Y10 Graphics End of Year

1/112

Earn XP

Description and Tags

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

113 Terms

physical properties of a material

ones that can be observed or measured without changing the composition of a material

absorbency, density, fusibility, electrical conductivity, thermal conductivity

physical properties: absorbency

the ability of a material to soak up a liquid

physical properties: density

the mass per unit volume - a measurement of the mass of a material and how much space it takes up. a more dense material will feel heavier for its size

physical properties: fusibility

the ability of a material to melt into a liquid or molten state when heated. normally associated with metals & polymers

physical properties: electrical conductivity

the ability to conduct electricity. metals are good conductors, while polymers are good insulators

physical properties: thermal conductivity

the ability to conduct heat. metals are good conductors, while polymers are good insulators

working/mechanical properties of a material

the material’s ability to resist certain external forces being applied to it

strength, hardness, toughness, malleability, ductility, elasticity

working/mechanical properties: strength

the ability to withstand force e.g. by resisting compression (squashing) or tension (stretching)

working/mechanical properties: hardness

the ability to resist abrasive wear

working/mechanical properties: toughness

the ability to withstand sudden stress or shocks

working/mechanical properties: malleability

the ability to permanently deform when worked without breaking. also known as plasticity

working/mechanical properties: ductility

the ability to be drawn out or stretched without breaking

working/mechanical properties: elasticity

the ability to bend and return to shape without breaking when subjected to a force

selection of materials or components: functionality

what the material is intended to do and how it performs for the user

selection of materials or components: aesthetics

how attractive/pleasing the material needs to be in a product in terms of form, colour, and texture

selection of materials or components: environmental factors

the energy consumption, pollution, and sustainability from the material’s initial sourcing and extraction, manufacture, use, and disposal

selection of materials or components: availability

materials need to be readily available in their raw form / as components

materials that are specialist, scarce, or difficult to source will have a higher cost. the use of stock materials will benefit designers and customers

selection of materials or components: cost

the cost of the raw material and processing, through to the manufacture of the product

heavily influenced by the scale of production

selection of materials or components: social factors

companies must consider social factors when selecting materials.

the needs of the people have high priority, for example the specific needs of children, disabled, or elderly

factors in a consumer society e.g. trends & fashions may be a factor

selection of materials or components: cultural factors

different faiths & beliefs may impact the development of products

this doesn’t just impact design - the origin of materials may also be important e.g. materials derived from animals need to be carefully considered

selection of materials or components: ethical factors

materials can be purchased from ethical sources e.g. wood that has been responsibly managed by the FSC or products endorsed by the fairtrade foundation (means workers haven’t been exploited)

why are standard/stock forms of materials helpful in selection of materials or components

makes the material more cost effective as it gives designers ready-made materials that can be incorporated into their designs

force definition

a load that has been applied, measured in newtons (N)

stress definition

produced as a load is applied to a material and may cause it to deform

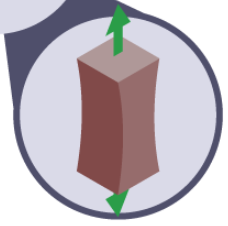

tension

pulling force e.g. a rope

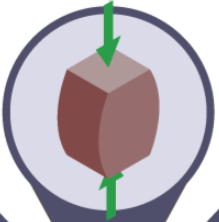

compression

force pressing on a material - being squashed

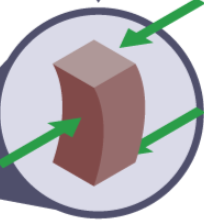

bending

forces at an angle to the material causing both tension & compression at the same time

neutral axis: the point between the tension and compression forces

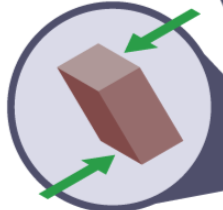

torsion

twisting force, often along the length of a material

shear (force)

when two parallel forces that are out of alignment are acting against each other e.g. blades of scissors acting against each other to shear paper

static load

load that doesn’t move and is constant e.g. books sitting on a shelf

dynamic load

load that is unstable or moving, which tends to increase the force applied to the material e.g. someone walking over a footbridge

