Question 4 - Industrial + commercial practice

0.0(0)

0.0(0)

Card Sorting

1/16

Earn XP

Description and Tags

Study Analytics

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

17 Terms

1

New cards

3 scales of production

* one-off - producing a single product

* batch - made in a specific quantity

* mass/continuous - made in large quantities usually 24/7, are in high demand

* batch - made in a specific quantity

* mass/continuous - made in large quantities usually 24/7, are in high demand

2

New cards

advantages of one-off production

* unique product

* answers exact customer needs and wants

* answers exact customer needs and wants

3

New cards

disadvantages of one-off production

* highly skilled workers required

* individually designed so more expensive

* company needs to be flexible to adapt to jobs

* individually designed so more expensive

* company needs to be flexible to adapt to jobs

4

New cards

examples of one-off products

* clothing for certain celebs

* personalised/custom sneakers

* personalised/custom sneakers

5

New cards

advantages of batch production

* end product will be cheaper to sell than process of production

* good for when an item goes out of fashion or sells poorly

* good for when an item goes out of fashion or sells poorly

6

New cards

disadvantages of batch production

* expensive to set up production lines and equipment

* production line needs to be flexible

* initial set up can be expensive

* production line needs to be flexible

* initial set up can be expensive

7

New cards

examples of batch products

* limited edition products

* electronic products

* electronic products

8

New cards

advantages of mass/continuous production

* products usually are simplistic and don’t require too many components to assemble

* end product is usually cheap

* labour costs are cheap, not many skilled workers required

* end product is usually cheap

* labour costs are cheap, not many skilled workers required

9

New cards

disadvantages of mass/continuous production

* initial set up is very expensive

* quality control issues need to be in place

* quality control issues need to be in place

10

New cards

examples of mass/continuous production

* food products

11

New cards

JIT manufacturing

* just in time, sometimes known as LEAN manufacturing

* aims to reduce flow times within production system and response times from suppliers and to customers

* focuses on efficient use of time and storing small amounts of stock/components

* no warehouse or storage

* aims to reduce flow times within production system and response times from suppliers and to customers

* focuses on efficient use of time and storing small amounts of stock/components

* no warehouse or storage

12

New cards

advantages of JIT manufacturing

* reduces waste

* no warehouse thus lower costs

* reduces time

* no warehouse thus lower costs

* reduces time

13

New cards

disadvantages of JIT manufacturing

* very sensitive to any type of error

* will not be able to adapt to sudden increase in demand

* will not be able to adapt to sudden increase in demand

14

New cards

examples of JIT manufacturing

* car manufacturers

15

New cards

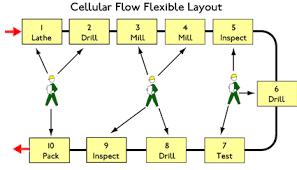

modular/cell production

* horse-shoe shaped

* involves a team of workers to finish a product

* workers can move around, makes them more skilled, less monotonous

* different cells for different parts of product

* involves a team of workers to finish a product

* workers can move around, makes them more skilled, less monotonous

* different cells for different parts of product

16

New cards

quality assurance

* ensuring issues don’t happen before production

* e.g. using trained staff, high quality tools

* e.g. using trained staff, high quality tools

17

New cards

quality control

* ensuring issues don’t happen during production

* e.g. checking product over production

* e.g. checking product over production