DDS MODULE 6

1/117

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

118 Terms

Tablets

Cheapest type

prepared with the aid of suitable pharmaceutical excipients

vary in size, shape, weight, hardness, thickness, disintegration and dissolution

most widely used dosage form

GENERAL PROPERTIES OF A TABLET

strong and hard to withstand mechanical shock during manufacturing, packing. shipping, dispensing and use.

must be bioavailable, must be able to release its content in a predictable and reproducible manner

must be chemicallt and physically stable, during manufacturing, storage, and use

Should have an elegant product identity, free form any tablet defect.

must be uniform in weight and in drug content

Advantages (PLESMT)

Precision and low content variability

Low manufacturing cost

Ease of packaging and shipping

Simple to identify

Most-stable of all dosage forms

Tamper proof

Disadvantages

Resis compressions, requires encapsulation prior to compression

TABLETS FOR ORAL INGESTION

by mouth

COMPRESSED TABLETS

provide rapid disintegration in the gastric fluid following ingestion hence, allowing rapid release of the drug and, ultimately, systemic absorption of the dosage form.

pumcher & dier

Diluents or fillers

necessary bulk to a formulation to prepare tablets of the desired size

Binders or adhesives

promote adhesion of the particles, allowing granulation

Disintegrants or disintegrating agents

promote breakup of the tablets after administration to smaller particles

Antiadherents, glidants, lubricants, or lubricating agents

flow of the material, produce tablets with a sheen.

Miscellaneous adjuncts

colorants and flavorants.

MULTIPLE COMPRESSED TABLETS

more than a single compression, multiple-layer tablet, the inner tablet being the core and the outer portion being the shell. TRI-LAYER / PI-LAYER

Layered tablet

initial compaction of a position of ill material in a die followed by additional fill material & compression, two-layered or three layered tablets, EX: Neozep

Physical or chemical incompatibility

Staged drug release

Simply for the unique appearance of the layered tablet

Compression coated tablets

completely surrounded by the coat, coats prevent drug release, from the core, like sugar-coated or film-coated tablets in, may cover a bitter substance

SUGAR COATED TABLETS

coated with concentrated sugar, improve patient’s compliance, mask objectionable tastes or odours, Ex: Poten-cee

Disadvantages:

Expertise is required in the coating process .

Increase in size, weight and shipping costs

FILM-COATED TABLETS

coated with a thin layer of a polymer capable of forming a skin-like film. The coating is designed to rupture, durable, less bulky and less time consuming to apply.

GELATIN COATED TABLETS

capsule-shaped compressed tablet, about one-third smaller than a capsule filled with an equivalent amount of powder.

facilitates swallowing, and gelatin-coated tablets are more tamper evident than unsealed capsules.

ENTERIC-COATED TABLETS

delayed-release properties, coated with polymeric substances, drug dissolution and absorption in the intestine. Ex: Buscopan

TABLETS USED IN ORAL CAVITY

BUCCAL & SUBLINGUAL TABLETS

CHEWABLE TABLETS

IMMEDIATE RELEASE TABLETS

INSTANTLY DISINTEGRATING TABLETS

BUCCAL & SUBLINGUAL TABLETS

flat, oval tablets intended to be dissolved in the buccal pouch (buccal tablets) or beneath the tongue (sublingual tablets), oral mucosa.

pouch (buccal) 1 - 2 hours sublingual - 3 - 5 minutes

CHEWABLE TABLETS

intended to be chewed and then swallowed by the patient rather than swallowed whole. palatable and be easily chewed and swalloed, children and adults who have dificulty swallowing solid dosage forms

Ex: Ceelin, Meclizine(Bonamine)

IMMEDIATE RELEASE TABLETS

designed to disintegrate and release their medication with no special rate-controlling features, 75% of the labeled amount dissolves in 45 minutes.

INSTANTLY DISINTEGRATING TABLETS

Rapid-release tablets (rapidly dissolving tablets or RDTs), dissolving in the mouth within 1 minute, some within 10 seconds.

mourh within approximately 15-30seconds, Anything slower would not be categorized as rapidly dissolving

TABLETS USED TO PREPARE SOLUTIONS

EFFERVESCENT TABLETS

MOLDED TABLETS

TABLET TRITURATES

HYPODERMIC TABLETS

DISPENSING TABLETS

EFFERVESCENT TABLETS

uncoated tablets, organic acids (such as tartaric or citric acid) and sodium bicarbonate, react rapidly in the presence of water by releasing carbon dioxide, disintegrator

MOLDED TABLETS

such as tablet triturates, molding rather than by compression, are very soft, designed for rapid dissolution. Ex: Flumucil

TABLET TRITURATES

small, usually cylindrical, molded, or compressed tablets containing small amounts of usually potent drugs, provide accurate amounts of potent drug substances. similar w/ molded

HYPODERMIC TABLETS

no longer available, originally used by physicians in extemporaneous preparation of parenteral solutions.