ecological issues associated with product design

deforestation = loss of wildlife & soil erosion

mining = changes to the landscape, loss of habitat, noise and vibration

farming = loss of habitat (as farmers expand into new areas to find good soil)

transportation of products = pollution (from fuel usage)

production of carbon (during manufacture)

use of finite raw materials

use of landfill = chemical leaks into the ground, poisoning wildlife & humans

ecolocical issues - sustainability

companies must consider sustainability of the manufacture, use, and disposal of their products

sustainable products reduce demand on non-renewable raw materials and energy sources, produce less waste, and reduce pollution

carbon footprint

the amount of CO2 emissions that is directly or indirectly attributed to an individual / company, including:

extraction, transportation, processing and manufacture of products

power consumption (e.g. electrical power)

recycling & end-of-life disposal of products

travel e.g. commuting, holidays etc

how to reduce carbon footprint

energy: efficient house insulation, low energy lighting, alternative energies, turn down heating

water: reduce water use, turn off taps

travel: low carbon vehicles or car sharing, minimise number of journeys

recycling: recycle used glass, plastics, and paper

offsetting: offset carbon emissions by a tree planting programme

sustainability improvements - transportation

materials, parts, and product need to be transported, resulting in lots of ‘product miles’. these can be minimised by:

reducing the number of journeys by fitting more onto transport vehicles by making products smaller, lighter, and with less packaging

reducing length of journeys by using distribution hubs & moving processing plants closer to the source of materials

changing the energy source of vehicles to renewable sources (from fossil fuels)

sustainability improvements - leaner design

ecological impact needs to be considered at the beginning of the life of a product - at the design stage. the designer could:

use less materials / parts & include renewable materials / standardised parts

use easily separated parts for recycling

use energy efficient / repeatable manufacturing processes

reduce the amount / type of packaging

make products more sustainable - rechargeable, easy maintenance

ecological issues - recycling & reuse

recycling/reuse of products/materials is ecologically responsible, improves sustainability, and benefits the environment

goods can be made cheaper by not using new materials e.g. newly extracted aluminium costs 2x as much as recycled ones & 90% more energy is needed to extract raw aluminium

ways to reduce ecological issues - paper & boards

farm trees effectively to renew supply & reduce deforestation

recycle to reduce demand on raw material

use fewer toxic chemicals in processing

ways to reduce ecological issues - timber

FSC management of timber use & supply

farm trees effectively to sustain supply

ways to reduce ecological issues - systems

create rechargeable, energy efficient products to conserve energy

recycle batteries to reuse chemicals

use efficient processing methods

make printed circuit board parts easier to recycle

ways to reduce ecological issues - metals

recycle to reduce demand on raw materials

reduce environmental impact of mining, deforestation etc

use more efficient processing methods

ways to reduce ecological issues - textiles

recycle to reduce demand on raw materials

use natural (not synthetic) fibres

use reuse schemes e.g. charity donations

use fewer toxic chemicals in processing

ways to reduce ecological issues - polymers

minimalize environmental impact of drilling, fracking & processing oil

development of biodegradable polymers

recycle to reduce demand on raw material

society definition

a large organised group of people living together, such as a town, country, or continent

social issues: safe working conditions

companies have to ensure (so far as is practical) the health, safety, and welfare at work of all employees

health & safety at work act 1974 - strictly monitored & enforced (by the health & safety executive HSE) legislation about health & safety at work, covering welfare facilities, ventilation, cleanliness, space, lighting, temps, working hours, shift patterns, training etc

workers’ pay protected by minimum wage since 1999

safe working conditions - the fairtrade organisation

the fairtrade organisation looks at the interests of farmers & workers in other countries (who don’t have the same protection as in the UK) to ensue they have good working conditions, aren’t discriminated against, and are paid fairly

social issues: impact on others

companies must ensure that their products have a positive impact on people e.g:

source local products to help the local economy & support other jobs

design products so they don’t offend e.g. offensive logos / banding

donate to local / national / world charities or help at local volunteer events

social issues: reducing pollution

pollution has harmful effects on people’s lives e.g. it can cause respiratory diseases & chemical pollution of soil / water contributing to illnesses

atmospheric pollution is due to substances (e.g. CO2 emissions, toxic fumes, particles from factories) being released into the atmosphere, and contributes to global warming

some countries committed to reducing atmospheric pollution in the Paris agreement (2014) which was signed by 175 countries & aims to keep the rise in global temps below 2oC in the century

oceanic pollution is due to harmful substances (e.g. household waste, chemicals, particles of plastics) released into the ocean. 80% is from outside the water e.g. dumping of waste, sewage, chemical spills etc. legislation is being introduced to reduce this e.g. a ban on microbeads in cosmetics

the six Rs

checklist of points that should be considered in the development of a product

reduce the amount of material, consumables, energy usage in product

reuse the product for the same or a different purpose

recycle the product & use recycled materials

rethink whether there’s a better way of doing the product’s job

refuse to by products that are unsustainable

repair the product & ensure it’s easy to do so

the six Rs: 1. reduce

consider if it’s possible to reduce the amount of:

material in the manufacture of the product

consumables needed in the product (e.g. changing a vacuum cleaner to be bagless)

energy usage by using more energy efficient processes

the six Rs: 2. reuse

consider if it’s possible to reuse:

the product again for the same purpose by refilling it (e.g. ink cartridges / carrier bags)

try to get the max use out of the product before it wears out / has to be discarded

the product/parts of it for a different purpose (e.g. drinks bottles, textile insulation, bags for life)

the six Rs: 3. recycle

polymers, metals, textiles, timbers, paper and boards can all be recycled. consider if you can:

reprocess the waste in a product in the same system or to make something else

collect waste for commercial recycling

use recycled materials in a product

substitute unrecycled materials for recyclable ones

design/use products that are easy to dismantle to make recycling parts easier

the six Rs: 4. rethink

rethink product & how we use them - is there a better what of doing the same job that has less of an effect on the environment

the six Rs: 5. refuse

refuse to buy materials/products that are unsustainable

the six Rs: 6. repair

when designing the product, ensure that:

the product can be easily repaired to extend its life & reduce need for replacement to reduce manufacturing

spare parts are available

what is paper made from

wood specifically grown for making paper

other sources include recycled newspaper & recycled cloth

which type of wood is traditionally used to make paper

softwoods as their fibres are longer so they make stronger paper

however demand for paper is high so hardwoods & softwoods are also used

recycled fibres can’t be used endlessly so you need to have new fibres from wood pulp

most timber comes from coniferous trees (also used are deciduous trees, straw, bamboo, flax, ehmp)

pulping

breaking down wood / recycled materials to extract the fibres - the process used in making paper

paper making process

process removes lingin (what gives fibres structure) to allow fibres to be separated & reformed

trees are specifically grown for paper & harvested

logs are de-barked (bark is poor quality) and timber is chipped - cut into small pieces (2.5cm)

chips are made into pulp (mechanically or with chemicals) and the pulp is washed, refined, cleaned, and sometimes mixed with chemicals e.g. bleach, dyes, sizing agents

water is drained away on a wire screen (pulp is 99% water before) leaving a mat of damp fibres

damp fibres are calendared (put through a roller to remove the rest of the water & press it into a uniform thickness). more calendaring = more gloss

finished paper is dried and wound into rolls to be distributed & sent to factories to be cut into size

life cycle assessment

a method of assessing the environmental impact of the manufacture and use of materials and products

allows us to assess the impact of a product’s life ‘cradle to grave’

life cycle assessment of paper

lots of trees & vegetation are cut down to make paper & some companies replace the threes they cut down but it’s difficult to replace old ones with young ones of the same value - new trees take years to grow & old trees have established wildlife habitats, and are more effective at absorbing CO2. trees lost near rivers can cause banks to fall in causing flooding & loss of marine life (streams & rivers become blocked)

paper can be recycled but only a set number of times as it becomes weaker when recycled

