Strain Gauges

1/18

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

19 Terms

Definition of Transducers

convert sensored variable into detactable signal form

e.g

mechanical quantity → change in electrical signal (strain gauge)

What type of transducers is strain gauges

device that strain → change in electric resistance

tension→ increase in resistance

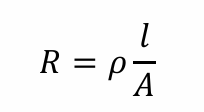

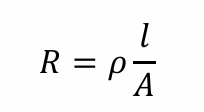

Basic equation of resistance

Reason why strain gauge create change in resistance

when strain,

there is changes to l and A values due to conservation of volume

piezo-resistive effect changes resistivity of material

(increases with tension)

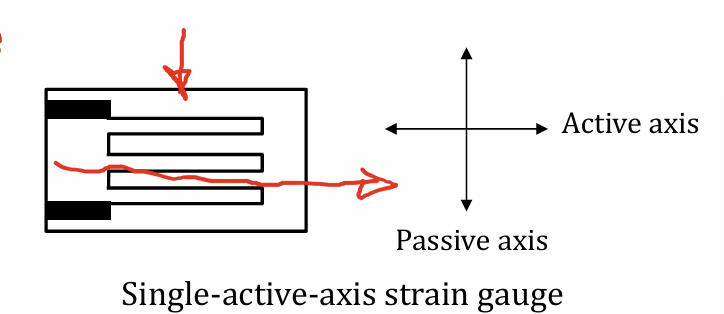

Structure of simple wire strain gauge

wire folded on flexible sheet

change in resistance in active axis is much greater than in passive axis

Definition of gauge factor

Gauge factor changes with different gauge

1.8<G<2.2

Structure of foil strain gauge

rolling thin foil of the resistive material on thin insulating paper

cutting away parts of the foil by a photo-etching process, to create the required grid pattern

adhesive to paper should be creep-free and allow heat dissipation

wire vs foil strain gauge

Foil is better

larger surface area for adhesion

accurate reproducibility due to photo-etching technique

small dimension for localised strain measurement

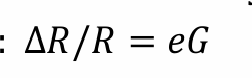

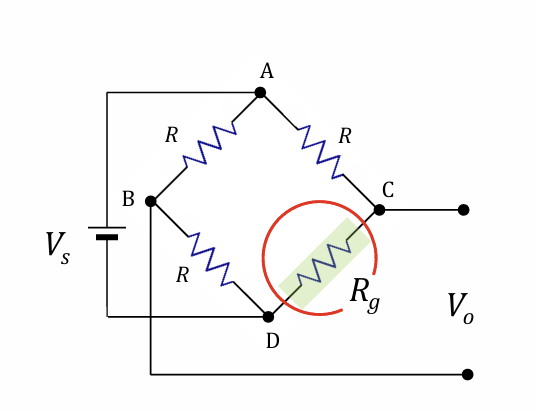

Derivation of V0/e=1/4VsG

Reasons for temperature influencing strain gauge measurements

changes in temperature:

thermal expansion → change in dimensions of specimen and gauge

resistivity of gauge

Method of temperature compensation

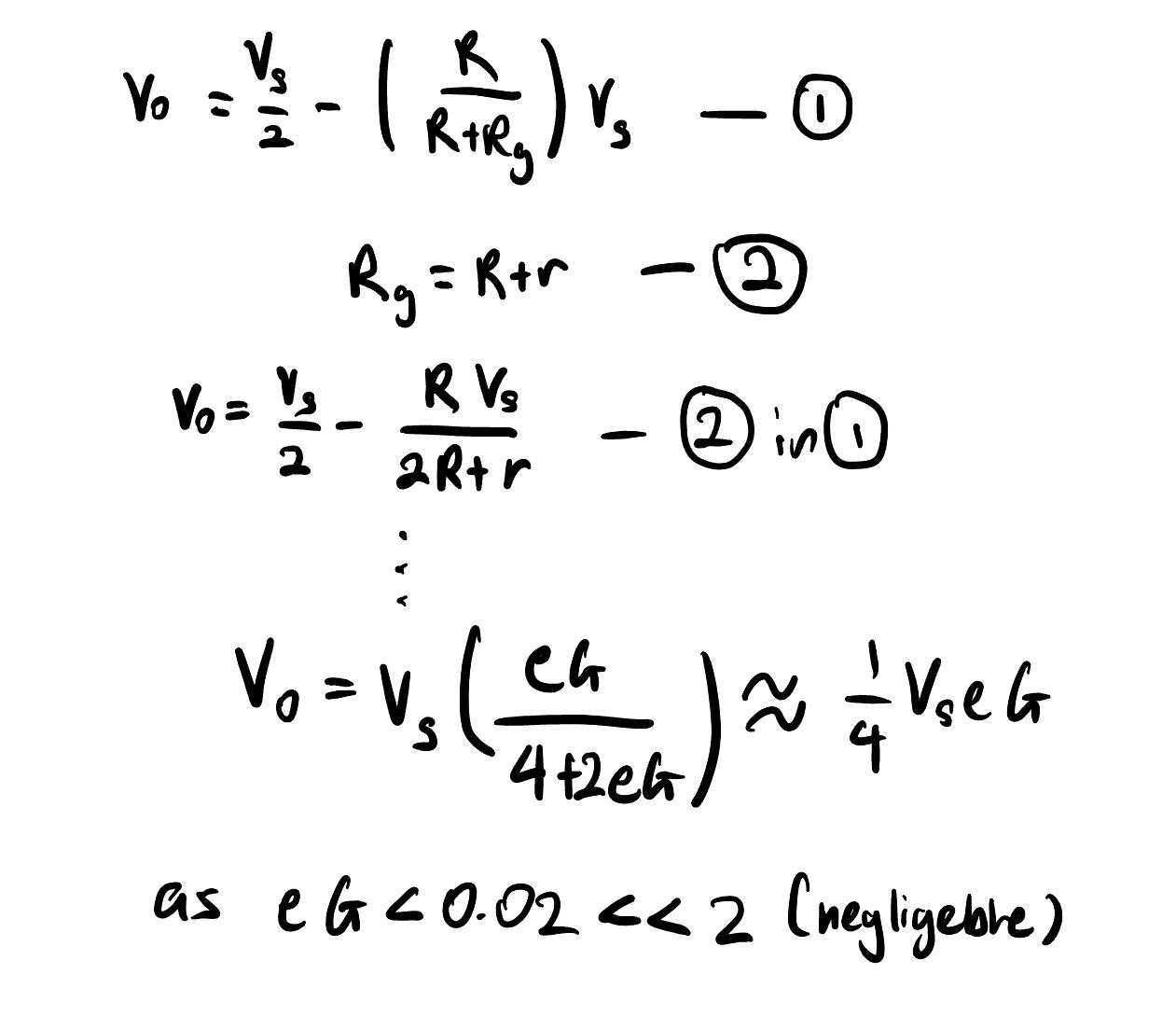

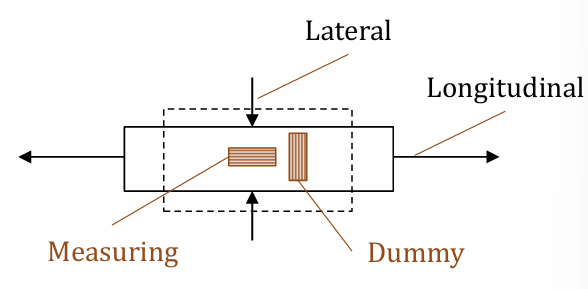

Dummy gauge on separate specimen not under strain

Dummy gauge on same specimen perpendicularly

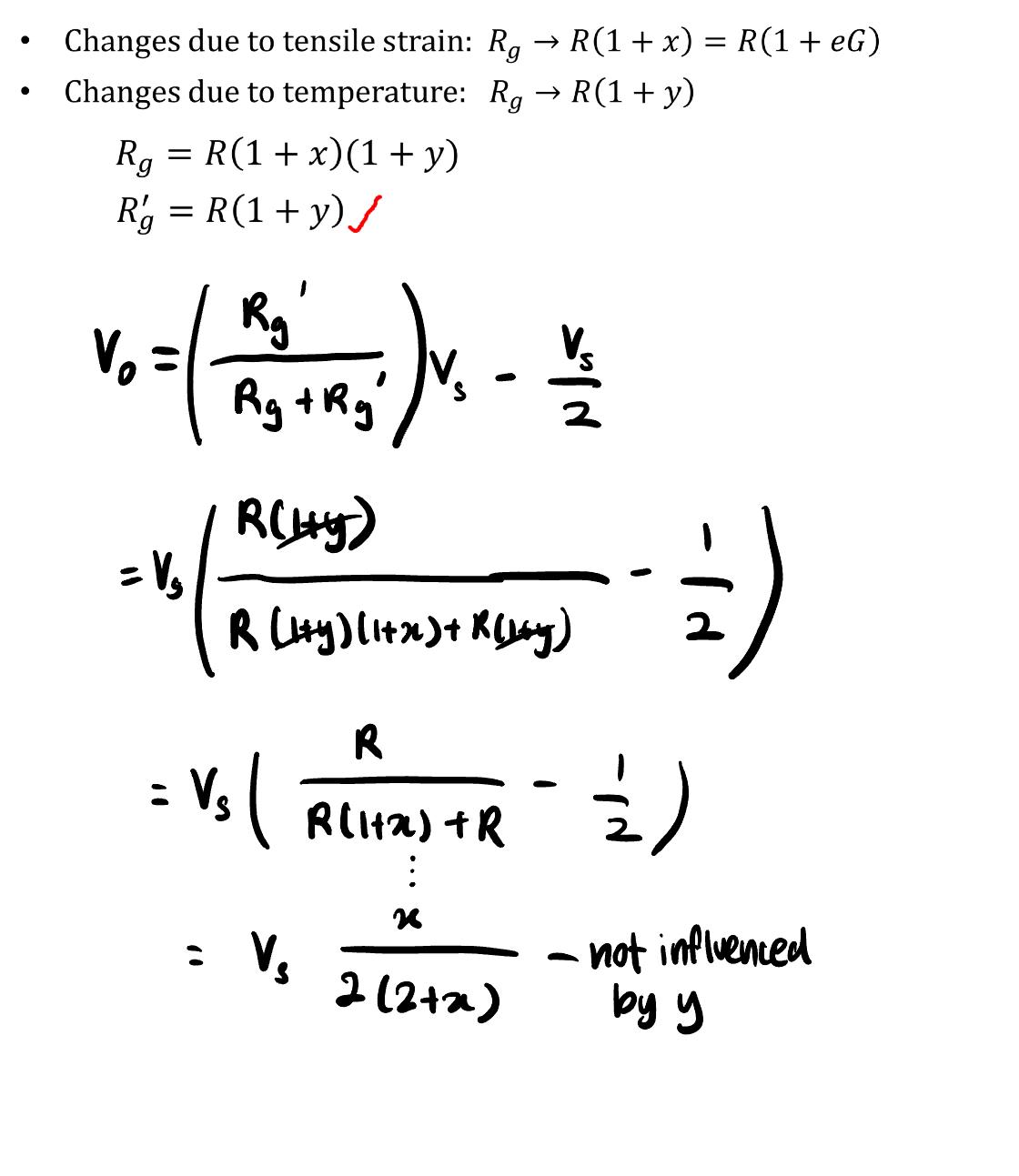