DISPENSING TABLETS

AKA. compounding tablets,

no longer in use

used them to compound prescriptions; they were not dispensed as such to the patient

contained large amounts of highly potent drug substances

dangerous potential of being inadvertently dispensed as such to, patients.

can caure overdorage of toxicity

Ex: Hgcl-antiseptic, neomycin sulfate - ophtalmic drug, Basitracin - Antibiotic

MISCELLANEOUS

EXTENDED-RELEASE TABLETS

VAGINAL TABLETS

EXTENDED-RELEASE TABLETS

controlled-release tablets, release their medication in a predetermined manner over an extended period.

Ex: drugs that once a day to be taken

VAGINAL TABLETS

also called vaginal inserts, are uncoated, bullet-shaped, or ovoid tablets inserted into the vagina for local effects.

nonspecific vaginitis caused by Haemophilus vaginalis or antifungals for the treatment of vulvovaginitis candidiasis caused by Candida albicans and related species.

Ex: Canesten (1-day therapy or 6-day therapy)

QUALITY STANDARDS AND COMPENDIAL REQUIREMENTS FOR TABLETS

Tablet Weight & USP Weight Variation Test

Content Uniformity

Tablet Thickness

Tablet Hardness

Tablet Friability

Tablet Weight & USP Weight Variation Test

In the test, 10 tablets are weighed individually, and the average weight is calculated. The tablets are assayed, 10 tablets is calculated assuming homogeneous drug distribution. The tablet passed the U.S.P. test if no more than 2 tablets are outside the percentage limit and if no tablet differs by more than 2 times the percentage limit.

Content Uniformity

ensure content consistency of active drug substances within a narrow range around the label claim in dosage units. This test is crucial for tablets having a drug content of less than 2 mg or when the active ingredient comprises less than 2% of the total tablet weight.

10 dosage units are individually assayed

les within the range of 85% to 115% of the label claim and the standard deviation is less than 8%.

Tablet Thickness

determined by the diameter of the die

important in reproducing tablets identical in appearance and also it ensures that every production lot will be usable with selected packaging components.

determined with a caliper in milimeters, Using vermier caliper

Tablet Hardness

refers to the resistance to breakage under conditions of storage, transportation and handling.

A force of about A Kg

Importance of tablet hardness

Hardness (or more appropriately crushing strength) determination are made throughout the tablet runs to determine the need for pressure adjustments on the tableting machine.

Equipment used for hardness testing

Stokes or Monsanto Hardness Tester

Strong-cobb Hardness Tester

Pfizer Hardness Tester

Schleuniger Apparatus

Tablet Friability

tendency of tablet to powder, chip or fragment and can affect the elegance, appearance, consumer acceptance, property that is related to the hardness of the tablet.

how well a tablet resists chipping and crumbling, Compressed tablets that lose less than 0.5%-1% of their weight are usually considered acceptable

TYPES OF TABLET PRESS

Single Punch | Rotary Press

PARTS OF A TABLET PRESS

Hopper - For strong material for compression

Feed Shoe - For distribution of materials into the die

Punch - For compaction; determines the hardness of the tablet

Die - Determones the size and shape of the tablet

Cam Tracks - For guiding the movement of punches

TABLET COATING

Reasons for tablet coating:

To protect the medicinal agent against destructive exposure to air/humidity

To mask the taste of the drug

To provide special characteristics of drug release

To prevent contact with a drug which is irritating or potentially allergicTo separate reactive ingredients

To delay or prolong absorption of the drug component by retarding release of drug from the dosage form (sustained-action)

To provide aesthetics or distinction to the product

Compression Coating

Basic Processes used in the application of coating

Equipments

Uncoated Tablets should be

Friabilator

Basic Processes used in the application of coating

Compression Coating - special dosage forms

Pan Coating - both sugar & film-coating -makes use coating pans provided w/a hot & cold air

Air suspension coating - atomized & applied to tablets

Dip coating - dipped into containers of coating solutions - has not been widely accepted because of the difficulties encountered. during the coating procedure & lack of coat uniformity.

