TC 441 - Quiz: Technical Design Book

1/36

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

37 Terms

The 1st Fit should be measured…

before it can be fit on a form or live model.

Should the garment be pressed/steamed? And why?

No because this could shrink the garment, which could result in specs being incorrect.

The designer, merchandiser, buyer along with technical designer will be involved in the 1st fit to

ensure the desired look they wanted on the garment.

The garment is sent to who for the 2nd fit?

Wholesaler

Once the garment goes past two fittings, the lead time for production gets…

smaller and harder to fulfill.

Are only tech designers involved in the fitting for 2nd fit ?

Yes only for the 2nd fit

A fit sample must be put on the correct hanger of the particular retailer it was sold to…

ensuring the garment hangs correctly.

Once the fit has been approved …

it is ready to go into pre production stage.

In pre-production, garments are sent to…

wholesalers from the factory. Garment is made in correct fabrication, trims, colors, labels, washes, hangers, bags in production.

A graded nest must be provided…

to make sure the garment has been graded properly.

Some companies may have different sizes of models for pre production and fit. Why?

This is so a different size other than the 1st fit medium can be fit and approved in another size.

Preproduction cannot be approved until…

all sizes are correct.

Is Fit the most crucial part of the garment? True or False

True

A production fit is the first sample to come off the…

production sewing line. (supposed to be the very first but usually is the last sample.)

A tech designer should know how to correct a pattern and

have the knowledge of different fabrications and how they fit.

