chp 5 receiving, storing, inventory. ethics

1/96

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

97 Terms

what are the elements for receiving activity (8)

-Competent personal

-Facilities and equipment

-Specification

-Critical control in receiving

-Sanitation

-Adequate supervision

-Scheduled hours

-security

define receiving

Activity for ensuring that products delivered by suppliers are those that were ordered

receiving involved what besides acceptance and signing of delivery

-verifying that quality, size, and quantity meet specifications

-the price on the invoice agrees with the purchase order

-perishable goods are tagged or marked with the date received

what & or revenue is spent on food purchasing in foodservice establishment

30-50%

competent personell

Responsibility for receiving should be assigned to a specific member of the foodservice staff and person assigned needs to be well trained to it correctly

facilities and equipment

want there to the enough space and equipment to perform receiving correctly

-like thermometer, lifting equipment, storage area

specifications

-the employee who is receiving should know the standards the supplier must meet

-delivery should be checked against the specifications

- and copy of all purchase orders should be provided to the receiving personnel

critical control in receiving

receiving is MAJOR critical control point for many foods so need use HACCP

sanitation for receiving

receiving area should be designed for easy cleaning and have cleaning supplies conveniently located

adequate supervision

The management of a foodservice operation should monitor the receiving area at irregular intervals to check security and ensure that established procedures are being followed

scheduled hours

-Suppliers should be directed to make deliveries at specified times.

-Reduces confusion and wasting of tim

security

should have security to prevent internal theft of supplies

(security can help reduce 60% internal theft)

what are the 5 steps of the receiving process

1. Inspection against the purchase order

2. Instructions against the invoice

3. Acceptance and rejection of orders

4. Completion of receiving records

5. Removal of storage

how do we inspect the purchase order

received order needs to be checked against purchase order and all established specifications

-if too many are below tolerance levels it should be rejected

after product have been checked against the purchase order and specifications, what should be done

delivery should be compared to the invoice prepared by the supplier

what are the 3 main receiving methods

invoice received, blind receiving, electronic receiving

what is invoice receiving

The receiving clerk checks the quantity of each product against the purchase order. Any discrepancies are noted on both the purchase order and the invoice

-method is quick but can be unreliable if the receiving clerk does not compare the two records and only looks at the delivery invoice

blind receiving is what

The receiving clerk uses an invoice or purchase order with the quantity column blanked out and records on it the quantity of each product received. This method requires that each product be checked because the amount ordered is unknown

-time consuming for both receiver and deliverer

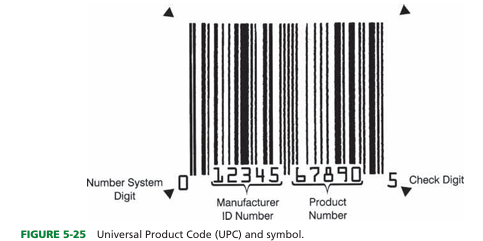

what is electronic receiving

Technology is speeding up the receiving process, although it is still too expensive for small foodservice operations.

-UPC (universal product code) makes this easy — is the barcode

if quantites and prices are correct and quality is correct, what should be done

invoice should be signed

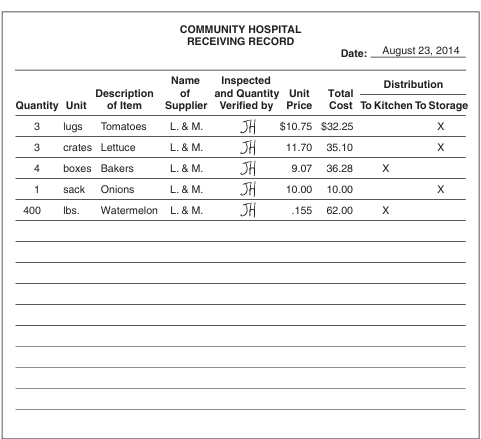

what is completion of receiving records

The receiving record provides an accurate list of all deliveries of food and supplies, date of delivery, supplier’s name, quantity, and price data

removal to storage

Products should be transferred immediately from receiving to the secure storage area

spoilage and deterioration may occur if refrigerated and frozen products are held at room temperature for any period of time

after food has been received properly, we move onto what

storage

define storage

Holding of products under proper conditions to ensure quality until time of use

what are major considerations in ensuring quality of stored food (3)

