SR10-Thermochemical Processing

1/14

Earn XP

Description and Tags

LO: 1. Understand the nature of redox reactions 2. Know means to chemically reduce minerals to produce oxygen 3. Be able to evaluate the different processes associated thermochemical reduction

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

15 Terms

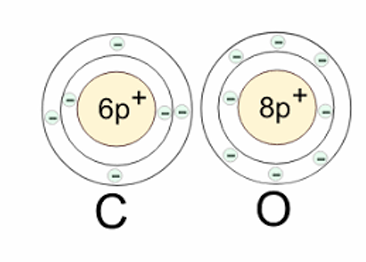

Define what Redox-Reaction is in terms of electrons ?

Oxidation: Loss of electrons; increase of charge

Reduction: Gain of electrons; reduction of charge

Redox Reaction: Reduction and Oxidation occur simultaneously (one subtance reduces, the other oxidises)

Example: Combustion/Oxidation of Carbon: C + O_2 —> CO_2

C donates 2 electrons to each O to fill the valence shell (complete the octet on the valence shell) —> Oxygen is an oxidising agent (gains electrons)

Remeber:

In ISRU applications, reduction of metal oxides yields metal and oxygen

These reactions are redox reactions based on the transfer of electrons

To enable these reactions, we need reducing agents (electron donors) and temperature (activation)

What is the correct result for the oxidisation of a metal?

a) M + O⟶M^+2 + O^-2

b) M + O⟶M^-2+ O^+2

c) M + O⟶M^+2 + O^+2

What are the main practical challenges for solid-gas interaction?

Main challenges are:

