Dental Waxes

1/50

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

51 Terms

What type of material are dental waxes and what can you do with them?

what state are they on heating and room temperature?

Thermoplastic moulding material that is a solid at room temperature

Heating converts the wax to a liquid phase - easily mouldable

At some point dental waxes are P—ed?

Pyrolysed

What does pyrolysed mean?

At some point, they melt and/or decompose into water vapour and carbon dioxide

Waxes are O—— C——— compounds?

Organic crystalline compounds

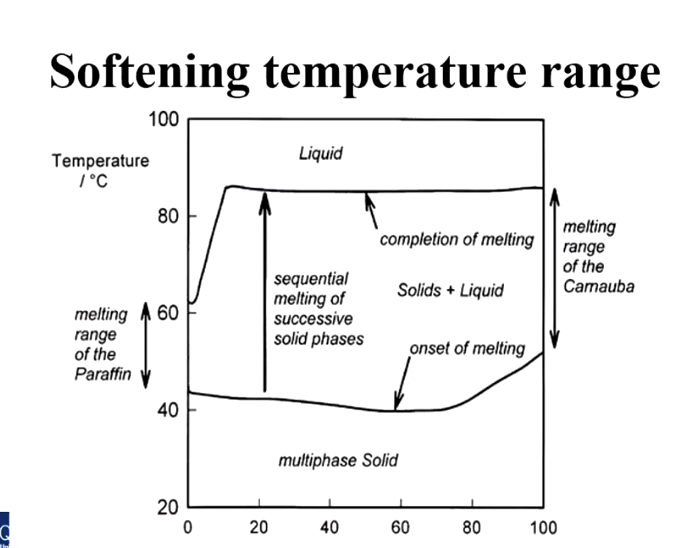

What are the melting properties of individual waxes and how are they changed by manufacturers for dental use?

Individual wax has a sharp well-defined melting point, above which it is a mobile liquid and below which is a solid, as such it would be of little practical use

for dental use, manufacturers blend two or more waxes to give a material with a softening temperature range over which it is a useful mouldable material

What is melting range?

A range of temperatures at which each component of the wax will start to soften and then flow

What is flow in wax?

[occurs at what temp?

what is the viscosity?]

control of flow/melting range is important how?

this happens as the wax approaches what?

The movement of wax molecules which slip over each other

at high temperature the wax has low viscosity and flows

the wax is mobile as it approaches the melting range

important in manipulating wax

What does the melting range for a bite registration wax need to be ?

Needs to be only slightly higher than mouth temperature - if too high a softening temperature then it would be uncomfortable for the patient

What about the melting range for lab wax?

these may have a much higher melting range

Dimensional changes affecting wax?

Compared to other dental materials?

What happens if wax is heated too far above melting range or heated unevenly?

On standing, dimensional changes to waxes occurs from?

therefore what should you do, important in?

Wax expands when heated and contracts when cooled

The thermal expansion and contraction of waxes is greater than any other dental material

expansion above acceptable standards will result in inaccuracies in the final casting

occurs from the release of residual stresses

invest and cast within 30 min after carving the wax

important for pattern waxes-duplicate of the restoration carved in the wax

After wax removal what may remain on the object?

how is his a problem?

important when?

Excess residue - wax film remaining on an object after wax removal

if excess residue remains it may result in inaccuracies in the item being produced

important in the lost wax technique when the wax pattern is melted out of the investment mold

so in summary, 4 main properties of dental waxes?

melting range, flow and dimensional changes, excess residue

waxes in dentistry are composed of? (3 Main)

synthetic and 2 or more natural waxes

small amounts of additives such as - gums, fats, fatty acids, oils, natural and synthetic resins, pigments of various types

What is the aim of this? (3 main)

To give a set of properties over a specific range of temperatures

Contain a range of molecular weights that affects the melting and flow properties of wax

Chemical components of both natural and synthetic waxes impart characteristic physical properties to the wax - determines their usefulness for the intended application

Natural waxes are found where?

C—- combination of O——- compounds?

