space analysis:

determines the amount of area required for each of the functional areas of the foodservice operation.

Determination of adjacency:

what functional areas need to be located next to each other?

Foodservice program statement:

narrative description of the requirements for each functional area, used by the design team.

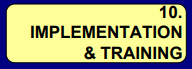

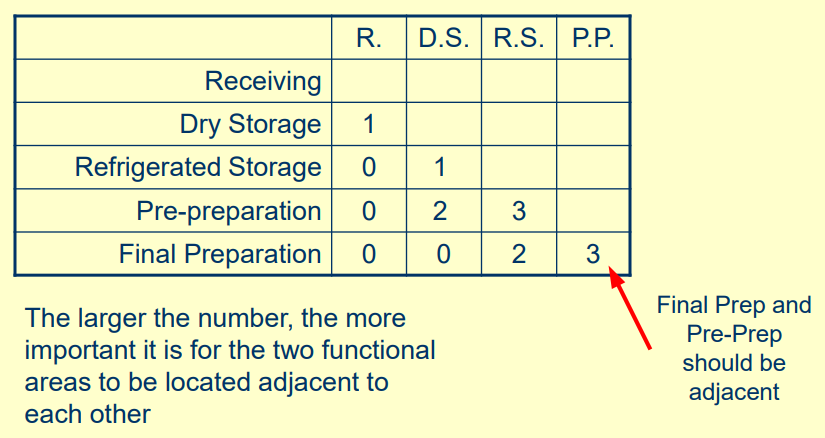

Adjacency Matrix (Portion)

Example of a Bubble Diagram

Foodservice Program Statement Elements – Partial Example

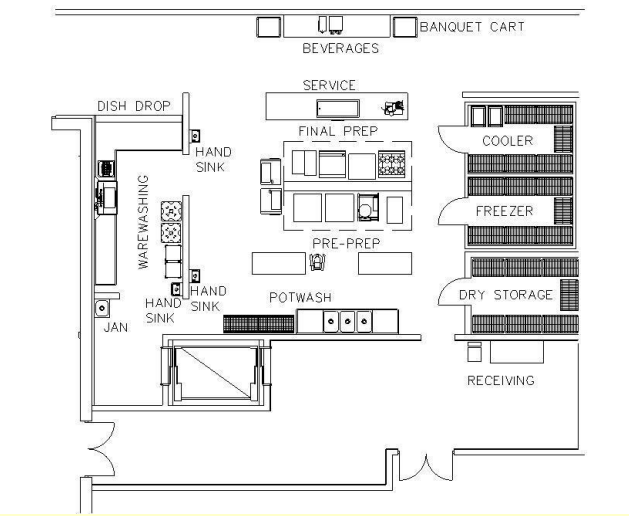

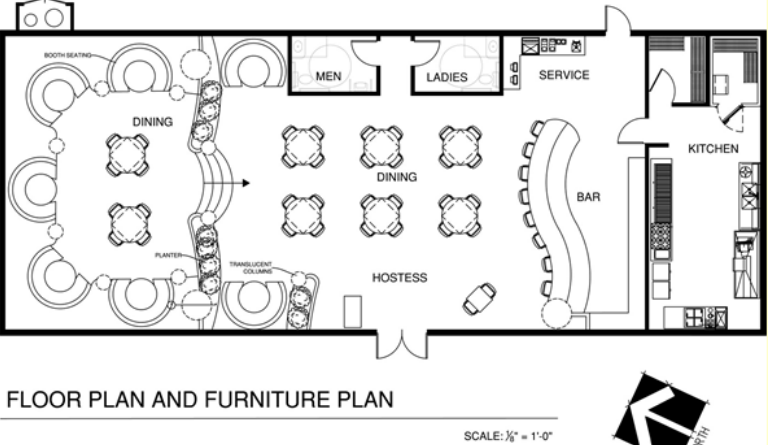

Schematic Design (Phase I)

Shows the shape of the building, the entrances & flow patterns, location of dining rooms, kitchen, & other major components of the foodservice facility.

Typically prepared, presented to the owner, & revised several times.

A preliminary estimate of the cost of construction is typically prepared near the end of the schematic design phase.

Schematic Design Example

Design Development (Phase II)

The team “fleshes out” the design of the project through increasingly detailed drawings.

