Plain carbon steels and steel designation

1/8

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

9 Terms

Types of irons

Wrought iron: Fe with a very low carbon content (0.08 wt%C) and contains high fibrous (natural or synthetic inclusions embedded in the host material) up to 2wt%

Charcoal iron: Fe smelted into a bloomer charged with charcoal and iron ore with air being blown to heat the ore below the mp of iron. Iron coalesced into a sponge like mass called bloom containing Si slag impurities.

Reheated and hammered to remove slag

Puddled iron: Created wrought iron from pig iron (high C and impurities). Uses a reverberatory furnace using coke (carbon rich fuel). Melt stirred (puddled) with rods causing O from oxides to react with impurities (Si, Mn, S, P) and removed. Carbon burns off too. Fe removed when turning spongy and the material is hammered to expel slag.

Plain carbon steel

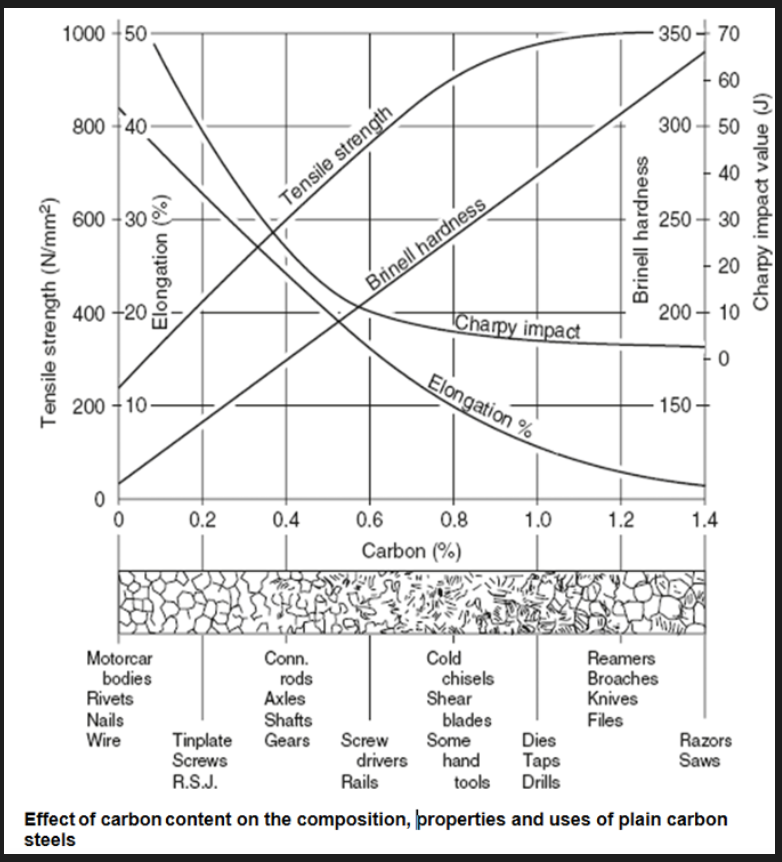

Consists of Fe and C where C is the main alloying element. This C varies between 0.1% to 2.1% (low, medium, high). Limit to 1.4 wt% C. Maximum solubility of carbon in austenite. The amount of carbon will affect the properties of steel. A steel by definition would not contain free carbon, carbon present in a material in an uncombined or loosely bound form.

Other elements in plain carbon steel

Added by design to modify mechanical properties (TS, fracture toughness)

Manganese: aids to obtain a sound ingot. Combines with S so S does not weaken steel. Increases yield point, UTS and toughness. Higher tendency towards cracking and distortion during quenching. Limited to 1% in medium and high carbon steel.

Added through processing or unexpectedly. Usually detrimental.

Phosphorus: Present in the ore. Embrittles steel. Limited to a very low amount (0.05%). Coarsens the grain size and produces large segregates.

Silicon: Also introduced from the ore. Usually limited to 0.1 - 0.3% to avoid breakdown of cementite. Tries to oxidise.

Sulphur: Introduced from the fuel in the blast furnaces during extraction of the ore. Forms FeS which weakens steel. Limited to 0.05%. Sulphur will react with Mn to form MnS instead (soft). Free cutting steels make use of this improved machinability as chips will be much smaller and MnS acts as a dry lubricant.