MWt?

composition can vary depending on what (2)

Distributed in nature

Complex combination of organic compounds

high molecular weight

Composition varies depending on source and time of collection

What are different natural waxes? (7)

obtained from what and reasons for addition?

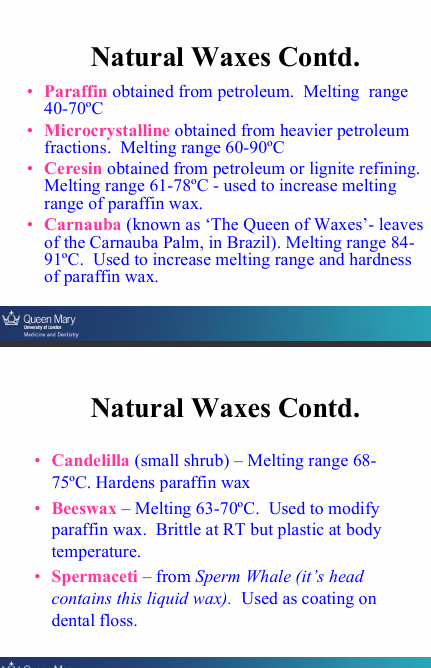

Paraffin - obtained from petroleum (mainly - everything else are additions)

Microcrystalline - obtained from heavier petroleum fractions

Ceresin - obtained from petroleum or lignite refining - M

Carnauba - leaves of Carnauba palm in Brazil - M, H

Candelilla - small shrub H

Beeswax - Brittle at RT but plastic at body temp

Spermaceti - sperm whale - coating on dental floss

M - increases melting point of paraffin

H - increases hardness of paraffin

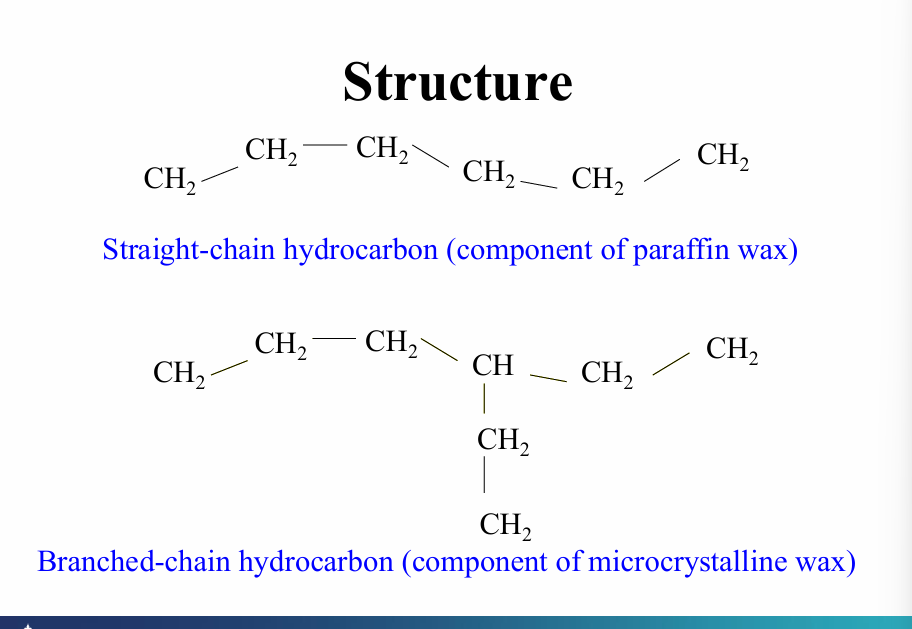

What is the structure of paraffin wax and microcrystalline wax?

