P2 LECTURE 2 MATERIALS, HARDWARES AND EQUIPMENT FOR PRESTESSING

1/51

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

52 Terms

Concrete

Mechanical properties of ____that are relevant to the prestressed ___ design:

Compressive Strength

Modulus of Elasticity

Modulus of Rupture

28-70 MPa at 28 days

For prestressed concrete, the compressive strength should be from ___

16-70 MPa at 28 days

For reinforced concrete, the compressive strength should be from ___

True

Concrete with f’c > 70 MPa can be used when supported by test data

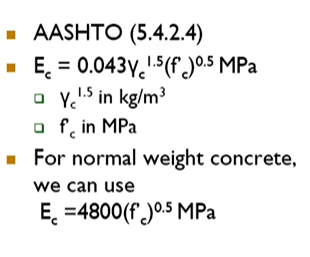

Modulus of Elasticity

Ec= 4800 (f’c) 0.5 MPa

For normal weight concrete, we can use

Modulus of Rupture

Indicates the tensile capacity of concrete under bending

Tested simply-supported concrete beam under 4-point bending configuration

fr = My / l = PL / b * d2

fr= 0.63 (f’c)0.5 MPa

Time-Dependent Deformation of Concrete

resulting from creep and shrinkage

result in a partial loss of prestress force and significant changes in deflection.

Creep

property of materials by which they continue to deform over considerable lengths of time at constant stress or loads

Elastic strain

initial deformation due to load

Creep Strain

the additional strain due to the same sustained load

time

mix proportions

humidity

curing conditions

age of the concrete when first loaded

Creep strain for concrete has been found experimentally to depend on:

Shrinkage

In a concrete element, ___

results to a decrease in volume when the concrete loses moisture by evaporation.

resulted from the release of heat during the process of mixing or process of hydration of the concrete

it can be attributed to the weather

Prestressing Tendons

may be in the form of strands, wires, round bar, or threaded rods

High Strength Steel

Fiber-Reinforced Composite (glass or carbon fibers)

Prestressing tendon Materials

Plan round wire

2.0-9.0 mm

Indented wire

5.0-7.0 mm

Sumi-Twist

7.3-13.0 mm

Two-wired strand

2.9 × 2 mm

Seven-wired strand

6.2 - 15.2 mm

Nineteen-wire strand

17.8 - 21.8 mm

Round bar

9.2-32.0 mm

Threaded bar (dywidag)

23.0-32.0 mm

Grade 250 (fpu=250 ksi or 1725 MPa)

Grade 270 ((fpu =270 ksi or 1860 MPa)

Prestressing strands have two grades

Stressed Relieved Strand

Low Relaxation Strand

Types of strands

Low Relaxation Strand

lower prestress loss due to relaxation of strand

Prestressing Strand (Modulus of Elasticity )

197000 MPa for Strand

207000 MPa for Bar

strand is made from twisting of small wires together.

The modulus of elasticity of strand is lower than that of steel bar because

Cold-drawn round wires

Stranded cable

Alloy steel bars

Types of Prestressing Steel

Round Wires

The individual wires are manufactured by hot-rolling steel billets into round rods

After cooling, the rods are passed through dies to reduce their diameter to the required size.

In the process of this drawing operation, cold work is done on the steel, greatly modifying its mechanical properties and increasing its strength

The wires are stress-relieved after cold drawing by a continuous heat treatment to produce the prescribed mechanical properties

Available in Grades 235 (minimum ultimate strength 235,000 psi) to Grade 250 (minimum ultimate strength 250,000 psi)

Stranded Cables

Fabricated with six wires wound tightly around a seventh of slightly larger diameter

The pitch of the spiral winding is between 12 to 16 times the nominal diameter of the strand

The same type of cold-drawn stress-relieved wire is used in making stranded cable as is used for individual prestressing wires

However, the apparent mechanical properties are slightly different because of the tendency for the stranded wires to straighten when subjected to tension because the axis of the wires do not coincide with the direction of tension

Strands may be obtained in a range of sizes from 0.25 in to 0.60 in diameter

Cable is stress-relieved by heat treatment after stranding

Two grades are manufactured:

