MIDTERM OPS KILL ME

1/57

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

58 Terms

The Operation realities

Better quality, high productivity, lower costs and the ability to respond quickly to customer needs

Organizational strategies

Overall strat. That relate to the entire org

Support the achievement of organizational goals and mission

Functional level strategies

Strategies that relate to each of the functional areas and that support achievement of the organizational strategy

Tactics vs Operations

Tactics:

The methods and actions taken to accomplish strategies

The “how to” part of the process

Operations

Actual “doing” part of the process

Order qualifiers

Characteristics that customers perceive as minimum standards of acceptability for them to consider purchase

Order winners

Characteristics that lead customers to prefer one product over another, providing a competitive advantage.

Have/ offering that causes you to get the order (transaction to happen)

Competitive Dimensions

Cost or price

Quality

Delivery speed

Delivery reliability

Responsiveness to demand changes

New products and flexibility

Support functions (after sale)

Risk Mitigation Framework

Identify the source of potential disruptions

a. Look @ highly unlikely events— that cause significant disruption to normal ops

Assess the potential impact of the risk (risk mapping)

a. Quantify probability and potential impact of risk (prob frequency & amount of loss)

Develop plans to mitigate the risk

a. Detailed strat. for minimizing the impact of risk (could take many diff. forms)

FMEA

Failure

Modes

Effects

Analysis

Productivity

Relative measure

Measure of effective use of resources

Normally dimensionless number (unless specified)

Efficiency

Quality

How well do you perform

Look 4 underlying costs

Refined measure

Doing something at the lowest possible cost

Getting the most out of a given set of resources

Productivity

Quantity

Performance

No look 4 underlying costs

Raw measure

Looks at alternative easy to increase the output or reduce the input

Phases of product development

Phase 0: Planning

Corporate strategy /// Tech. assessment

Mission: What will we develop?

Phase 1: Concept Development

Market needs identified /// Alternative concepts generated and evaluated

Concept(s) selected for further development

Phase 2: System-Level Design

Product architecture /// Sub-systems and components

Layout, functional specifications, production process flow

Phase 3: Design Detail

Complete specification of geometry, materials, and tolerances /// Suppliers and tooling for parts

Drawings, process plan

Phase 4: Testing and Refinement

Prototypes tested to evaluate product performance /// Multiple preproduction versions evaluated

Phase 5: Production Ramp-up

Production system used for final product /// Pre-production samples sent to customers

Worker training

Complexity:

# of steps involved in a service & the possible actions that can be taken at each step

Divergence

# of ways a customer/service provider interaction can vary at each step according to the needs & abilities of each

Complexity and Divergence Determine:

The resources (worker skills)

Layout changes that might be required

Process controls needed for the new service

Steps to determine capacity requirement

Forecast to predict sales

Calculate equipment and labor requirements

Project labor and equipment availability

Operating capacity:

Volume of output that can be sustained that minimizes the average unit cost (Involves tradeoffs, fixed costs, equipment wear, etc.)

Sometimes called rated capacity

Capacity utilization rate:

a measure of how close the firm is to its best possible operating level

Economies of scale:

as a plant gets bigger and volume increases, & average cost per unit drops

Diseconomies of scale:

at some point, the plant becomes too large & average cost per unit begins to increase

How to fix capacity Imbalances

Add capacity (overtime, equipment leasing)

Add buffers to ‘smooth’ out fluctuations

Decouple operations

Where is best operating point?? (service utilization)

Best operating point is near 70 percent of maximum capacity

Fixed cost:

An expense that remains constant regardless of output level

Variable cost:

Expenses that are directly proportional to the level of output

Sunk cost:

Past expenses/ investment with no salvage value or current expenses that will have no bearing on the decision

Opportunity cost:

Benefits foregone bc of choosing an action as opposed to the “best” known action

Capital Expenditure (CAPEX):

Spending associated increases in plant, property and equipment

Expected Value

The likelihood of a particular outcome happening is its probability

The ________ Value = expected outcome X the probability of that outcome happening

NPV

_ _ _ is the value today of money you’ll receive or pay in the future

It’s the difference between Pv of money coming in and Pv of $ going out over time.

Internal Rate of Return (IRR)

Is a discount that make the NPV of all cash flows equal 0

At a minimum IRR should be > WACC

Payback Period

the length of time required for an investment to recover its initial outlay in terms of profit savings

