Chapter 6 - Capacity Planning

1/18

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

19 Terms

Capacity

The maximum rate of output of a process or a system

Equipment

Space

Employee Skills

Capacity Planning

Economies and diseconomies of scale

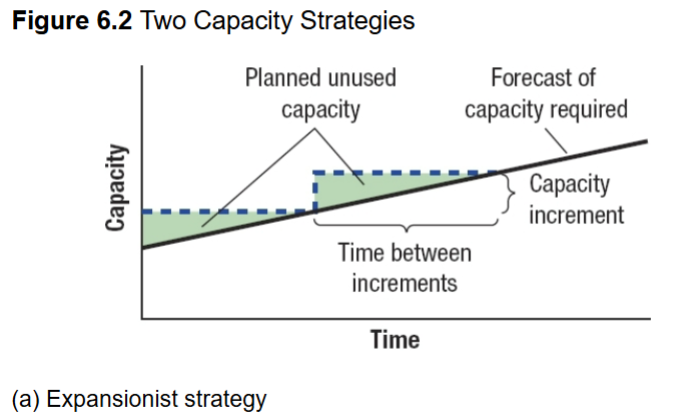

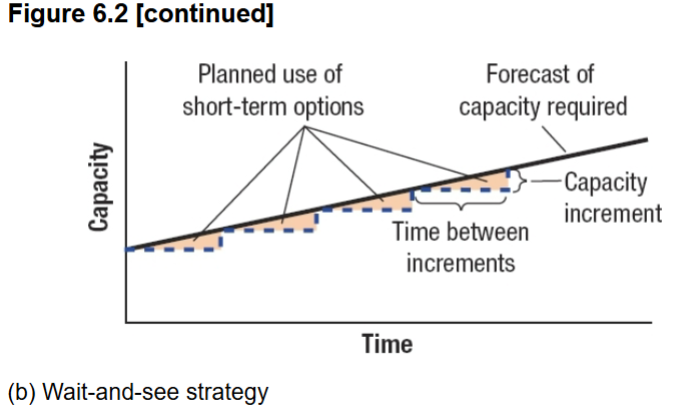

Capacity timing and sizing strategies

Systematic approach to capacity decisions

Output Measures of Capacity

Best utilized when applied to individual processes within the firm or when the firm provides a relatively small number of standardized services and products

Input Measures of Capacity

Generally used for low-volume, flexible processes

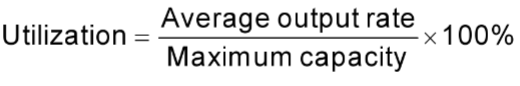

Utilization

– The degree to which equipment, space, or the

workforce is currently being used

– Measured as the ratio of average output rate to

maximum capacity (expressed as a percentage)

Economies of scale

The average unit cost of a service or good can be reduced by increasing its output rate

Spreading fixed costs

Reducing construction costs

Cutting costs of purchased materials

Finding process advantages

Diseconomies of scale

The average cost per unit increases as the facility’s size increases

Complexity

Loss of focus

Inefficiencies

Sizing Capacity Cushions

The amount of reserve capacity a process uses to handle sudden increases in demand or temporary losses of production capacity

It measures the amount by which the average utilization (in terms of total capacity) falls below 100 percent.

Capacity cushion = 100% − Average Utilization rate (%)

Capacity cushions vary with industry

Capital intensive industries prefer cushions well under 10 percent while the less capital-intensive hotel industry can live with 30 to 40 percent cushion

A Systematic Approach to Long-Term Capacity Decisions

1. Estimate future capacity requirements

2. Identify gaps by comparing requirements with available capacity

3. Develop alternative plans for reducing the gaps

4. Evaluate each alternative, both qualitatively and quantitatively, and make a final choice

Capacity Requirements

What a process’s capacity should be for some future time period to meet the demand of customers (external or internal) given the firm’s desired capacity cushion

Using Output and Input Measures

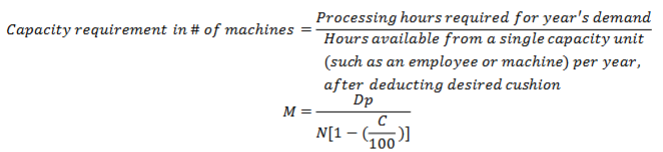

Step 1: Estimating Capacity Requirements (For one service or product processed at one operation with a one-year time period, the capacity requirement)

Where:

D = demand forecast for the year (number of customers served or units produced)

p = processing time (in hours per customer served or unit produced)

N = total number of hours per year during which the process operates

C = desired capacity cushion (expressed as a percent)

M = Number of machines required

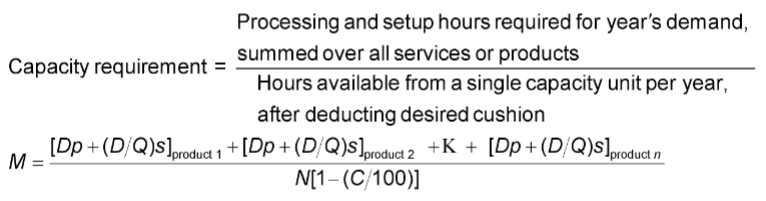

Step 1: Estimating Capacity Requirements Setup times (time required to change a process or an operation from making one service or product to making another may be required if multiple products are produced)

Where:

Q = number of units in each lot (batch)

s = setup time in hours per lot (batch)

Step 2: Capacity Gap

Positive or negative difference between projected capacity requirements (M) and current capacity

Steps 3 and 4 – Develop and Evaluate Alternatives

Base case is to do nothing and suffer the consequences

• Many different alternatives are possible

• Qualitative concerns include uncertainties about demand, competitive reaction, technological change, and cost estimate

• Quantitative concerns may include cash flows and other quantitative measures

Cash flows

the difference between the flow of funds into and out of an organization over a period of time

Tools for capacity planning

Waiting-line models

Simulation

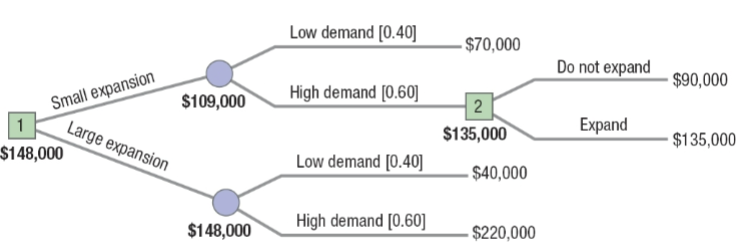

Decision trees

Waiting-line models

Useful in high customer-contact processes

Simulation

Useful when models are too complex for waiting-line analysis

Decision trees

Useful when demand is uncertain and sequential decisions are involved