Module 1 Exam

1/50

Earn XP

Description and Tags

Quality Control & Quality Assurance

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

51 Terms

Measuring overall patient quality from check-in to check-out

Quality Assurance

properly functioning equipment

Quality Control

acceptance within 2%

collimator test tools

Device used for centering

Device used for SID

checks spacial resolution and filament wire size

Focal Spot Size

space charge forms around filament and causes electron clouds to swell

focal spot blooming

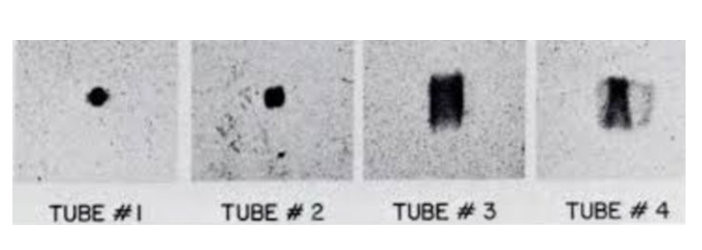

Device used for focal spot size (difficult to use)

Pinhole camera

Device used for focal spot size (easy to use; limit for FSS < 0.3 mm)

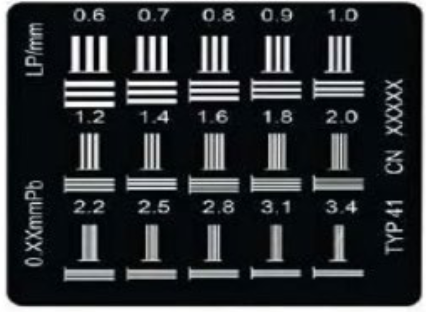

Star Pattern

Device used for focal spot size ( preferred method)

Slit Camera

acceptance within 10% of selected kVp (ion chambered meter)

kVp accuracy with use of generator

measured with photodiode/ion chamber with diff times within tolerance amount

exposure timer

acceptance within 5% of selected time for exposures > 10 ms

acceptance within 20% of selected time for exposures < 10 ms

Exposure timer

repeats same overall technique setting and obtain same results

exposure reproducibility

acceptance within 5% ( same technique = same exposure)

exposure reproducibility

acceptance within 10% (same mAs value= same exposure)

Exposure linearity

acceptance within 2%; consistency of exposures with varying factors

AEC Consistency

Radiation outputs within 5%; optical densities within 1% ( same kVp & AEC setting = same exposure = same optical density)

AEC reproducibility

terminates at 600 mAs / 6 secs

back up timer

removes low-energy x-rays from beam (measured with ion chamber & minimum of 2.5 mm Al)

Filtration

ability to distinguish between adjacent structures (contrast & spatial resolution)

contrast & noise

measures uniformity of grid spacing ( uses wire-mesh screen)

distortion assessment

shading test; evaluates brightness

image uniformity

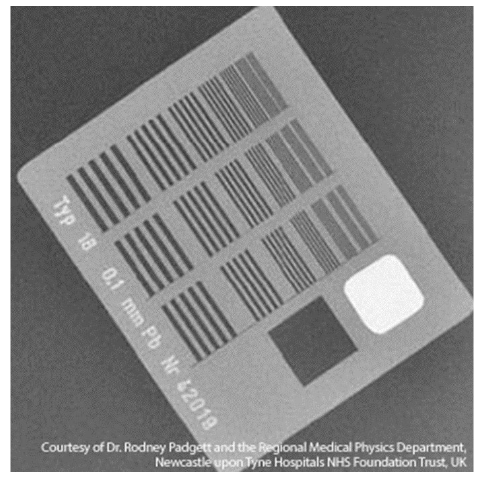

shows clear crisp lines and high lpmm

Spatial Resolution

Spatial Resolution device

compares pixel values ( pixel values increase as exposure increases)