when chemicals (fillers, colours etc) are washed into water supplies they can cause environmental concerns e.g. contamination of water

making boards

when it’s a single sheet it’s made the same way as paper, but they can also be made up of more than one layer (e.g. duplex board, foil-lined board)

some have a complex structure to provide impact resistance / increased strength e.g. corrugated card

how to select materials

materials are selected based on their working properties:

how they look

what they’re commonly used for

how they’re manufactured

how they perform in use

what makes them unique

selecting papers & boards

functionality: what the design does, for who, measurable performance factors

scale of production: processing, joining methods, manufacturing capability

environmental factors: sustainability, waste management, energy demands, recycling

aesthetics: how it looks, use of colour, texture, form

availability: availability of standard sizes/forms and components

cost: cost of the raw material, conversion into usable material, budget available, target price

mechanical properties: strength, tension, compression, shear

physical properties: absorbency, density, weight, fusibility

social factors: disabilities, religious groups, age of consumer, obsolescence

ethical factors: sourcing raw materials, manufacture, fair trade organisations

cultural factors: fashion, trends, faiths, background / beliefs of user

finishes: how long it’s intended to last, whether further protection is needed against decay

improving properties for papers & boards

flexibility - by scoring lines so the material can be bent into boxes / packaging

rigidity - by folding (stiffening)

surfaces - by lamination & encapsulation, also reinforcing the material

available formats for papers & boards

commercially available paper & card is available in standard forms. this is more cost effective & designers can incorporate standard forms into designs

sheet: a single piece of paper

roll: used on an industrial scale as they can be fed into machinery for continuous printing e.g. books & magazines

ply: two or more layers of paper combined together using embossing / adhesive to form multi-ply (or two-ply) paper e.g. napkins, receipts that self-copy to a second layer

set standards of paper & boards

measured by:

length & width normally in mm

weight in gsm (grams per square meter)

thickness in microns (1/1000th of a millimetre, μm)

colour - white paper is graded on whiteness

common gsm, micron, whiteness measurements for paper & board

gsm (weight)

60-120gsm = printing paper

over 160gsm = card

over 220gsm = board

microns (thickness)

a greetings card would be ~300microns (0.3mm) thick

whiteness (colour)

the higher the number, the whiter it is

copier paper between 130-170

types of paper & board

mounting board (1000-2000μm) - relatively thick & rigid with colour on one side, used for picture framing

newsprint (45-55gsm) - thin, low quality, low cost, lightweight paper. rough surface, off-white colour

tissue paper (10-35gsm) - lightweight, coloured, used for absorbency properties and crafts

copier paper (80gsm) - low cost, available, smooth surface, good whiteness

standard sizes for paper (A, B, C series)

A series: used at home & work, A0-A10, halve in size with every increase in number (A10 is the smallest, A0 is huge)

B series: larger sizes used for posters & in industry

C series: smaller sizes used for envelopes, the size of a A series piece of paper folded in half (C5 = A5 in half)

fasteners

used to join paper / card temporarily or permanently

treasury tag: connects sheets through punched holes

binder clip / bulldog clip: holds sheets together using a variety of actions

paper fastener: connects smaller numbers of sheets through punched holes

slide bunder: temporarily holds sheets together

staple: applied with stapling tool to hold sheets together

paperclip: simple method to hold a few sheets

sealing

paper & board can be closed securely through sealing in various ways

gummed envelope: water soluble gum along envelope flap is moistened to seal

self-adhesive envelope: covering over glue is peeled off to seal, or a flap can have a strip of latex which seals when pressed together

wax seal: wax is melted over area and is left to harden

string and button: string wrapped around two buttons to close package

binding

binding methods are used to combine multiple sheets of paper

perfect binding: pages gathered in smaller groups with a hard / flexible outer cover and glued at the spine - used in most books

comb binding: combs fit through punched holes allowing pages to lie flat - low cost & popular

coil / spiral binding: spiral of plastic / metal wire is threaded through holes, allowing pages to lie flat