Proof that temperature is compensated for in strain gauge on unstressed specimen

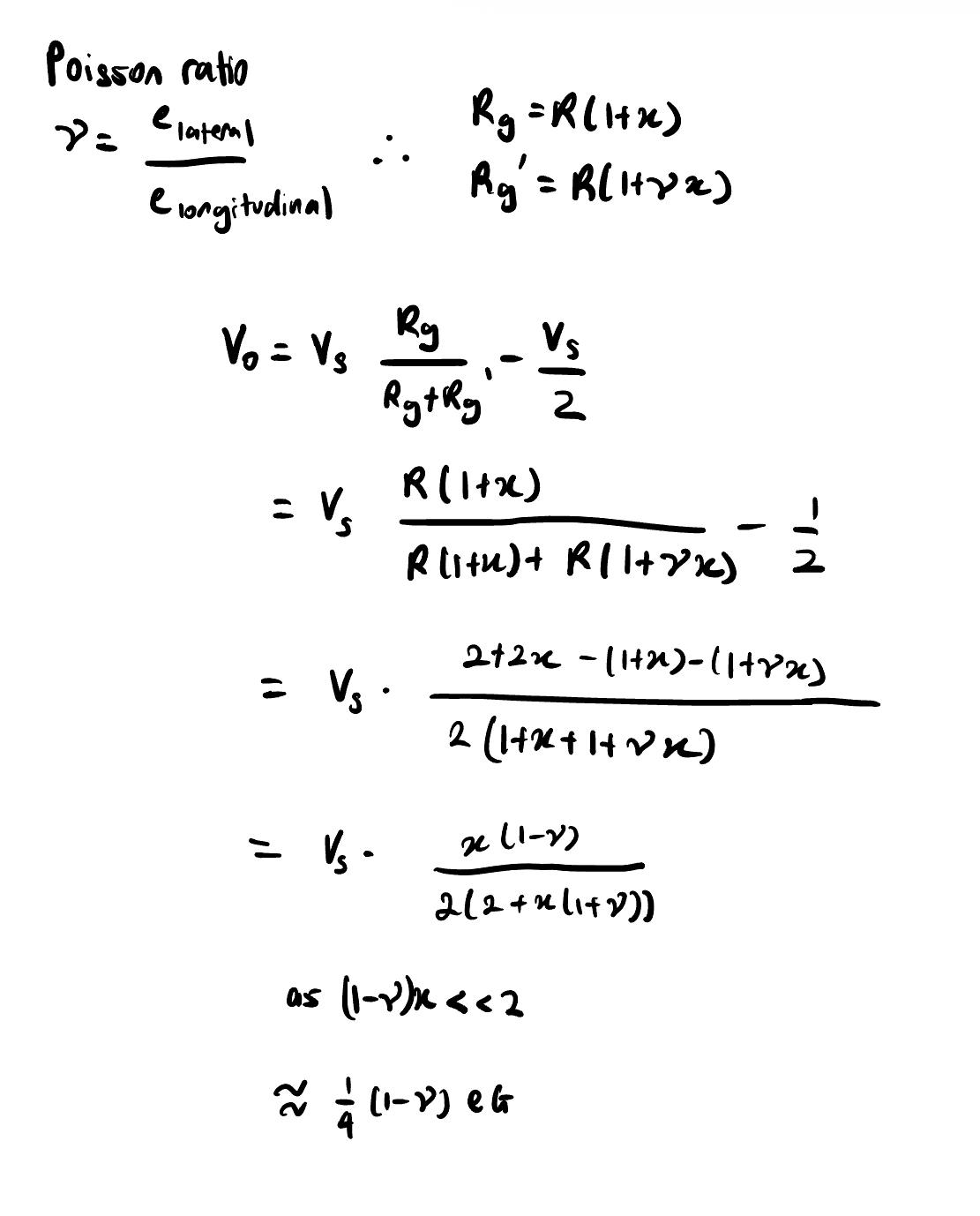

Proof that temperature is compensated for in perpendicular strain gauges

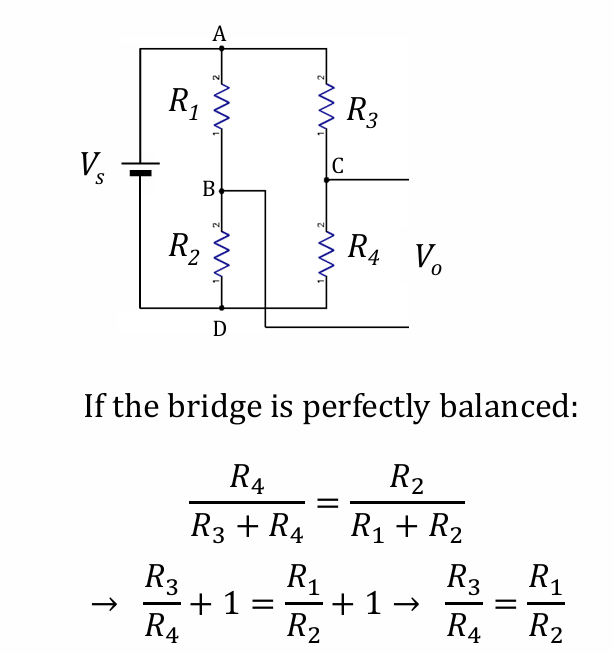

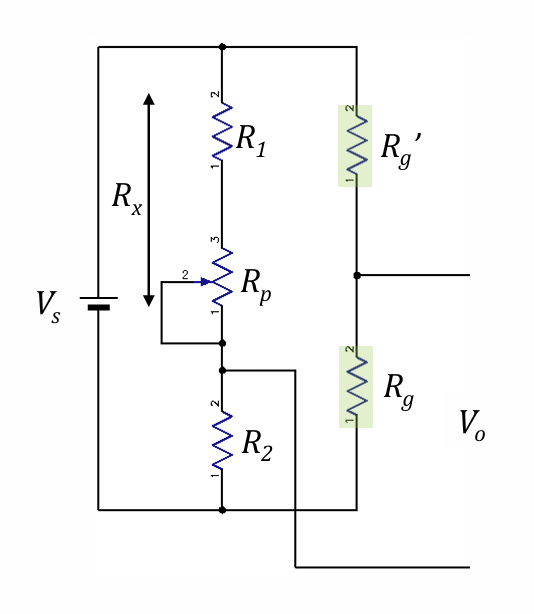

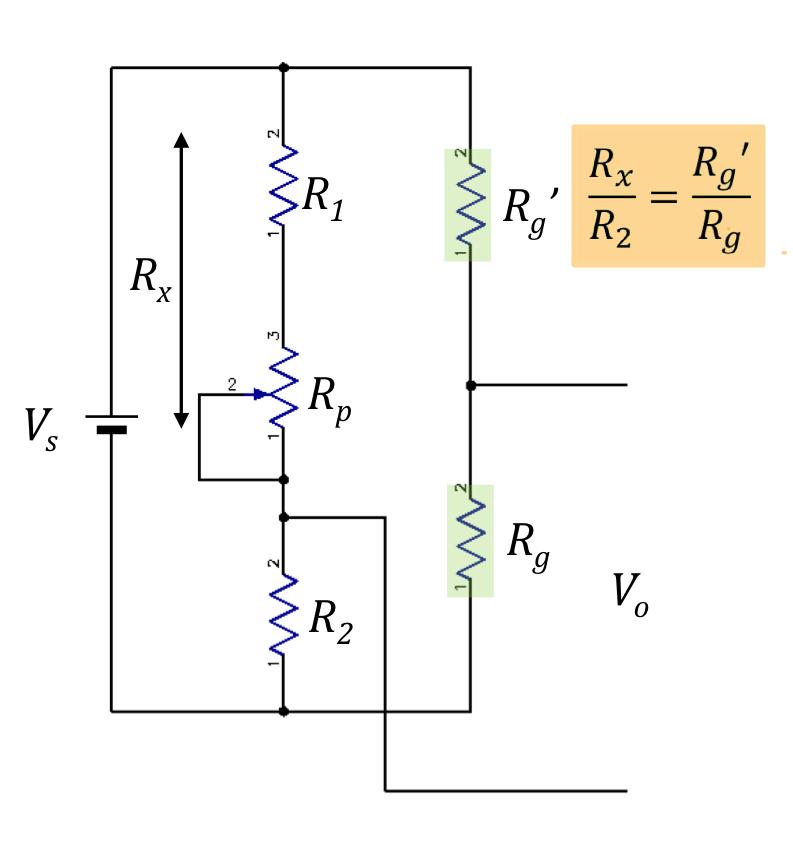

Reason for bridge balancing

resistance of each arm in bridge differ due to

manufacturing variance,

temperature difference btw gauges

static strain in one member

therefore cannot assume that ^^

Method of bridge balancing

Connect a pot (potentiometer) before measurement

adjust pot ^^^, where Rx=R1+Rpot

Method of semiconductor strain gauges working

semiconductor material has very large piezo-resistive effect

reach gauge factor from 100 to 300

magnitude of piezo-resistive effect determines sensitivity of gauge

Limitations of semiconductor strain gauge

Strain gauge material has a much smaller elastic limit than metal (4000microstrain compared to 20k microstrain for metal)

