Core Technical Principles

1/131

Earn XP

Description and Tags

AQA GCSE Design & Technology - Core Technical Principles

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

132 Terms

Input (Automation)

All the materials, tools, and equipment to make the product

Process

All the work required to make the product

Output (production/automation)

The finished product

Flexible Manufacturing Systems (FMS)

Factories where a series of machines are put together to make a product. Automated systems process each step from an input to an output.

This system is expensive

Just in time (JIT)

Form of manufacturing which minimizes the waste. Materials are ordered when they’re needed. Saving on storage costs.

Market Pull

Consumers demand a redesign of a product to satisfy a new need

Technology Push

Manufacturers & designers inspire new products or improve old ones

Visual Marketing

Popup advertisements, spam emails, and virtual retailing

Crowdfunding

People invest in the development of products or services

Co-operatives

Groups of people who share their investment & develop products together

Ethical Issues

Deducing whether a product harms the environment or unfairly treats people

Fair Trade

Principle where everyone in the chain is offered a minimum price & good working conditions

Continuous Improvement (Kaizen)

Process of making small changes to improve the way a company works

Planned Obsolescence

Products are intended to require repairs and become obsolete quicker than others

Computer Aided Design (CAD)

Process of creating a 2D or 3D design using computer software

Computer Aided Manufacturing (CAM)

Manufacturing a part or product from CAD using computer-controlled machinery (E.g. A 3D printer)

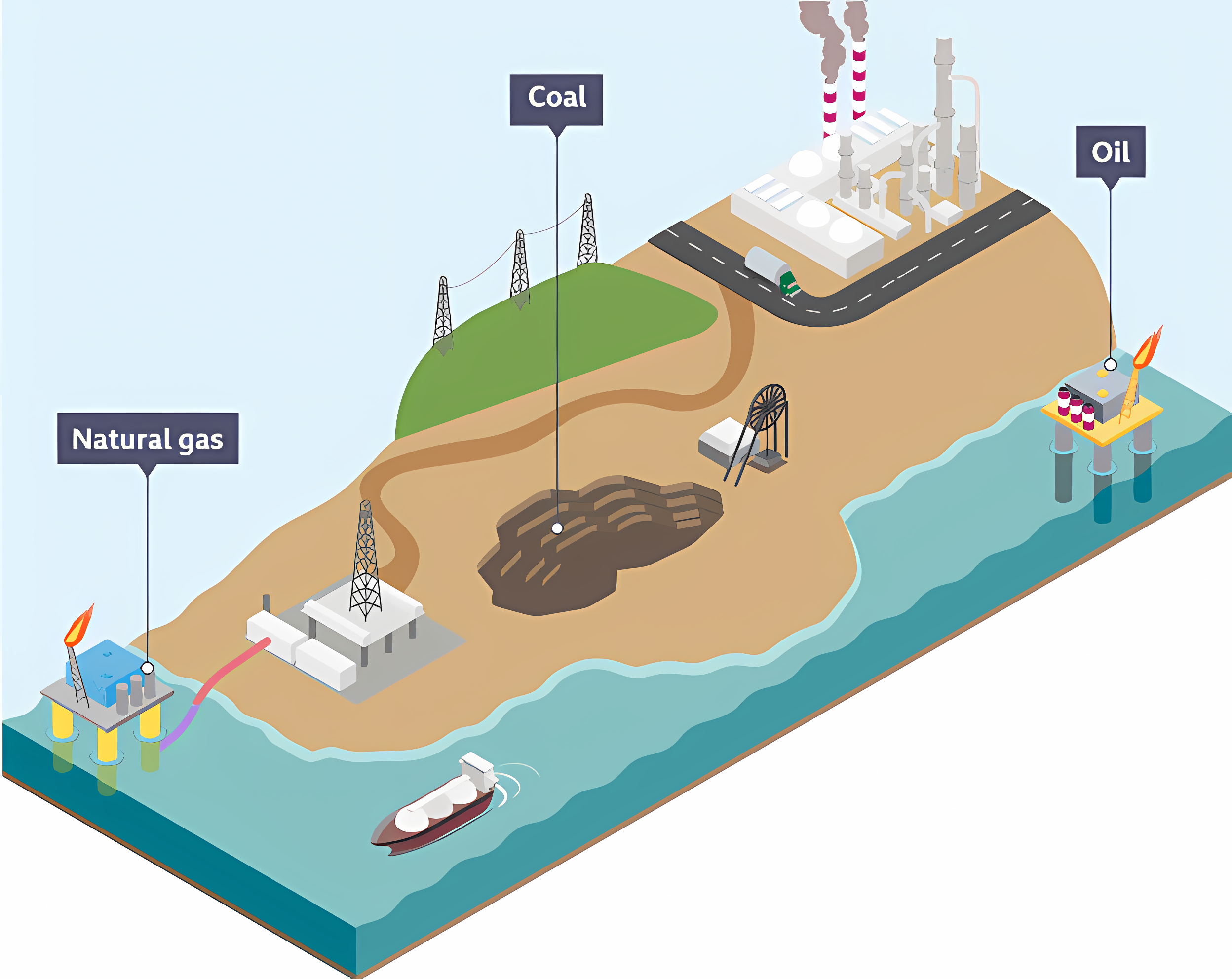

Fossil Fuels

Formed underground over millions of years. They are burnt to generate power by heating water to turn a turbine to generate power.

The 3 types include:

1) Coal

2) Oils

3) Gas

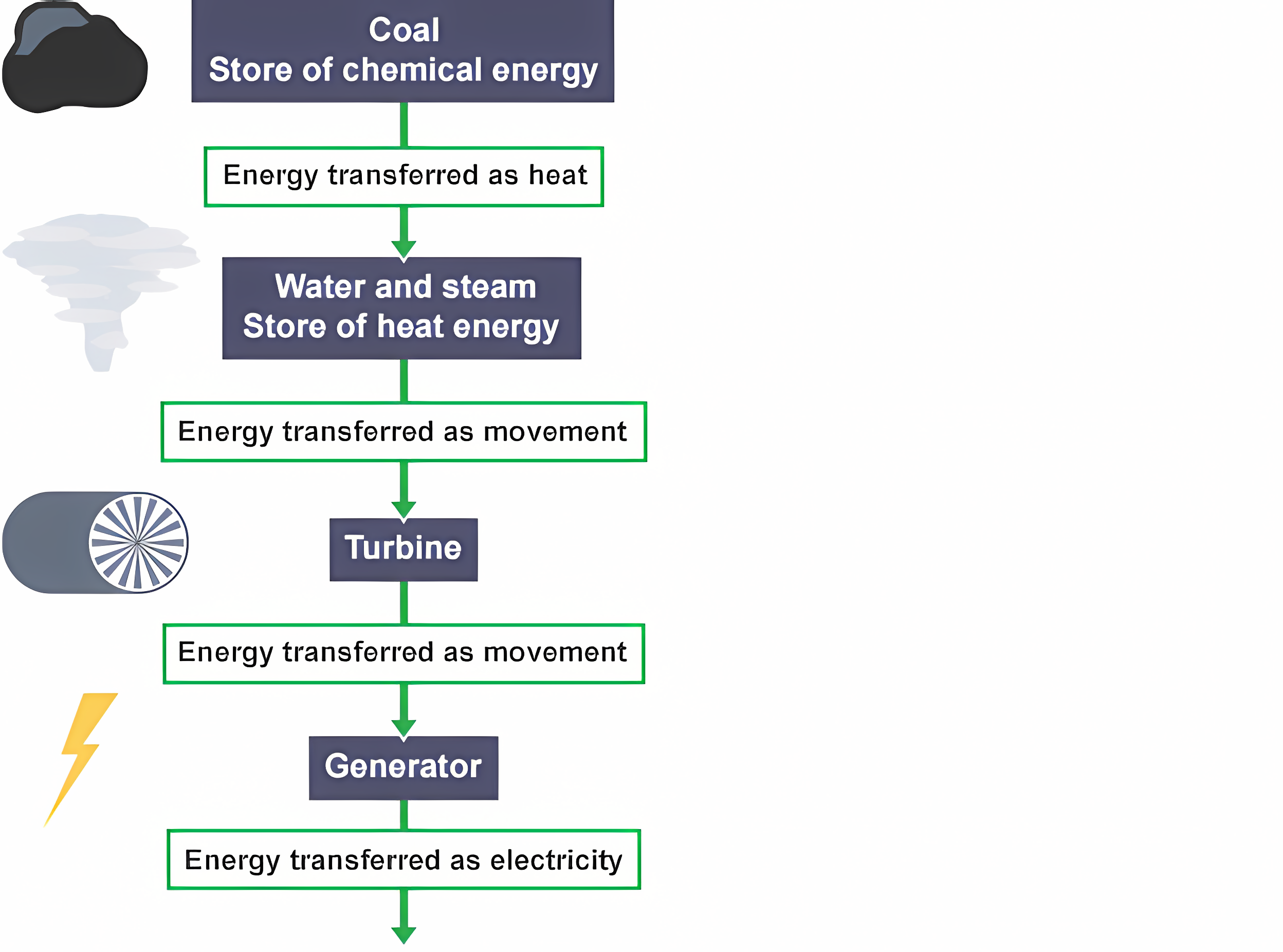

Coal

Energy generated as the coal is burned, the hot coal heats water turning it into steam. The steam builds a high pressure which spins a turbine. The turbine is connected to an electrical generator, creating electricity

Advantages of Coal

Enough coal on Earth to last hundreds of years

Produces high amounts of energy

Disadvantages of coal

Produces carbon dioxide when burned, contributing to global warming

Damage is caused to natural land when mining takes place

Natural Gas

Used for heating & cooking. Produced off-shore & transported through pipelines to a gas-powered electricity station.

Advantages of Natural Gas

It emits less carbon dioxide than coal or oil

The UK has shale gas deposits

Disadvantages of Natural Gas

Gas is highly flammable - if there is a gas leak, an explosion can easily happen

Extracting gas might cause the pollution of water

Oil

Used for fuel or turned into plastics.

Advantages of Oil

A small amount of oil can produce a lot of energy

It is relatively easy to store and transport

Disadvantages of Oil

Creates significant air pollution when burned

Considerable impact on water, land use and disposal

Nuclear Fission

Uranium generates heat to power turbines in the same way as fossil fuels.

Advantages of Nuclear Power

No harmful gases are released in the process

More efficient than fossil fuels

Disadvantages of Nuclear Power

Nuclear power stations have to close after around 40 years of use when the uranium becomes less efficient at heating the water

Disposal of uranium is difficult and costly

Cost of nuclear power stations is very large

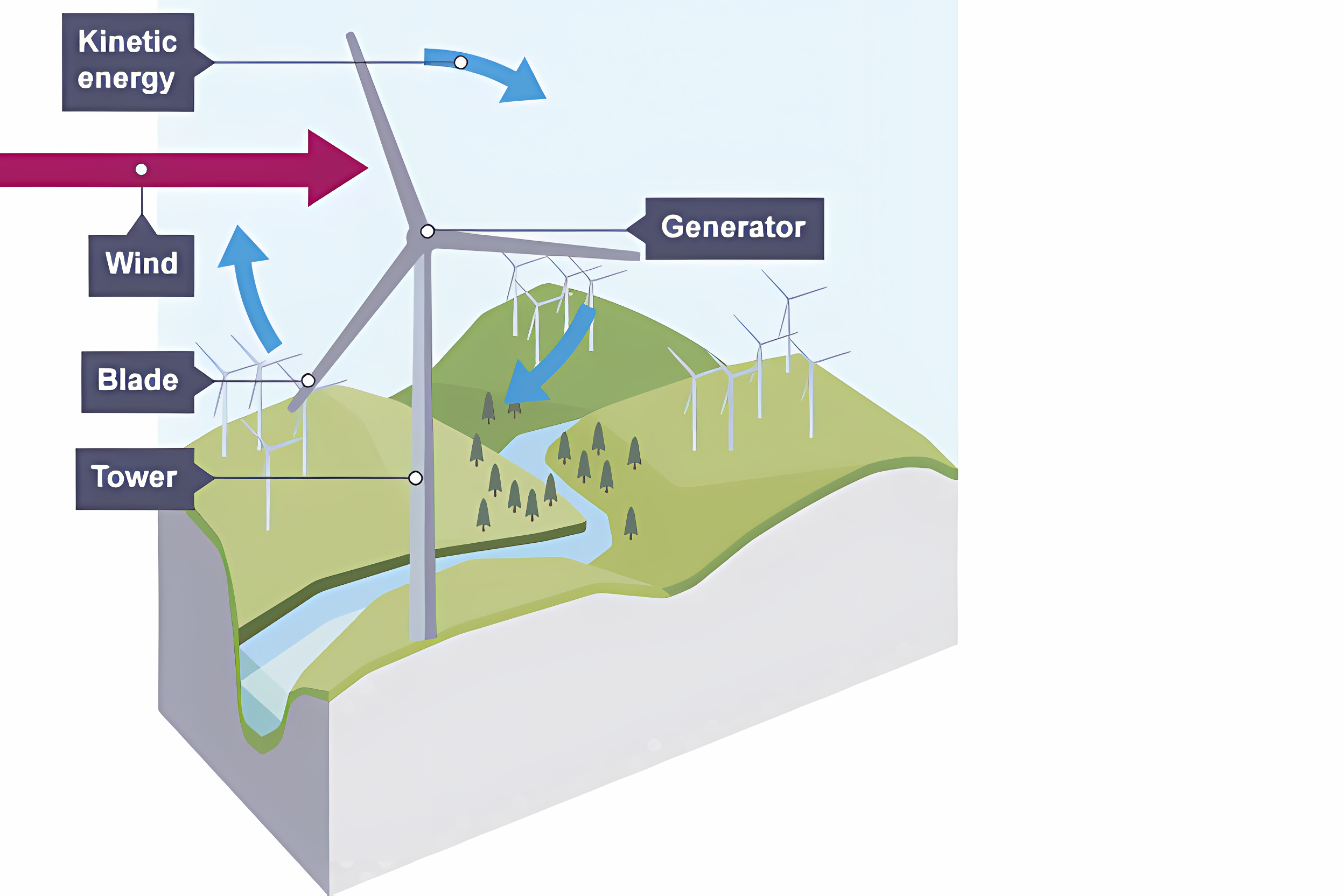

Wind Power

Harnesses the wind to turn a turbine to generate power.