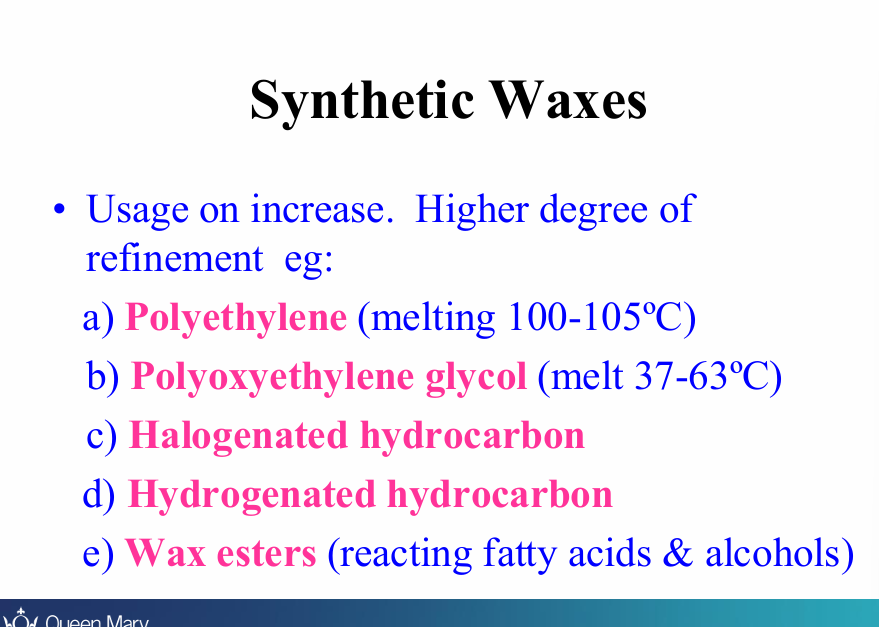

How are synthetic waxes produced? (2)

Produced by combination of various chemical in the lab or by chemical action on natural waxes

Give 5 examples of synthetic waxes

Polyethylene

Polyoxyethylene glycol

Halogenated hydrocarbon

Hydrogenated hydrocarbon

Wax esters - (reacting fatty acids and alcohols)

What are 3 other additives ?

Gums - Gum Arabic

Fats - various fatty acids with glycerol

Resins - natural e.g dammar, rosin or shellac from insects

Synthetic resins e.g polyethylene and vinyl resins

What are classifications of natural waxes - initially classified according to their origin? (3)

Mineral: Paraffin, Microcrystalline, Ceresin

Plant: Carnauba, Candelilla

Animal: Beeswax, Spermaceti

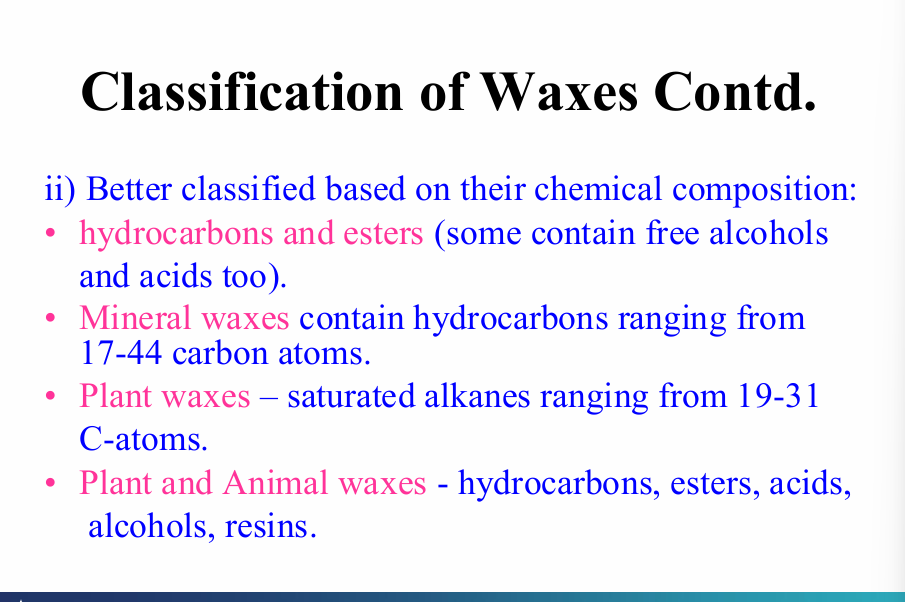

Better classified based on their chemical composition: (4)