Homogeneous heat distribution

Solid-gas exposure

Energy requirements

Solution: Adoption of terrestrial industry processes

- Rotary dryer

- Rotary kiln

- Fluidised bed

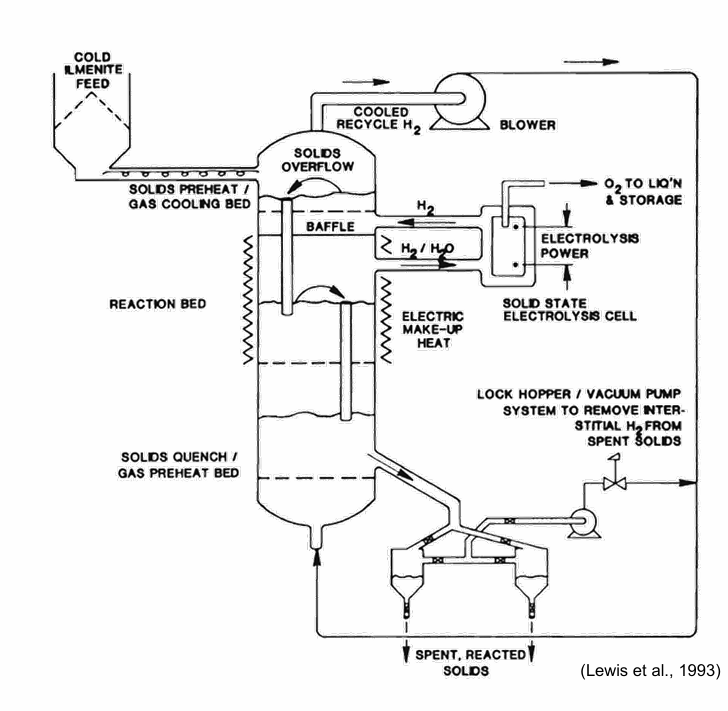

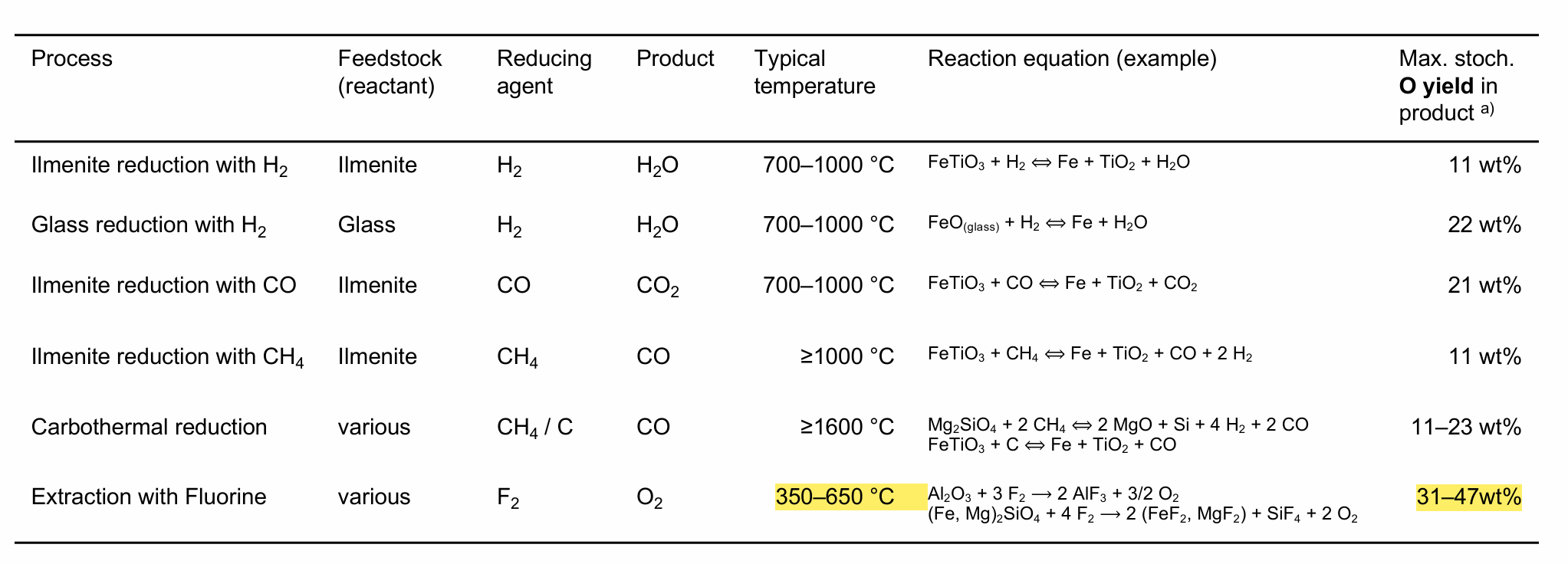

How is the mineral Ilmenite reduced with H_2? What is its redox reaction ?

Reduction: FeTiO3 + H2 ⟺ Fe + TiO2 + H2O

Electrolysis: H2O ⟺ H2 + ½ O2

Ilmenite is reduced at 700–1000 °C in the presence of hydrogen

Equilibrium reaction, mildly endothermic (∆H = 9.7 kcal/(g·mol) at 900 °C)

Mole fraction of water needs to remain <10% to maintain the reaction

Ilmenite is most susceptible to reduction of iron (next comes glass, then olivine, then pyroxene)

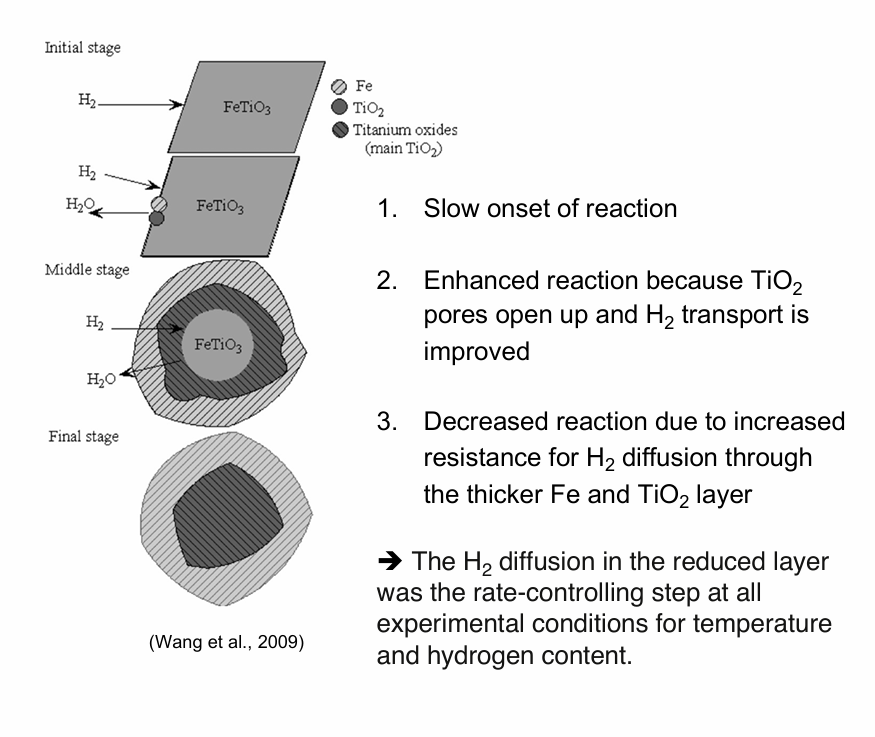

How does the shrinking core process/shrinking core model of illeminite look like (in steps)?

Diffusion of the reactant through a product TiO2 layer

Reaction with the ileminite core

Diffusion of iron out of the TiO2 pores

Formation of metallic iron outside the ileminite grains

What is the goal of the Illeminite reduction process proposed and patented by Carbotek Inc. in 1989 ?

→ Lunar Liquid Oxygen (LLOX) production by fluidised bed reactor

How is the Glass reduced with H_2? What is its redox reaction ?