POM

Point of Measure

POS

Position

PLM

Product Lifecycle Management

RTW

Ready To Wear

SNTS

Single-needle topstitch

SN

Single Needle

SPI

Stitches Per Inch

S/S

Short Sleeve

SS

Side Seam

TOL

Tolerance

TOP

Top of Production

TS

Topstitch

WL

Waistline

STRTCH

Stretch

RLXD

Relaxed

SHT

Short

SPECS

Specifications

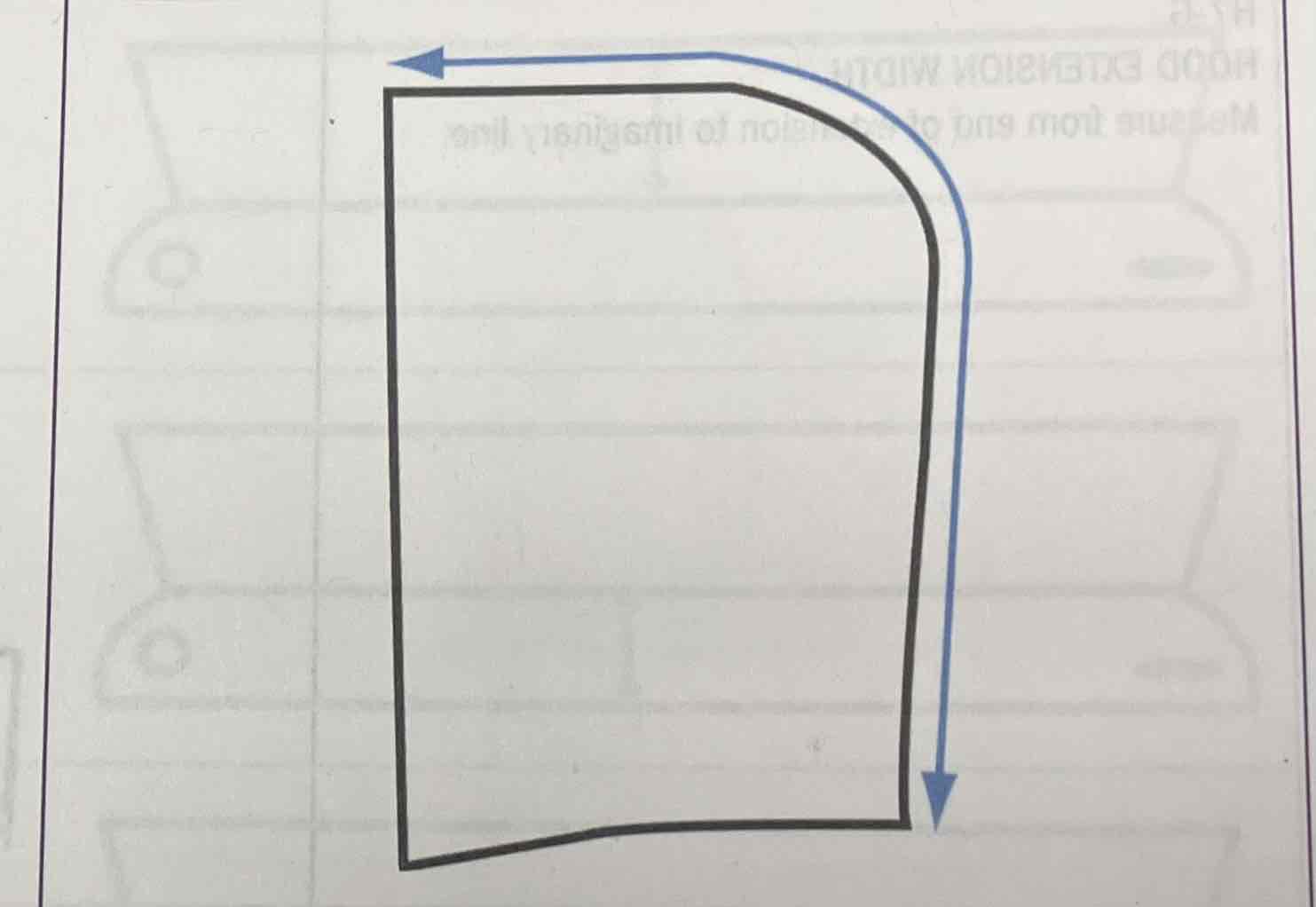

How to measure: Total Hood Length Along Outside Curve

Measure from hood opening along outside curve to center back neck seam.

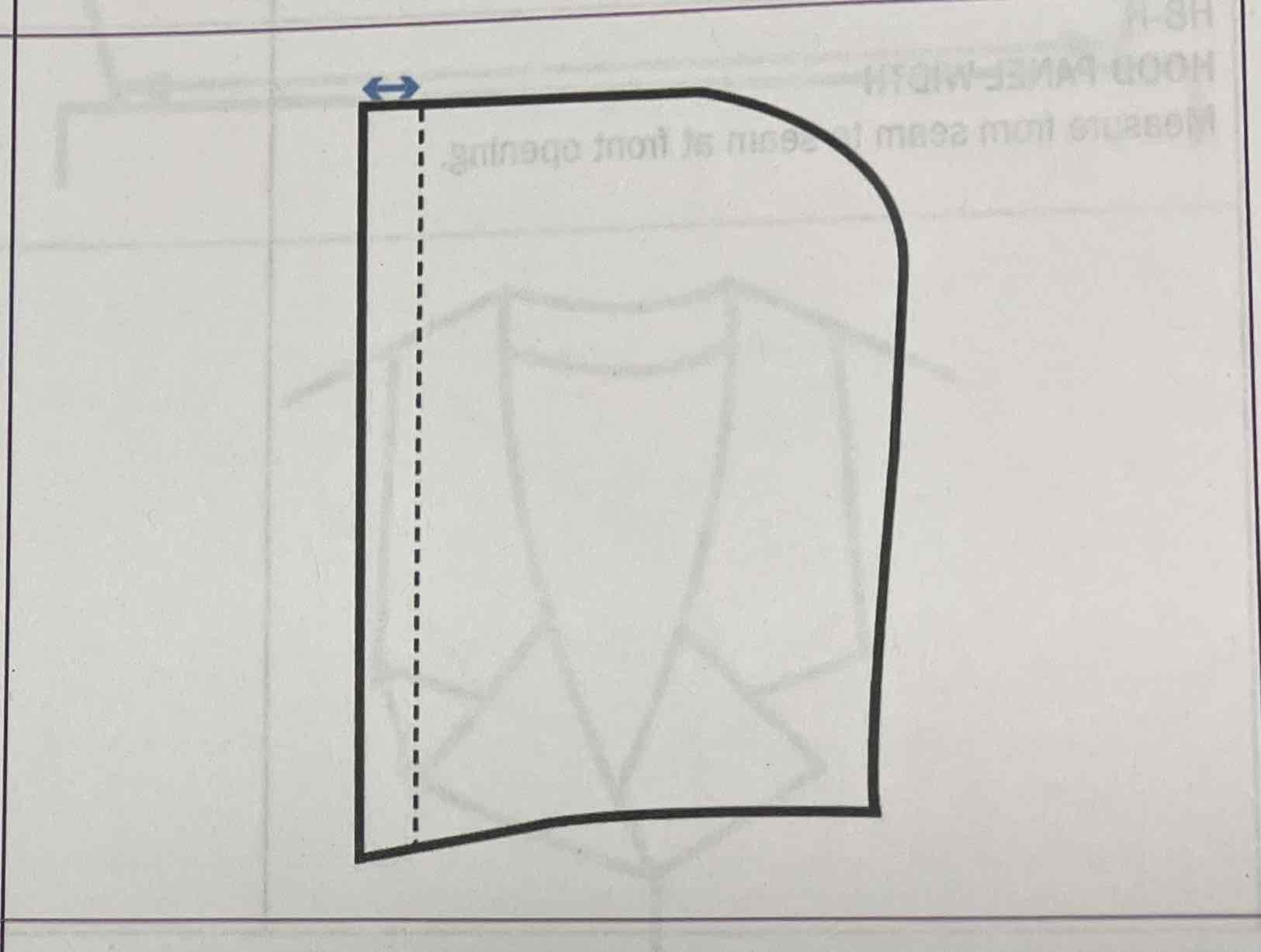

How to Measure: Hood Tunnel/Seam Width

Measure from front hood opening to stitch seam.