Hydrocarbons and esters:

Mineral waxes

Plant waxes

Plant and animal waxes

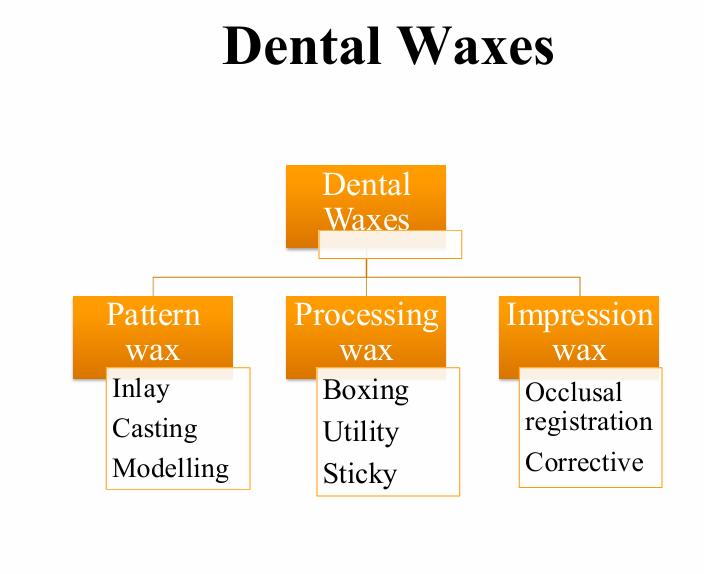

Dental waxes can be classified according to use?

Pattern wax - inlay/casting/modelling

Processing wax: Boxing/utility/sticky

Impression wax: occlusal reg/corrective

Inlay Wax:

Classification according to?

What type of wax is it again - based on use

Type 1 is used for what technique?

Type 2 is used for what technique

What is inlay wax used for?

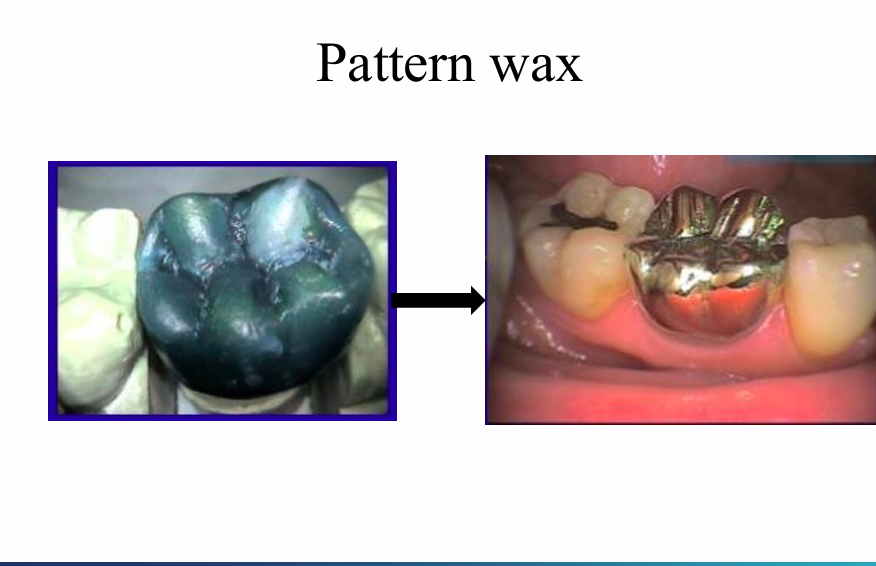

ADA Sp no 4

Pattern wax

Type 1 (medium) - Direct (wax pattern made inside the Pts mouth)