saddle stitching: wire on a roll fed through pages and cut to make staples, limited number of pages, e.g. magazines

scales of production: one-off/prototype

a single unique product that’s individually designed e.g. furniture, wedding dresses

prototype is a type of one-off production that’s a unique concept experimental model, the first example of a design

high quality to exact specifications, made by skilled workers, is unique

expensive (cost of materials is higher), labour intensive, long production times

scales of production: batch

a set number of products made in limited quantities or limited time e.g. textbooks, designer clothes

allow customers a wider choice of designs, quick response to demand, economics of scale (high unit output) so materials can be bought in bulk, can respond to seasonal demand

must be stored, re-tooling machines for different processes could be costly, some processes will be repetitive as larger numbers made

scales of production: mass

efficiently & consistently produces many products at a low cost per unit, with automated systems and parts added in sequence in a production line e.g household appliances, kids toys & clothes - design changes are limited

cheaper materials in high quantities, high level of quality control, low unit cost, cheaper labour

high initial set up cost, if production line breaks manufacture is halted, repetitive, less flexibility to respond to market

scales of production: continuous

manufacturing thousands of identical high-demand product components / materials 24 hours a day e.g. standard single components e.g. buttons, nuts, bolts, rivets, lego blocks, drinks cans, sheet materials e.g. glass & steel

removes cost of stopping & starting production process, cheaper materials in high quantities

automation = staff redundancy, little flexibility to change production without large costs

need for production aids

manufacturing can be very labour intensive so manufacturers use aids to speed up processes

production aids: reference points / datums

it’s important to have a constant point to make measurements from that’s identified before marking out

reference point will usually be a square edge or corner, and it can be a datum edge for metal / plastics or a face side & face edge for wood

reference point can be machined first so it’s accurate & all measurements are taken from it

production aids: patterns

patterns: replicas of the product that’s to be made

accuracy of pattern is related to quality of the product to be made

patterns can be made from cheaper material e.g. paper / wood which is easier to work and can be used many times or re-made as the design changes

can be made by hand but using CAD (computer aided design) is quicker

wallpaper is an example of use of patterns

production aids: templates

templates are used to ensure shapes, positions, or markings are accurate & consistent throughout the design & production process. they guarantee that information is placed correctly and shapes are drawn & cut precisely

they’re often made to the exact size of the shape to be cut / location of holes to be drilled. they can be fitted onto a material to easily transfer markings, and can be used once then discarded, with more copies made when needed

templates can be used for quality control by checking the final product’s shape after it’s been made

production aids: jigs

jig: a device for holding work in place to help when carrying out repetitive manufacturing methods

jigs hold work in the same position and the cutting tool is guided to the correct place e.g. for drilling accurate holes in wood

advantages of patterns, jigs & templates

greater productivity

quicker production

simplifies more complex processes

reduced costs

increased accuracy, quality, and tolerance

tolerance

an allowable margin of error to ensure that a part will still function as long as it’s in the tolerance range

tolerances are set with an upper & lower limit and can relate to size, weight, colour, strength, quantity etc

parts manufactured within tolerance always fit, and it can be dangerous if they don’t do this e.g. a nut & bolt being loose in an aircraft engine

quality control

a quality control system is set up throughout the manufacturing process to check that parts & assembled product are to the correct standard & within tolerance

QC equipment is expensive to set up so most companies use random sampling - more cost effective than checking every product individually

quality control tests

paper & boards - registration marks / colour charts: used for multiple printing processes to show that each process has been accurately lined up

timber - go/no go fixture tool / gauges: used to check the upper & lower limits of tolerance - it’s in tolerance if it fits within the larger opening (go) and doesn’t fit within the smaller opening (no go). can be used quickly as there’s no measurement involved

textiles - inspection of printed material: printed fabric often has a mismatch in pattern & this is particularly important when fabric is joined. fabric is visually inspected in manufacture & when sewn together

electrical & mechanical systems - timbers for exposure ‘soak’ times: timing how long a PCB should be exposed to the UV light, developer or etchant, as overexposure can lead to breaks in tracks