Proper storage maintenance, temperature control, and cleaning and sanitation

what is a major concern when storing

prevention of theft and pilferage

define theft

premeditated burglary

define pilferage

inventory shrinkage caused by employees stealing food

when should food be stored

ll foods should be placed in storage as soon as possible after delivery, unless they are to be processed immediately. Dry groceries, canned foods, and staples should be placed in dry stores. Perishable foods must be placed in refrigerated or frozen storage promptly

storage facilities should be: (floors, cleanability, doors, windows, ventilation, temp, humidity)

-Slip resistant floors

-Easy to clean

-Light colored walls and smooth surface

-Doors should be limited

-Windows opaque

-Good ventilation

-50-70F

-Humidity not above 60% (50-60% is fine)

low temp storage units can be categorized into what 3 types

refrigerators, tempering boxes, storage freezers

define refrigerators

Storage units designed to hold the internal temperature of food products below 41°F

define tempering boxes

Separate units for thawing frozen foods, specially designed to maintain a steady temperature of 40°F regardless of room temperature or product load.

define storage freezers

Separate units for thawing frozen foods, specially designed to maintain a steady temperature of 40°F regardless of room temperature or product load.

what are the 3 types of thermometers needed

remote reading thermometer, recording thermometer, and refrigerator/freezer thermometer

what humidity for most foods, for perishable foods

between 75-95% for most foods

-85-95% for perishable foods

what is remote reading thermometer

Placed outside the unit to permit reading the temperature without opening the door

what is recording thermometer

Mounted inside or outside the unit, continuously records temperatures in the unit or transmits temperatures to computer for tracking.

what is refrigerator/freezer temp

Mounted or hung on a shelf in the warmest area inside the unit.

temps should be checked how many times a day

2

what foods absorb odors? give off odors?

critical control in storage

Storage can be a critical control point for food items. The microbiological safety of raw food products while in storage before production is critical. The HACCP flowchart should identify storage procedures.

INVENTORY NOW

what are a significant investment of the orgs assets?

materials held in storage

for inventory to control to be effective what should be done (4)

access to storage should be limited, authorized people to remove goods from storage, and inventory levels monitores, as well as recordkeeping

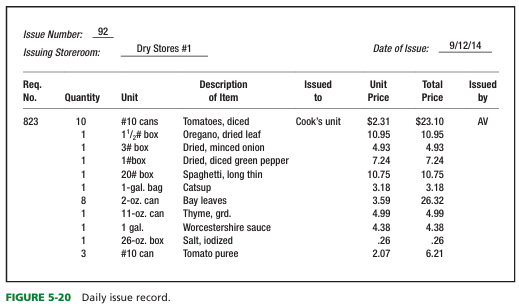

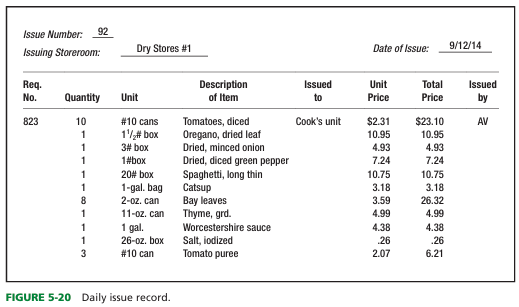

what do we mean by issuing products

Issuing is the process used to supply food to production units after it has been received

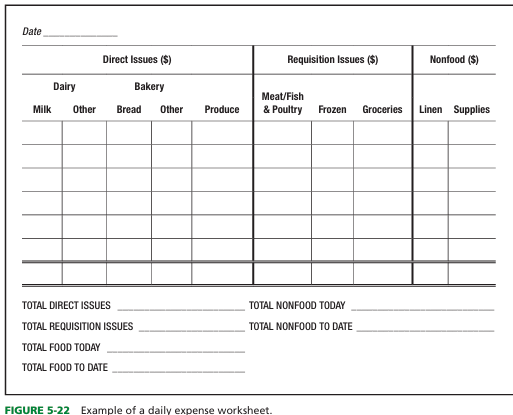

WHAT IS IT: entails control of food and supplies removed from storage

what are direct issues/purchases?