Solar Power

Photovoltaic cells harness the sun’s light energy & convert it into electricity

Photovoltaic

Converting light energy into electrical current

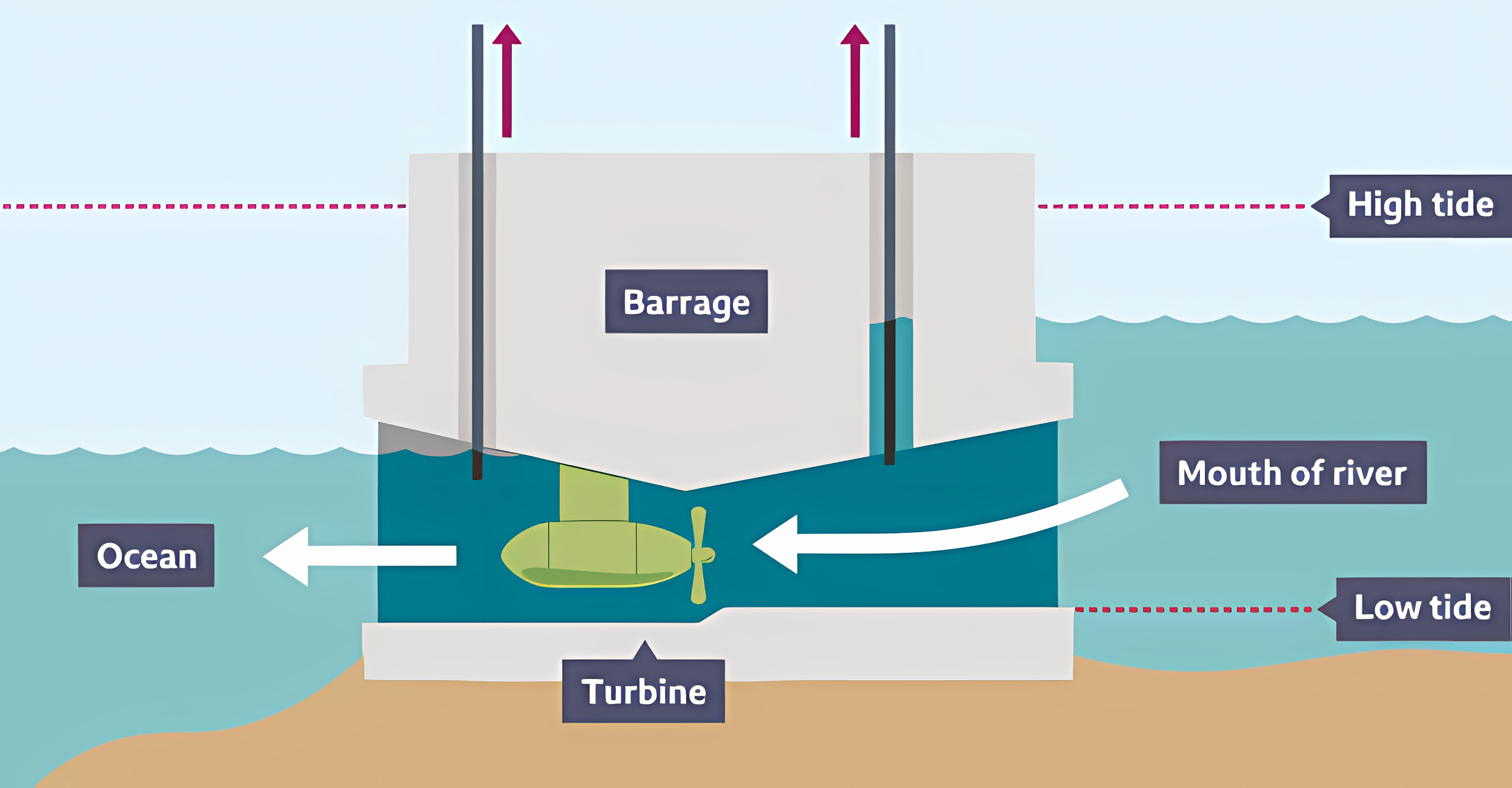

Tidal Power

Barrages generate power by turning a turbine as the tide comes in and out.

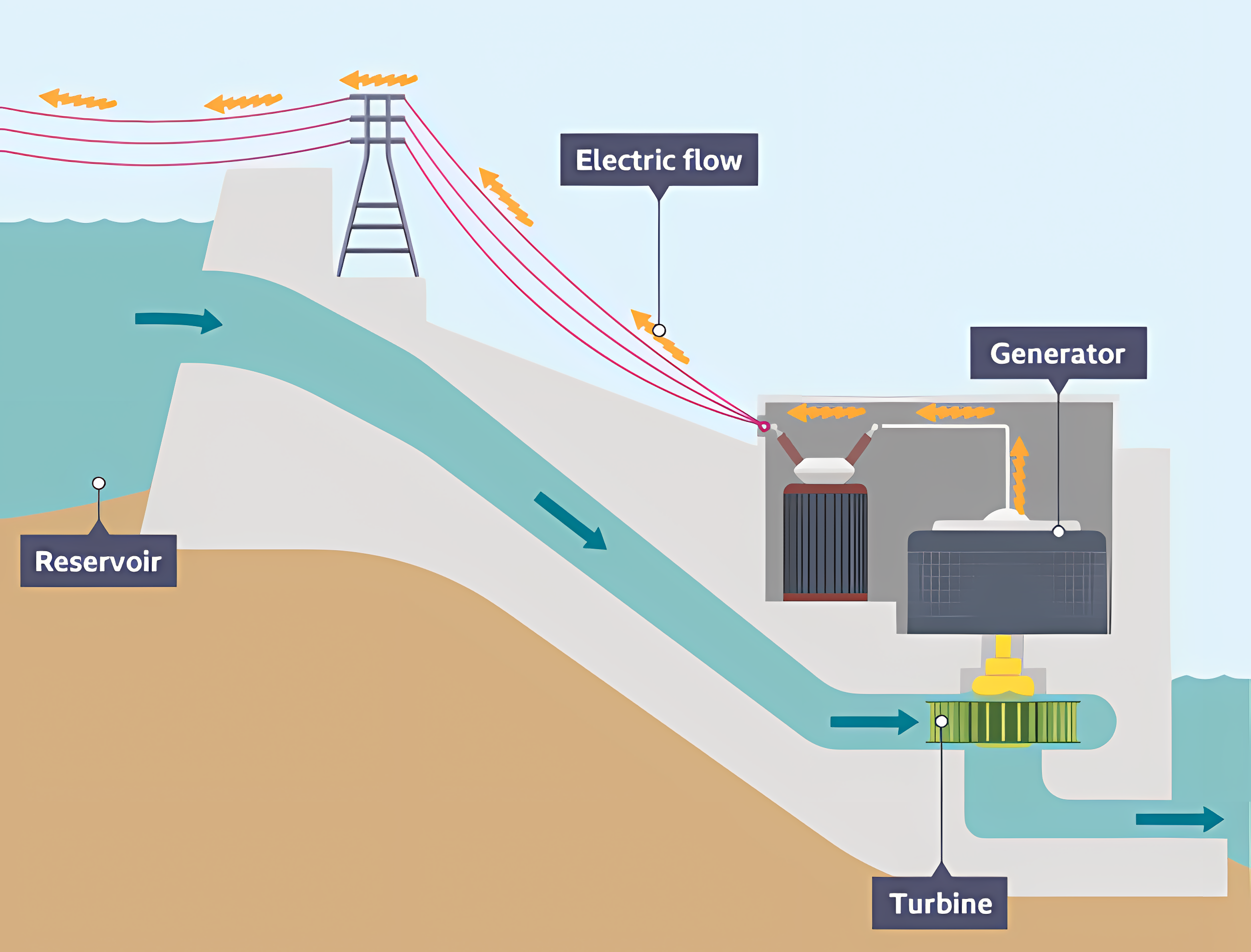

Hydro-electric Power

Generates power through water falling through a turbine, from the top of a hill to the bottom.

Biomass Power

Use waste products from wood or crops to burn creating the heat to turn the turbine.

Alkaline Batteries

Can’t be used again once the power is used, hard to dispose.

Rechargeable Batteries

They can have power put back into them, they are more expensive but also more environmentally friendly.

Traditional Materials

Materials that have been in use for centuries, such as paper, wood, stone and metals.

Modern Materials

Materials that have been engineered to have improved properties.

Smart Materials

Materials that exhibit a physical change in response to some external stimuli.

Shape-memory alloys (SMA)

Metal alloys that can remember their shape when heated.

Thermochromic Pigments

Change color when their temperature changes.

Photochromic Pigments

These pigments change their properties when exposed to Ultraviolet (UV) light.

Composite Materials

Materials made of different materials, which are combined to improve their properties.

Fiber-based composites

Mixture of 2 materials:

one part is a material in fiber strands, and the other is a resin.

Particle-based composites

Mixture of 2 materials:

one part is small particles, and the other is a liquid that sets.

Sheet-based composites

Mixture of 2 materials:

one part is thin sheets of a material, and the other is a resin.

Technical Textiles

Modern materials developed to help make fabrics.

Kevlar

Synthetic fiber which is woven to create a super strong, lightweight fabric which has uses for protective clothing.

Fire-retardant fabrics (Nomex)

Fire resistant fabric with resistance built into the fibers (so it can’t be washed out).

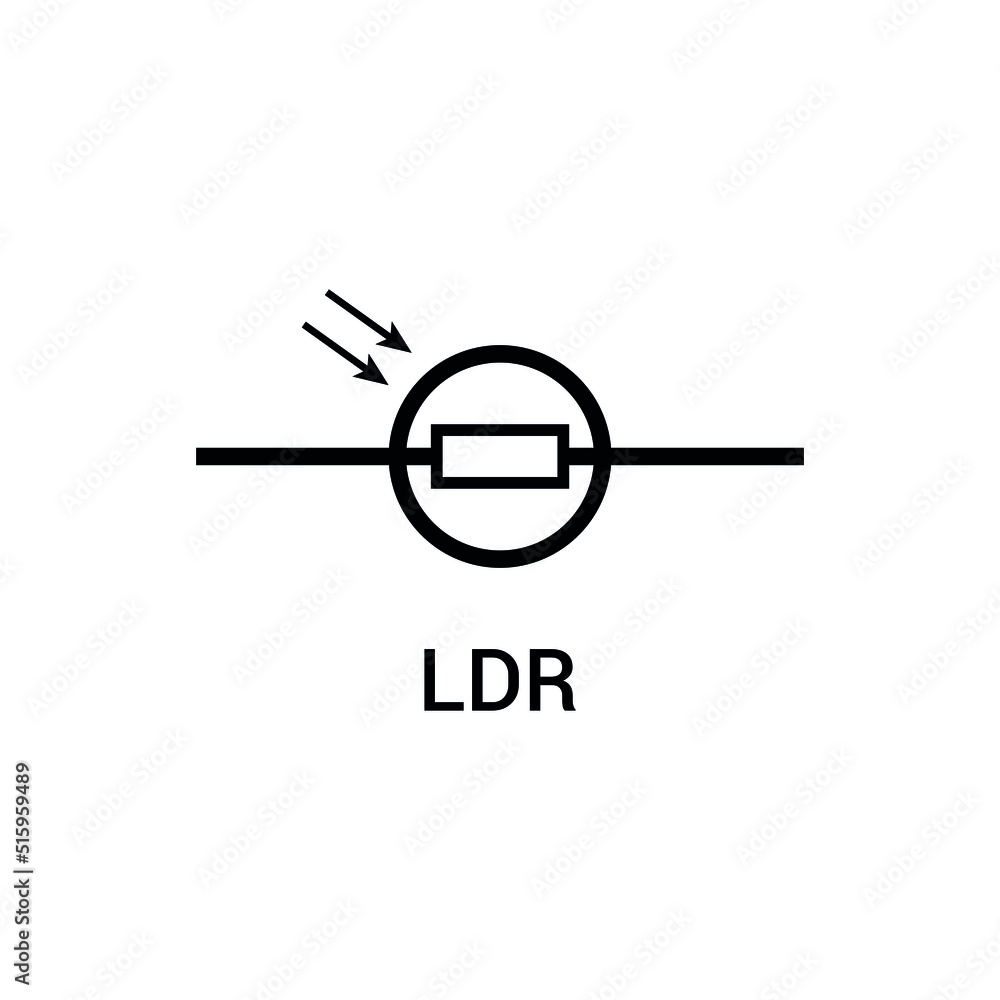

Input devices

Devices which allow systems to understand changes in environments. (E.g. a sensor like a light-dependent resistor).

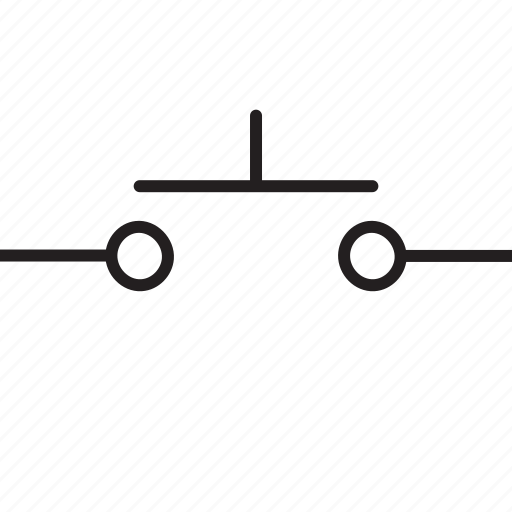

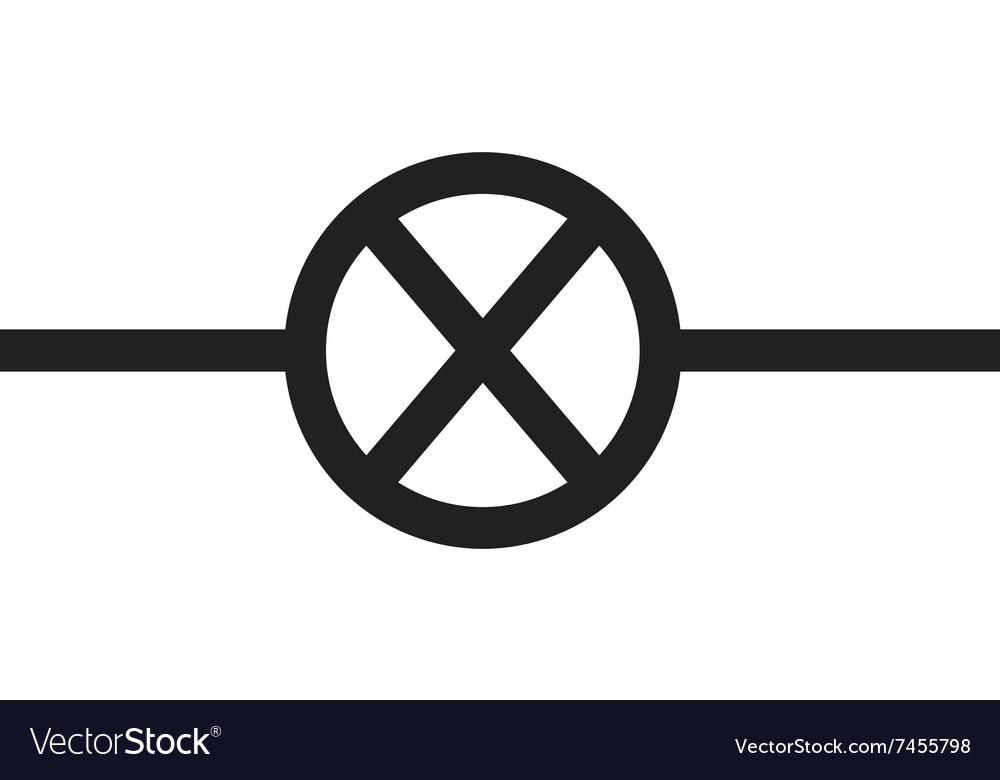

Switches

Devices which allow currents to flow through them, when the contacts inside are joined together.