Alternative systems are evaluated through value engineering.

Foodservice equipment selections are made in consultation with the owner.

Detailed floor plans, utility drawings, elevations & sections are prepared.

Preliminary specifications are prepared.

Cost estimates for the project are revised & refined.

Plan

A drawing or a diagram showing the proportion and relation of parts or details of a structure without a roof (floor, electrical/lighting, plumbing, etc.)

Elevation

A drawing showing one side of a structure (front, side)

Perspective

A drawing that exhibits the objects represented as having evident depth and distance (interior)

Blueprint

A set of illustrations of how the building or equipment should look like currently, or what will exist in the future (Plan, Elevation, Perspective)

Façade (Exterior Perspective)

Elevation

Interior Perspective

Floor Plan

Construction Documents (Phase III)

Drawings: show construction of the new or renovated facility, including all site work, structural systems, rooms & other spaces, utility systems, equipment, finishes, & details

Specifications: describe the materials & products, the standards of workmanship, the methods of fabrication & construction, the applicable code requirements, & the methods of installation, cleaning, & testing.

General conditions of the contract: defining terms, assigning responsibility, establishing payment schedules, describing how changes are to be handled, & listing the specific project conditions .

Drawings:

show construction of the new or renovated facility, including all site work, structural systems, rooms & other spaces, utility systems, equipment, finishes, & details

Specifications:

describe the materials & products, the standards of workmanship, the methods of fabrication & construction, the applicable code requirements, & the methods of installation, cleaning, & testing.

General conditions of the contract:

defining terms, assigning responsibility, establishing payment schedules, describing how changes are to be handled, & listing the specific project conditions .

Types of Specifications

Descriptive specifications identify all the important characteristics of the material or product.

Proprietary specifications identify the product by reference to a manufacturer & model number, & require the contractor to provide that item & no other.

Performance specifications establish performance criteria that are relatively independent of the specific description of the item.

Descriptive specifications

identify all the important characteristics of the material or product.

Proprietary specifications

identify the product by reference to a manufacturer & model number, & require the contractor to provide that item & no other.

Performance specifications

establish performance criteria that are relatively independent of the specific description of the item.

Bidding & Contract Negotiation (Phase IV)

Putting the project “on the street”.

Interested contractors prepare proposals following the requirements of the documents.

Questions regarding the requirements are addressed by the design team.

Bids are due by a deadline.

Bids are evaluated for conformance to the contract requirements.

The successful bidder (often the lowest qualified price) is identified & a contract is negotiated.

Bidding & Contract Negotiation (Phase IV)

• Foodservice equipment contractors often propose substitutions & alternates to what was specified in the bid documents:

Substitutions: proposals to provide materials, products, equipment, or systems from a manufacturer other than the one named in the specifications.

Alternates: proposals to provide materials, products, equipment, or systems different from what was described in the specifications, generally at a significantly lower price.

• Substitutions & alternates are evaluated by the foodservice design consultant, who makes a recommendation to the owner regarding their acceptance.

Construction Coordination (Phase V)

Submittal review: review of the “shop drawings” & equipment submittals prepared by the foodservice equipment contractor.

Coordination with the architect & contractors where questions arise in the construction process about the foodservice installation, often through job site meetings.

Construction Coordination (Phase V)

Review of proposed changes to the work.

Attend job site meetings.

Examination of the construction progress & installation of the foodservice equipment.

Inspection/Acceptance

Prior to turning the completed facility over to the owner, the architect, engineers, foodservice design consultant, & interior designer examine their parts of the project.

A punch list is prepared by each member of the design team, describing all work that remains to be done to complete the project according to the plans & specifications.

A punch list

is prepared by each member of the design team, describing all work that remains to be done to complete the project according to the plans & specifications.

Inspection/Acceptance

The completed facility is turned over to the owner when the project team is satisfied that the work is complete & fulfills the requirements of the contract.

The submission of the letter recommending acceptance of the project by the owner is often the final step in the design sequence.

Implementation & Training

Benefit employees by:

Explaining the intent of the design.

Learning the most efficient & effective ways of using the new facility.

Demonstrating the proper use & maintenance of new equipment.

Employees who are involved in the planning process gain a sense of ownership, & ownership leads to commitment to the success of the new facility.