Type 2 (soft) - Indirect technique (Take impression first)

inlays and crowns - made in wax then converted to metal

making patterns of metallic restorations, patterns for inlays

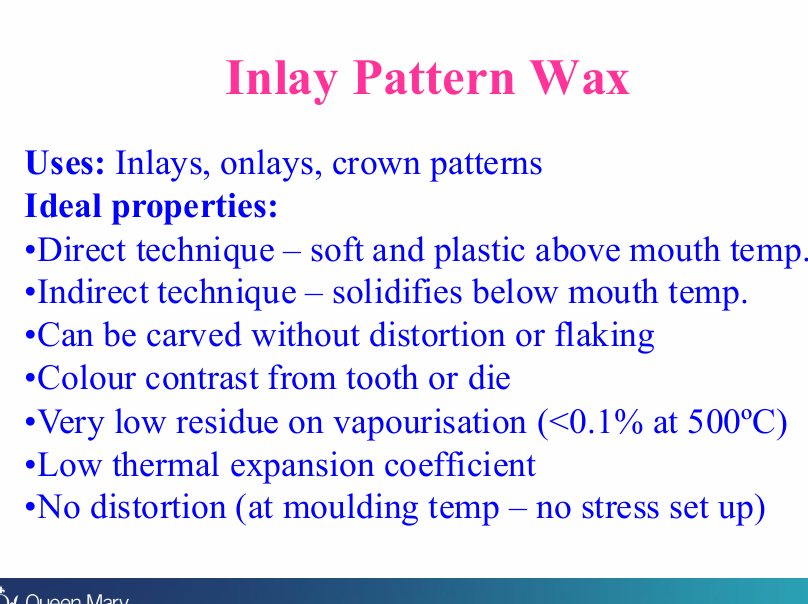

Again uses: (3)

inlays, onlays crown patterns

Ideal properties of inlay pattern wax:

Direct technique

Indirect technique

during use (5)

Soft and plastic above mouth temp (solid at mouth temp)

Solidifies below mouth temp

Can be carved without distortion or flaking

colour contrast from tooth or die

very low residue on vaporisation

low thermal expansion coefficient

no distortion - at moulding temp - no stress set up

Constituents of inlay pattern wax? (5 and why?)

Paraffin - flakes on trimming

Carnauba - increases melting range/glossy surface

Ceresin - toughness and carving

Beeswax - reduces flow and brittleness

dammar resin - improves smoothness, resistance to cracking and flaking, gloss to surface

What is casting wax ?

composition?

property? (1)

Type of pattern wax used in patterns for denture framework (construct metal framework of partial and complete dentures)

exact composition not known but similar to inlay wax

highly ductile - can bend double at 23 degrees Celsius without cracking

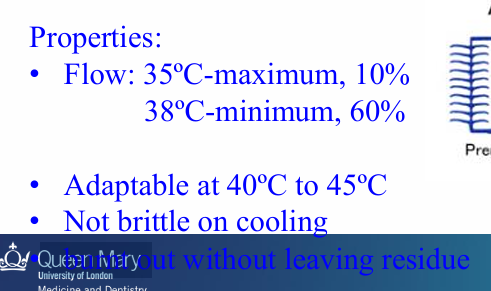

Classification of casting wax?

Class: A, B, C

Properties (4 main):