Reduction: FeO(glass) + H2 ⟺ Fe + H2O

Electrolysis: H2O ⟺ H2 + ½ O2

Glass produced by impacts (agglutinates) or volcanic activity contains up to 20 wt% FeO

Glass has faster reaction kinetics compared to silicates

Glass found in pyroclastic deposits is comparably pure (less beneficiation required), but not as abundant across the lunar surface

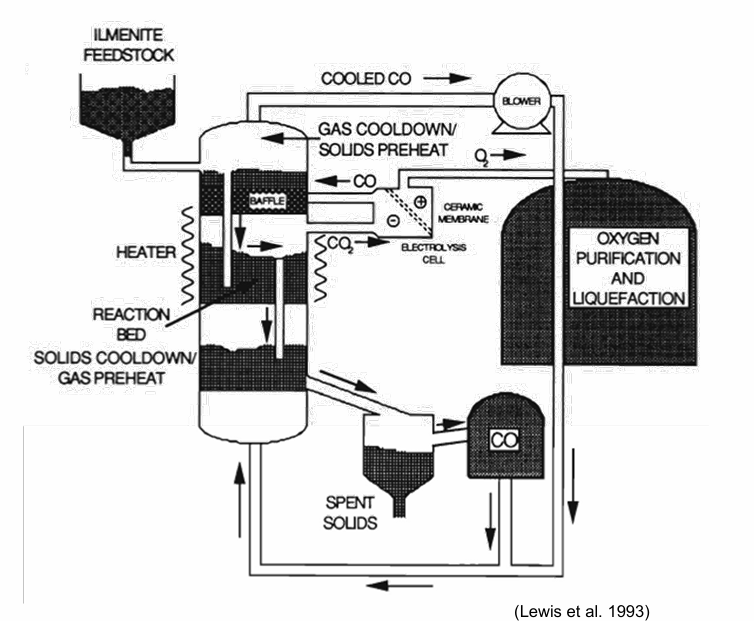

How is the Illeminite reduced with CO? What is its redox reaction ?

Reduction: FeTiO3 + CO ⟺ Fe + TiO2 + CO

CO2 cracking: CO2 ⟺CO + ½ O2

Similar process as for reduction with hydrogen, but with slower reaction rate

Activation energy using CO is 29.6 kcal/mol as compared to 22.3 kcal/mol using H2

Similar to hydrogen, the reduction follows the shrinking core model

CO2 cracking, e.g. via a plasma, is a highly endothermic reaction

Solar wind implanted carbon could be used to replenish the reactant (but only several tens of ppm)

How is the Illeminite reduced with CH4? What is its redox reaction ?

Reduction: FeTiO3 + CH4 ⟺ Fe + TiO2 + CO + 2 H2

Hydrogenation: CO + 3 H2⟺CH4+ H2O

Electrolysis: H2O ⟺ H2 + ½ O2

Similar process as for reduction with hydrogen

Reaction temperature starts around 1000 °C and involves decomposition of CH4 into C and H2 (the respective reaction with H2 might apply depending on conditions)

Solar wind implanted hydrogen and carbon could be used to replenish the reactan

What are the two different reduction variants in Carbothermal reduction? What is its redox reaction ?

Reduction (variant 1): Mg2SiO4 + 2 CH4 ⟺ 2 MgO + Si + 4 H2 + 2 CO (here: olivine and methane)

Reduction (variant 2): FeTiO3 + C ⟺ Fe + TiO2 + CO (here: ilmenite and carbon)

Hydrogenation: CO + 3 H2⟺CH4+ H2O

Electrolysis: H2O ⟺ H2 + ½ O2

No beneficiation required, different silicates and oxides are reduced in the process

Carbothermal includes all processes involving molten reactant and carbon in some form

As CH4 decomposes into the two reactants C and H2 prior to the reaction, C/CO/CO2 can also be used

For highest efficiency and reduction of silicates this process requires a melt (1600–2000 °C)