metals - depth stops and guides: depth stops fitted to machinery to ensure work is cut to the right length / depth

polymers - CNC laser settings: make sure laser cutters have the correct info about kerf allowance, material and thickness so they cut accurately

offeset lithography

used for long printing runs (books, magazines, packaging, posters) by transferring the image to be printed from the plate to a roller / blanket cylinder and then to the paper - plate doesn’t come into contact with the paper

the litho-printing plate cylinder has a relief image on it(image stands out from the surface), and plates are made from flexible polymers / aluminium

litho-printing plate is dampened with water (to repel ink from non-image areas)

ink is applied to litho-printing plate as it rotates

ink is transferred to offset blanket cylinder as they rotate against each other

ink is transferred to the paper / card as it’s pulled through the rollers from the pressure of the blanket cylinder & impression cylinder

only one colour can be printed at a time

colour models: CMYK

uses layers of coloured ink to partially or entirely reduce the light reflected from the lighter background e.g. white paper. colours used are cyan, magenta, yellow, and key (black)

colour models (RGB)

adds layers of the three primary colours to produce a broad array of colours

die cutting

once printing is completed, the finished sheet needs to be accurately cut to shape using a die cutting machine

dies: the cutters used to create the shapes. made of hardened steel blades (rules) that are expensive to produce but reusable. they are fitted to stamping machines to carry out the process

the material is cut with the dies and rubber ejectors push it out. waste is recycled

the paper/board can be creased using rounded rules to allow for folding

rollers can sometimes be fitted with cutters to cut continuous runs

measuring equipment

ruler to measure distance and draw a straight line

protractor to measure angles

set square to draw lines at specific angles

french curves to draw curves of different sizes

cutting equipment

guillotine to cut a large number of paper sheets at once with a straight edge

craft knife to cut & score paper & cardboard, particularly useful when cutting internal shapes

compass cutter to cut a circle / arc from paper / thin card

rotary cutter to cut a circle / arc from thicker cardboard

die cutter to cut, crease, and perforate paper & card at high speed & accuracy

laser cutter to perform perfect intricate cuts to paper & card

coatings & surface alterations

paper & board can be protected by laminating, giving a shiny water resistant surface while being thick and durable, making the material last longer. the paper / board is put in a plastic sleeve which is heated & pulled through rollers, bonding the two surfaces of the film together and sealing the product in

paper can be modified with chemicals e.g. bleach to make it whiter

sizing is when chemicals are added to give the paper a protective glaze that prevents it from being absorbent and makes it suitable for use with wet marker pens - the ink won’t bleed

clay can be added to card to make a paper plate

clear UV sensitive liquid can be applied to card to give it a high gloss finish - this is better for the environment than lamination as laminated polymer is harder to recycle

printing: offset lithography

relief printing plate on rollers onto paper

advantages: inexpensive, prints on a variety of papers, high speed, good quality images

disadvantages: high set up costs, needs to be flat, damp can stretch paper / affect colour

uses: books, magazines, packaging, posters

surface treatments & finishes

used to enhance functional & aesthetic properties of papers & boards

printing, embossing, UV varnishing

printing: flexography

flexible relief printing plate on rollers, papers fed from a roll

advantages: inexpensive as high volume, inks dry quickly, high speed

disadvantages: high set up costs, lower quality, print runs in excess of 500k

uses: newspapers, sweet papers, low cost magazines

printing: screen printing

ink printed through finely woven fabric, non-print area masked

advantages: prints of a variety of surfaces, good for short runs

disadvantages: long drying times, lack detail

uses: posters, mugs, t-shirts, point of sale displays

printing: gravure

rotary printing using engraved cylinder

advantages: high speed, consistent colour & quality on a variety of papers

disadvantages: high set up costs

uses: high quality magazines & books, stamps

printing: photocopying

drum charged when exposed to original copy, toner fixes to charged areas, transferred to paper and fused by heat

advantages: high speed, good for small batches, can be double sided, low cost, convenient

disadvantages: can fade over time, variable quality as ink is used, expensive for long runs

uses: home or business, flyers, documents