DT GCSE AQA

1/259

Earn XP

Description and Tags

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

260 Terms

3 Main elements of a system

Input, process, output

What are systems used for?

To add additional functionality to designs

What is an input

component which either adds energy or information to a system

example of an input

switch

sensor

what are programmable microcontrollers

computer chips that can be programmed to perform specific tasks

what do programmable microcontrollers do

provide functionality and intelligence to products and systems

what can programmable microcontrollers do

Counting

Timing

Decision making

Advantages of programmable microcontrollers

Reduces size of circuit - programming replaces physical components

They can be reprogrammed many times - so changes can be made without replacing actual components

They have pins for connecting several input and output devices - adding to flexibility

What is an output

components which provide information to the outside world

Examples of output components

lamp or buzzer

components that emit light and sound

What products use output components

speaker

What products use input components

keyboard

webcam

microphone

what is a design brief

A design brief is the statement a client gives the designer outlining what they want their product to be like

What is a design specification

List of criteria a product needs to address.

functionality

application of use, ease of working

aesthetics

surface finish, texture, colour

environmental factors

could materials be renewable

could they be upcycled

which material would have the least environmental impact

FSC - forest stewardship council

Availability

ease of sourcing and purchase

Social factors

social responsibility

cultural factors

sensitive to cultural influences

What is collaboration

Working with others on proposals and solve problems as well as gathering data.

advantages of collaboration

improve range and quality of items

designers can feed off the ideas of others

disadvantages of collaboration

issues with communication

different time zones

different access

different units of measurement

what is User Centered designed

product is designed to fulfill the wants and needs of the consumers

advantages of user centered design

helps companies understand any potential issues and how the product can be modified even after the launch

disadvantages of user centered design

extra time

not targeted towards overall market

cost

what is systems approach

Plans the layout for the correct inputs, processes and outputs things that need logical and ordered methods

advantages of systems approach

easy to understand

disadvantages of systems approach

might need to be edited a lot

may be issues with programming

what is iterative design

each iteration gets better as a result of the small refinements being made after each design