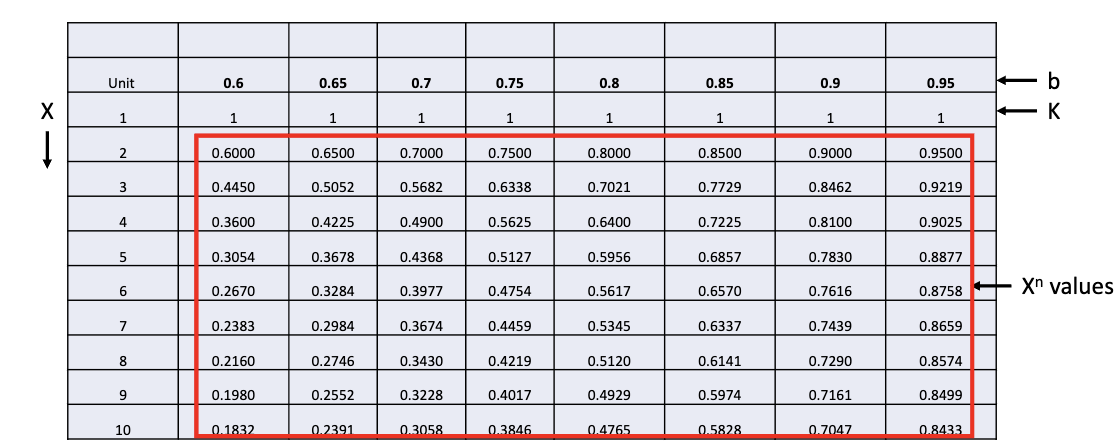

Learning Curves?

As output doubles, there is a fixed percentage reduction in the time needed to produce each unit

3 Assumptions:

Time required to complete a given task will be less each time the task

is undertakenUnit time will decrease at a decreasing rate

Reduction in time will follow a predictable pattern

Individual learning:

Improvement that results when people repeat a process and gain skill or efficiency from their own experience

Practice makes perfect

Organizational learning:

Biz learning

Can come from changes in administration, equipment, and product design

Improvement Factor Table

Job Shop

Nature of business: Customized goods or services

Pros: Able to handle a wide variety of work.

Cons: Slow, high cost per unit, complex planning, and scheduling.

Organization: Product areas.

ie. operating room

Batch

Nature of business: Semi-standardized goods or services.

Pros: Flexible, easy to add or change.

Cons: Moderate cost per unit, moderate scheduling complexity.

Organization: Processes are continuous, but ____es can differ in flow and duration.

ie mas catering

Repetitive

Nature of business: Standardized goods or services.

Pros: Low unit cost, high volume.

Cons: Low flexibility, high cost of downtime.

Organization: Assembly lines.

ie Auto manufacturing

Continuous

Nature of business: Highly standardized goods or services.

Pros: Very efficient, very high volume.

Cons: Very rigid, lack of variety, costly to change, very high cost of downtime.

Organization: Runs continuously, materials are typically gases, liquids, powders, slurries.

ie Plant??

Lead Time:

Time from when an order is placed to when customer receives the order

The sum of all the cycle times in process from start to finish (assume no parallel processes)

Types of Manufacturing Environments

Make to stock: Customer purchases from existing finished goods inventory

Trade-off between the costs of inventory and level of customer service

Assemble to Order: Product is assembled from limited set of options upon receipt of order

Computers ordered online with selection of options

Make to Order: Higher degree of customization than assemble to order

Aircraft manufacturing

Engineer to Order: Designed to customer specifications

Satellites

Variety Leads to Complexity

N1 x N2 x N3 x N4 ....x Ni

4 different models, each model with 3 different case colors, 3

different memory configurations

Total combinations 4 x 3 x 3 = 36 possible configurations

Breakeven Analysis

The choice of equipment or process involves a cost tradeoff

General purpose (do many different things slower) vs. special purpose (few things fast)

________ _______ compares choices in processes/ equipment on the basis of TC,

which will vary with Volume of productionThe point of indifference between them because total cost is the same

Process technology

Methods, procedures, and equipment used to produce goods and provide services

Information technology

The science and use of computers and other electronic equipment to store, process and send information

Product layouts: _______ line

Layout that uses standardized processing operations to achieve smooth,

rapid, high-volume flowSubway or Car build lines

Pro: High output, low unit cost, high utilization equip/labor

Con: Boring, no changes, shutdowns

Process layouts: Work Center, Functional or Job-shop layout

Non-repetitive

Layouts allocate similar machines or activities into an area

Fixed-position layout: Project layout

Layout in which the product or project remains stationary, and workers,

materials, and equipment are moved as neededLarge construction projects: Shipbuilding/ aircraft manufacturing, Space mission

(very specific sequence of task order)

Combination layouts: Manufacturing cells

Some operational environments use a combination of the three basic layout types:

Hospitals

Supermarkets

Shipyards

Cells: allocate dissimilar machines into cells

Cycle time

It is the average elapsed time between any two parts

In ACTUAL production the cycle time SHOULD be < the Takt time in order to meet demand

BC there will always be delays and variation when doing things

Takt time

Maximum allowable cycle time in order to meet the production goals

Line Balancing

The sequence and process times are ordered to keep the line balanced and flowing

The longest process time (including wait time) are early in the sequence

The operations with the longest process time will be the bottleneck

Mixed-Model Line Balancing

Objective is to meet demand and avoid high inventories when you

have more than one product being made on the same lineOne means scheduling this varied production

Information needed

1. Total amount of time available for prod

2. Total quantity needed in that time

3. Cycle times

4. Ratio of different models (calculated based on total quantity)

5. Changeover time

Service Layout

Categorized as: product, process, or fixed position

Requirements:

Degree of customer contact

Degree of customization

Retail Layout

Goal is to maximize net profit per square foot of floor space

One-piece

Shorter lead time when finished Inventory is not carried!!!

Fast casual restaurants

Can get same OR higher output w/ less capital equipment

Batch

Used where setup time/ costs are high (more efficient to produce more per setup)