Products sent directly from receiving to production without going through storage

-For foods that will be used the day they are delivered

what are storeroom issues?

products are issued from a storage area when needed for production or service

-for food received but not used that same day

control of issuing from storage has what 2 important aspects:

-First, goods should not be removed from the storeroom without proper authorization

-Second, only the required quantity for production and service should be issued

inventory records contain what 4 basic objectives

-Provision of accurate information of food and supplies in stock

-Determination of purchasing needs

-Provision of data for food cost control

-Prevention of theft and pilferage

define physical inventory

Periodic actual counting and recording of products in stock in all storage areas

-usually done at end of each month

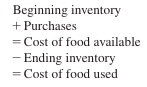

what is the simplest way to do food cost

For inventories conducted as infrequently as 2 or 3 months, daily food cost is determined

computing the cost or direct and requisition issues

requisition issues are made only when

on requisitions from using units and are taken from inventory

define perpetual inventory

Purchases and issues continuously are recorded for each product in storage, making the balance in stock available at all times.

perpetual inventory is usually restricted to only what products

those in dry and frozen storage

define Just-in-time (JIT) purchasing

Purchasing of products for immediate production and consumption by the customer without having to record it in inventory records.

what is the technique of maintaining assets at desired quantity levels

inventory control

what permits managers to conduct physical inventory and calculate the value of stock faster than manual operation

bar codes and scanning technology

define universal product code (UPC)

System for uniquely identifying products that consists of a rectangular box with vertical lines of various widths

what are the 4 inventory control methods

-ABC method

-mini-max method

-economic order quantity method

-inventory valuation method

what is a indicator that can be used to monitor the effectiveness of inventory control

inventory turnover

define inventory turnover

Estimate of how rapidly product is being brought in and used.

formula for inventory turnover

food cost/average food inventory

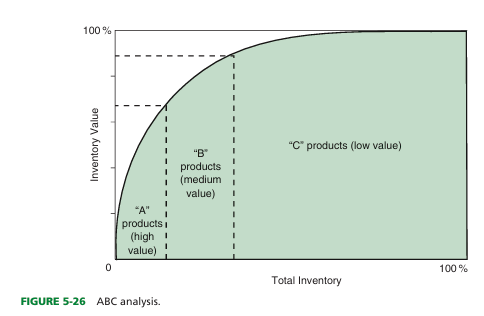

define the ABC method

Tool for classifying products as A, B, or C according to value, with A being the highest value

what is the principle for ABC method

that effort, time, and money for inventory control should be allocated among products according to their value

high, medium, and low value (what letter assigned, what % of inventory they represent, and % of total inventory they account for

-The high-value A products represent only 15 to 20% of the inventory but typically account for 75 to 80% of the value of total inventory.

-The medium-value B products represent between 10 and 15% of total inventory value and 20 to 25% of the products in inventory.

-C products are those whose dollar value accounts for 5 to 10% of the inventory value but make up 60 to 65% of the inventory