Push-to-make Switch (PTM)

A switch that ‘makes’ a circuit when pressed.

Push-to-break Switch (PTB)

A switch that ‘breaks’ a circuit when pressed.

Toggle or Rocker switch

A Switch which has 2 conditions, on or off.

Sensors

Devices that detect changes in the environment. They are inputs.

Light-dependent resistor (LDR)

Special type of resistor whose resistance changes with light levels. (Brighter light = Less resistance)

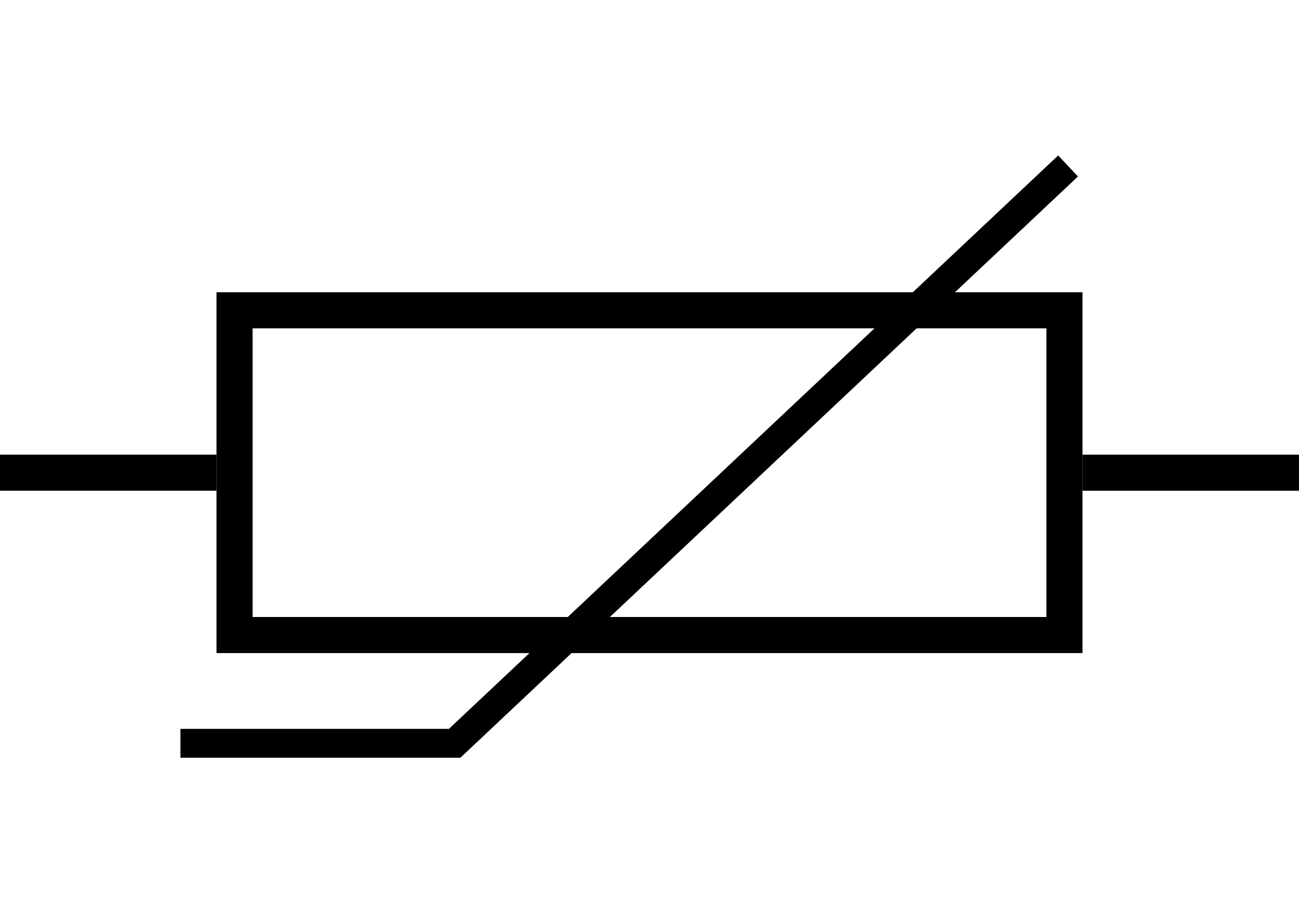

Thermistor

Special type of resistor whose resistance changes with temperature levels.

Name a suitable input device for a greenhouse cooling system

A Thermistor

Microcontrollers

A small computer chip used instead of a CPU that contains a processor, memory and inputs/outputs.

Advantages of Microcontrollers

The size of a circuit can be significantly reduced. This is because programming replaces physical components.

They can be reprogrammed many times. This allows changes to be made without replacing actual components.

They have pins for connecting several input and output devices, adding to flexibility.

Disadvantages of Microcontrollers

They often cost more than traditional integrated circuits. They are therefore not always the best option for simple systems.

Programming software and hardware is required. This can be expensive to buy.

The language of the system must be learned and this adds to training costs.

Process devices

Device that takes the signal from the input stage, and changes it in some way.

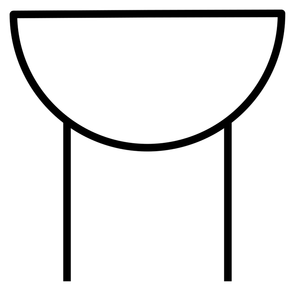

Output devices

Device which allows a system to present information back to the real world.

Name a suitable output device for an MP3 amplifier system

A Speaker

Lamp

Current flows through a filament, heating it up, creating light. It is an output.

Buzzer

Current flows through the oscillator, producing a buzzing sound.

Linear Motion

Moving something in a straight line (E.g. Train moving)

Rotary Motion

Something moves around an axis or pivot point (E.g. a wheel)

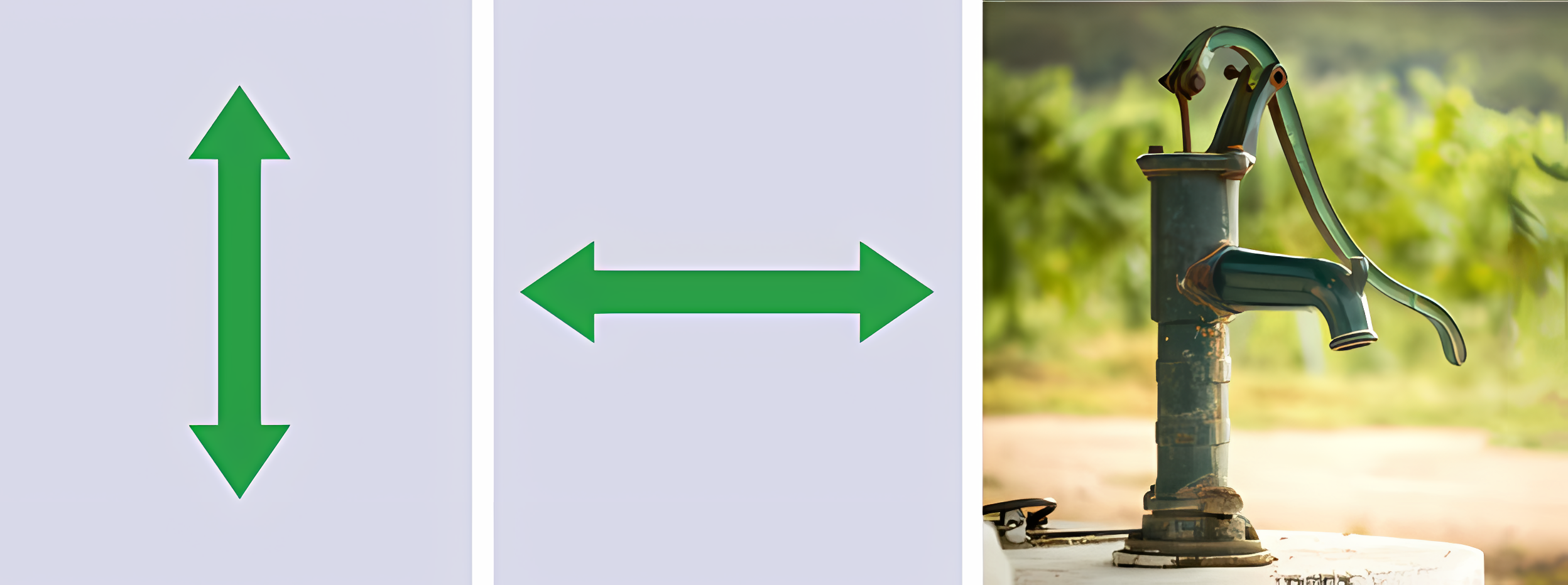

Reciprocating Motion

Repeated up & down motion or back-and-forth motion (E.g. Piston or Pump)

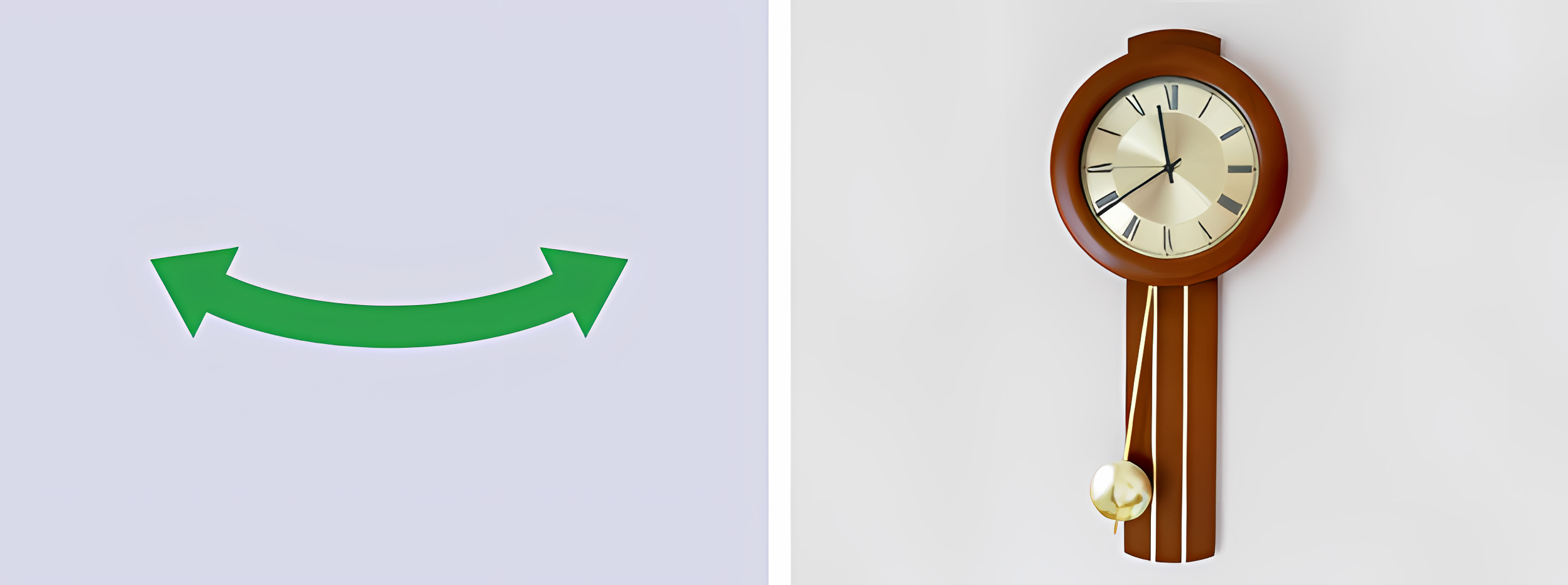

Oscillating Motion

Curved backwards & forwards movement, swinging on an axis or pivot point.

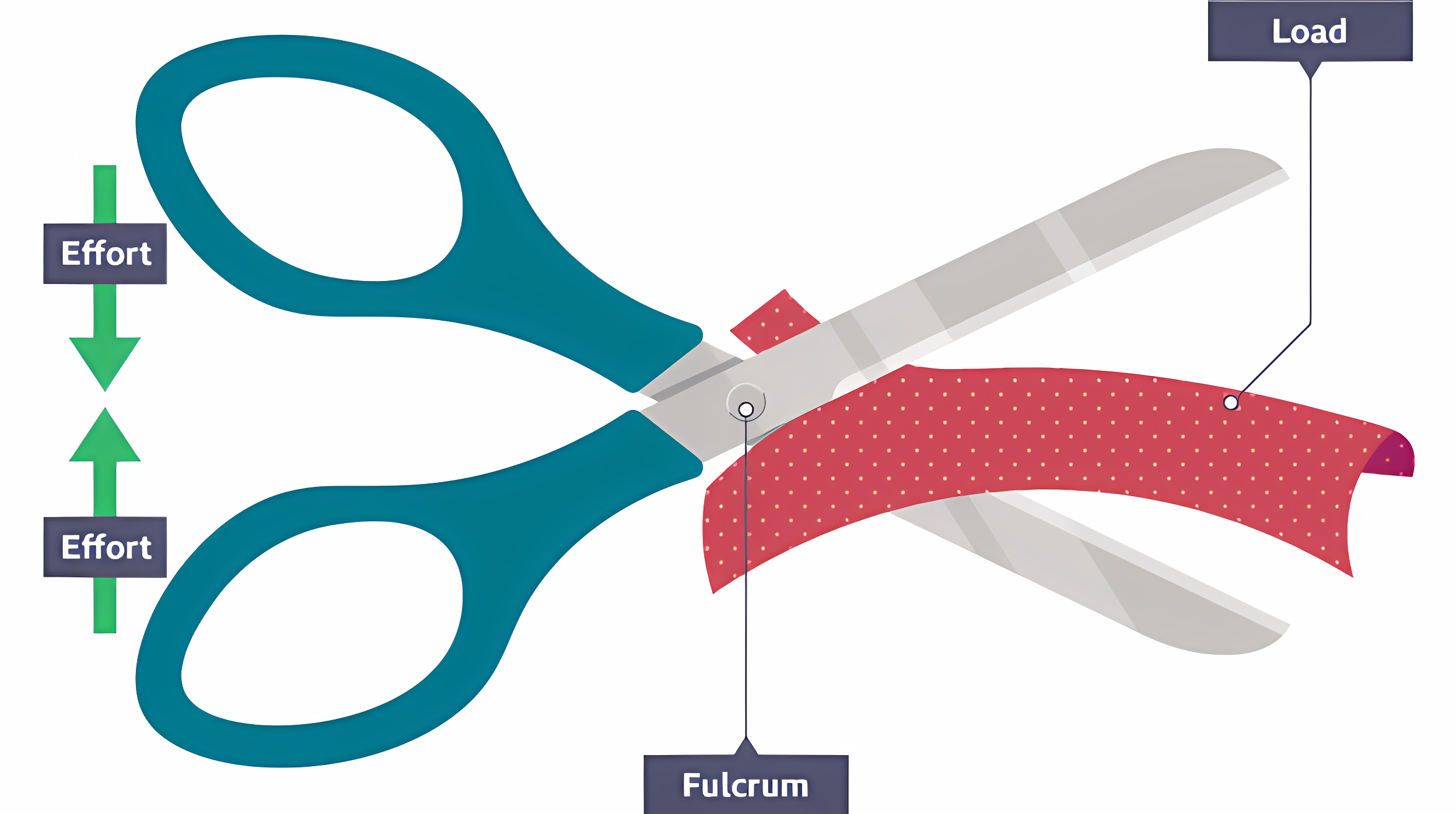

Effort

Amount of force applied by the user (Input)

