Inspection Concepts and Techniques (FAA General Test Prep)

1/30

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

31 Terms

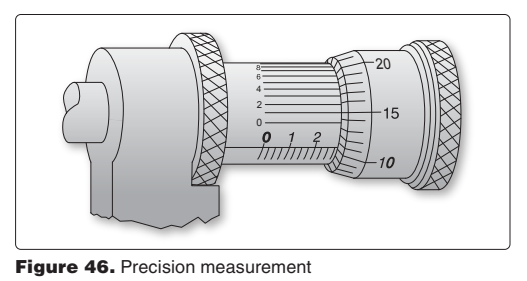

8290. (Refer to Figure 46.) The measurement reading on the illustrated micrometer is

A—0.2851

B—0.2911

C—0.2901

[a] The thimble has been screwed out more than 0.275 inch (the third mark beyond the 2 is visible). The thimble has rotated just a bit more than ten hundredths of the way around, as is shown by the line on the sleeve. It is just beyond the 10 on the thimble. This means that 0.010 is added to the 0.275 on the sleeve. The vernier line on the barrel for 1 is lined up with one of the marks on the thimble, and this means that we add 0.0001 inch to the two other numbers we have. The total reading of this vernier micrometer is 0.275 + 0.010 + 0.0001 = 0.2851 inch. (AM.I.K.K1) — FAA-H-8083-30

8291. Identify the correct statement.

A—An outside micrometer is limited to measuring diameters.

B—Tools used on certificated aircraft must be an approved type.

C—Dividers do not provide a reading when used as a measuring device.

[c] Dividers do not provide a reading when they are used as a measuring device. They are used by placing their points at the locations between which the measurement is to be taken. Then the distance between the points is measured with a steel machinist’s scale. (AM.I.K.K1) — FAA-H-8083-30

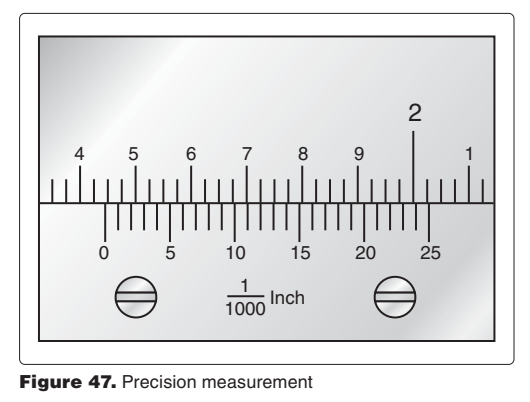

8292. (Refer to Figure 47.) What is the measurement reading on the vernier caliper scale?

A—1.411 inches.

B—1.436 inches.

C—1.700 inches.

[b] The zero on the vernier scale is beyond the 1. This shows the measurement is more than 1 inch. It is beyond the 4. This shows it is more than 1.4 inch. It is beyond the first 0.025 mark on the bar. This shows that it is more than 1.425 inch. The 11 line on the vernier scale lines up with one of the marks on the bar. This 0.011 is added to the reading we have. The total reading is 1.425 + 0.011 = 1.436 inches. (AM.I.K.K1) — FAA-H-8083-30

8293. Which tool is used to measure the clearance between a surface plate and a relatively narrow surface being checked for flatness?

A—Depth gauge.

B—Thickness gauge.

C—Dial indicator.

[b] A part is checked for flatness by putting it on a surface plate and sliding a thickness gauge (a feeler gauge) between the part and the surface plate. The thickness of the feeler gauge that will slip between the part and the surface plate is the amount the part lacks being flat. (AM.I.K.K1) — FAA-H-8083-30

8294. Which number represents the vernier scale graduation of a micrometer?

A—.00001

B—.001

C—.0001

[c] The vernier scale (the series of parallel lines on the sleeve) on a vernier micrometer caliper is used to give an indication of one ten thousandth of an inch (0.0001 inch) of spindle movement. (AM.I.K.K1) — FAA-H-8083-30