Low carbon steel

Properties

High ductility

Good joinability for welding

Can be formed easily

Used in non-hardened form

Micro alloy steels: Very tiny amounts of elements (total 1.8%) and subjected to controlled rolling or thermomechanical processing

Applications

0.1 - 0.15 % C for sheets (car body panels), wires, rods, drawn tubes

0.16 - 0.29% C for bars, boiler plates, girder (a large iron or steel beam or compound structure used for building bridges and the framework of large buildings

Effect of elements

0.1% C, 0.4% Mn. Cold rolling and process annealing. UTS 300 MPa. Ductility 28%. Car body panels (drawing and pressing)

0.2% C as rolled. YS 240 MPa, UTS 450 MPa. Ductility 25%. General purpose mild steel ex: bars

0.2%, 1.5% Mn. YS 350 MPa, UTS 525 MPa. Ductility 20%. Weldable, high TS mild steel for construction ex: girders

Mild steel is a type of plain carbon steel that contains a low percentage of carbon, making it soft, ductile, and easy to work with.

Composition

Carbon content: about 0.05–0.25% C

Small amounts of Mn, Si, S, and P may be present

No significant alloying elements

Key properties

Good ductility and toughness

Low strength and hardness compared to high-carbon steels

Excellent weldability and machinability

Can be easily cold worked and hot worked

Microstructure

Mainly ferrite with some pearlite

More ferrite → softer and more ductile

Common uses

Structural components (beams, plates)

Sheets and pipes

Nuts, bolts, and rivets

Automobile bodies

General-purpose fabrication

Advantages

Low cost

Easy to form and shape

Good surface finish

Medium carbon steel

Applications:

0.3 - 0.59 % C for crankshaft forging, axles, leaf springs, cold chisels

Effects of elements

0.4% C, 0.8% Mn. Quenched from 850 degrees, tempered at 600. YS 500 MPa, UTS 700 MPa, ductility 20%. Used for axles, crankshafts, i.e a moderate load

0.55% C, 0.7% Mn. Quenched from 828 degrees, tempered at 600. YS: 550 MPa, UTS 750 MPa, ductility 14%. Used for gears, hard parts subjected to wear

High carbon steel

Applications:

0.6 - 1.4% C for coil springs, wood chisels, files, drills, taps and dies, knives and blades

Effects of elements:

0.7%, 0.35% Mn. Water quenched from 800 degrees. Temper at 150-300 degrees. Hardness HB: 780. Used for hand chisel, screwdriver blades

1% C, 0.35% Mn. Water quenched from 780/760 degrees. Temper at 150-300 degrees. Hardness HB: 800. Used for: taps, files, hand tools, screwing dies

1.2%, 0.35% Mn. Water quenched at 780/760. Temper at 150-400 degrees. Hardness HB: 820. Used for knives and other blades with a fine edge, files, surgical instruments

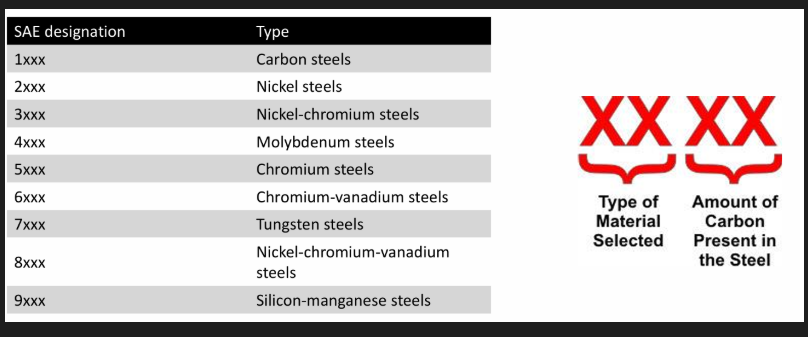

Alloy steel

Alloying elements added to enhance mechanical properties or corrosion resistance .

Common alloying additions:

Mn - improves mechanical properties and hardenability

Ni - austenite stabiliser, improves mechanical properties and hardenability

C

Mo - improves mechanical properties and hardenability

V - carbide formation

B

Cr - corrosion resistance, improves mechanical properties and hardenability, carbide formation

Less common alloying additions:

Al

Cu - corrosion resistance

Co - solution strengthening

W - carbide formation, solution strengthening

Ti

Nb

Some examples include tool steels and stainless steels. Weldability for alloy steels with a medium-high % C is difficult. To improve weldability and formability of steel, C and the alloying elements contents are very low (0.1-0.3%)

Common steel specs - EN standards

Steel designations according to their application and mechanical and physical properties:

S - structural steel

P - pressure purposes

L - line pipe

E - engineering

The number after specifies the min. YS. Example: S420; S = structural steel with YS of 420 MPa

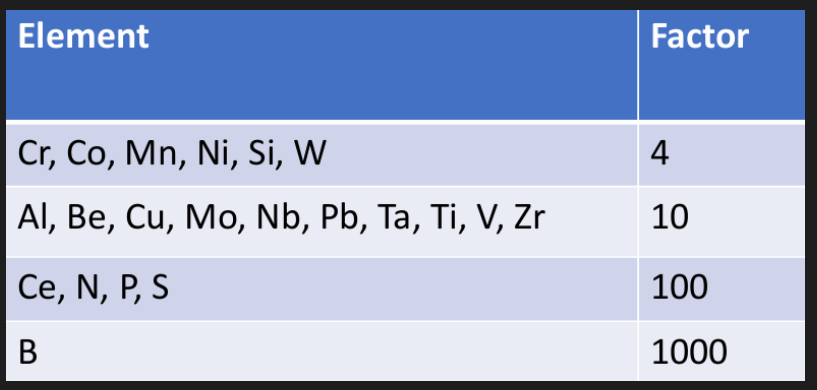

Steels based on their chemical composition

Non alloy steels: code consists of steel followed by 2 numbers indicating C content x 100

Example: C45; 45/100 = 0.45 wt%C

Alloy steels with Mn content ≥1% and non alloy free cutting steels and alloy steels where wt% content of every average alloying element content ˂5% (except high speed steels): code consists of 100x C % then chemical symbols indicating most important alloys then number indicating fraction % of alloy content. Divided by factor to get the element %.

10CrMo9-10 = 10/100 = 0.1 wt% C, 9/4 = 2.25 wt% Cr, 10/10 = 1 wt% Mo

13MnNi6-3 = 13/100 = 0.13 wt% C, 6/4 = 1.5 wt% Mn, 3/4 = 0.75 wt% Ni

28Mn6 = 28/100 = 0.28 wt%C, 6/4 = 1.5 wt% Mn

First number is the carbon content unless carbon alone, second numbers are the alloys divided by the respective factor.

For alloy steels with alloy content of one of the elements ≥ 5% (except high speed steel): code starts with an X followed by C content and then chemical symbol with most important alloying elements and their %. No factor is used here.

Example: X2CrNi18-9 = alloy steel with: 2/100 % C, 18% Cr and 9% Ni

For high speed steels, code starts with HS followed by n-n (numbers separated by hyphens), indicating percentage content of alloy elements in the following order: tungsten (W), molybdenum (Mo), vanadium (V) cobalt (Co)

Basic numerical designation for steel: code consists of 1 followed by 4 figures Example 1.4400

1.00xx base steels

1.2xxx tool steels

1.44xx stainless steels

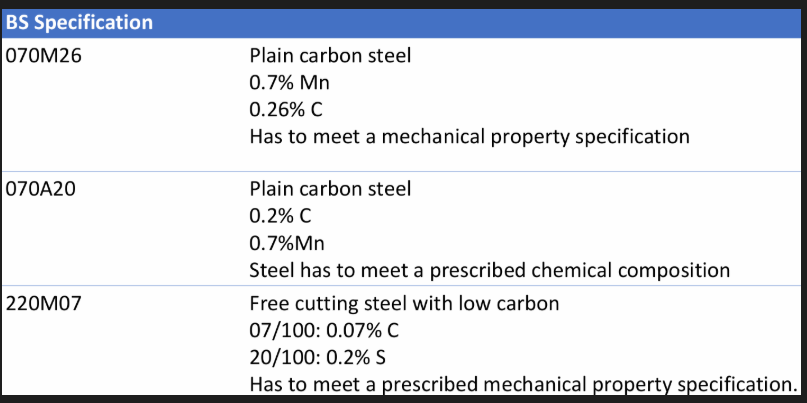

Common steel specs - British standards

3 digits for a number code used to indicate type of steel

000 to 199: carbon and carbon manganese steel. Number indicates 100 times the manganese content.

200 to 240: free cutting steels. Second and third digit indicate 100 times the Sulphur content

250: silicon manganese valve steels

300 to 499: Stainless and heat resistant steels

500 to 999: Alloy steels

4th digit is a symbol

A: steel has a chemical composition determined through chemical analysis of a batch sample

H steel supplied to a hardenability specification

M: supplied to a mechanical property specification

S: Material is stainless steel

5th and 6th symbols are numbers indicating 10 times the C content.