Flow: 35 - max flow 10%

38 degrees - minimum flow of 60%

adaptable at 40-45 degrees

not brittle on cooling

burnt out without leaving residue

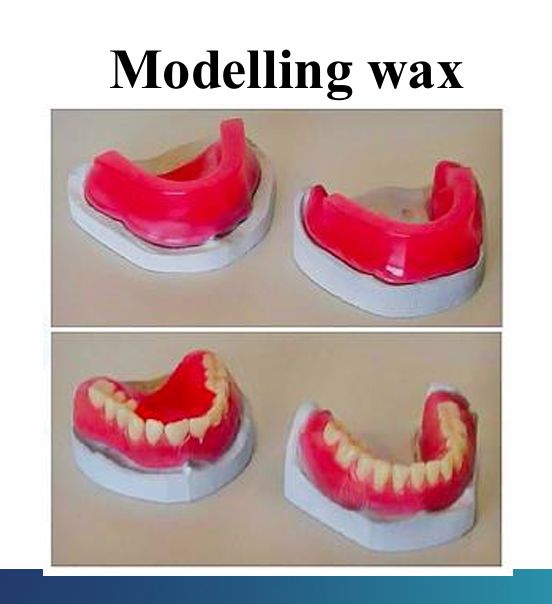

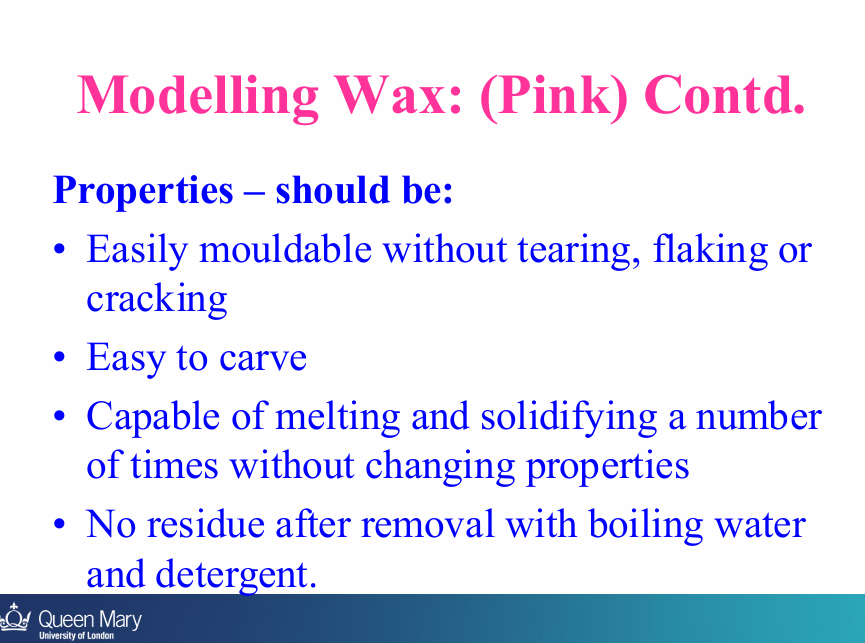

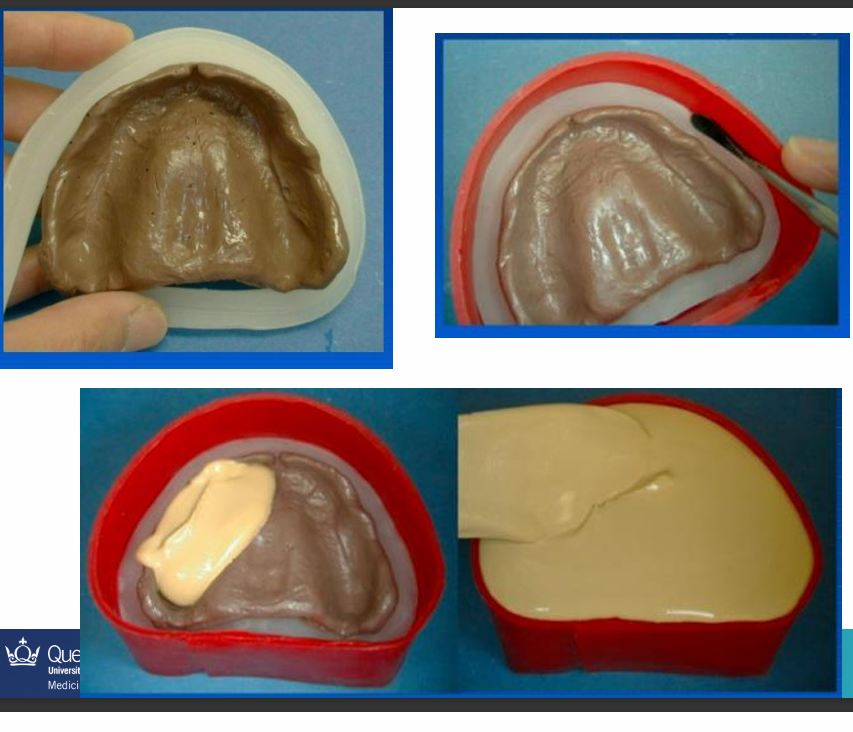

What is modelling wax used for?