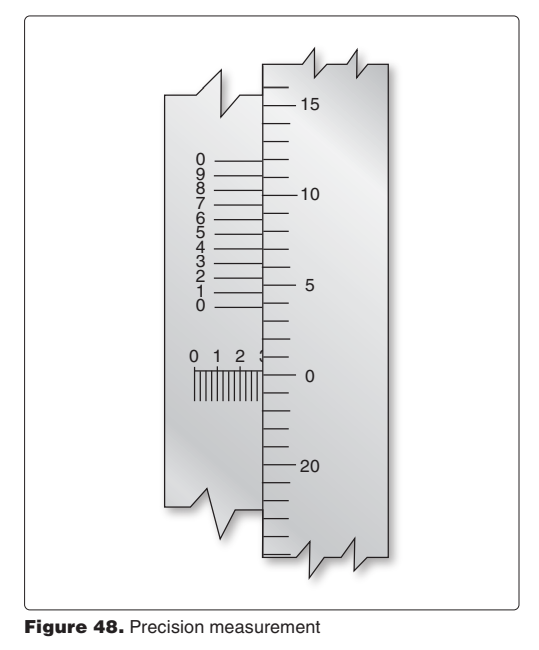

8296. (Refer to Figure 48.) What does the micrometer read?

A—.2974

B—.3004

C—.3108

[b] The thimble has been screwed out slightly more than 0.300 inch (the line by the 3 is just barely visible). The thimble has rotated just a bit beyond the zero line on the sleeve. The vernier line on the barrel for 4 is lined up with one of the marks on the thimble, and this means that we add 0.0004 inch to the other numbers we have. The total reading of this vernier micrometer is 0.300 + 0.0004 = 0.3004 inch. (AM.I.K.K1) — FAA-H-8083-30

8297. If it is necessary to accurately measure the diameter of a hole approximately 1/4 inch in diameter, the mechanic should use a

A—telescoping gauge and determine the size of the hole by taking a micrometer reading of the adjustable end of the telescoping gauge.

B—0- to 1-inch inside micrometer and read the measurement directly from the micrometer.

C—small-hole gauge and determine the size of the hole by taking a micrometer reading of the ball end of the gauge.

[c] The diameter of a small hole is measured by placing a ball-type, small-hole gauge in the hole and expanding it until its outside diameter is exactly the same size as the inside diameter of the hole. Remove the small-hole gauge from the hole and measure its outside diameter with a micrometer caliper. (AM.I.K.K1) — FAA-H-8083-30

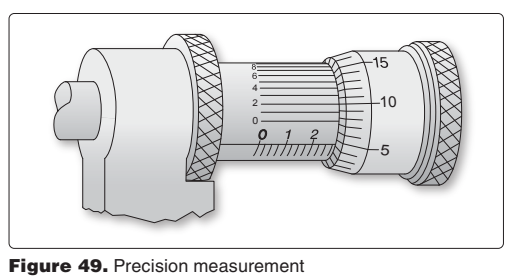

8298. (Refer to Figure 49.) The measurement reading on the micrometer is

A—.2758

B—.2702

C—.2792

[c] The thimble has moved out beyond two tenths of an inch (0.200 inch). It has moved out to a point that is beyond the third twenty-five thousandths of an inch mark. (0.075 inch.) The 4 mark on the thimble has just passed the scale on the sleeve (0.075 + 0.004 inch = 0.079). The 2 line on the vernier scale lines up with a number on the thimble. This adds 0.0002 inch. The total measurement is 0.2792 inch. (AM.I.K.K1) — FAA-H-8083-30

8299. What tool is generally used to set a divider to an exact dimension?

A—Machinist scale.

B—Surface gauge.

C—Dial indicator.

[a] Dividers are set with a machinist’s scale. One of the points of the dividers is placed at the one-inch mark on the scale. The other point is moved out until it touches the mark for the distance you want between the points. (AM.I.K.K1) — FAA-H-8083-30

8301. What precision measuring tool is used for measuring crankpin and main bearing journals for out-of-round wear?

A—Dial gauge.

