Print Media Production: Test 2

1/48

Earn XP

Description and Tags

Lectures 6-8

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

49 Terms

Turnaround

the whole production process from start to finish

Q

quantity needed - number of finished pieces, ask for 2-3 times higher quality that you think you need

M

If quantity is more than 1000, specify quantity in M

M=1000 5M=5000 10M=10,000

MM

If quantity is more than a million (1,000,000) specify quantity in MM

MM=1,000,000 2MM=2,000,000

Price Break

printing cost per unit decreases with an increase, in quantity; this is where the cost per unit drops significantly

Over/Under

printers generally allow a 10% over/under tolerance for print runs under 10,000; this means that you could get 10% over the quantity you asked for or 10% under the quantity you asked for - bc there is some paper waste when setting up and shutting down the press

Cost Per Unit

the individual cost of an item after a large quant has been printed; the higher the quantity, the lower the per unit cost

production planing

a roadmap or a strategic approach which defines the specifications, plans, parameters, costs, activities, to achieve goal of project

production planning 7 considerations

Purpose, Audience, Use of Piece, Other Processes, Scheduling, Quantities, Quality

Production planning 7 considerations:

Purpose

physical form (stationary package, brochure, bound publication, etc)

determines quantity - generic — more for various uses at multiple times (ex: letterhead)

- specific — once only usage, exact quantities (ex: invitation)

determines audience

Production planning 7 considerations:

Audience

primary force for Quality - inter-office memo can be different quality than letterhead or business card where customer has contact

who client is changes quality — upscale broker vs local butcher, Fortune 500 vs 25 person small business

Internal/client, viewed only by employees — business documents

external, viewed by a customer — billing, to marketing/advertising materials

Production planning 7 considerations:

Use of Piece

• Life—short term vs archival - affects paper and ink choices

• Durability - menu vs direct mail piece

• Flexibility - will info change in piece frequently or never

• Short term - used to disseminate information then discarded, such as a poster for an event

• Long term or archival - some archival papers can last more than 1000 years, this can affect paper and ink choices

Production planning 7 considerations:

Other Processes

Mailing — meet postal regs

glued

folded/perforated

bound

specialty effects - die cuts, coatings, embossing

Production planning 7 considerations:

Scheduling

turnaround - the whole process from start to finish

schedule backwards from deadline to delivery

factors you control when scheduling

delivery of files on time

delivery of files to printer’s specifications

check proofs promptly (24hrs)

minimize changes

paying on time

Factors the printer controls

scheduling job workflow inhouse

ordering paper

ordering inks if necessary

scheduling subcontractors for special needs, binding, etc

If you are late, expect the printer to be late an equal amount of time

quality can be affected when printer is forced to rush

rush jobs are usually subject to overtime fees

scheduling is more difficult when using multiple vendors

an all-in-one printer may be slightly more expensive but more flexible in meeting deadlines when problems arise

Production planning 7 considerations:

Quantities

consult with client about best quantity

printing cost per unit decreases with an increase in quantity

points where cost per unit drops significantly are called price-breaks

usually a good idea to quote quantities 1.5, 2, and 3 times greater than projected amount

other costs are constant and one-time fees

prepress/trapping

stripping/film-processing

proofing/press checks

plate-making

wet-up/wash-ups

for quantities under 1000 a digital press may be more economical

digital presses are the same cost per unit at any quanity

printers allow a 10% over under tolerance for print runs under 1000

if an exact quantity is necessary specify it in the bid

press size can affect quantity/cost relationships

a smaller sheet quantity with more pieces per sheet may be more economical

plant size of printer affects cost/scheduling/quality

Production planning 7 considerations:

Quality

different printers can deliver different quality printing

four main divisions of printing quality

Basic - standard materials and little quality control, primarily copy shops and quick printers

use toner and sometimes inks

generally handles a maximum of colors and handles small quantities

adequate for line art but contionous tone work loses detail

Commercial - standard materials, trained quality control; color work

sometimes have higher end digital presses

general commercial printing

offset sheet and web

CMYK and spot capability

Premium - high quality materials, refined quality control

color matching is very close

few flaws

4CP+ capability

Showcase - best machines and materials available

exact reproduction of artwork

generally used for pieces that are works of art

prints, museum/archival books, finest/most expensive marketing materials

specking

the process of selling our and submitting a specified proposal for printing work - a printer will us this as a guideline for coming up wit a price for printing services

generally spec a job with 2-5 printers depending on quantity

prepare a comprehensive spec sheet organized with all costs including labor broken out

this forces printer to price a job based on your needs allowing a better comparison between vendors

the printer’s bid is the basis for the printing contract - itemizing all tasks and prices inhibits any add-ons or surprise charges

include a dummy when possible

Preparing the Spec Sheet

description of the job

brochure, letterhead, etc. for company A

frequency of printing

once, every 3 months, yearly

materials to be furnished

quantity

number of finished pieces, ask for 2-3 Q’s to look for price break

specified in hundreds if less than 1000. Q is specified in M’s

trim size

# of colors over # of colors with # of bleeds and what sides; specific inks; specify coverage (ex: 1/0, no bleeds, 4CP/1 bleeds all sides, 4CP+2/2, bleeds top and right)

default color of a press is black

page count

plate changes

paper stock

inserts

binding

delivery/shipping

storage

special effects

InDesign

layout program for multiple page documents; .indd is the suffix to save files

PSD

native Photoshop Document - usually your layered (or unflattened) files before you save to another format; work in this while you make changes, then change appropriate file type for output