Equipments

Coating Pan (Ex. Accela Cota, Fellegrini)

Steam Jacketed Tanks

Drying Oven

Polishing Drum

Uncoated Tablets should be

Sufficiently hard

Optimum convexity

Minimal friability

Rapid disintegration

Friabilator

apparatus to be used in determining the tablet's friability. or tendency to crumble.

Tablet Disintegration

is a measure of the time required under a given set of conditions for a group of tablets to disintegrate to particles

Complete disintegration is defined as "that state in which any residue of the unit, except fragments of insoluble coating or capsule shell, remaining on the screen of the test apparatus is a soft mass having no palpably firm core"

usually 30 minutes, but varying from about 2 minutes for NTG tablets to up to 4 hours for buccal tablets.

Parts of Disintegration Apparatus

Basket-rack assembly - six open-ended transparent tubes, 10-mesh stainless steel wire screen

Mesh - Attached under the surface of the lower plate

Disks - permitted only where the specified in the monograph

Tablet Dissolution

process by which a substance forms a solution, measures the amount of time required for a given percentage of the drug substance in a tablet into solution under a specified set of conditions.

Reasons for conducting in-vitro dissolution testing for solid dosage forms: assurance program, It is a requirement for regulatory approval

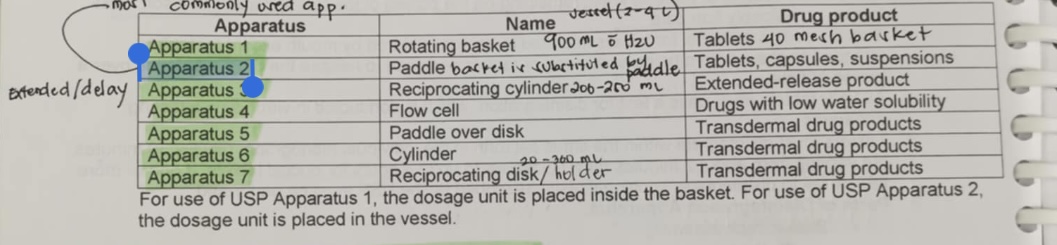

Dissolution Apparatus

Variable-speed stirrer motor.

Dossolution Testing

37*C + 0.5*C

Most commonly used app

Apparatus 2

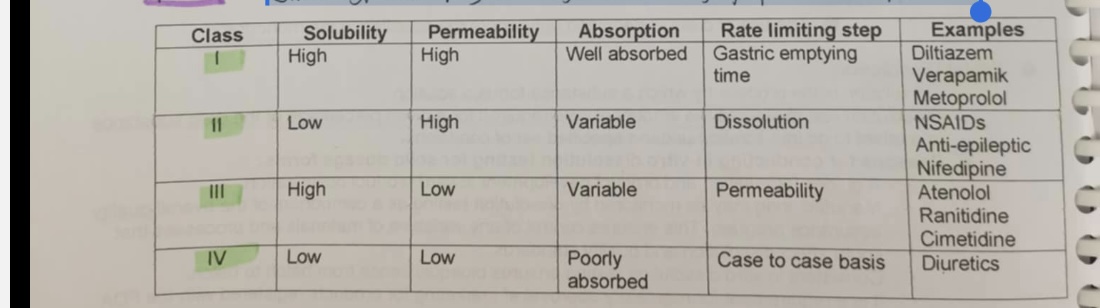

BIOPHARMACEUTICS CLASSIFICATION SYSTEM

is a system to differentiate the drugs on the basis of their solubility and permeability, restricts the prediction using the parameters solubility and intestinal permeability, based on a United States Pharmacopoeia (USP).

checking/ dassifying ē drugs that is highly permeable | soluble

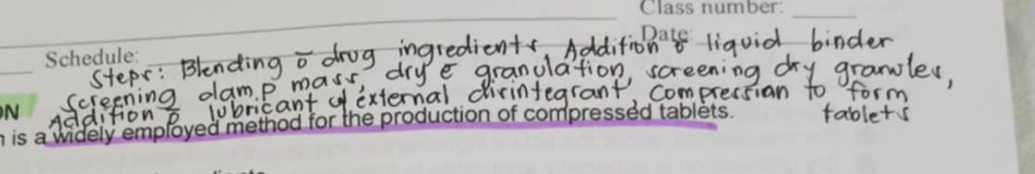

METHODS OF PREPARATION OF COMPRESSED TABLETS

wet granulation, dry granulation, and direct compression.