Grade 250-minimum ultimate strength of 250,000 psi

Grade 270-minimum ultimate strength of 270,000 psi

Alloy Steel Bars

The high strength is obtained by introducing certain alloying elements, mainly manganese, silicon and chromium during the manufacture of the steel

In addition, cold work is done in making the bars, further increasing the strength

After cold-stretching, the bars are stress-relieved to obtain the required properties

Available in diameters ranging from 5/8 in to 1 3/8 in, and in Grade 145 (minimum ultimate strength 145,000 psi) and Grade 160 (minimum ultimate strength 160,000 psi)

The lack of success of most early attempts to PSC was the failure to employ steel at a sufficiently high stress and strain.

The time-dependent length changes permitted by shrinkage and creep of the concrete completely relieved the steel of stress.

Importance of High Strength Steel

Pretensioned Members

Posttensioned Members

Hardware for Prestressing

Pretensioned Members

Hold-Down Devices

Posttensioned Members

Anchorages

Ducts

Posttensioning Procedures

Anchorages

Stressing

Dead-End

VSL type SO

VSL Type S

VSL Type Bondtech

VSL Type S5-2

VSL Type S5-1, S6-1

Type of Anchorages

T6Z-08 Air Powered Grout Pump

Colloidal Grout Plant

T7Z Hydraulic Jacks

T80 Post-Tensioning Jacks

T8Z Torque Wrench

T8Z-04 Torque Multiplier

T1Z & T2Z Long Fitting Tool Adapters

K3F-26 Long Fitting Wrench Adapter

Equipment of Prestressing

T6Z-08 Air Powered Grout Pump

Pumps cement grout only, no sand. 32 Gallon Mixing Tank. Mixes up to 2 sacks of material at once and allows for grout to be pumped during mixing or mixed without pumping.

Approximate size : 50" long 30.5" high 52" wide

Weight : 560 lbs.

Production Rate : 8 gallons per minute at 150 psi

Colloidal Grout Plant

favored for precision post-tension grouting. All controls are conveniently located on the operator platform for easy one-man control.

T7Z Hydraulic Jacks

Used for testing and pre-stressing anchor bolts. Available with up to 5-1/8" center hole. Unit comes with ram, pump, gauge, hoses, jack stand, high strength coupling, high strength test rod, plate, hex nut and knocker wrench. Calibrations

T80 Post-Tensioning Jacks

With the ___ the enclosed bearing housing contains a geared socket drive to tighten the bolt hex nut during tensioning. Test jack housing will accommodate up to a 9" deep pocket.

T8Z Torque Wrench

For applying torque to the anchor bolt when setting the anchor

T8Z-04 Torque Wrench

For use with T8Z Torque Wrench.

T1Z & T2Z Long Fitting Tool Adapters

For driving hex nuts and setting tools, typically with our Spin-Lock anchor systems. Works with torque wrench or impact g*n.

K3F-26 Long Fitting Wrench Adapter

For applying torque to recessed anchor nuts that are under tension when using hydraulic jacks. Available in all anchor sizes.

Hot Dip Galvanizing

Epoxy Coating

Pre-Grouted Bars

Extruded Polyethylene Coating

Corrosion Inhibiting Compound

Corrosion Protection Type

Epoxy Coating

Fusion bonded ___ of steel bars to help prevent corrosion has been successfully employed in many applications because of the chemical stability of epoxy resins. ___ bars and fasteners should be done in accordance with ASTM ___ patch kits are often used in the field for repairing nicked or scratched epoxy surfaces.

Pre-Grouted Bars

Cement Grout filled corrugated polyethylene tubing is often used to provide an additional barrier against corrosion attack in highly aggressive soils.

Hot Dip Galvanizing

Zinc serves as a sacrificial metal corroding preferentially to the steel. Galvanized bars have excellent bond characteristics to grout or concrete and do not require as much care in handling as epoxy coated bars

Extruded Polyethylene

Williams strand tendons contain an extruded high density polyethylene sheathing around each individual strand in the free-stressing portion of the anchorage. The sheathing is minimum 60 mils thick and applied once the 7-wire strand has been coated with a corrosion inhibiting compound.