iterative design advantages

leads to desired quality and functionality

iterative design disadvantages

time consuming

uses lots of material

high cost

How to avoid design fixation

use of mood boards

different approaches to design generation

modelling

quick sketches

CAD

abstract drawings which can be interpreted

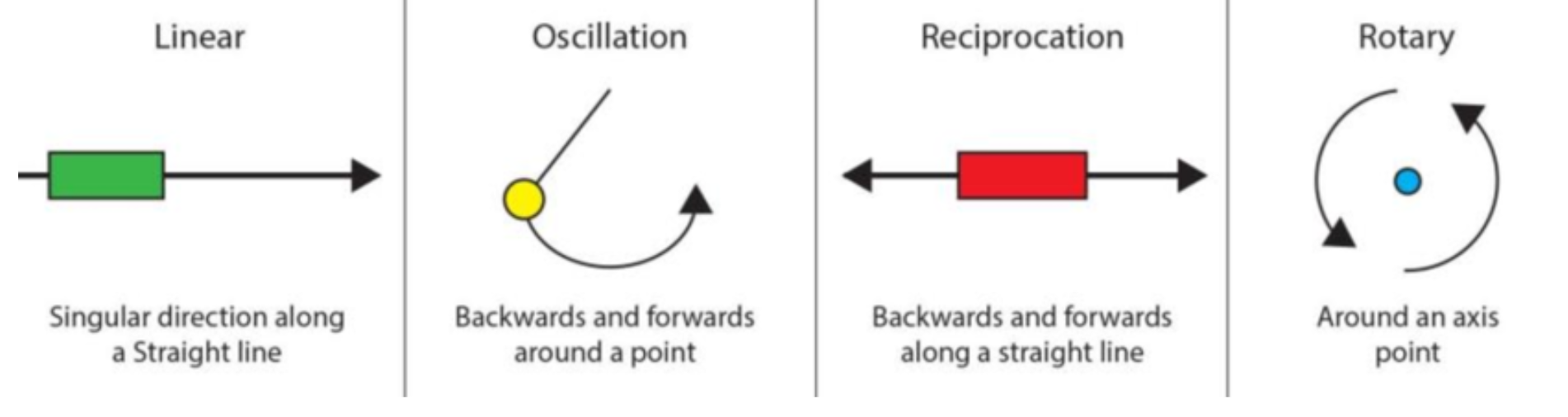

what are the different types of movement

linear

oscillation

reciprocation

rotary

First order lever

pivot point in center

load then pivot then effort

e.g. seesaw

Second order lever

pivot point at one end

load in the center

effort at opposite end to point

e.g. wheelbarrow

third order lever

pivot point at one end

effort in middle

load at opposite end to point

e.g. tweezers

how to calculate mechanical advantage

load = mechanical advantage x effort

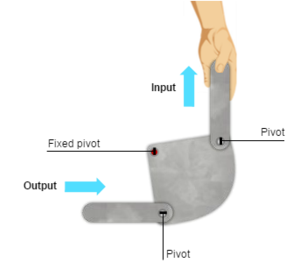

Bell crank

used to change the direction of movement through 90 degrees using 2 moving pivots and a fixed pivot point

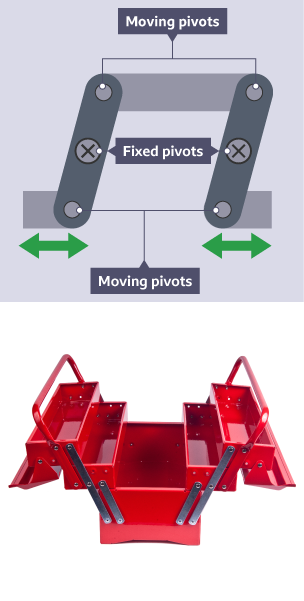

push-pull

also called parallel motion linkages

input and out motion the same

they may be created for avoiding a fixed component or making 2 parts of an object move at the same time

CAMS and followers

used to convert rotary movement to reciprocating movement

Circular cam

off center pivot - follower moves um and down

e.g. pistons or steam engines

Pear cam

stationary for half a turn then rises and falls gently

e.g. carousel horses

Snail or drop cam

remains stationary for half a turn then rises and falls quickly

only rotate in one direction

drops at regular intervals

e.g. production lines - make regular cuts

heart-shaped or constant velocity cam

follower rises and falls steadily with uniform velocity

no stationary period

flat follower

flat bottom that sits on the cam

cope well under load

aren’t accurate

lots of friction

Point or knife follower

very accurate

quick to wear away at the pointed edge

roller follower

accurate

low on friction

can withstand load

more costly to produce

what are gear trains

series of cog wheels

drive gear is powered and other gears are driven by this wheel

what are pulleys and belts

create a mechanical advantage for moving objects

prototype

a single sometimes highly specialised item is produced

workers highly skilled

unit cost higher

prosthetics, machinery, wedding dresses

personalisation

mass produced item adapted to an individual

personalised coffee cup

Batch

usually up to 1000 units

works along various different production points where different processes are complete

workers skilled in a few different processes

used for seasonal products or if only a limited number of products are needed or the product is seasonal

mass

large scale

automation may be used in the factory where large amounts of CAD/CAM is used

injection moulding or casting may be used

high set up costs

why are product manufactured in various ways

Products are manufactured in various quantities, depending upon demand and the requirements for the product.

continuous

mass production - products are made 24 hours a day 7 days a week

low cost consumable items due to high demand and continuous nature

e.g. toilet paper

what is a production aid

They are used to ensure the shape of your design is accurate and can be used repeatedly to ensure the same shape is produced each time.

what is a jig

holds a material in place and guides cutting told to ensure that a process can be repeated accurately and consistently.

what is a former

solid shape that is placed in a vacuum former to create a hollow mould

What is a template

tool used to mark out shapes repeatedly - ensuring information is being placed correctly

what is a mould

a cavity or matrix that shapes a plastic or fluid substance into a desired product - the substance is poured or forced into the mould then allowed to harden

what is a die

wooden block with mounted steel knives used to cut, crease and perforate card and paper - used to cut precise shapes from various materials.