Fulcrum

Where the lever pivots

Load

The weight that needs to be moved

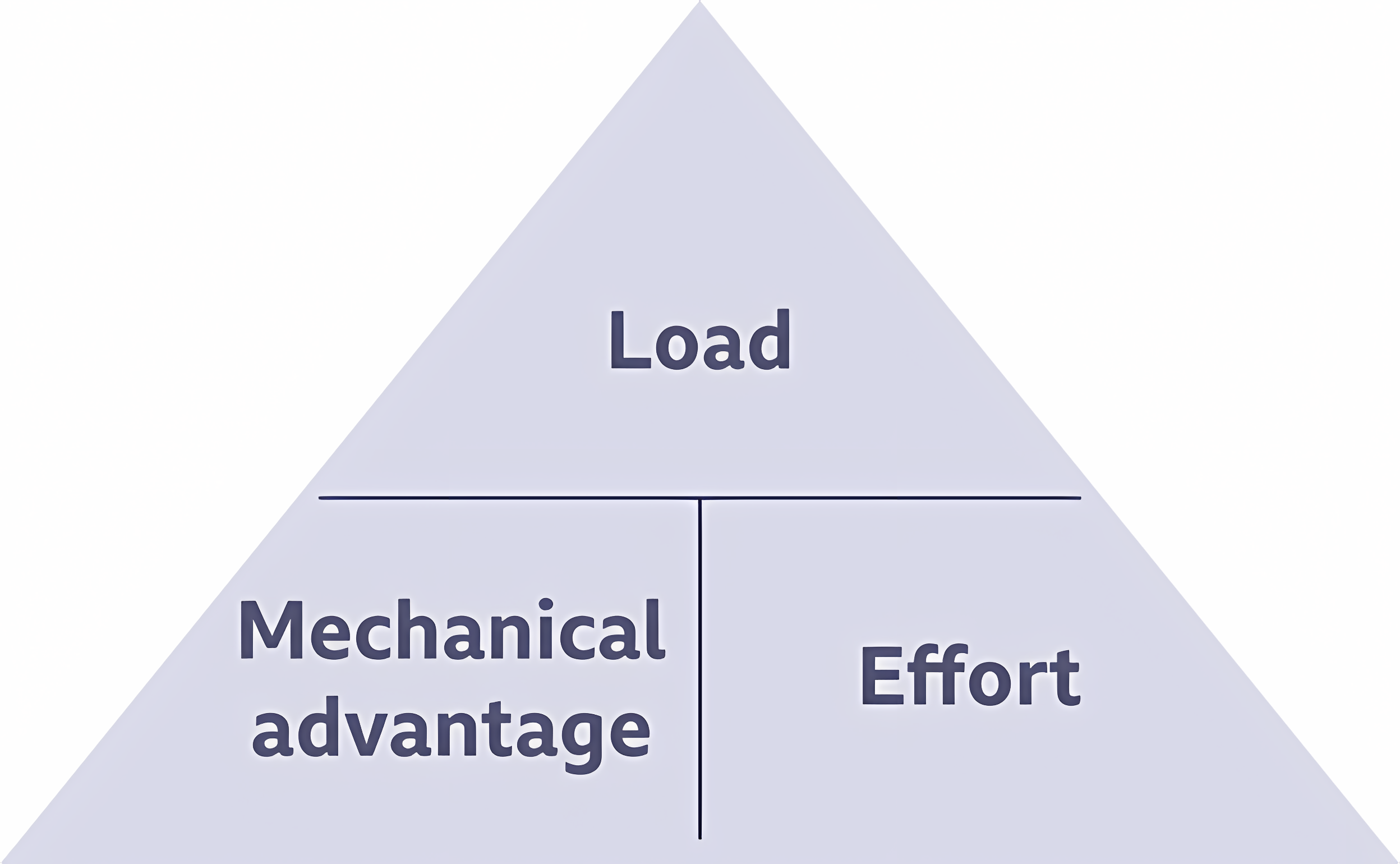

Mechanical Advantage (Formula)

= Load (N) ÷ Effort (N)

A person is using a lever to lift a rock with a 50 N load. The mechanical advantage is 5:1. How much effort is the person having to give?

effort = 50 N ÷ 5 = 10 N

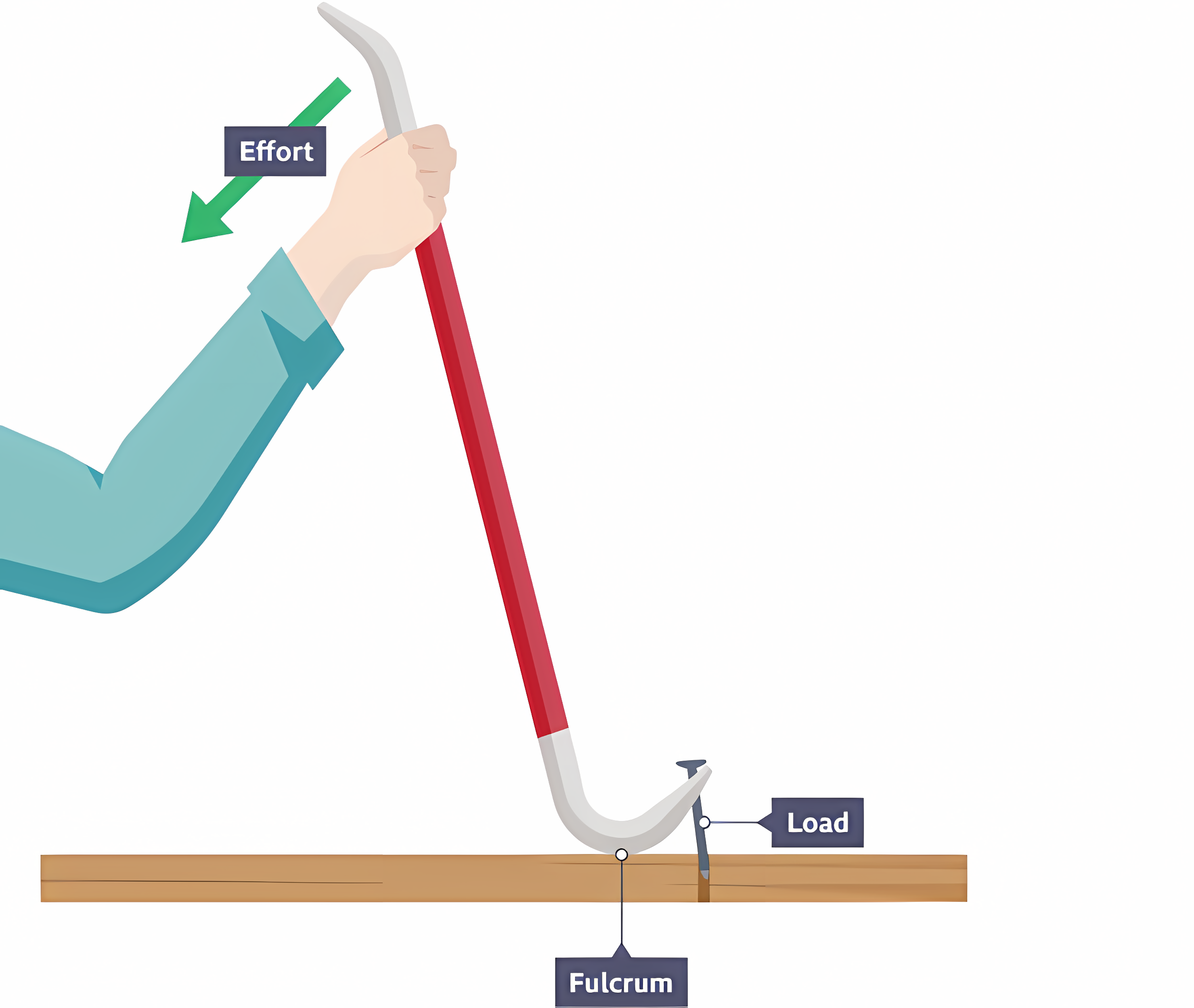

First order levers (Class #1)

The pivot (fulcrum) is between the effort and the load. (E.g. Seesaws or crowbars)

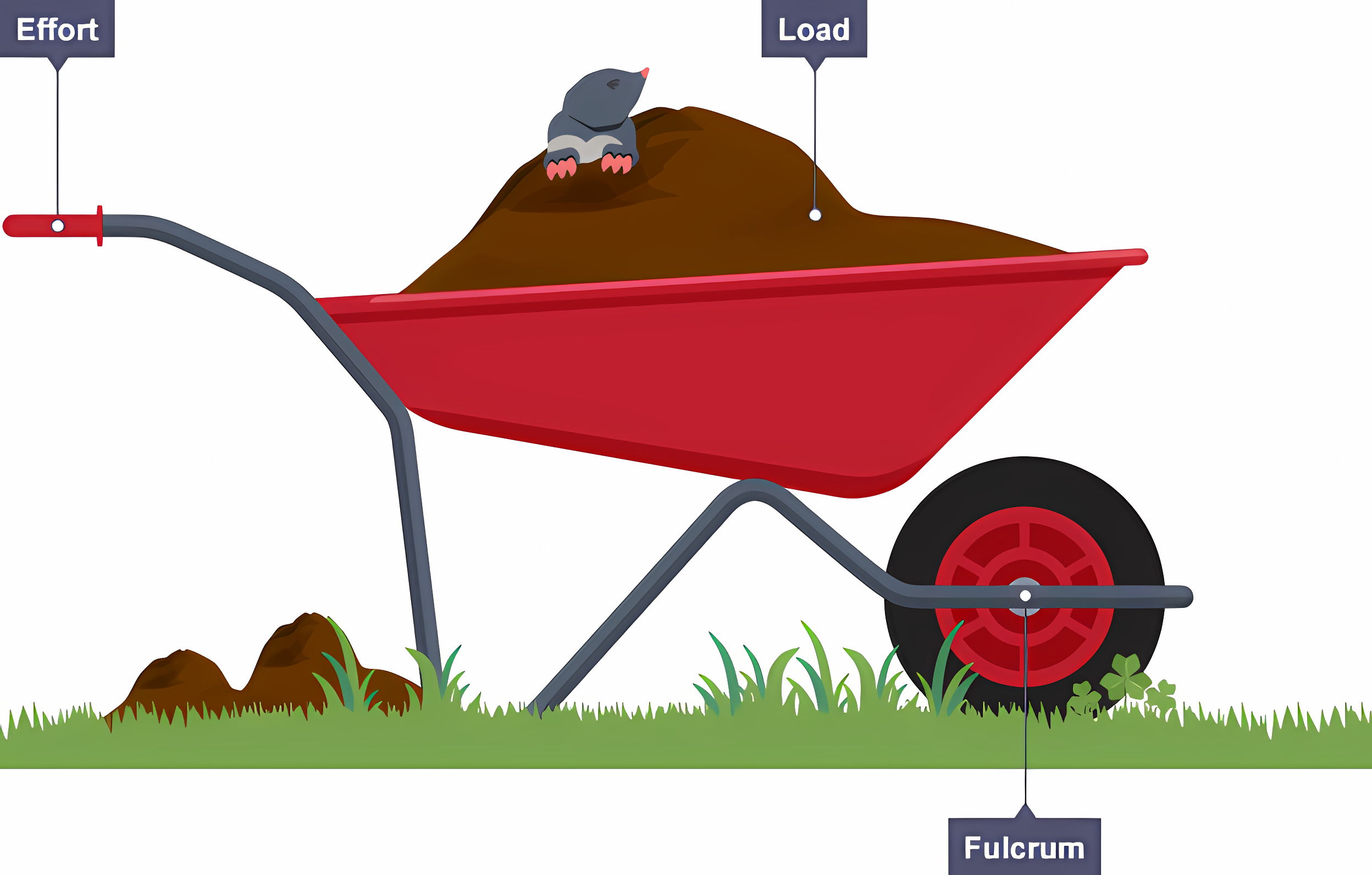

Second order levers (Class #2)

The pivot (fulcrum) is at the end of the lever, away from the user. The load is in the middle, and the effort is near the user. (E.g. Nutcrackers, Wheelbarrows, or bottle openers)