Used for setting up of artificial teeth for full dentures

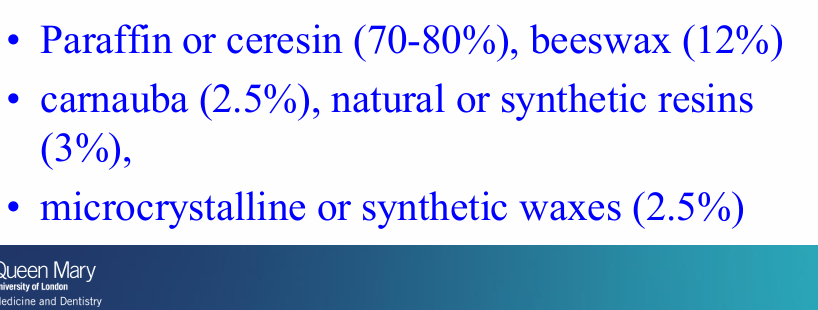

Constituents of modelling wax? (5)

paraffin or ceresin

beeswax

carnauba

natural or synthetic resin

microcrystalline or synthetic waxes

4 ideal properties of moulding wax?

Easily mouldable without tearing, flaking or cracking

easy to carve

capable of melting and solidifying a number of times without changing properties

no residue after removal with boiling water and detergent

Carding or boxing-in wax:

Type of wax?

What is it used for? (2

Processing wax

Build up vertical walls around the impression - box impressions before pouring with gypsum

As beading wax adapted around impression borders

(box as sheets or beading as ribbon)

Ideal properties of carding or beading-in wax? (3)

Pliable at RT

Retain shape at 35 degrees

Slightly tacky

Sticky wax is what type of wax?

uses? (2) for acrylic and partial dentures?

processing wax

an adhesive wax used for temporary joining of items e.g align fractures parts of acrylic denture

align fixed partial denture parts before soldering

e.g preparatory for soldering

constituents to sticky wax? (3)

Resin (rosin), yellow beeswax, gum dammar

Properties of sticky wax?

at RT?

when melted? (2)

does what when movement occurs?

At RT hard and brittle

when melted will adhere closely to applied surface

it is sticky when melted

fracture when movement occurs instead of distorting

Impression wax (corrective or bite wax)

is used for? (2)

replaced by what?

corrective for edentulous impressions

occlusal registry

silicones

Constituents of impression wax?

Hydrocarbon waxes - paraffin, ceresin, beeswax

Metal particles - Al or Cu

Properties of impression wax?

limited to what arches because?

mouth temp it does what (2)/ rt its what?

available as?

Limited to edentulous portions of mouth - distorts when withdrawn from undercut areas

soft at mouth temp, flows a mouth temp - rigid at RT

sheets and cakes

Other waxes: wax rims (bite rim)

are what type of wax?

softening temp is above or below mouth temp?

properties?

uses? (2)

Pattern wax

Above mouth temp

Restoring occlusal relationship

Arrangement of teeth

Other waxes: utility wax

use?, availability in (2) ss

Used to adapt border of impression tray

sticks and sheets

Other waxes: shellac denture base?

properties? (2)

type of wax like resin, which is stable at mouth temp and has a high softening point