Hardwood properties

Sourced from Deciduous trees

Slower growing

More expensive than softwoods

Worldwide

Types of Hardwood

Beech

Oak

Mahogany

Balsa

Ash

Softwoods Properties

Coniferous trees

Faster Growing

Cheaper than Hardwoods

Used by inexpensive furniture brands

Prone to having knots

Knots can affect the structure of the woods and leave holes id the dop out when dried

Types of softwoods

larch

pine

spruce

Manufactured Boards properties

Manufactures from timbers combined with adhesives

Can be made from waste material

Available in large consistent thickness sheets without faults

Suitable flat pack furniture

Can have a veneer pf plastic or tin wood attached to disguise the board and make it more attractive of functional

can be recycled

Types of Manufactured Boards

Medium Density Fiberboard

Plywood

Chipboard

Stock Forms of Manufactured Boards

Boards - varying thicknesses

Mouldings - Dowels, crown, pediment, dado, reed

Planks - varying thicknesses up to 3600mm lengths

Why standardized sizing

consistency of manufacture

availability of specific sizing

availability of materials

components can be efficiently arranged to reduce waste and costs

quality materials are used in manufacture

Examples of Standard Components

Butt hinges

Piano Hinges

Countersunk screws

pan head screws

slotted screw

corner block fitting

cam lock fitting

Absorbency

The ability of a material to take in moisture

Density

The mass of a material in a standard volume of space

Fusibility

The ease at which the material can be fused together or the temperature required to melt

Conductivity

electrical - allows the flow of electricity to pass through it

thermal - allows heat to transfer through it

insulation - the ability of a material to prevent the transfer of heat or electricity

Strength

Compressive - the ability to withstand being crushed or shortened by pushing forces

Tensile - the ability to resist stretching or pulling forces

Hardness

The ability to resist abrasive wear and indentation through impact

Toughness

The ability of a material to withstand an impact

Malleability

The ability of a material to bend or be hammered into another shape without breaking

Ductility

The ability of a material to be drawn out into wires

Elasticity

The ability of a material to be stretched or deformed and then return to its original shape.

What contributes to choosing materials

Cost

Availability

Working properties

Process of Timber production

Trees are felled

Branches removed

Cut to a suitable length to transport

Logs to timber mills

Timber is debarked and converted into planks

Planks are seasoned

Moisture levels are reduced to 6-8% for internal use and 9-14% for external use

Timber if checked for warping, cracks and damage

Maybe PAR

Examples of Timber Conversion

Through and through sawn

Quarter sawn

Air seasoning

A structure with a solid roof and open sides is used to ensure there is airflow around the timber

Timber is stacked using spacing

Dried naturally

For 25mm woods 3-4 months for softwoods 6 months for hardwoods

Kiln seasoning

Timber is stacks within the kiln and spacing planks are used

water is heated to produce steam

over time the humidity

Timber remains in the kiln for 2-5 days

Warping shapes

bow

crook

kink

cup

twist

how MDF is made

trees are felled

timber is debarked

broken down into chips

wood chips washed

Further broken down into fibres

wax and resin is mixed in

pressed and heated to the desired thickness

it is sanded

cut to shape

manufacture of plywood

Gluing at least three layers of sheet timber together at right angles to each other - laminating

Examples of wastage processes

cut

saw

drill

chisel

sand

plane

Surface treatment step by step

Timber is assembled

filler is applied

sanded low grit 40-80

finer grit 120-180

finer grit 220-240

primer applied paint primer needed, stain/ varnish - no primer needed

if primed the primer will be sanded with a fine grit 240 grit paper

final finish

Wax

applied with a cloth with a direction of the grain

Multiple layers needed to be applied to achieve the required finish

can be applied over paint

does not yellow or crack over time

Varnish

applied with a brush

can be oil or water based

provides a tough water resistant finish

available in a variety of wood colours

dries slowly, can be difficult to clean

discolours over time

Oil

rubbed into the grain with a cloth

multiple layers required

easier to apply than wax and more durable

longer drying times

easily repaired

Paint

applied with a brush

knots can produce stains if not sealed

A primer or undercoat is needed to prepare

wide variety of colours

can crack and discolour over time

Spray Paint

health and safety consideration needed for application

well ventilated area and mask required to ensure it is not inhaled

primer/ undercoat required

wide variety of colours

Lamination

Process used to create curved shapes in Timber

layers of thin timber is glued together and clamped

Living Hinge

Cuts which allow the timber to flex. They can then be laminated.

What are Alloys

Alloys are a mix of a minimum of 1 metal and other materials. Often to change their working properties.

Examples of Metal

Brass - Copper and Zinc

Stainless Steel - Iron, Chromium and Carbon

High speed steel - Iron, Carbon, Chromium, Tungsten