Making Operational Decisions (EdExcel)

1. Operations

The department responsible for managing production processes, suppliers, and overall operational efficiency within an organization. It ensures that goods and services are produced efficiently and meet quality standards.

Production Processes

The transformation of resources into finished goods or services.

Businesses can organise their production processes in three ways.

Job Production

Involves creating unique, custom products tailored to individual customer needs.

Each product is made start-to-finish before the next job begins.

Advantages: High levels of customization, increased customer satisfaction, and higher prices due to uniqueness.

Disadvantages: Higher costs, longer production times, and dependency on skilled labour.

Batch Production

Involves producing a limited quantity of identical products in batches.

After one batch is completed, production can switch to a different batch.

Advantages: Economies of scale, reduced production costs per unit, and flexibility to produce different products.

Disadvantages: Downtime between batches, potential for higher storage costs, and risk of obsolescence.

Flow Production

Also known as mass or continuous production, involves the continuous production of standardized goods.

It is highly automated for consistency and speed.

Advantages: High output rates, lower per-unit costs, and consistent quality.

Disadvantages: High initial setup costs, inflexibility in product design, and dependency on demand.

Purpose of Operations

The purpose of operations is to create or deliver goods and services efficiently, optimizing productivity and resource utilization. This includes managing processes to ensure they are cost-effective, time-efficient, and produce high-quality outputs.

Productivity vs. Efficiency

Productivity

Quantity of output produced over a period, irrespective of resources used.

Example: A factory producing 100 units per hour.

Efficiency

Making the most out of resources to achieve maximum output, often measured by the ratio of input to output.

Example: Producing the same 100 units per hour using fewer raw materials or less energy.

Labour Intensive vs. Capital Intensive

Labour Intensive

Relies more on human labour and skills, suitable for tasks requiring creativity or flexibility.

Examples: Handcrafted goods, artistic work, and custom tailoring.

Capital Intensive

Relies more on machinery and automation, efficient for tasks requiring consistency and high volume.

Examples: Car manufacturing, semiconductor production, and automated assembly lines.

Impact of Technology

Technology can help reduce costs, increase productivity, quality, and flexibility.

2. Supplier Management

Supplier management involves working with suppliers to ensure timely and quality deliveries of goods and services needed for production. Effective supplier management is crucial for maintaining production schedules and quality standards.

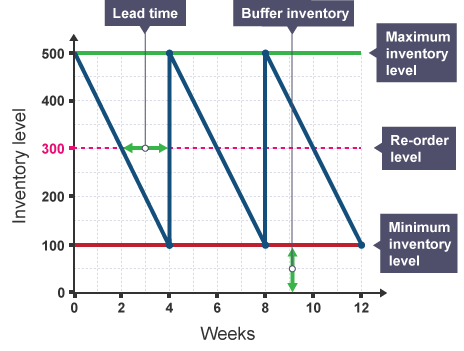

Bar Gate Stock Graph

A graphical representation of stock levels over time, including maximum and minimum stock levels, buffer stock, reorder points, and lead times.

Procurement

Involves finding the right suppliers, and ordering the right quantities at the right time and to the right standard.

Just in Time (JIT) Stock Management

A process in which raw materials are not stored on-site but ordered as required and delivered by suppliers 'just in time' to be used

3. Quality Management

Quality management ensures that products meet customer expectations and regulatory standards. It involves systematic activities to maintain and improve product quality.

Quality Control

Inspection and testing of products at the end of the production process to ensure they meet standards. It ensures that finished products meet quality standards before reaching customers.

Methods: Sampling, testing, and inspection.

Quality Assurance

Continuous monitoring and improvement of processes to ensure consistent product quality throughout production. It prevents defects and ensures quality standards are met at every stage of production.

Methods: Process audits, quality audits, and implementing quality management systems (QMS) like ISO 9001.

4. Sales Process

The sales process includes all stages involved in selling a product, from initial contact with potential customers to post-sales support.

An effective sales process enhances customer satisfaction and drives business growth.

Steps in the sales process

Gain customer interest: make a customer aware of its product through marketing activities.

Provide a speedy and efficient service: be flexible enough to be able to take orders, produce and deliver to customers promptly.

Engage the customer: when customers order a product and need to wait for some time for it to be delivered, a business should ensure that there is regular communication with the customer. Customised products may also need customer approval before they are manufactured, so meetings may be arranged.

Provide post-sales service: support given to customers after the purchase of a product.

Achieve customer loyalty: achieving customer loyalty is important to businesses, as it leads to repeat sales and valuable word-of-mouth reviews.

The importance of customer service

Good customer service generates customer loyalty, which drives repeat purchases and helps the firm to reduce marketing costs when launching new products.