B—Micrometer caliper.

C—Depth gauge.

[b] A vernier micrometer caliper is used to measure a crankpin and a main bearing journal for an out-of-round condition. Two measurements are made at right angles to each other. The difference between the two readings is the amount the shaft is out-of-round. (AM.I.K.K1) — FAA-H-8083-30

8302. The side clearances of piston rings are measured with a

A—micrometer caliper gauge.

B—thickness gauge.

C—dial gauge.

[b] A thickness gauge is used to measure the side clearance of a piston ring in its ring groove. The ring is installed in the groove and its outside edge is held flush with the side of the piston. A thickness gauge is placed between the side of the piston ring and the edge of the ring groove to measure the amount of clearance between the ring and the groove. (AM.I.K.K1) — FAA-H-8083-30

8303. How can the dimensional inspection of a bearing in a rocker arm be accomplished?

A—Depth gauge and micrometer.

B—Thickness gauge and push-fit arbor.

C—Telescopic gauge and micrometer.

[c] A dimensional inspection of a bearing in a rocker arm can be made by expanding a telescopic gauge inside the bushing (bearing) until its length is exactly the same as the inside diameter of the bushing. Remove the gauge and measure it with a vernier micrometer caliper. Measure the rocker arm shaft with the same vernier micrometer caliper. The difference between the diameter of the shaft and that of the hole is the fit of the shaft in its bushing. (AM.I.K.K1) — FAA-H-8083-30

8304. The twist of a connecting rod is checked by installing push-fit arbors in both ends, supported by parallel steel bars on a surface plate. Measurements are taken between the arbor and the parallel bar with a

A—dial gauge.

B—height gauge.

C—thickness gauge.

[c] Connecting rod twist is measured by fitting a thickness gauge between the ends of arbors and the parallel bars. (AM.I.K.K1) — FAA-H-8083-30

8306. What may be used to check the stem on a poppet-type valve for stretch?

A—Dial indicator.

B—Micrometer.

C—Telescoping gauge.

[b] The stem of a poppet valve is checked for stretch by using a vernier micrometer caliper to measure the stem diameter in the center of the stem and at the spring end. If the center diameter is less than the diameter at the spring end, the valve stem has been stretched. (AM.I.K.K1) — FAA-H-8083-30

8307. Which tool can be used to determine piston pin out-of-round wear?

A—Telescopic gauge.

B—Micrometer caliper.

C—Dial indicator.

[b] Piston pin out-of-round can be measured with a vernier micrometer caliper. Measure each end of the pin in two directions at right angles to each other. The difference in the two readings is the amount the pin is out-of-round. (AM.I.K.K1) — FAA-H-8083-30

8300. What tool is generally used to calibrate a micrometer or check its accuracy?

A—Gauge block.

B—Dial indicator.

C—Machinist scale

[a] Micrometer calipers are checked for accuracy by using gauge blocks. A 0- to 1-inch micrometer is checked with the thimble screwed down against the anvil. No gauge block is used. A 1- to 2-inch micrometer uses a 1-inch gauge block. A 2- to 3-inch micrometer uses a 2-inch gauge block. (AM.I.K.K2) — FAA-H-8083-30

8221. Which of these nondestructive testing methods is suitable for the inspection of most metals, plastics, and ceramics for surface and subsurface defects?

A—Eddy current inspection.

B—Magnetic particle inspection.

C—Ultrasonic inspection.

[c] Ultrasonic inspection uses high-frequency sound waves to detect faults in a material. It can be used on a wide variety of materials such as ferrous and nonferrous metals, plastics and ceramics. It can detect subsurface as well as surface defects. (AM.I.K.K3) — AC 43-3

8222. What nondestructive testing method requires little or no part preparation, is used to detect surface or near-surface defects in most metals, and may also be used to separate metals or alloys and their heat-treated conditions?

A—Eddy current inspection.

B—Ultrasonic inspection.