Exposure Indicator Linearity Test

no ghosting and complete erasure

Plate erasure - PSP plate

no image retention

plate erasure - DR systems

designated EI # appears on designated exposure; ensures uniformed calibration

Exposure indicator calibration

visible light emitted from surface and measured in brightness (source)

luminance

visible light strikes surface (actual light)

illuminance

close proximity (photometers)

near-range

distance of 1 meter (photometers)

telescopic

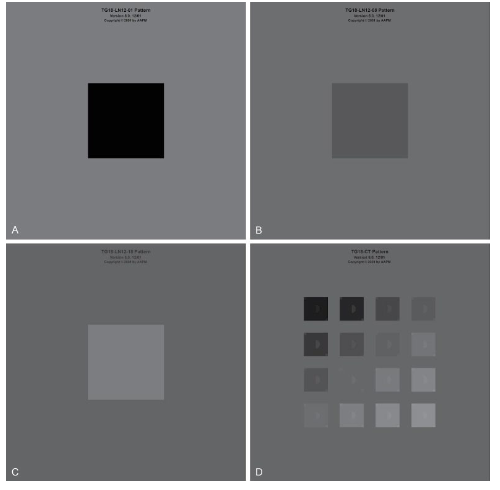

brightness & contrast ( display luminance)

color uniformity (gray across entire test pattern)

variation in shape and image displayed from original (appearance of straight line)

geometric distortion

evaluation of image nonuniformity and effects of viewing from different angles

Luminance Dependencies

dynamic range; how well monitor displays grayscale

luminance response

high frequency fluctuations/patterns that interfere with detection of true signal