G is not linear at high strain

G changes significantly with temperature(temp coeff is large)

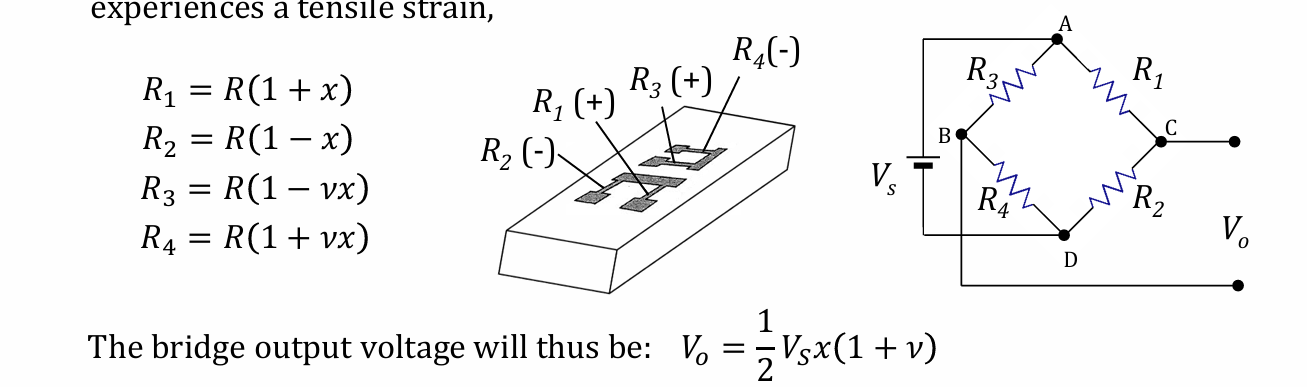

Method of temperature compensation for semiconductor strain gauges

connect 2 crystal in series but aligned parallel

All the crystal have the same temperature coefficient, temperature changes affect all crystal equally

As R1 and R2 increase/decrease same magnitude, and same for R3 and R4, changes in dimension cancels out.

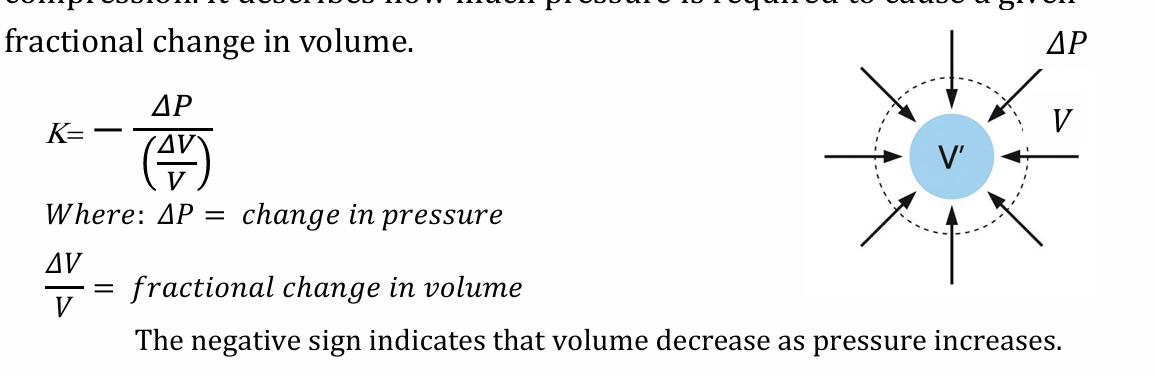

Definition of bulk Modulus [K]