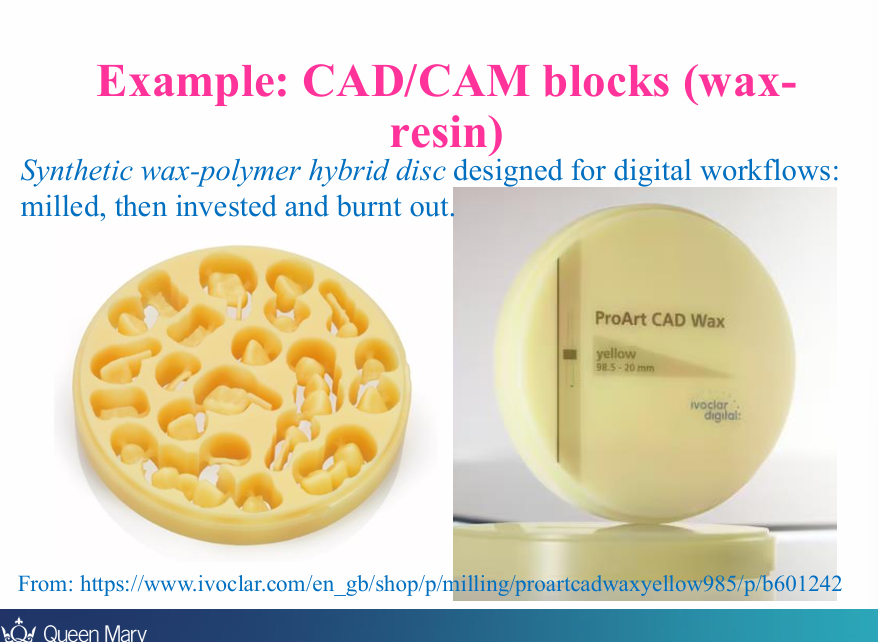

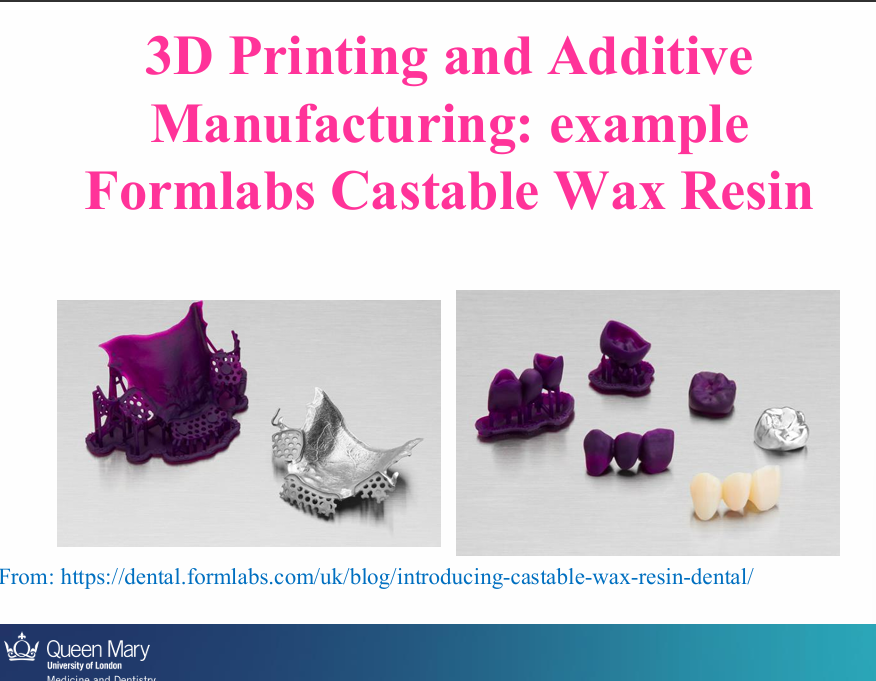

Digital dentistry (2 types) vs traditional pattern waxes?

Traditionally, pattern waxes are the foundation materials for pattern fabrication for casting

CAD/CAM blocks pattern materials and 3D printable resins are used

CAD/CAM blocks (wax-resin)

designed for what? (2)

property of the wax? (2 main)

designed for milling frameworks or castable patterns

can be used for fabrication of crown and bridge frameworks and denture framework

blocks are dimensionally stable, can be milled and burn our completely without residue

3D printing resins properties? (3)

no residue on burnout

dimensional accuracy

smooth surface finish

Applications of 3D printing resin? (2)

printing Wax patterns for inlays, onlays and crowns

fabricating frameworks for removable partial dentures

In general dental waxes are composed of 3 major components?

a base wax - usually paraffin

modifier waxes

colorants

Why are there no fillers present?

because it is pyrolyzed - don’t want fillers remaining