Noise

ambient light; distinguish between lines

Reflection

distinct patterns of black and white pairs

Spatial resolution

Veiling Glare

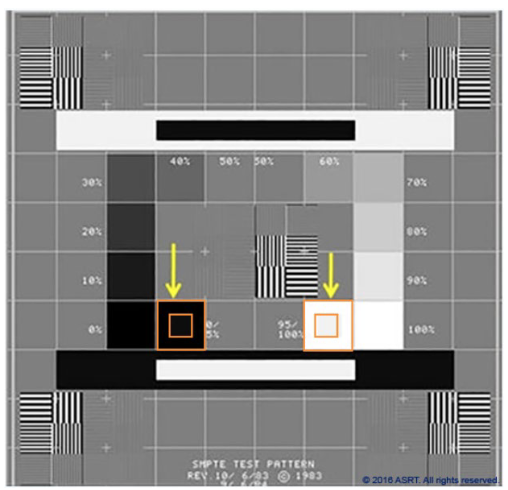

What device

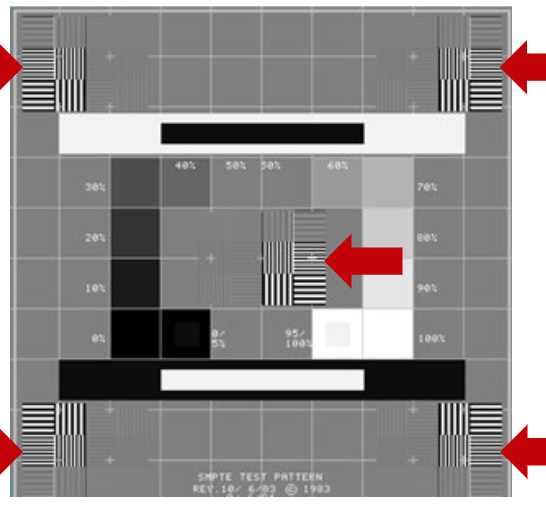

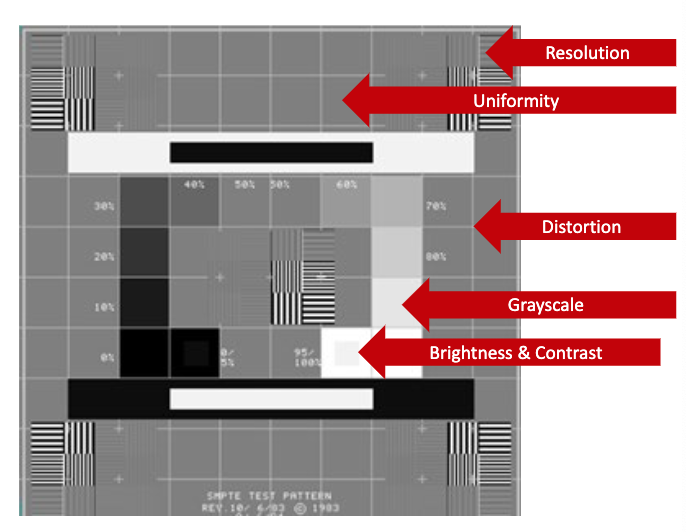

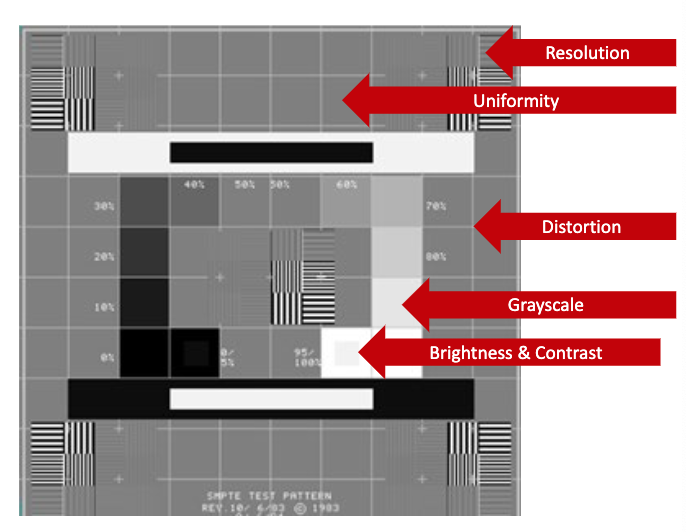

SMPTE

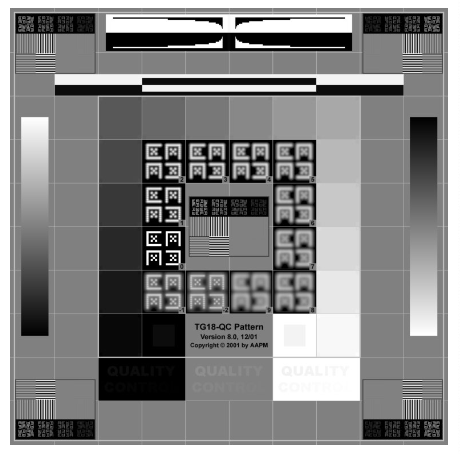

what test pattern

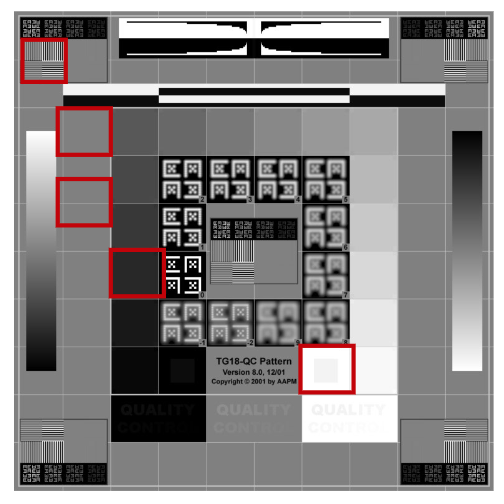

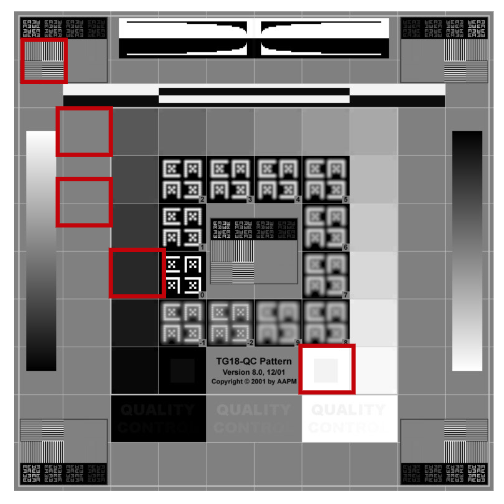

TG18 - QC

What test pattern

What tests uses this pattern?