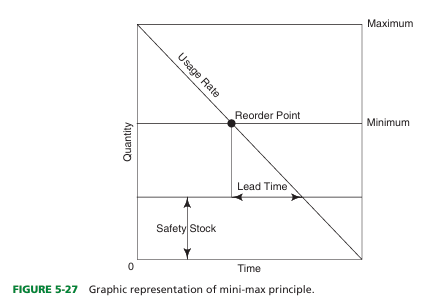

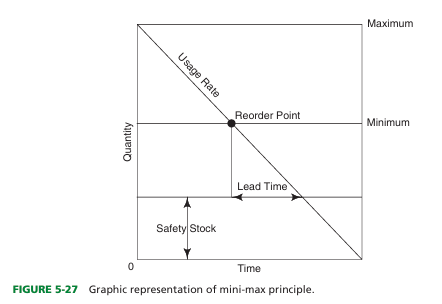

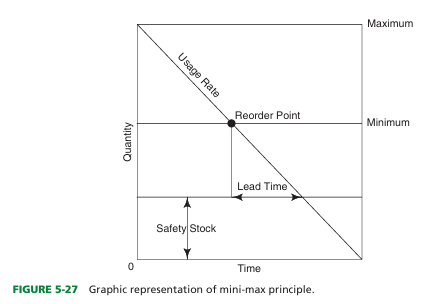

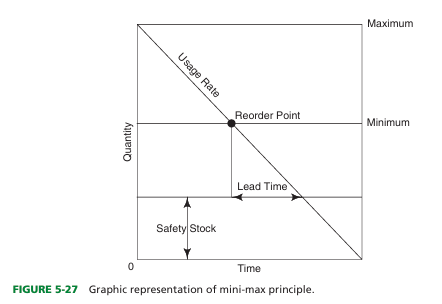

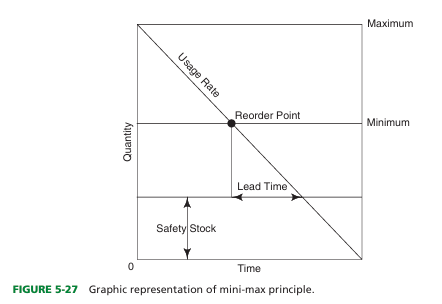

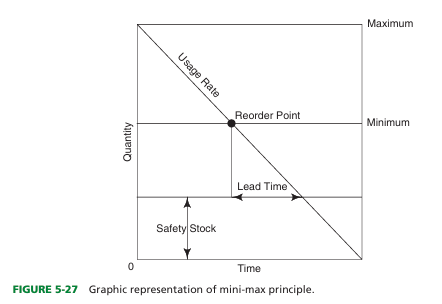

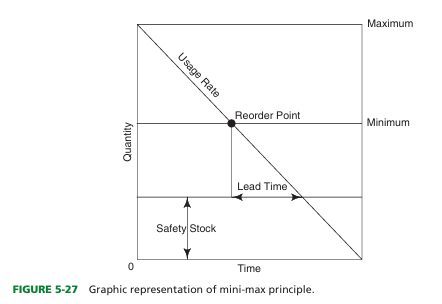

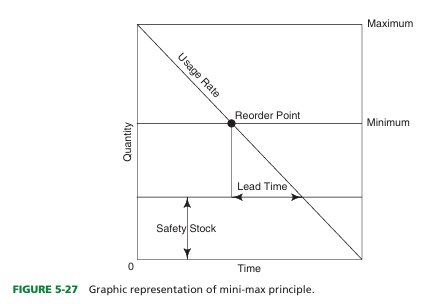

define mini-max method

Tool for controlling inventory by establishing lower and upper levels for each product in storage.

what is the safety stock in min-max method

Backup supply to ensure against sudden increases in product usage rate.

-There instead of minimum being 0

define lead time

Interval between the time that a requisition is initiated and receipt of the product.

define usage rate

How rapidly a product is used

define reorder point

Lowest stock level that safely can be maintained to avoid emergency purchasing.

reorder minimum inventory

Lowest quantity that safely can be maintained in inventory to avoid a stock-out or emergency purchasing

The difference in the safety stock amount and the minimum inventory amount occurs because

of impact of time and usage

what is impact of time

he impact of time occurs because a product will not be delivered immediately after it is ordered, and it will take time (sometimes days) to get product into the organization once it is ordered.

what is impact of usage

he impact of usage is that products continue to be used after that product is reordered, so the amount of ordered product on hand when a delivery arrives is less than what it was when the order was placed

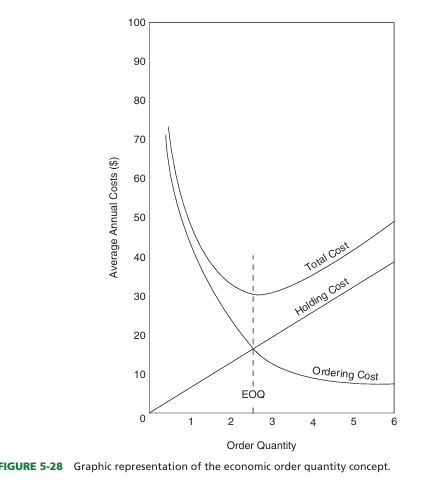

what is economic order quantity (EOQ) method

Inventory concept based on a sensible balance of ordering cost and holding cost

-the ordering cost is a curve diminishing in ordinates as the abscissae, the order quantities, increase

