Robotics Kinematics

1/22

Earn XP

Description and Tags

Definitions for robotics kinematics and example of robotic arms

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

23 Terms

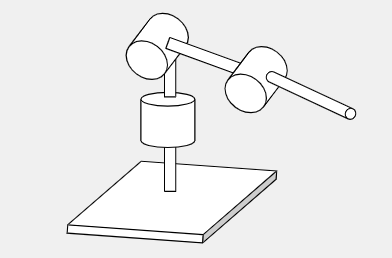

Anthropomorphic Robot Arm (RRR)

Spherical Workspace

Used for dexterous activities, i.e., welding or spray painting

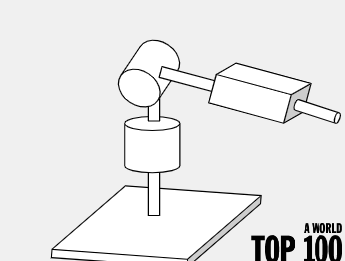

Spherical Robot Arm (RRT)

Spherical Workspace

Used for simple tasks that don’t require complex motion

Trades heavy loads for higher accuracy

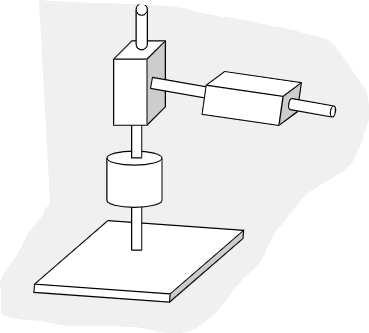

SCARA (Selective Compliant Articulated Robot for Assembly) (RRT)

Cylindrical Workspace

Used for factory assembly in single planes

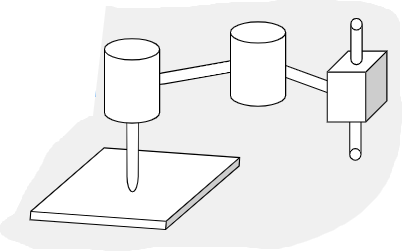

Cylindrical Robot Arm (RTT)

Cylindrical Workspace

Used for basic jobs

Cartesian Robot Arm (TTT)

Prism Workspace

Known for high accuracy with less capacity for high loads

Kinematics Definition

The study of motion without considering the forces and moments which are responsible for the motion.

The motion is described by trajectories, velocities and accelerations - in robotics the main interest is in trajectories and velocities.

Forward/Direct Kinematics

Given joint variables calculated the pose of end-effector

Forward/Direct Kinematics Additional Information

The solution is unique

Represents the simpler problemI

Inverse Kinematics

Given the pose of the end-effector calculate joint variables

Inverse Kinematics Additional Information

The equations are generally nonlinear

No closed form solution

No / Multiple / Infinite solutions may exist

Differential/Instantaneous Kinematics

Given joint velocities determine the end-effector linear and angular velocities

Inverse Differential Kinematics

Given end-effector velocities determine the joint velocities

Reachable Workspace

Set of points that can be reached by end-effector

Dexterous Workspace

Set of points that can be reached by end-effector with arbitrary orientation

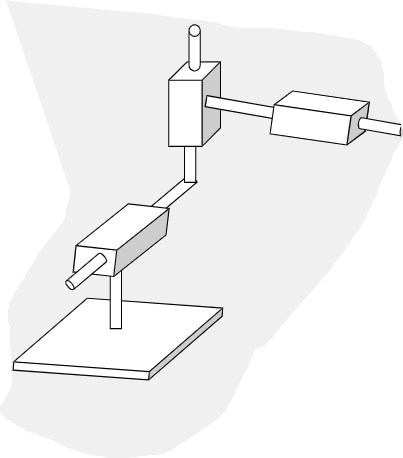

Mechanical Structure of Robot Manipulator

Consists of a sequence of rigid bodies (links) interconnected by means of articulations (joints)

Characterisation of Robot Manipulator

An arm that ensures mobility, a wrist that grants dexterity, and an end-effector (gripper) that performs the task required

Task of Manipulator

Place an object grasped by the gripper to an arbitrary position and orientation in 3D

Path

Locusts of points required for travel of the manipulator

Trajectory

The path plus the timings involved for those point

Kinematic Redundancy

Number of DOF > number of variables needed to describe task

Can be obvious (7 DOF) or less obvious (task makes it redundant)

Adds dexterity and versatility

Accuracy

Actual and computed kinematics not the same

Varies across the workspace

Error typically <1mm

Repeatability

Ability to return to same position

Depends on mechanical structure, sensors and controllers

Difference typically < 0.1mm

Singularities

Arise when Jacobian is rank deficient as the inverse is ill defined

Close to singular configurations small velocities in end-effector may cause large joint velocities

There may be infintie solutions to inverse kinematics, configurations where mobility is reduced