resolution

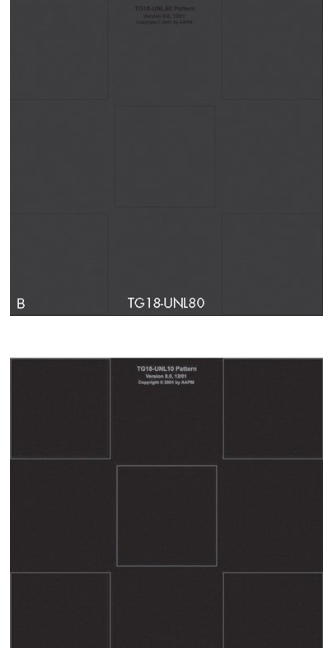

uniformity

distortion

grayscale

brightness & contrast

What tests use this pattern

general image quality

artifacts

geometric distortion

resolution

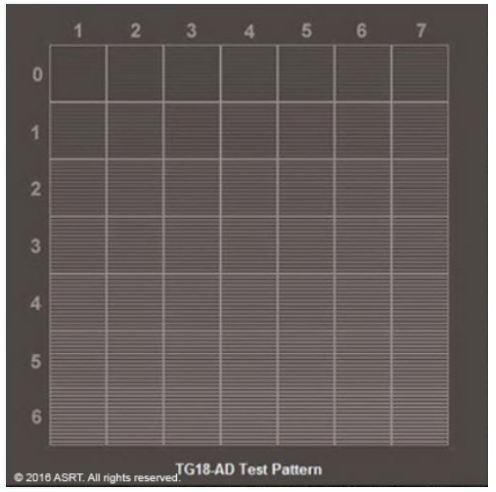

Reflection test

TG18 - AD

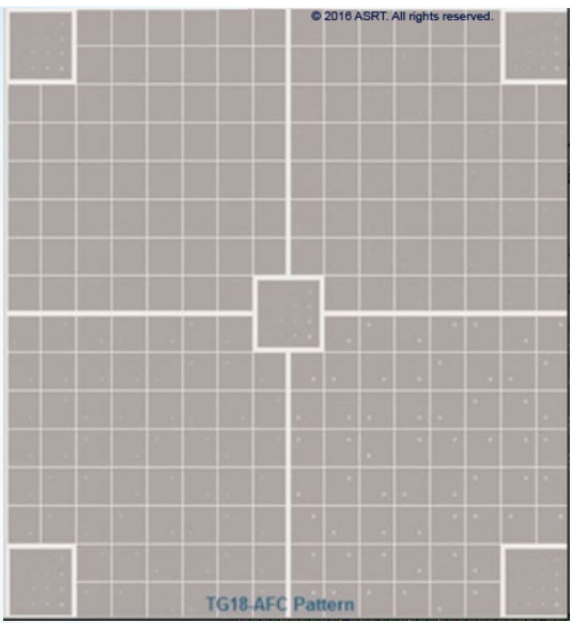

Noise test

TG18 - AFC

Luminance Response test

TG18 - CT

Spatial Resolution test

TG18 - CX

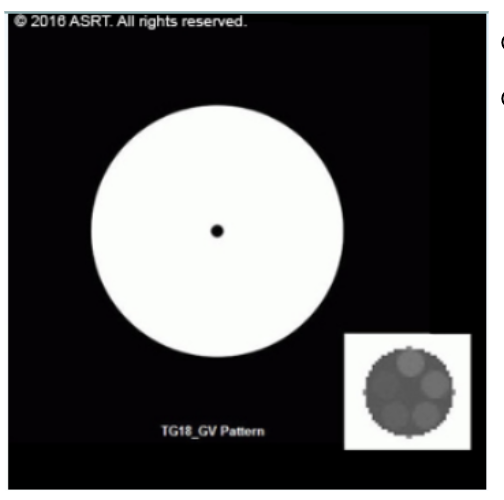

Veiling Glare test

TG18 - GV