C—Magnetic particle inspection.

[a] Eddy current inspection requires relatively little preparation of the part being inspected. It induces a magnetic field into the part which causes eddy currents to flow. Variations in the magnitude of the eddy currents affect this magnetic field, and when it is analyzed electronically, it gives information regarding such structural characteristics as flaws, discontinuities, thickness, and alloy or heattreated condition of the material. Eddy current inspection is used to locate defects both on the surface and below the surface. (AM.I.K.K3) — AC 43-3

8227. A mechanic has completed a bonded honeycomb repair using the potted compound repair technique. What nondestructive testing method is used to determine the soundness of the repair after the repair has cured?

A—Eddy current test.

B—Metallic ring test.

C—Ultrasonic test.

[b] After a bonded honeycomb repair has been made using the potted-compound repair technique, the soundness of the repair can be tested by using the metallic ring test. The repaired surface is tested by tapping it with the edge of a coin. If the repair is sound, the tapping will produce a metallic ringing sound. If there is any void in the material, the tapping will produce a dull, thudding sound. (AM.I.K.K3) — FAA-H-8083-30

8244. (1) In nondestructive testing, a discontinuity may be defined as an interruption in the normal physical structure or configuration of a part.

(2) A discontinuity may or may not affect the usefulness of a part. Regarding the above statements,

A—only 1 is true.

B—only 2 is true.

C—both 1 and 2 are true.

[c] Statement 1 is true. In nondestructive testing, a discontinuity may be defined as an interruption in the normal physical structure or configuration of a part. Statement 2 is also true. A discontinuity may or may not affect the usefulness of a part. (AM.I.K.K3) — FAA-H-8083-30

8445. During an annual inspection, if a defect is found which makes the aircraft unairworthy, the person disapproving must

A—void the aircraft’s Airworthiness Certificate.

B—submit a Malfunction or Defect Report.

C—provide a written notice of the defect to the owner.

[c] If, during an annual inspection, a defect is found which makes the aircraft unairworthy, the person disapproving the aircraft must give the owner a signed and dated written list of the discrepancies that caused the unairworthy condition. (AM.I.K.K4) — 14 CFR §43.11

8452-2. When a 100-hour inspection is completed, if separate maintenance records for the airframe, powerplant(s), and propeller(s) are maintained, where is the entry for the inspection recorded?

A—In each record.

B—In the airframe record only.

C—In any one of the records.

[a] AC 43-9 paragraph 10.d. states that if the owner maintains separate records for the airframe, powerplants, and propellers, the entry for the 100-hour inspection is entered in each, while the annual inspection is only required to be entered into the airframe record. (AM.I.K.K4) — AC 43-9

8454. Who is responsible for making the entry in the maintenance records after an annual, 100-hour, or progressive inspection?

A—The owner or operator of the aircraft.

B—The person approving or disapproving for return to service.

C—The designee or inspector representing the FAA Administrator.

[b] According to 14 CFR §43.11(a): “The person approving or disapproving for return to service an aircraft, airframe, aircraft engine, propeller, or appliance after any annual, 100-hour, or progressive inspection required by Part 91 shall make an entry in the maintenance record of that equipment…” (AM.I.K.K4) — 14 CFR §43.11

8455. An aircraft owner was provided a list of discrepancies on an aircraft that was not approved for return to service after an annual inspection. Which of the following statements is/are true concerning who may correct the discrepancies?

1. Only a mechanic with an inspection authorization.

2. An appropriately rated mechanic.

3. Any certificated repair station.

A—2 and 3.

B—2.

C—1.

[b] If an aircraft was not approved for return to service after an annual inspection, a list of discrepancies that prevented the aircraft from being airworthy is given to the aircraft owner or operator. These discrepancies may be corrected by an appropriately rated mechanic and the aircraft approved for return to service. (AM.I.K.K4) — 14 CFR §43.3(b)

8457. What is/are the appropriate action(s) concerning minor repairs performed on a certificated aircraft?

1. FAA Form 337 must be completed.

2. Entries must be made in the aircraft’s maintenance record.

3. The owner of the aircraft must submit a record of all minor repairs to the FAA at least annually.

A—2.