WET GRANULATION

a widely employed method for the production of compressed tablets.

Dry Granulation

AKA. Double compreccion or pre- comprescion

compacted in large pieces and subsequently, broken down or sized into granules.

Slugging

Advantage: Used for moisture | heat cencitive material

the powder mixture is slugged

Roller compaction

powder compactors, increase the density of a powder by pressing it between rollers at 1 to 6 tons of pressure

The roller compaction method is often preferred to slugging.

Disadvantage: Dusty, may result uneven color

Ex: Multiv, aspirin

Direct Compression

like potassium chlorde, possess Mae-lowing and cohesive properties that enable them to be compressed directly in a tablet machine without any need of granulation.

EXCIPIENTS USED IN TABLET FORMULATION

Diluents/Fillers

Binders/Adhesives

Disintegrants

Glidants

Lubricants

Anti-adherents

Absorbents

Coloring Agents

Diluents/Fillers

Ex: Lactose, starch, cellulose derivatives, mannitol, sorbitol, sucrose

Binders/Adhesives

Ex: starch, gelatin, methylcellulose, polyvinylpyrrolidone,

Disintegrants

Ex: starch, gums, clays, cellulose, alginates, surfactants

Glidants

Ex: Talc, corn starch, colloidal silica, calcium silicate, calcium phosphate, Zn, Mg, and Ca stearates

Lubricants

Ex: talc, magnesium stearate, and calcium stearate

Anti-adherents

Ex: Colloidal silica, corn starch, sodium lauryl sulfate, stearates

Adsorbents

Ex: Magnesium oxide, magnesium carbonate, bentonite, silicon dioxide

Coloring agents

Ex: FD&C - food, drug & cosmetics, D&C - drug & cosmetics, external D&C - external use only

Sugar Coating Tablets

Sealing

Subcoating

Syruping

Finishing

Polishing

Sealing

AKA “Waterproofing”, protect the tablet core from water in subsequent

Ex: Shellac, phthalic anhydride

Subcoating

This improves the bond between, build up standard size for tablets

Ex: Gelatin, Acacia

Syruping

Finalize the rounding-off of the tablet.

Grossing

base color, a syrup solution w/ subcoating powder

Heavy sugar coating

to guild up a solid color

Regular syrup coating

desired color - dilute syrup solution

Finishing

desired color is attained and to attain final smoothness of the tablet

Polishing

done in a canvas polishing pan for sheen or gloss

Ex: beeswax, carnauba wax

Film-Coating

thin, skin-tight coating of plastic like material

Non-aqueous solutions contain the following types of materials:

Film-Former

Alloying Substance

Plasticizer

Surfactant

Opaquants

Glossant

Volatile Solvent

Film-Former

capable of producing smooth, thin films reproducible under conventional coating conditions and applicable to a variety of tablet shapes.

Ex: Shellac: CAP (Cellulose Acetate Phthalate)

Alloying Substance

imparts eater-solubility/ permeability

Ex: PEG (Polyethylene Glycol)

Plasticizer

imparts flexibility & elasticity

Ex: Castor Oil; Sorbitol

Surfactant

imparts spreadability

Ex: Spans, Tweens; Polyoxythylene sorbitan derivatives

Opaquants

to enhance appearance

Ex: Titanium Dioxide

Glossant

provide luster to the tablets w/out a seperate polishing operation

Ex: Beeswax

Volatile Solven

allow the spread of the other components over the tablets while allowing rapid evaporation to permit an effective yet speedy operation

Ex: Alcohol mixed with acetone

Aqueous Film-Coating Formulation contains

Film-forming Polymer (7% to 18%): Cellulose ether polymers

Plasticizer (0.5 to 2.0%): Glycerin

Colorant & Opacifier (2.5% to 8%)

Vehicle (water, to make 100%)

Enteric Coating Tablets

intended to pass through the stomach intact to disintegrate and release their drug content for absorption along the intestines.

Coatings used are: Shellac and HPMC

Types of tablet printing

Debossed, Embossed, Engraved

Debossed

imprinted w/ a mark below

Embossed

imprinted w/ a mark above

Engraved

imrpinted w/ a code

TABLET PROCESSING PROBLEMS

Picking

Peeling

Orange peel effect

Mottling

Bridging

Wrinkling

Sweating

Blistering

Picking

flaking from the tablet surface (punch); removal of material

Peeling

large amounts of film fragments flaking

Orange peel effect

roughness of the tablet surface

Mottling

uneven color distribution

Bridging

filling-in of the score line