Ordering cost diminishes rapidly as the size of the orders is ______, and holding cost of the inventory ______directly with the size of the order.

increased; increases

objective of EOQ method

to determine the relationship between the ordering cost and the holding cost that yields the minimum total cost

what is the ordering cost is EOQ

includes the total operating expenses of the purchasing and receiving departments, expenses of purchase orders and invoice payment, and data processing costs pertinent to purchasing and inventory

what is the holding cost in EOQ

the total of all expenses in maintaining an inventory and includes the cost of capital tied up in inventory, obsolescence of products, storage, insurance, handling, taxes, depreciation, deterioration, and breakage.

assumptions made with EOQ (7)

-total annual usage is known and constant.

-Withdrawals are continuous at a constant rate.

-Quantity purchases are available instantly.

-Shortages are not tolerated.

-Unit cost is constant.

-Ordering cost is constant.

-Unit cost of inventory products is constant.

EOQ not suitable for most food servive orgs because

because of a variable demand for certain food products, seasonal menu changes, and indefinite lead times.

what are the 5 types of valuation methods

actual purchase price, weighted average, FIFO, (first in, first out), LIFO (last in, first out), and latest purchase price

every accounting period of generally 1 year, an accounting cycle usually begins and ends each month. Hence, inventories are taken monthly and the dol lar value is included as an asset, or a debit, on the monthly balance sheet. A beginning and ending inventory occurs each month; the ending inventory becomes what?

the beginning inventory for the next month.

define actual purchase price

Inventory valuation method involving pricing the inventory at the exact price of each product

define weighted average

Inventory valuation method in which a weighted unit cost is used and is based on both the unit purchase price and the number of units in each purchase.

define FIFO

first in, first out

-The oldest products in the storeroom are used before the newest ones.

-The ending inventory reflects the current cost of products because inventory is valued at the prices for the most recent purchases

define LIFO

Last in, first out

-based on the assumption that current purchases are largely, if not completely, made for the purpose of meeting current demands of production.

-The purchase price of the oldest stock, therefore, should be charged out first

define latest purchase price

Inventory valuation method in which the last price paid for a product is used

ETHICS

define ethics

Principles of conduct governing an individual or business.

define personal ethics

Person’s principles derived from religion, values, morals, or philosophy of life that govern conduct.

define business ethics

- Self-generating principles of moral standards to which a substantial majority of business executives in a firm gives voluntary assent.

define code of ethics

Set of rules for standards of professional practice or behavior established by a group.

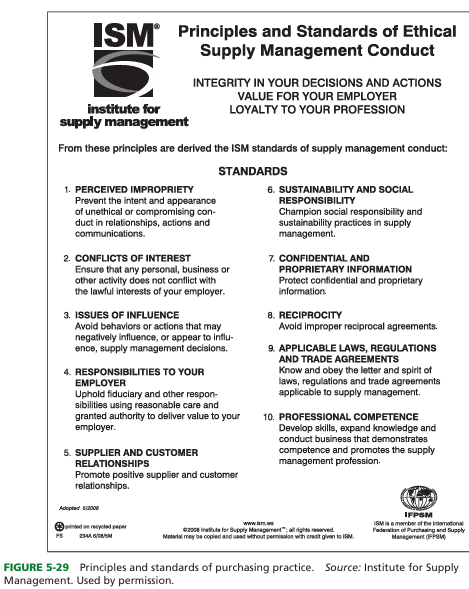

what is institute for supply management (ISM)

uses Principles and Standards of Ethical Supply Management Conduct as a guide for ethical behavior by members

- touch on many areas in which the buyer might err ethically

3 main categories of ethical issues

1.Efforts to gain inside information about competitors that will benefit competition (e.g., receiving information about competitors through shared suppliers)

2. Activities that allow buyers to gain personal benefits from suppliers (free lunches, dinners, entertainment, trips, and gifts)

3. Activities that manipulate suppliers to benefit the purchasing organization (overstating the seriousness of a problem to obtain concessions from the supplier, threatening the use of a second source, using the organization’s economic clout, and permitting information on bids from other suppliers)