B—2 and 3.

C—1 and 2.

[a] When a minor repair is performed on a certificated aircraft, an entry must be made in the aircraft permanent records. (AM.I.K.K4) — FAA-H-8083-30

8460. An aircraft was not approved for return to service after an annual inspection and the owner wanted to fly the aircraft to another maintenance base. Which statement is correct?

A—The owner must obtain a special flight permit.

B—The owner may fly without restriction up to 10 hours.

C—The owner may fly in the restricted category up to 10 hours.

[a] If an aircraft fails to pass an annual inspection but is considered by the technician conducting the inspection to be safe for flight, it may be issued a special flight authorization under the provision of 14 CFR §21.197(a)(1), to allow the aircraft to be flown to another maintenance base where the required maintenance can be performed. (AM.I.K.K4) — 14 CFR §21.197

8461. Each person performing an annual or 100-hour inspection shall use a checklist that contains at least those items in the appendix of

A—14 CFR Part 43.

B—14 CFR Part 65.

C—AC 43.13-3.

[a] All 100-hour and annual inspections must be conducted with the use of a checklist. 14 CFR Part 43, Appendix D, lists the basic areas that must be included on the inspection checklist. (AM.I.K.K4) — 14 CFR §43.15(c)

8463. After a mechanic holding an airframe and powerplant rating completes a 100-hour inspection, what action is required before the aircraft is returned to service?

A—Make the proper entries in the aircraft’s maintenance record.

B—An operational check of all systems.

C—A mechanic with an inspection authorization must approve the inspection.

[a] After a mechanic holding the appropriate ratings completes a 100-hour inspection of an aircraft, the appropriate entries must be made in the aircraft maintenance records before the aircraft can be returned to service. (AM.I.K.K4) — 14 CFR §43.9

8464. Which of the following may a certificated airframe and powerplant mechanic perform on aircraft and approve for return to service?

1. A 100-hour inspection.

2. An annual inspection, under specified circumstances.

3. A progressive inspection, under specified circumstances.

A—1, 2.

B—1, 3.

C—1, 2, and 3.

[b] According to 14 CFR §§65.85 and 65.87, a certificated mechanic with airframe and powerplant ratings may perform a 100-hour inspection on an airframe and powerplant and approve the aircraft for return for service.

An inspection authorization is required to conduct an annual and a progressive inspection and approve the aircraft for return to service. The exception to this is found in 14 CFR §43.15(d)(2) which states, regarding a progressive inspection, “If the aircraft is away from the station where inspections are normally conducted, an appropriately rated mechanic, a certificated repair station, or the manufacturer of the aircraft may perform inspections in accordance with the procedures and using the forms of the person who would otherwise perform the inspection.” (AM.I.K.K4) — 14 CFR §65.85, 65.87, 43.15(d)(2)

8523. The 100-hour inspection required by Federal Aviation Regulations for certain aircraft being operated for hire may be performed by

A—persons working under the supervision of an appropriately rated mechanic, but the aircraft must be approved by the mechanic for return to service.

B—appropriately rated mechanics only if they have an inspection authorization.

C—appropriately rated mechanics and approved by them for return to service.

[c] A 100-hour inspection of an aircraft that is operated for hire may be performed by an appropriately rated mechanic and approved by him or her for return to service. (AM.I.K.K4) — 14 CFR §65.87

8536. Who has the authority to approve for return to service a propeller after a 100-hour inspection?

1. A mechanic with a powerplant rating.

2. Any certificated repairman.

3. A non-certificated mechanic working under the supervision of a certificated mechanic with airframe and powerplant ratings.

A—1.

B—2.

C—1 and 3.

[a] A certificated mechanic holding a powerplant rating is authorized to perform a 100-hour inspection on a propeller and may approve the same for return to service. (AM.I.K.K4) — 14 CFR §65.87