Solar wind implanted hydrogen and carbon could be used to replenish the reactant

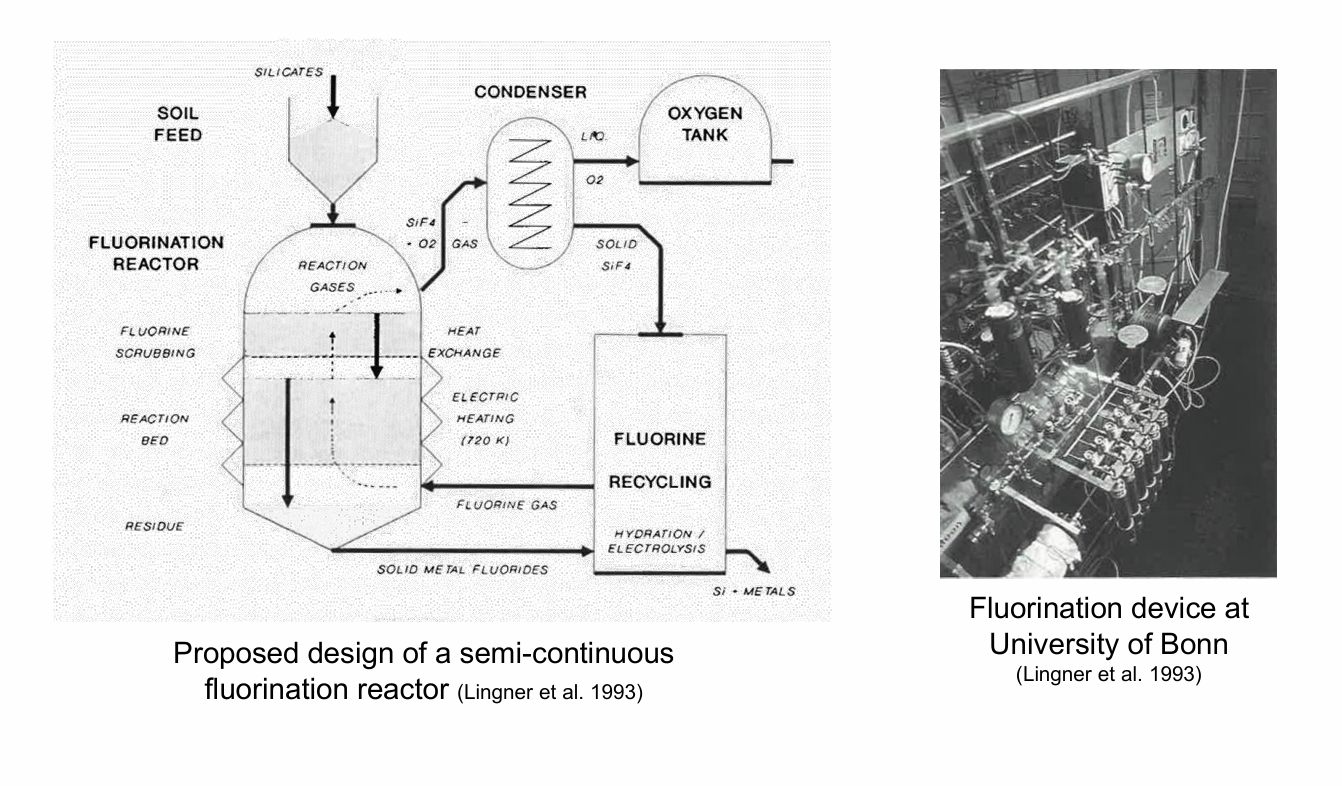

How does the extraction process with flourine look like?

Reduction (general): MxyOy + y F2 ⟶ xy MF2/x + y/2 O2

Reduction (Aluminium oxide): Al2O3 + 3 F2 ⟶ 2 AlF3 + 3/2 O2

Reduction (Olivine): (Fe, Mg)2SiO4 + 4 F2 ⟶ 2 (FeF2, MgF2) + SiF4 + 2 O

Fluorine is highly electronegative (strong oxidiser), about 80% of the total oxygen can be released (potentially 100% for olivine-free highland soil)

Moderate temperatures required (350–650 °C)

Silicates combine with fluorine to build fluorides, and oxygen is liberated

This is a common process for (lunar) rock analysis and first demonstrated in 1962

Fluorine is toxic to humans

Which solid-gas interaction process yields the most oxygen/O2 in wt%

What special process is used on the ISS to support the recovery of oxygen ?

→ Sabatier Process

Reaction: CO2 + 4 H2 ⟺CH4 + 2 H2O

Electrolysis: H2O ⟺ H2 + ½ O2

Atmospheric CO2 (96% on Mars) is converted to methane and water at 300–400 °C and ~30 bar

catalyst: Nickel or ideally ruthenium on alumina

Water is electrolysed and the residual hydrogen is fed back into the first reaction

The process is used on the ISS to support the recovery of oxygen

CH4 and O2 can be used as fuel (combustion: CH4 + 2 O2 = CO2 + 2 H2O)

Why could the Bosch process be more favourable than the Sabatier process in long-term mission? What does its redox reaction look like?

→ Venting of CH4 using the Sabatier process involves the loss of H2, thus production of solid C via the Bosch reaction would be favourable

Reaction: CO2 + 2 H2 ⟺C(s) + 2 H2O

Electrolysis: H2O ⟺ H2 + ½ O2

Atmospheric CO2 (96% on Mars) is converted to methane and water at 300–400 °C and ~30 bar

What are the shortcomings of the single-stage Bosch process ?

slow reaction rates

fouling of catalyst by surface carbon

less favourable thermodynamics than Sabatier