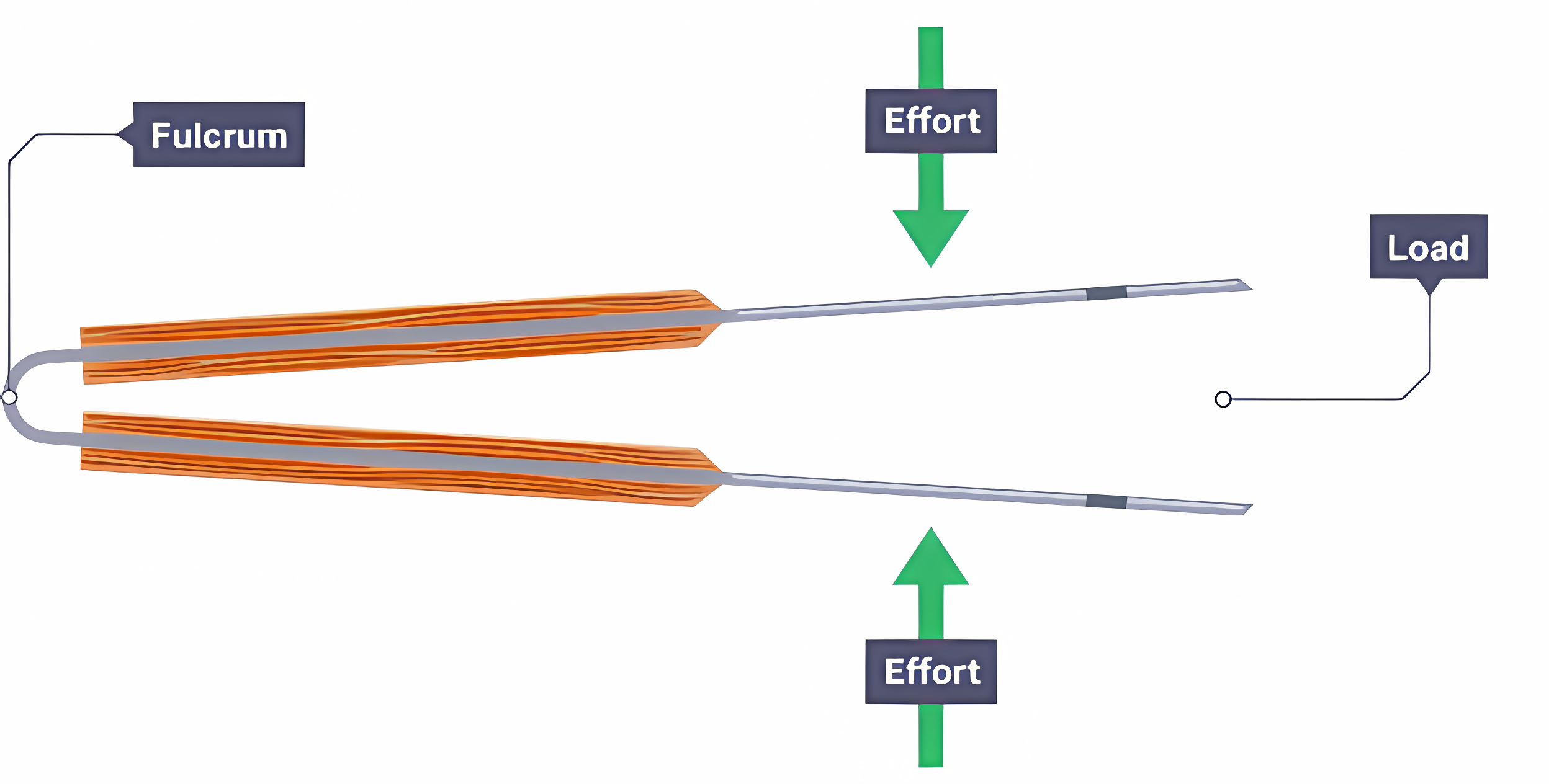

Third order levers (Class #3)

The pivot (fulcrum) is at one end, and the load is at the opposite end. The effort is in the middle. (E.g. Tweezers or fishing rods)

The blade on a pair of scissors is an example of which type of lever?

First order - the hand’s grip is the applied force, the fulcrum is the pin at the center of the scissors and the blade applies force to the load.

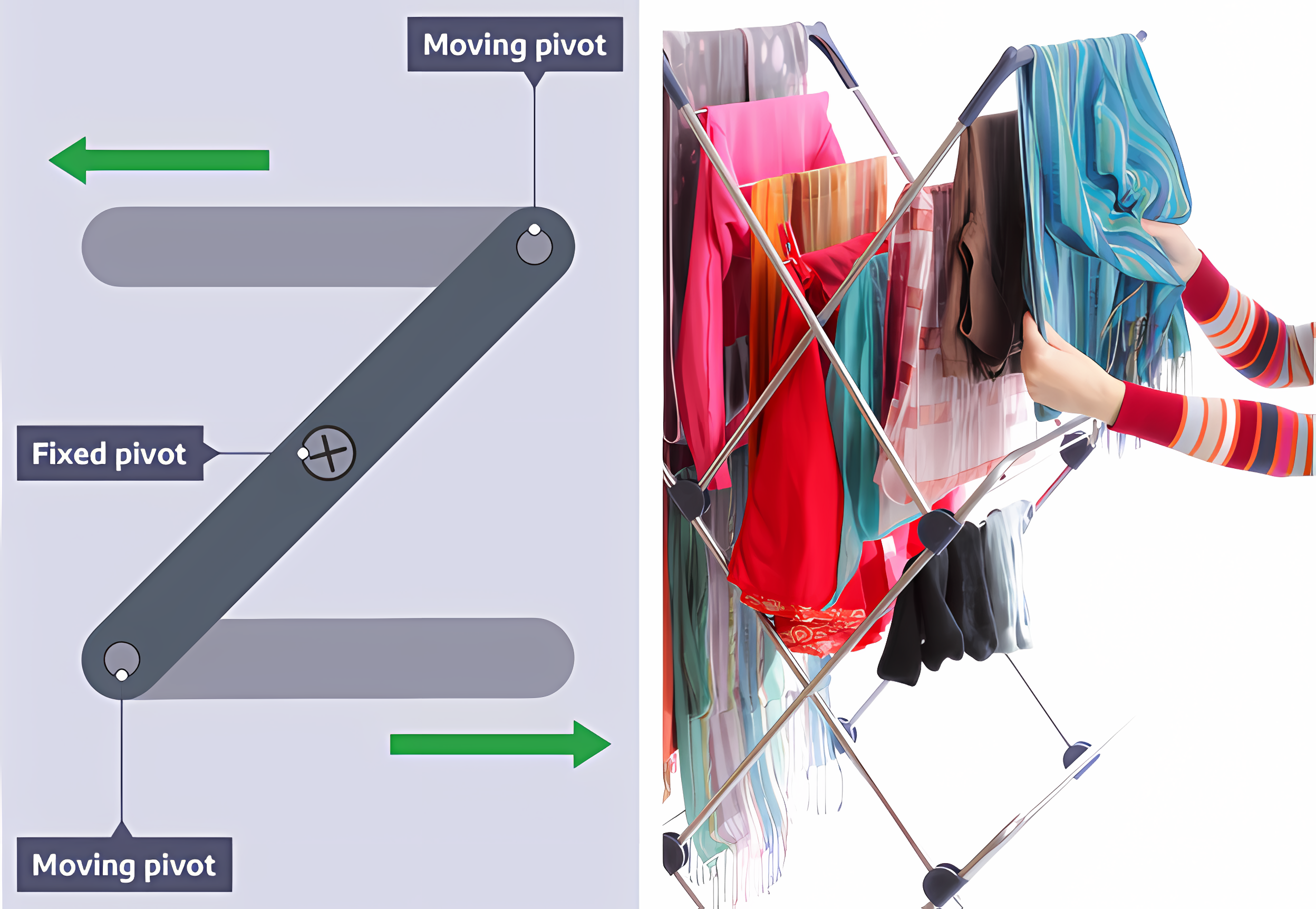

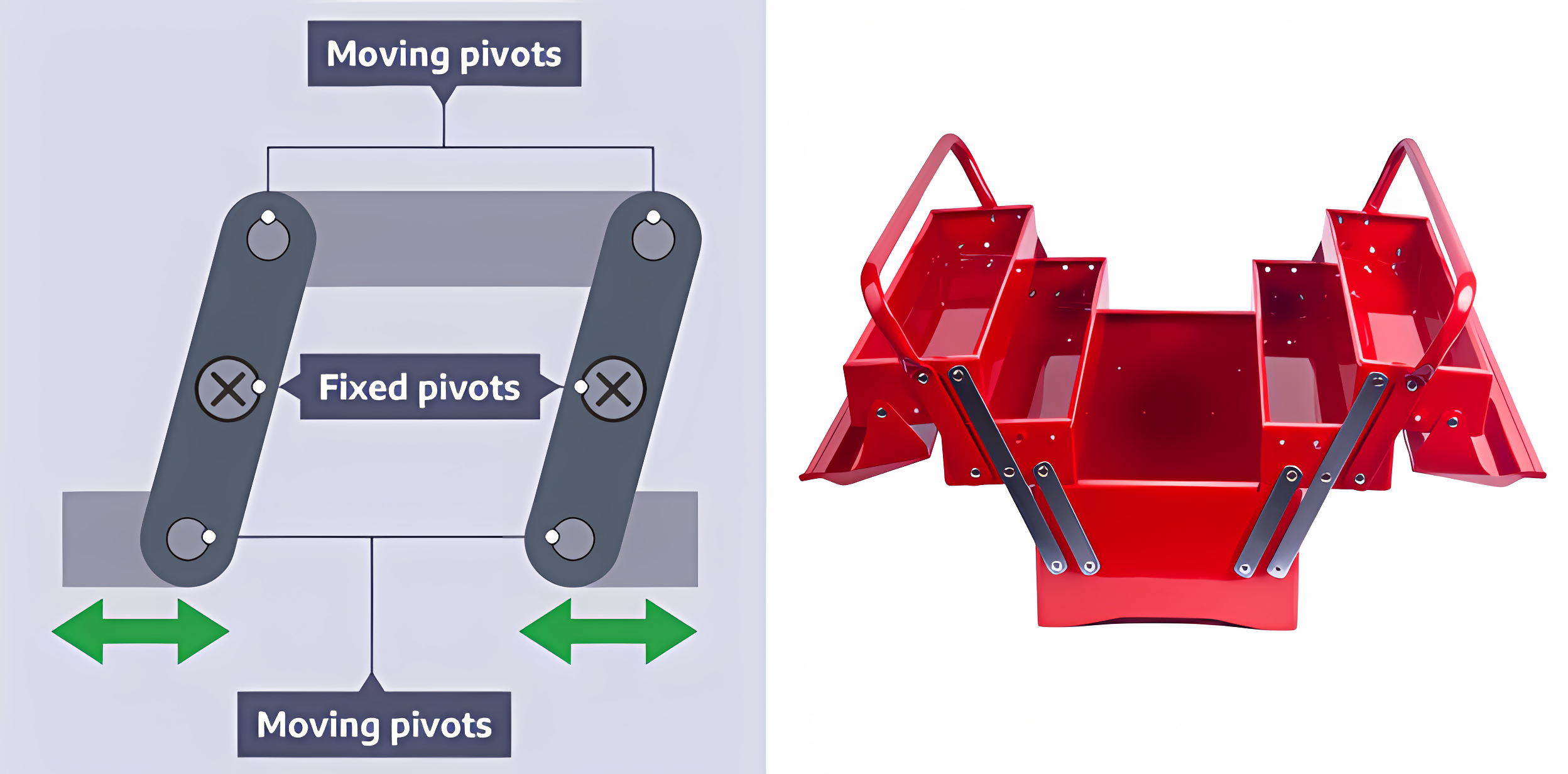

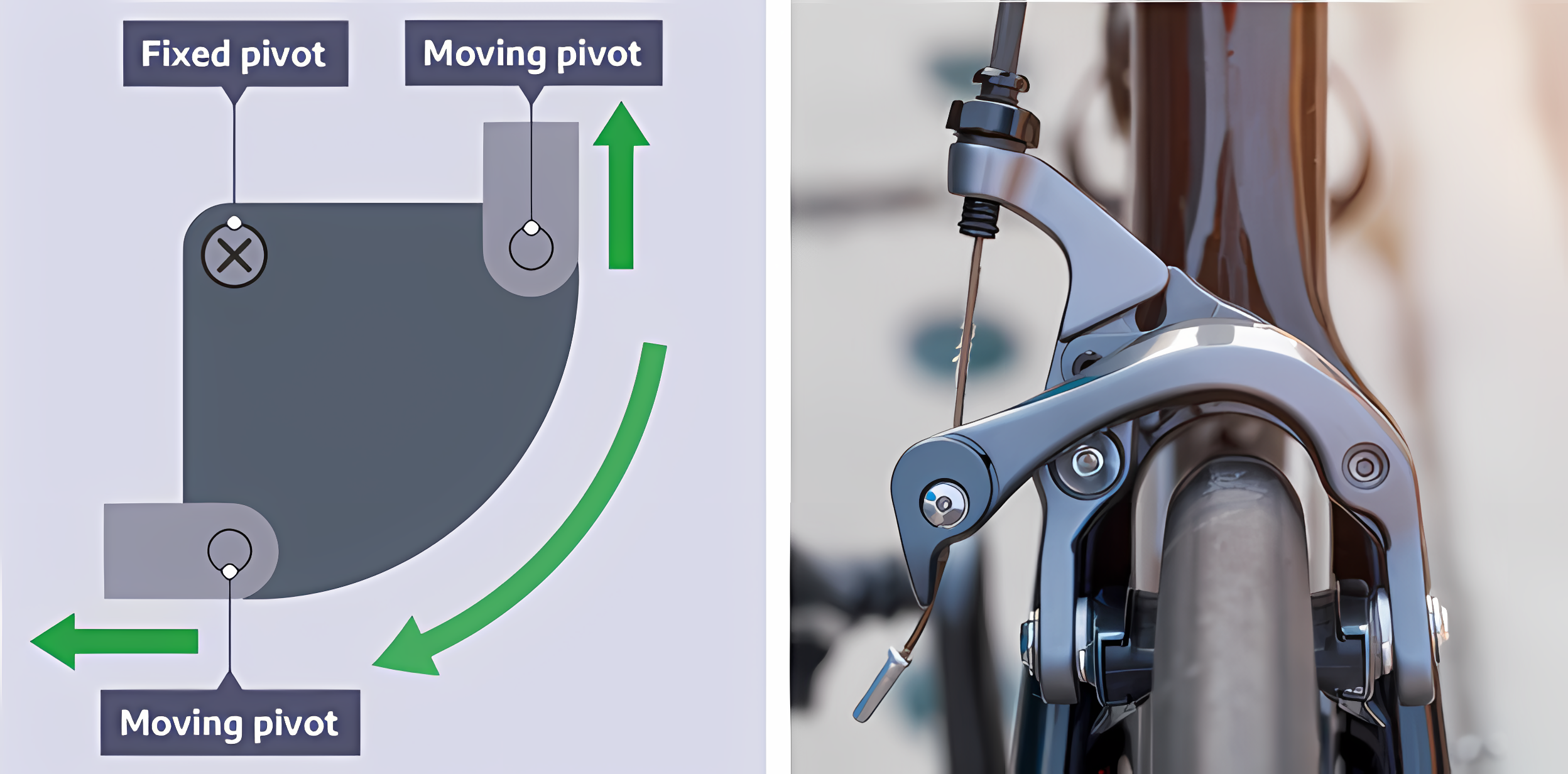

Linkages

Levers joined together, to change the direction or amount of force.

