7. Emulsions and microemulsions

1/22

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

23 Terms

Emulsion

A mixture of immiscible liquids (not insoluble, still some degree of solubility, however usually different phases).

Examples:

– Oil-in-water (e.g mayonnaise) (continuous oil phase)

– Water-in-oil (e.g. butter)

– Double emulsions (e.g. oil-in-water-in-oil) (emulsion drops in the emulsion, drops have to be quite large to have drops inside of them)

• Droplet size: <100 nm to 100 μm

• Surface layer of adsorbed emulsifier (surface active) (protein or polymer) stabilizes

– Surface layer is typically very thin (1-3 nm)

Emulsion instability

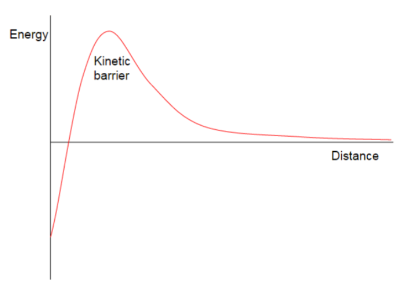

Emulsions are thermodynamically unstable (eliminating the dispersed phase)

A barrier needs to be created to prevent flocculation and coalescence

Add an emulsifier to create a barrier, stabilise by giving repulsive forces between oil drops (the main function of emulsifier, not to decrease surface tension)

Coalescence

fusion of several small droplets to larger droplets

Emulsifier

The main role of the emulsifier is to prevent the immediate coalescence of droplets when the emulsion is formed, and to prevent flocculation and coalescence. The main role is not to lower surface tension that the liquids can mix.

In order to stabilize an emulsion the emulsifier should:

Give rise to repulsive interaction between droplets

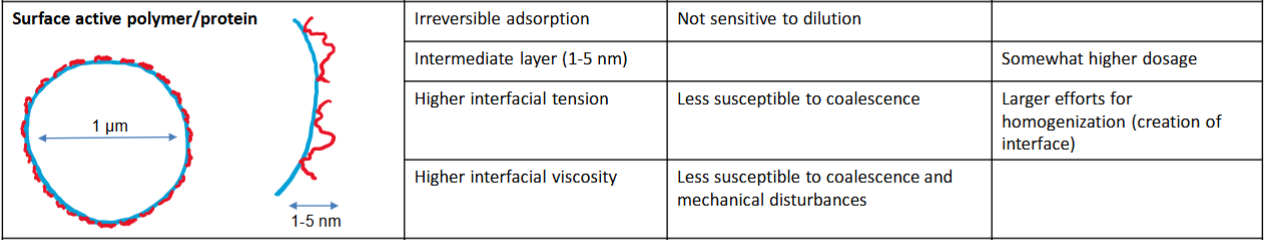

Contribute to the interfacial viscosity (more rigid (higher viscosity) the interface better resistance to deformation)

Should be well anchored at the interface

Coalescence requires:

Requires that droplets are in close contact either through:

High dispersed phase volume fraction (φ) (e.g mayonnaise, the particles are not spherical, the maximum phase volume fraction is 0.57 for spherical particles)

Flocculation

Creaming/sedimentation

Requires deformation of the interface

Large droplets (larger flexible interface) are typically more susceptible to coalescence

Coalescence influenced by the adsorbed layer stability

• Thick layer → more stable

• Rheological properties (viscosity) of the adsorbed layer and the dispersed phase

• The presence of other phases

• Solid particles wetted by the disperse phase can destabilize (example: fat crystals, can keep two oil droplets together called partial coalescence (e.g whipped cream and ice cream))

