Making Operational Decisions (EdExcel)

1/19

Earn XP

Description and Tags

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

20 Terms

Operations

The department managing production processes, suppliers, and operational efficiency to ensure goods and services are produced efficiently and meet quality standards.

Production Processes

The transformation of resources into finished goods or services, organized as job production, batch production, or flow production.

Job Production

Involves creating unique, custom products tailored to individual customer needs, made start-to-finish before the next job begins. Advantages include high customization, increased customer satisfaction, and higher prices, while disadvantages include higher costs, longer production times, and dependency on skilled labor.

Batch Production

Involves making a limited quantity of identical products in batches, allowing for economies of scale and flexibility to produce different products, but with drawbacks like downtime, storage costs, and risk of obsolescence.

Flow Production

Also called mass or continuous production, is the continuous manufacturing of standardized goods with high automation for consistency and speed. It offers advantages like high output rates, lower costs per unit, and consistent quality, but comes with drawbacks such as high initial setup costs, limited product design flexibility, and reliance on demand.

Purpose of Operations

Aiming to create or deliver goods and services efficiently, optimizing productivity and resource utilization.

Productivity

The quantity of output produced.

Efficiency

Making the most out of resources to achieve maximum output.

Labour Intensive

Relies more on human labor

Capital Intensive

Relies more on machinery and automation.

Impact of Technology

Technology can reduce costs, increase productivity, quality, and flexibility in operations.

Supplier Management

Involves working with suppliers for timely and quality deliveries, including procurement and Just in Time (JIT) stock management.

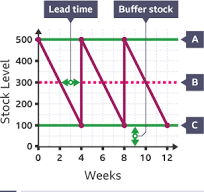

Bar Gate Stock Graph

A graphical representation of stock levels over time, including maximum and minimum stock levels, buffer stock, reorder points, and lead times.

Procurement

Involves finding the right suppliers, and ordering the right quantities at the right time and to the right standard.

Just in Time (JIT) Stock Management

A process in which raw materials are not stored on-site but ordered as required and delivered by suppliers 'just in time' to be used

Quality Management

Ensures products meet customer expectations and regulatory standards through quality control and quality assurance methods.

Quality Control

Inspection and testing of products at the end of the production process to ensure they meet standards. It ensures that finished products meet quality standards before reaching customers.

Quality Assurance

Continuous monitoring and improvement of processes to ensure consistent product quality throughout production. It prevents defects and ensures quality standards are met at every stage of production.

Sales Process

Involves stages from initial contact to post-sales support, aiming to enhance customer satisfaction and drive business growth.

Importance of Customer Service

Good customer service generates loyalty, repeat purchases, and reduces marketing costs for businesses.