Reverse motion linkage

A linkage that changes the direction of an input to make it go the opposite way. A fixed pivot forces the change in direction.

Parallel motion linkage (Push or Pull)

A linkage that uses 2 fixed pivots to make the input & output travel in the same direction. Each fixed pivot has a moving pivot on either side.

Bell crank linkage

A linkage that changes the direction of the force by 90 degrees. The amount of output force can be changed by moving the fixed pivot.

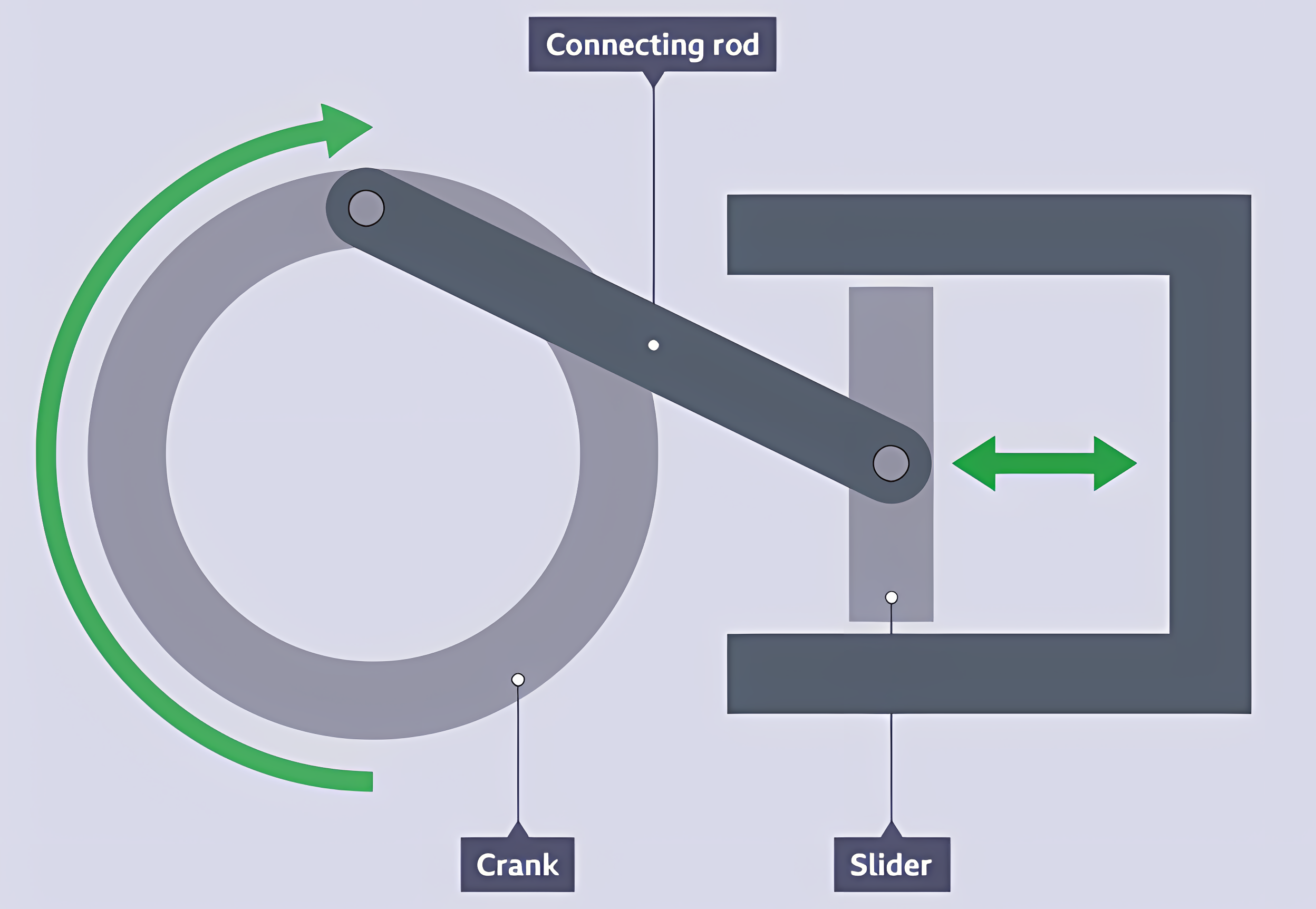

Crank & slider linkage

A linkage that changes rotary motion into reciprocating motion. A fixed pivot is attached to a crank, which turns around and pushes and pulls a slider.

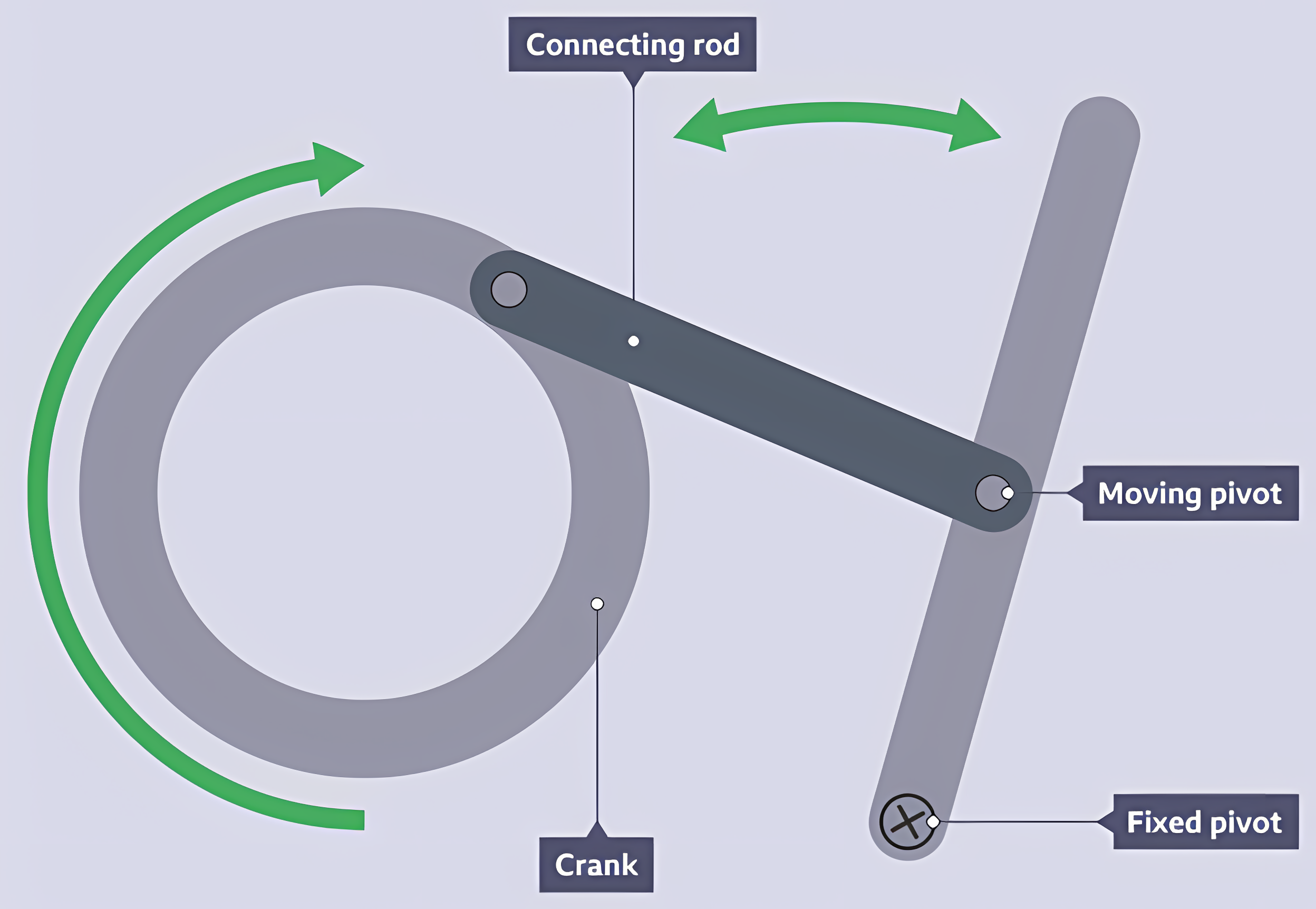

Treadle linkage

A linkage that uses a rotary input to turn a crank on a fixed pivot. A connecting rod joins two moving pivots to another fixed pivot.

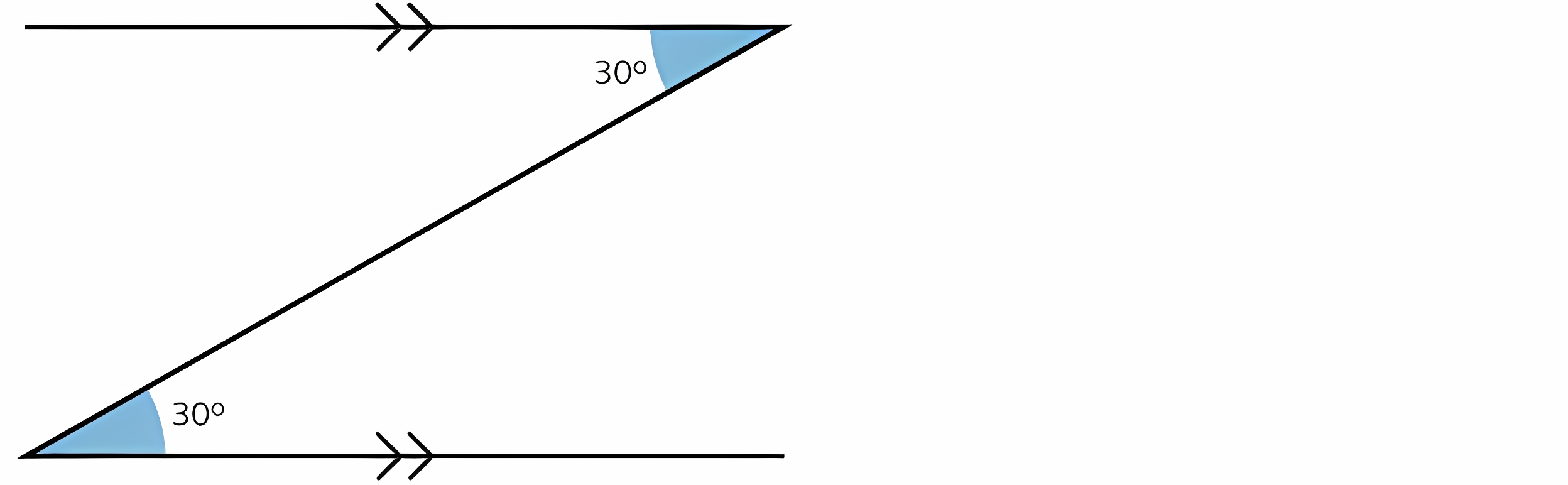

Reverse motion linkage (Angles)

Replicates a 'Z' angle. Z angles feature two internal angles, which will both be the same as long the input and output linkages remain parallel.

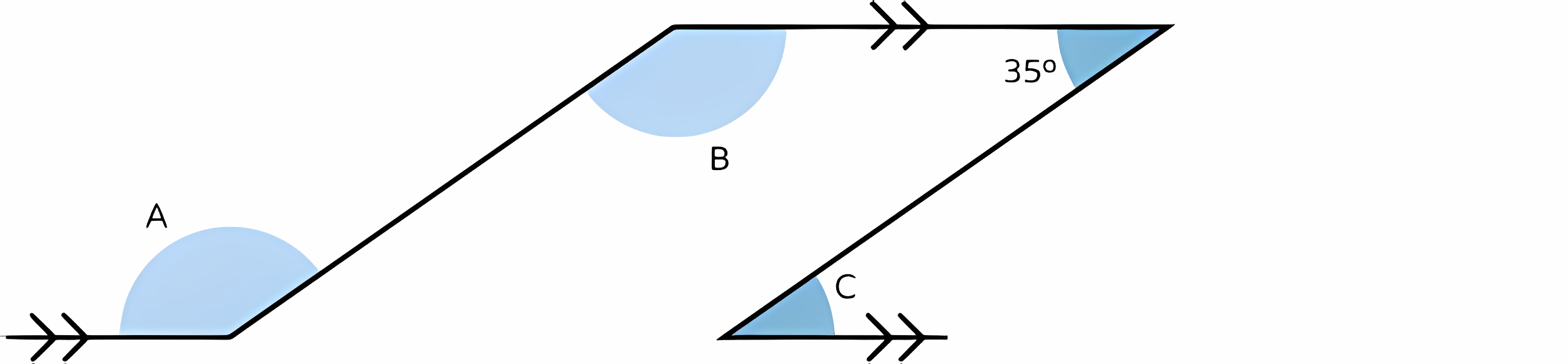

Calculate angles A, B and C in the parallel linkage:

A and B = 145°

C = 35°

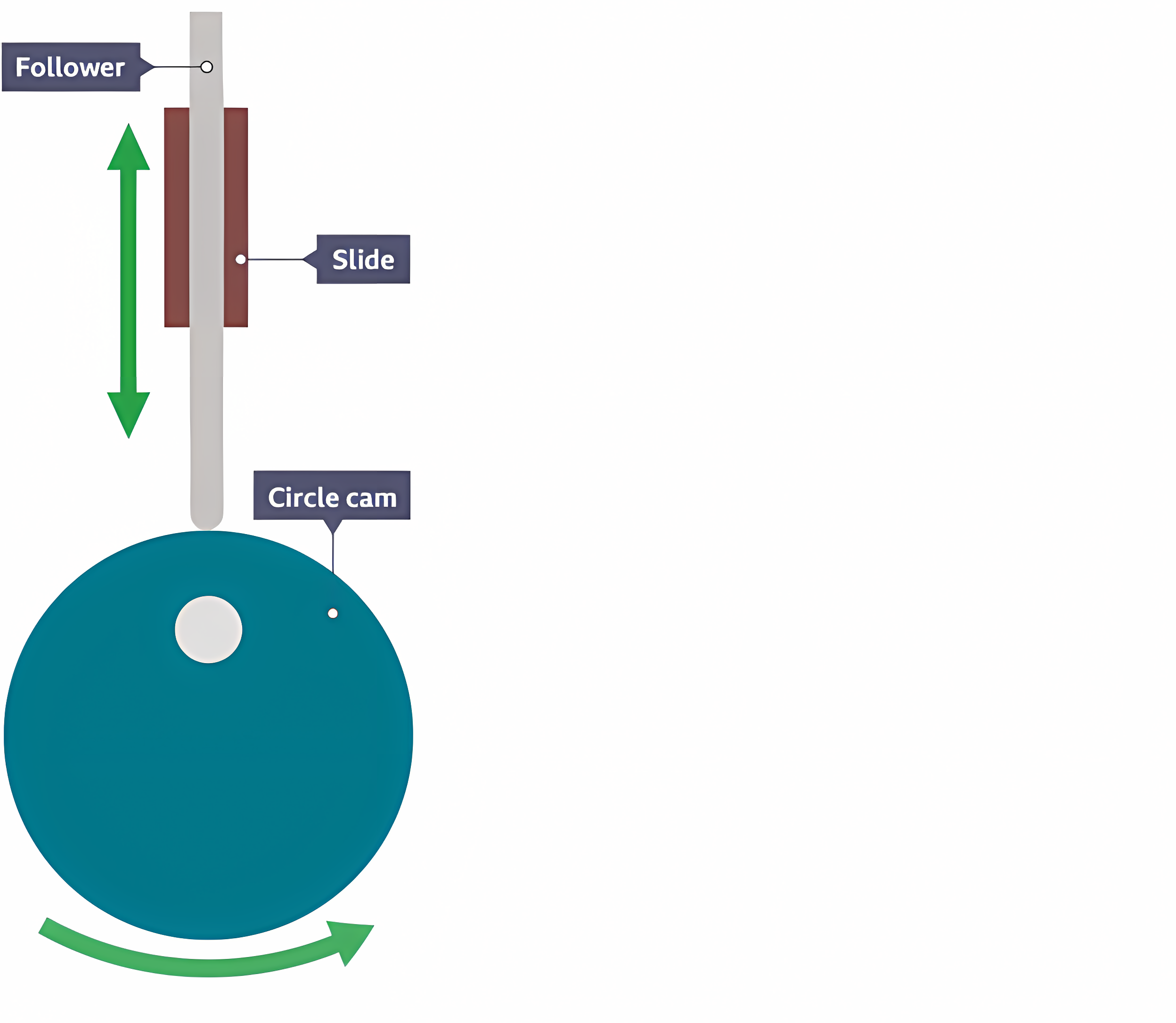

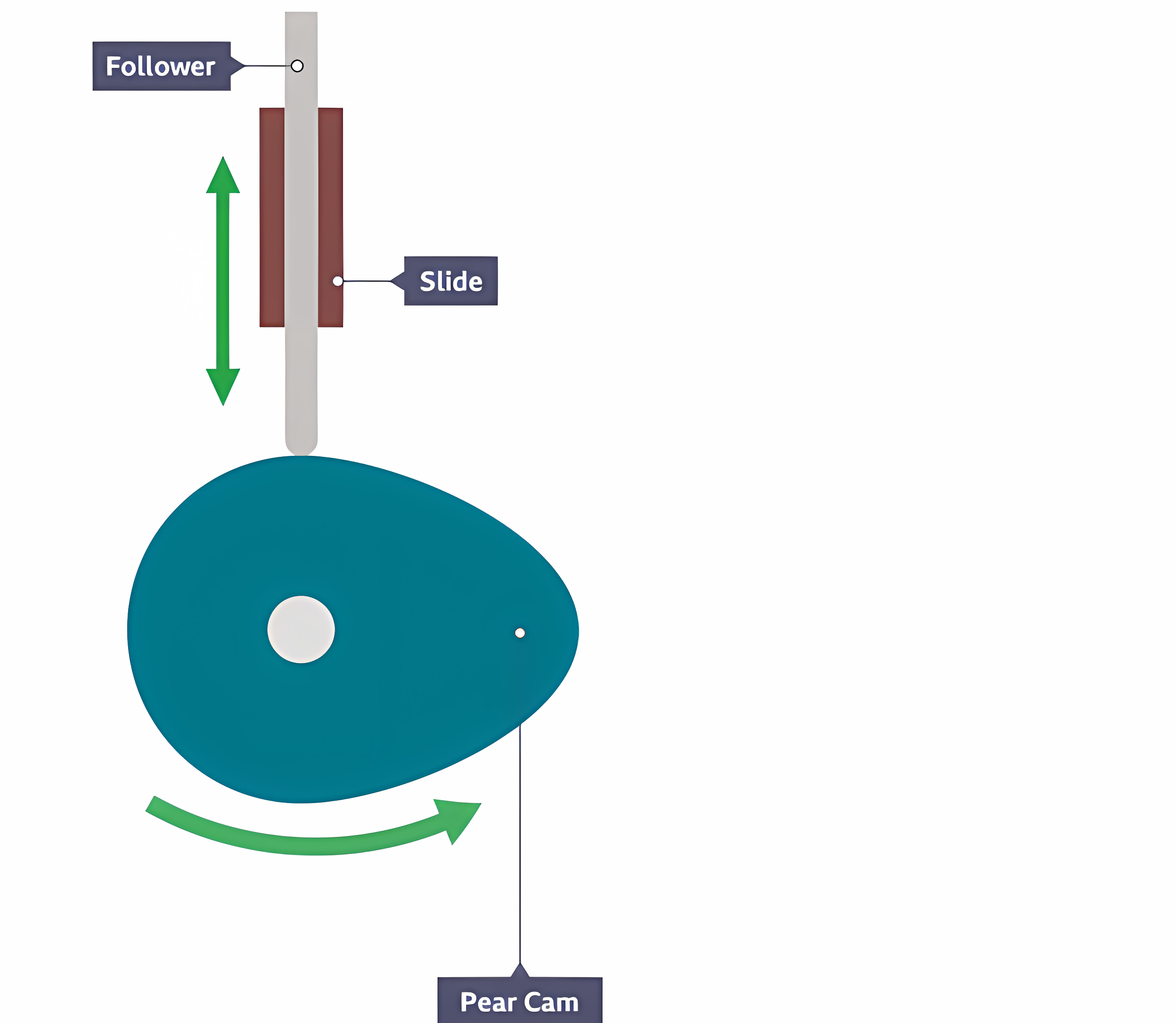

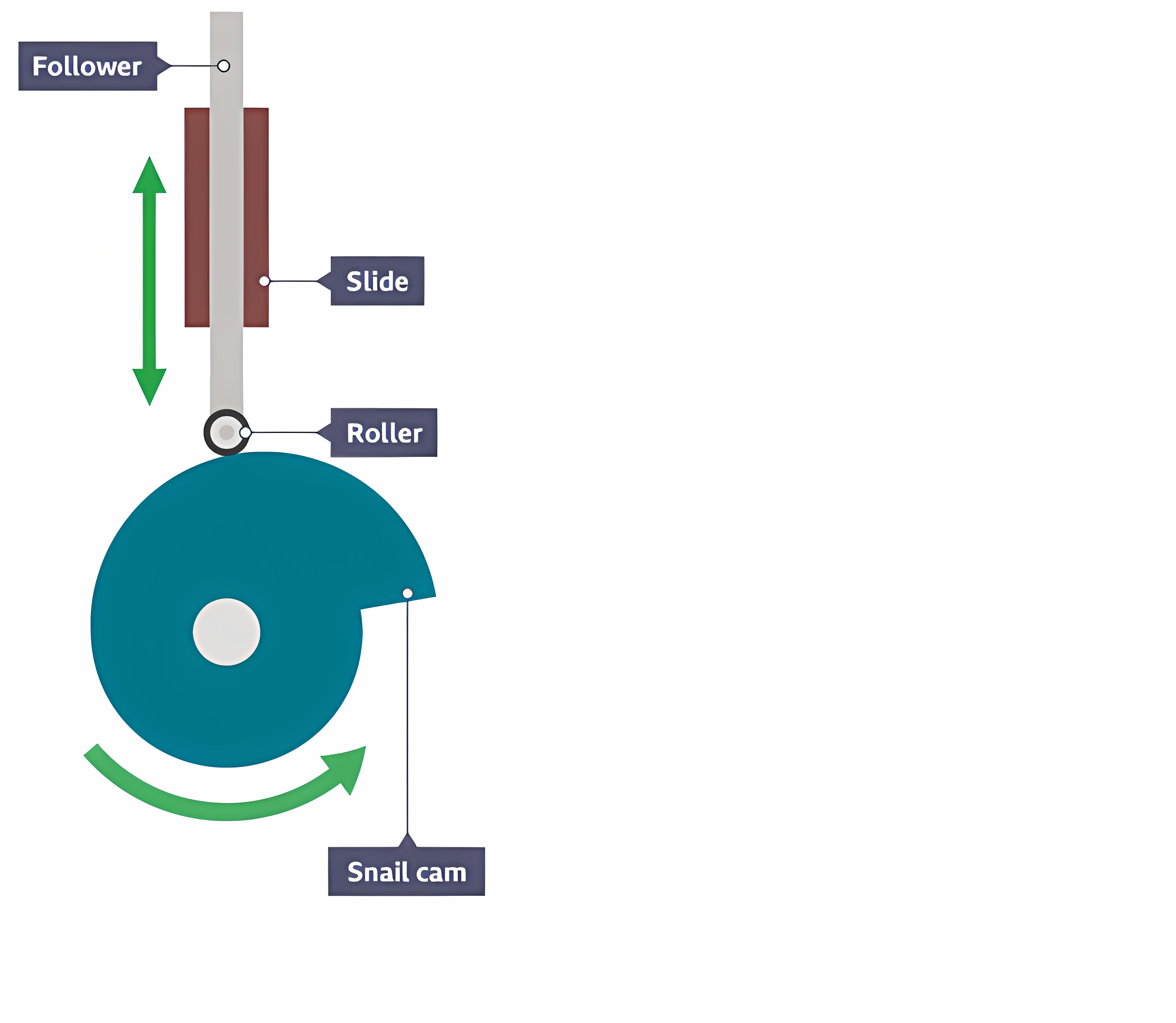

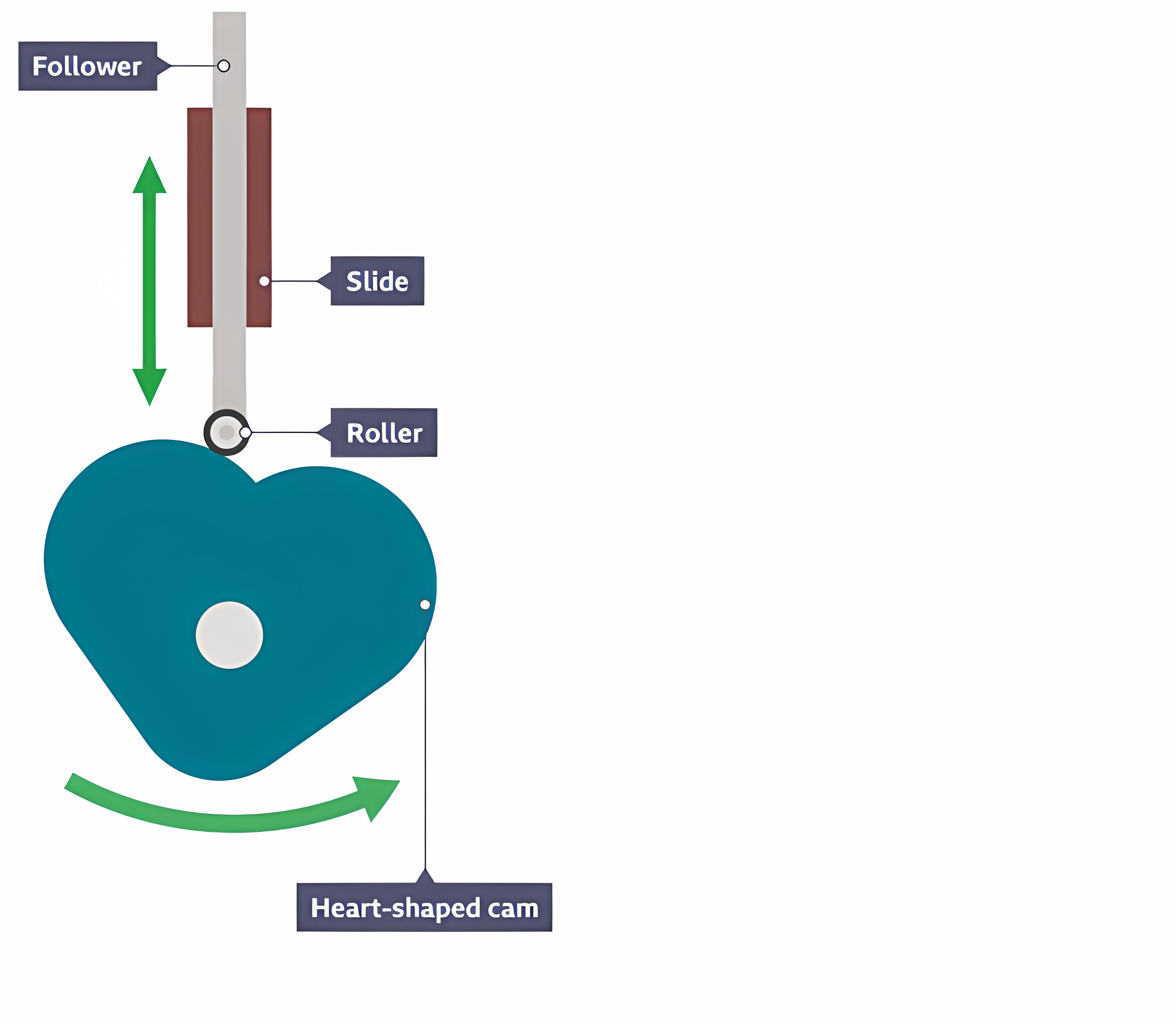

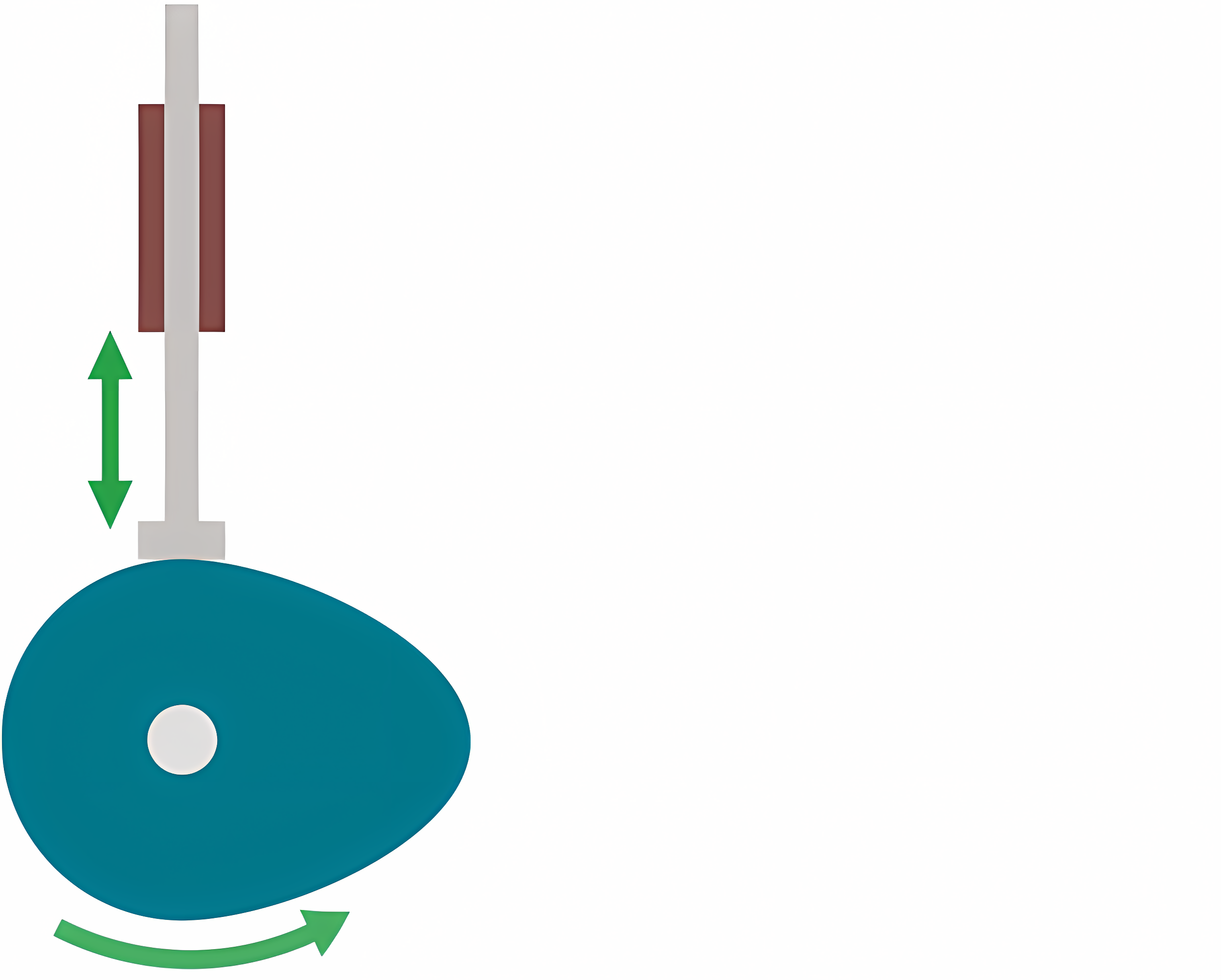

Cam

A wheel attached to a crankshaft

Follower

A bar that follows a cam around its circumference

Circular (cam)

Off-centered pivot causes the follower to move up & down.

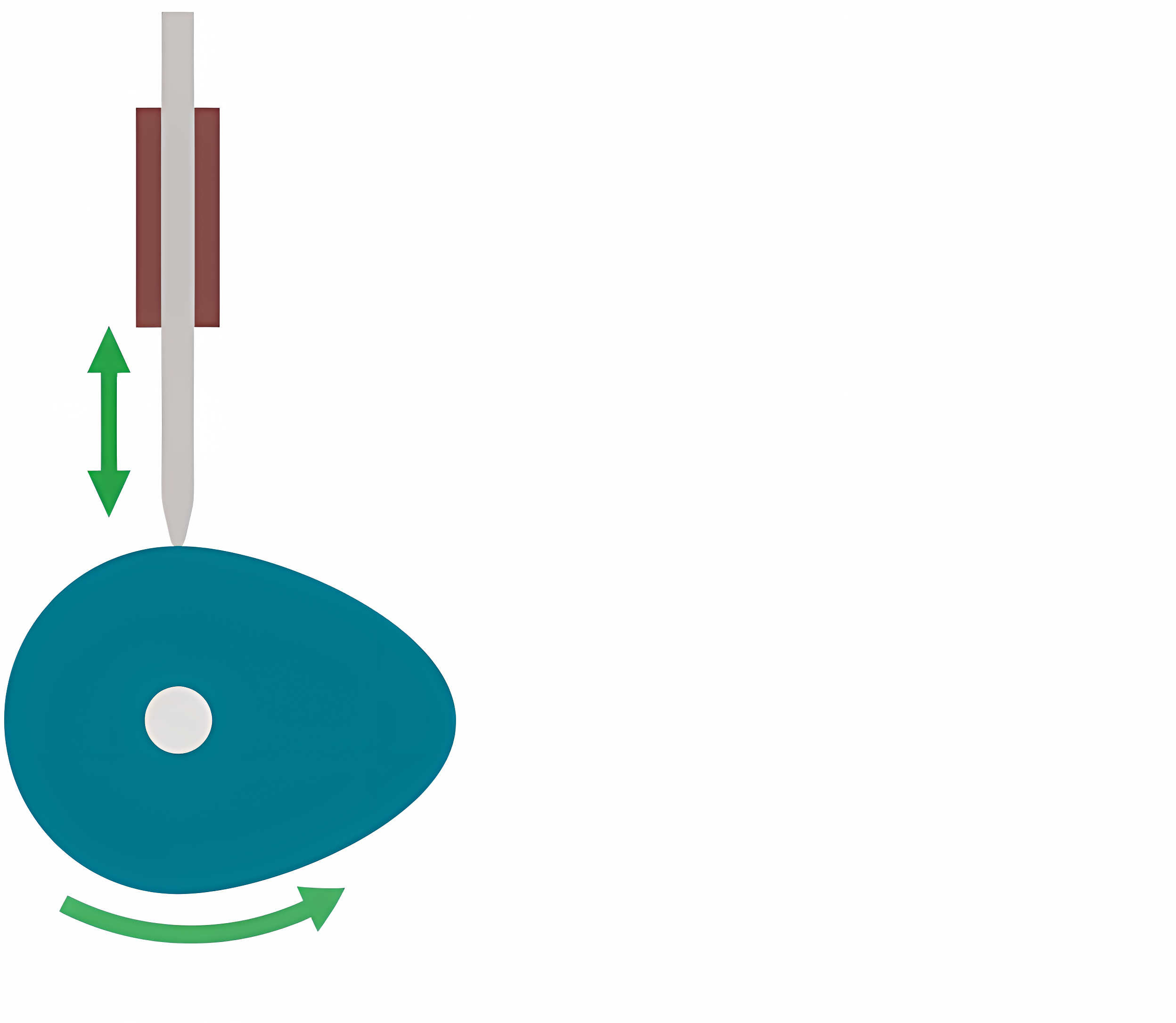

Pear (cam)

Remains stationary for half a turn, then gently rises and falls.

Snail or drop (cam)

Causes the follower to remain stationary for half a turn before gently rising and suddenly falling. They only work in one direction.

Heart-shaped (cam)

The follower rises and falls steadily with uniform velocity.