LWZ Compressions (Lempel Ziv Welch)

a compressed image is same as original when decompressed

TIFF

Tagged Image File Format - the American National Standards Institute (ANSI) and International Standards Organizations (ISO); RIPs same on only equipment

EPS

Encapsulated Post Script - contains bitmap information for preview image; in PS it is a file type that supports clipping paths, duotone, spot channels

JPEG

Joint Photographic Expert Group - developed for exchanging information via the internet - not suitable for printing

DCS

Desktop Color Separation files - separates data into files for preview images and for each color channel

Portable Document Format - allows user to view and print independent of program that created it (Adobe Acrobat Reader); Adobe Acrobat Pro will allow users to make minor edits to type and image placement; InDesign you can export several different quality levels; smallest file size - for emailing proofs; high quality print - for a printing comp

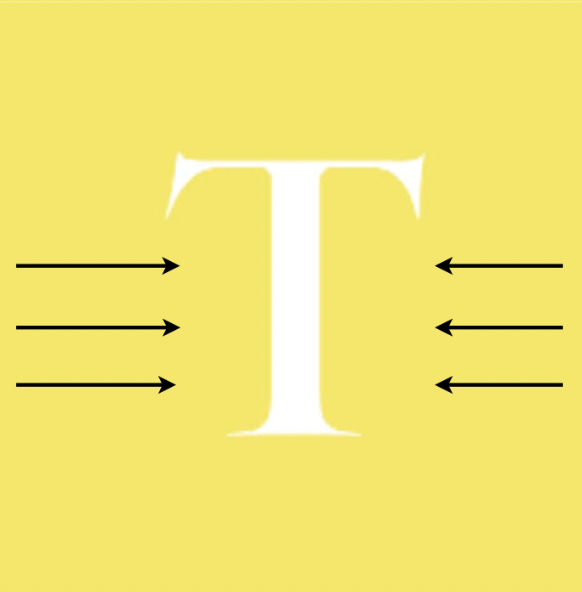

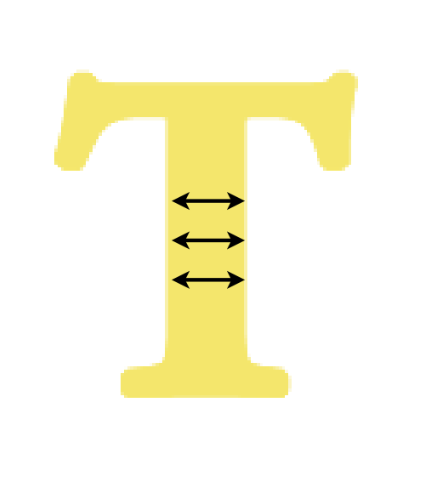

Trapping

the process where colors are set to slightly overlap each other so white gaps do not appear around objects; don’t do yourself - printers usually do this

What types of trapping are there?

choke and spread

Choke

technique of slightly reducing the size of an image to create a hairline trap or to outline - traps a surrounding light background to a dark, inner foreground object by expanding the edge of the lighter object so the two colors overlap

Spread

technique of slightly enlarging the size of an image to create a hairline trap or outline - traps a surrounding light foreground object to a surrounding dark background by expanding the edge in the inner so the two colors slightly overlap

surprinting

colors do not trap, but overlap or print directly over each other - be careful of black overprints that breaks the colors it overlaps with - can result in a diff tone of the black

proofing

a print made from negative for plates to check for errors and flaws, predict results on press and record how a printing job is intended to appear when finsihed

blueline

prepress photographic proof made from stripped negative where all colors show as blue images on white paper - ‘blueline’ is a generic term for proofs made from a variety of materials having identical purposes and similar appearances

Whiteprint or VELOX

a photographic reproduction of camera-ready art, made using a special photographic paper called velox-velox prints are used to make multiple copies of camera-ready art for distribution to various prints advertising media

integrals

color proof of separations shown on one piece of proofing paper-also called composition proof, laminate proof, plastic proof, and single-sheet proof

overlays (not used anymore)

color proofs consisting of polyester sheets laid on top of each other with image in register, as compared to integral proof-each sheet represents the image to be printed in one color

dot gain

phenomenon of halftone dots printing larger on paper than they are on films or plates, reducing detail and lowering contrast; also called dot growth, dot spread and press gain

problems on press:

Set Off (offsetting)

ink doesn’t dry properly and transfers from top of sheet to back of another

problems on press:

Hickies

dust, dirt on blanket prevents ink from printing creating halos

problems on press:

Show Through

printing from one side interfere with the other due to low opacity

problems on press:

Poor Trapping

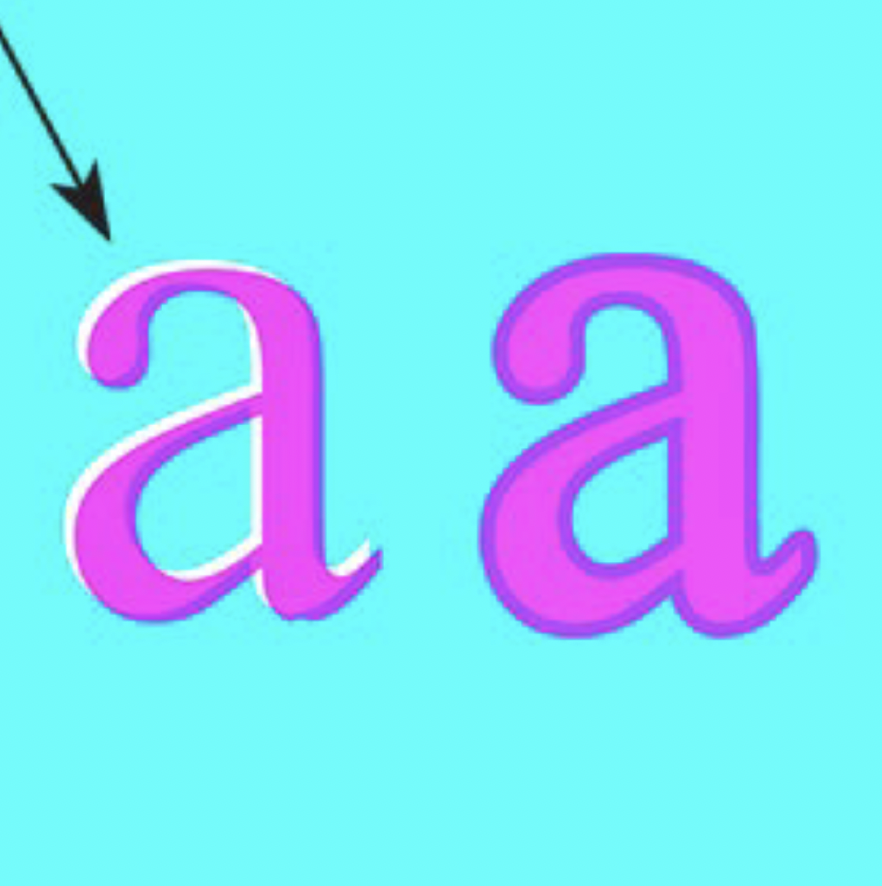

incorrect trap, too large/too small, wrong type makes boundary area/overlap very noticeable

problems on press:

Poor Registration

white gaps between colors, or blurriness due to screens misregistered

What is the purpose of mark ups?

To ensure the professional printer fully understands all aspects of the job that you are giving them, you will need to provide them with Mark-ups.

It allows the person handling your print job the opportunity to see the project without having to view it on the computer. It also acts as a safety net as it will reinforce any discrepancy in your digital file.

File Prep checklist

Name all files, folders and documents in a clear logical manner. Always include file extensions.

Turn in only the files/documents that are needed to open your file. Any extra files or unnecessary items will be confusing.

All images must be placed in the file at 100% of actual size to be used. Slightly larger or smaller is ok, but engaging an image too much in will hurt the print quality.

Include all images, fonts etc. with your file. Check and double check this. Any delay in opening your file could destroy a deadline and can be very costly.

Include a detailed markup with your disk. This is beneficial to you and the printer. It safeguards against potential problems.

A full size color comp should always accompany a print job. This ensures that the printer will understand your piece and back up the pages correctly. Never make a printer guess what you want.

Black and White printouts with mark-ups.

Check Usage of Fonts and Images

Window → Output → Preflight

LINKS AND IMAGES

Image type should be TIF or EPS

Image status should be Linked. If image is missing, locate it before collecting your file.

All images should be in CMYK mode. If your images are RGB, your separations will not print. Change the color mode of the original file.

FONTS

All fonts listed should be used in your document. If there is a font listed that you did not use, locate that font and remove if from your file.

COLORS AND INKS

All colors used in your document are shown in the Colors and link window

Separations Preview

Window → Output → Separations Preview

You can view all your color separated files before printing. Turn the layers off to view only specific separations.

Swatch and Swatch Options

Window → Colors → Swatches → Swatch Options

To highlight special effects including die cut and varnish, create a new spot color (CMYK mode) and change the swatch name. This will allow the effect to print as a separate plate.

Print Separations

File → Print

Marks and Bleeds - In the print window under the Marks and Bleed tab, check All printer’s Marks, this will print crop marks, registration marks, etc.

Under the Marks and Bleed tab, In Bleed and Slug box

uncheck “Use Document Bleed”

check include slug area

set the bleed margins to .25 on all sides

Output - In the print window under the output tab

Color to Separations

Trapping off

All plates that are listed will print as separate pages

Short answer: How to create a spot color to show effect?

draw shape around object you want a special effect

create new color swatch from this

change name to name of effect

change to spot color

change to CMYK

make it a color that will stand out

you know its right when a spot shows in the little grey box next to color

put on separate layer in file

should show up in separations window with CMYK colors