things that aren't springs but are in fact other things

1/13

Earn XP

Description and Tags

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

14 Terms

what is a loading curve?

the bit of the graph when the force being applied to the material is increasing

what is an unloading curve?

the part of the graph where the force is removed from the material

what does the force extension graph for a metal wire look like?

the loading section is a straight line which follows hooke’s law until the elastic limit

after the elastic limit it curves as plastic deformation happens

if elastic limit has been passed, unloading line doesn’t go back to starting point because the wire has been permanently extended

unloading line is very straight though and is identical to straight part of loading line

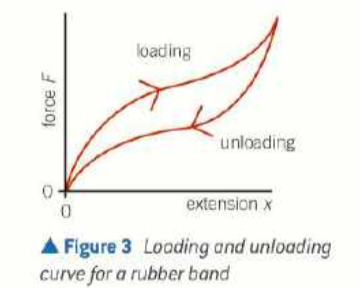

what does the force extension graph for rubber look like?

the loading and unloading lines are different and both curved

the rubber band returns to its original length after force is removed (elastic deformation)

the unloading line joins up to the start of the loading line because its elastic deformation

this forms a “hysteresis loop”

more work is done during loading than unloading (because area under graph= work done)

the area inside the loop represents the thermal energy released during the loading and unloading

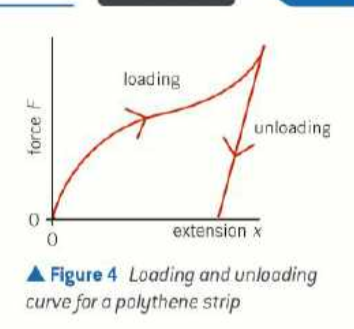

what does the force extension graph for polythene look like?

doesn’t obey hooke’s law

suffers plastic deformation under little force

don’t return to original size and shape

what does the extension of a wire depend on?

original length

diameter

tension

material

what is tensile stress?

force applied per unit cross sectional area

sigma= F/A

what is tensile strain?

fractional change in original length of wire

epsilon= x/L

what are brittle materials (and their stress-strain graphs actually)

materials that fracture before plastic deformation (they only deform elastically)

elastic behaviour is shown until breakpoint

loading and unloading curves are the same

what are ductile materials?

can easily be hammered into thin sheets or drawn into wires

can withstand large plastic deformation without breaking

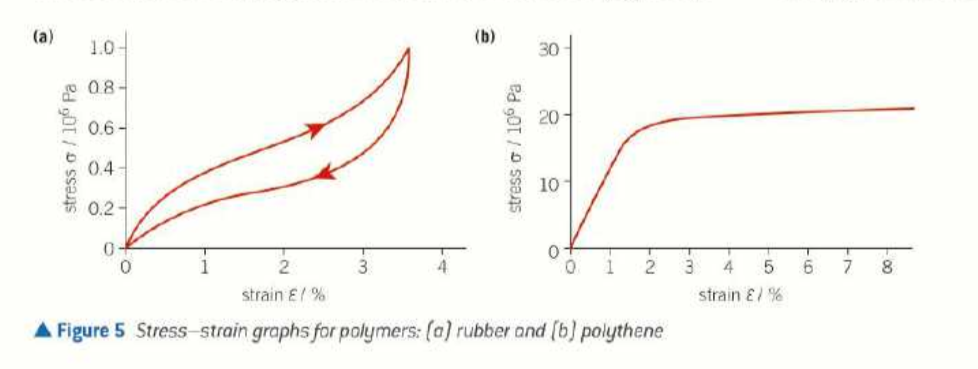

what are polymeric materials (and their stress strain graphs actually)

consist of long molecular chains

behave differently depending on molecular structure and temperature

eg rubber is elastic and polythene is plastic

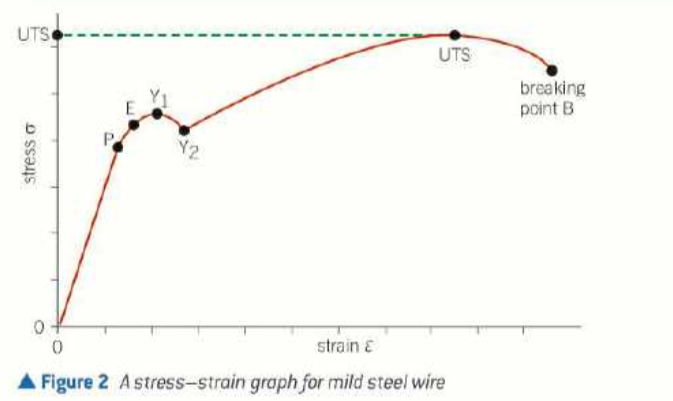

what does the stress-strain graph of a ductile metal look like?

straight line section is where material obeys hooke’s law and stress is directly proportional to strain

then reaches P, limit of proportionality

then reaches E, elastic limit

Y1 and Y2 are upper and lower yield points where the material extends rapidly, typical of mild steel

what is ultimate tensile strength?

the maximum stress that a material can withstand when being stretched before it breaks

beyond this point, material becomes longer and thinner at its weakest point

material snaps at breaking point B (yk on that graph) where it has a stress value of “breaking strength”

strong materials have high UTS

what is the young modulus?

a constant, ratio of stress to strain for a particular material

tensile stress/ tensile strain

units are Pa

it’s the gradient of the straight section of the stress-strain

the larger the young modulus, the stiffer the material