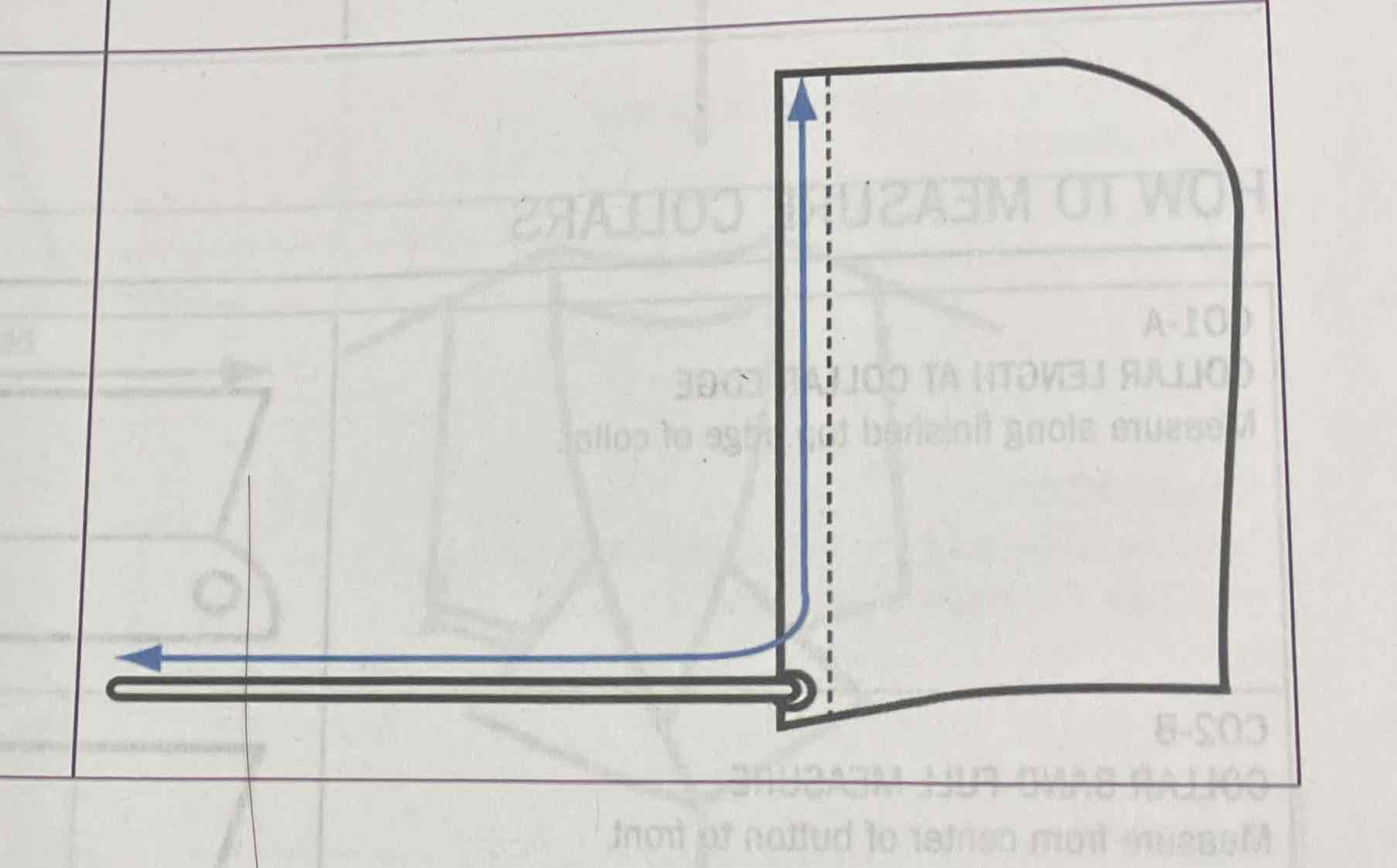

How to measure: Hood Drawstring Length

Measure drawstring length from top of opening of hood, straight down with drawstring extended straight out to end.

Women’s Plus Size Knit Top ranges from

sizes 14 to a 28

Order of Fitting/Spec for Women’s Plus Size Knit Top is:

Nk Width Seam, Frt Nk Drop Seam, BK NK Drop Seam, Bust 1’ BLW A/H, HPS to Waist POS, Waist, Min NK Stretch, Across BK Shoulder, CB to LNG SLV Edge, CB to SHT SLV Edge, SLV OPNG HEM, SHORT SLV, HPS Frt LNGTH