• The interfacial tension

• Low interfacial tension → work to deform interface lower → sensitive to

coalescence

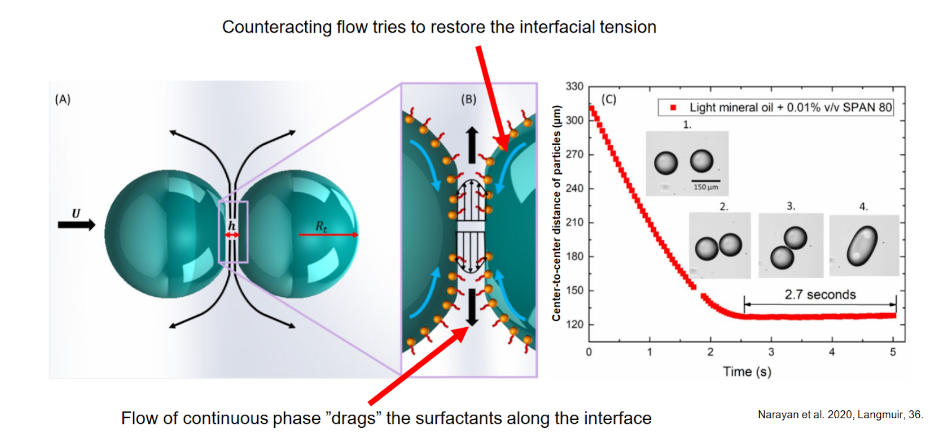

Deformation of the interfacial layer

Flow of continuous phase ”drags” the surfactants along the interface

Counteracting flow tries to restore the interfacial tension

Different types of emulsifiers

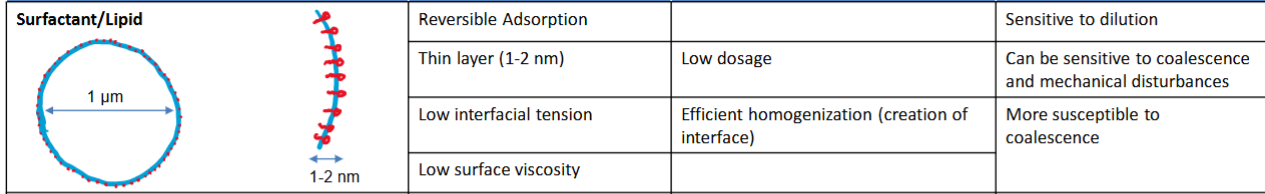

Low MW surfactants/lipids

Marcomolecules (surface active polymers and proteins)

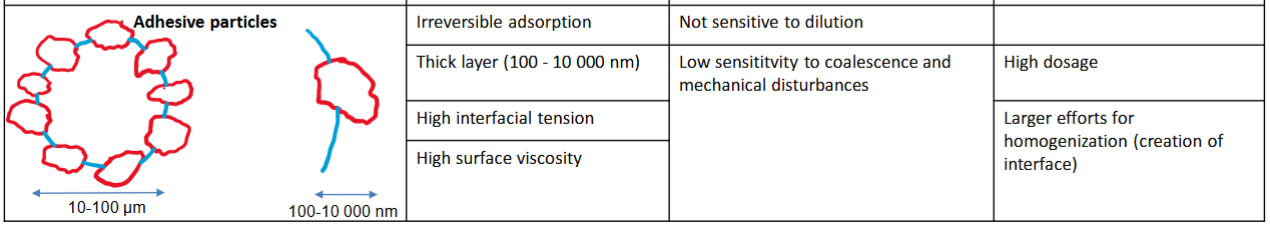

Adhesive particles (partial wetting - pickering emulsions)

Low MW surfactant/lipid

Surface active polymer/protein

Adhesive particles

Estimation of emulsifier dosage

Can also apply for other dispersions than emulsions

Rough estimation based on mass to cover interface

Length of surfactant molecule ~ 1 nm (i.e. thickness of adsorbed layer)

Density of surfactant molecules ~ 1000 kg/m3

10-9 * 1000 = 10-6 kg/m2 → 1 mg/m2

Calculate the total surface area in the emulsion/dispersion and compare with the mass of

emulsifier present

Estimation from thickness of emulsifier layer

Gives emulsifier amount relative to the dispersed phase

VE= Volume of emulsifier

VD= Volume of droplet

cE= Volume of emulsifier (in relation to the dispersed phase)

A= Area of droplet

d= diameter of droplet

Δ= thickness of emulsifier layer (length of emulsifier molecule)

Bancroft rule

The phase in which the emulsifier is most soluble in will be the continuous phase

Hydrophilic-Lipophilic Balance (HLB) concept

Emulsifier with a HLB value < 7 forms an oil continuous emulsion

Emulsifier with HLB > 7 forms a water continuous emulsion

Emulsification and stability

• For emulsification we need unstable interfaces

• For stability we need stable droplets

What should the emulsfication process accomplish?

• Create new interface (more and smaller droplets)

Energy cost: A*γ (surface area*surface tension)

• Overcome the viscous resistance of the disperse phase

Dynamic viscosity η

• Create a deformating force gradient over the droplets (intensive treatment to get small particles)

Phase inversion in emulsions

switch phase continuous phase becomes dispersed

• Spontaneous phase inversion

• Can occur at a high volume fraction (φ > 0.7) of dispersed phase

• Can also occur at a lower volume fraction

• For instance by increasing T in oil-in-water emulsion stabilized by an ethoxylated surfactant (sensitive to high temperature, hydrophilic drastically decreases → wants continuous phase rather polar)

• Phase inversion can also occur due to intense mechanical treatment

• Can be an approach to disperse very viscous oils

For example: Cream → butter

Different HLB value in relation to phase inversion

High HLB emulsifiers are hesitant to form water-in-oil emulsions

Low HLB emulsifiers are hesitant to form oil-in-water emulsions

Phase inversion is most likely when emulsifier has an intermediate HLB (get bicontinuous system, any of phases can become continuous)

Microemulsions

• Contains oil, water, surfactants and co-surfactants (can be a fatty alcohol (not surface active on its own))

• Gives additional lowering on the interfacial tension

• Requires relatively high amounts of surfactant

• Can be O/W, W/O or bicontinuous

• Are disordered

Properties of microemulsions

• Relatively low viscosity

• Solubilize both hydrophobic and hydrophilic molecules

• High diffusion of both oil and water soluble components (move quite freely)

• Low interfacial tension (close-packing of surfactant and co-surfactant)

Winsor classification of microemulsions

Winsor 3: The middle phase (M) can be a bi-continuous microemulsion

Winsor 2: W/O

Winsor I: O/W

Properties of microemulsions are changed by

Ionic strength (applied for ionic surfactants)

Temperature (applied for non-ionic ethoxylated surfactants)

Marcoemulsion vs microemulsions

M