Flat (Follower)

Flat bottom that sits on the cam. Cope well under load, but aren’t very accurate, and have a lot of friction.

Point or knife (Follower)

Narrow point that sits on the cam. Very accurate and low friction but are quick to wear away the pointed edge.

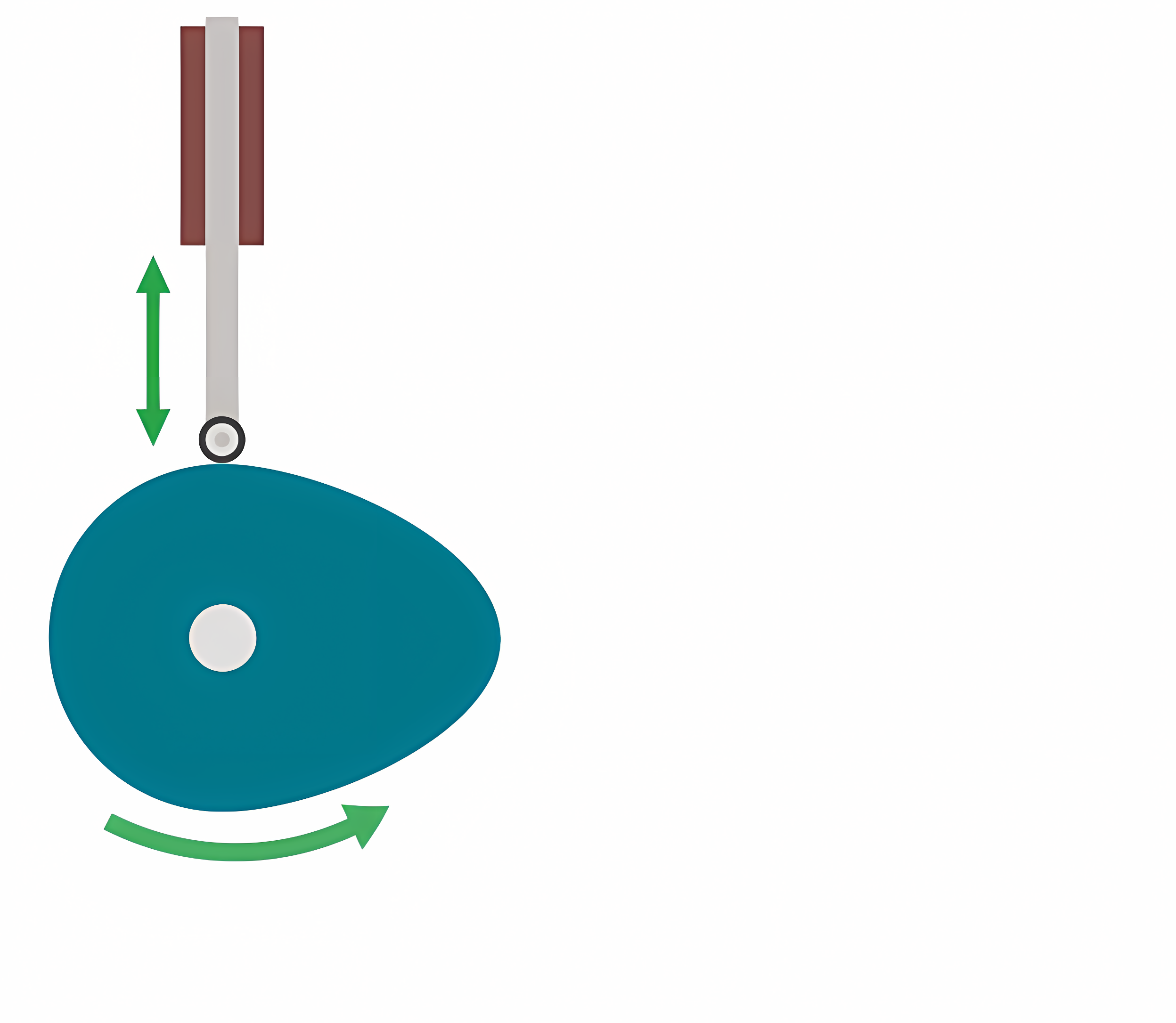

Roller (Follower)

Roller (E.g. ball bearing) attached to the bottom of the follower. Accurate, low friction and can withstand load, but are more costly to produce.

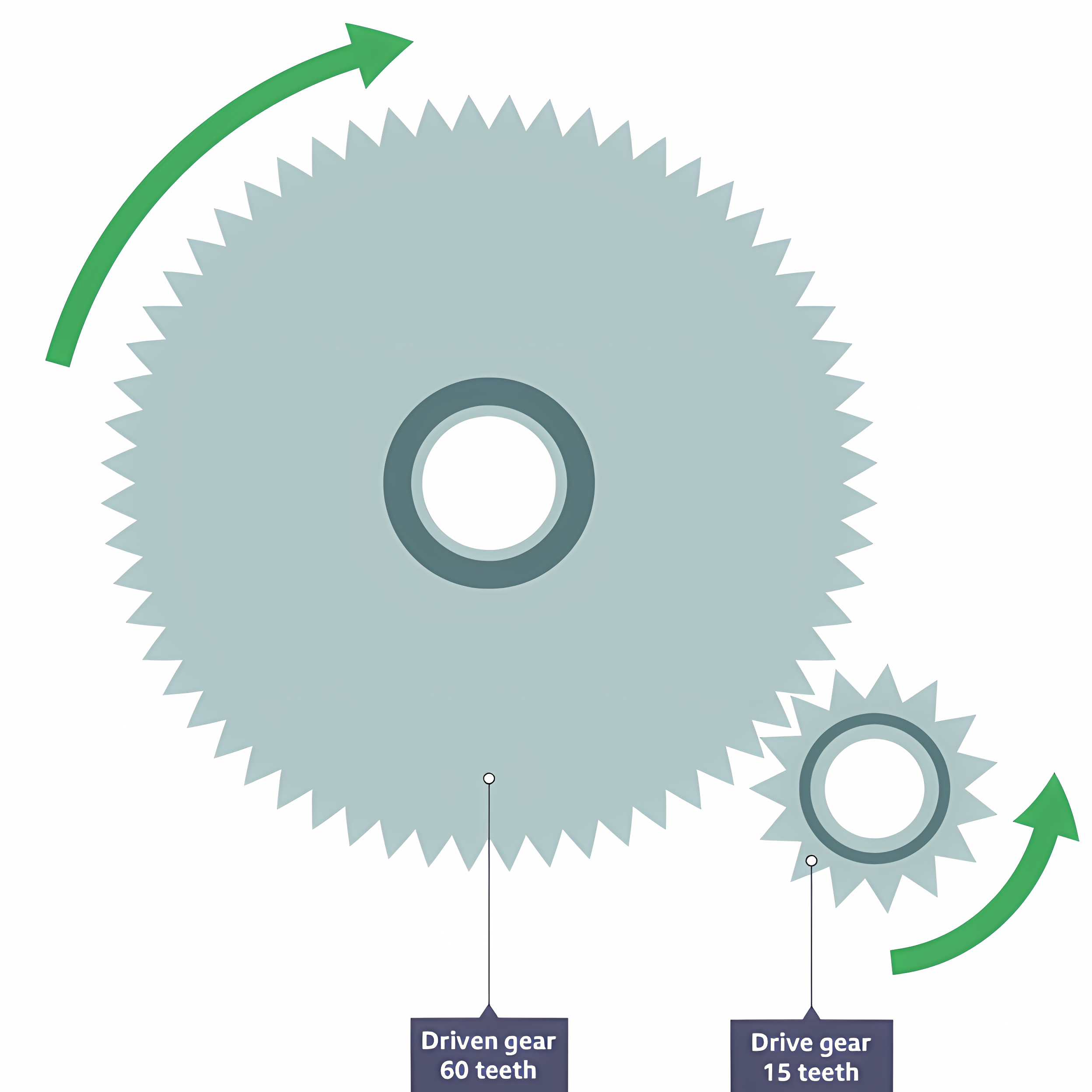

Gears

A wheel with teeth that can change the speed or direction in a mechanism.

Gear trains

2 or more gears are joined together. The drive gear causes the driven gear to turn in the opposite direction.

Gear Ratio

Driven (num of teeth) ÷ Driver (num of teeth)