Sustainable Packaging Exam 1

1/91

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

92 Terms

US- more of recommendation for recycling, not as heavily regulated

EU- banning, more content regulation

What are the main differences between European and U.S. sustainable plastic policies?

Steady State Economy

•A theory that describes equilibrium of consumption and production, birth rate and death rate, resource utilization and regeneration

•Is only achieved after growth or recession of an economy

•Cannot account for growing populations, i.e. need for population control

circular economy

•Economic theory / practice where production, use, and waste are combined in a single

system of reuse

•Oppose to a linear economy of production, use, dispose

•Accounts for dynamic systems of use and reuse, extraction and regeneration

•Takes into account both technical and biological regeneration

circular economy

open loop recycling

closed loop recycling

zero waste strategies

ecological footprint

•Measures demand and supply of nature

•“This includes all biological and ecological assets that a functioning population would require to produce natural resources for sustenance. ”

•Measured in global hectares, or gha, an average value of the productivity of different land types / regions.

•Measures how much regenerative capacity a process requires from the earth

pollution prevention act 1990

energy star program 1992

two acts of legislation fostered by the EPA that led to greater monitoring of sustainability and eventually the rise of LCA

energy

atmospheric emissions and quality

2 most monitored results of an LCA

socioeconomic impact assessment

what does SEIA stand for?

direct: if taken away, it would have an immediate impact on a community

indirect: those arising from changes in the system but not caused directly by changes

What is the difference between direct and indirect impacts in SEIA data?

primary: assess using surveys and focus groups, qualitative and quantitative data, often costly

secondary: analysis of existing data sources, trends in data over time, not costly

What is the difference between direct and indirect impacts in primary and secondary data?

•Analysis of existing data sources, trends in data over time

•Limitation: May not be same type or scale of data

•Minimal cost / time to procure

What is the difference between direct and indirect impacts in secondary data?

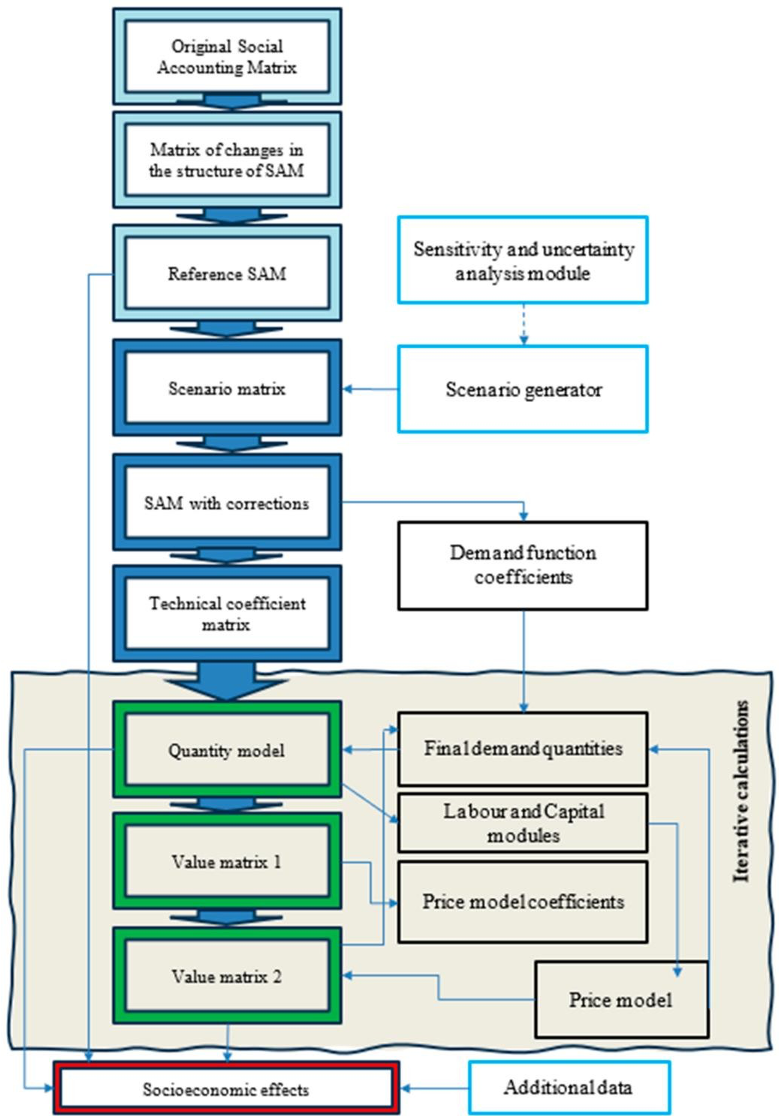

modeling techniques used to understand direct and indirect impacts in SEIA

all kinds of what?

input-output analysis

integrated modeling

computational general equilibrium

input-output analysis

- Prepares tables linking and quantifying transactions, prepares multipliers for each sector

-has trouble with changes that occur

integrated modeling

Combines I/O analysis and econometrics econometrics uses non-linear economic relationships to predict effect of changes to economic structures

computational general equilibrium

-Models the entire economy of nation or region

-Broader range of variables, incorporates changes in prices to goods etc.

-Very data intensive, most used in academic modeling

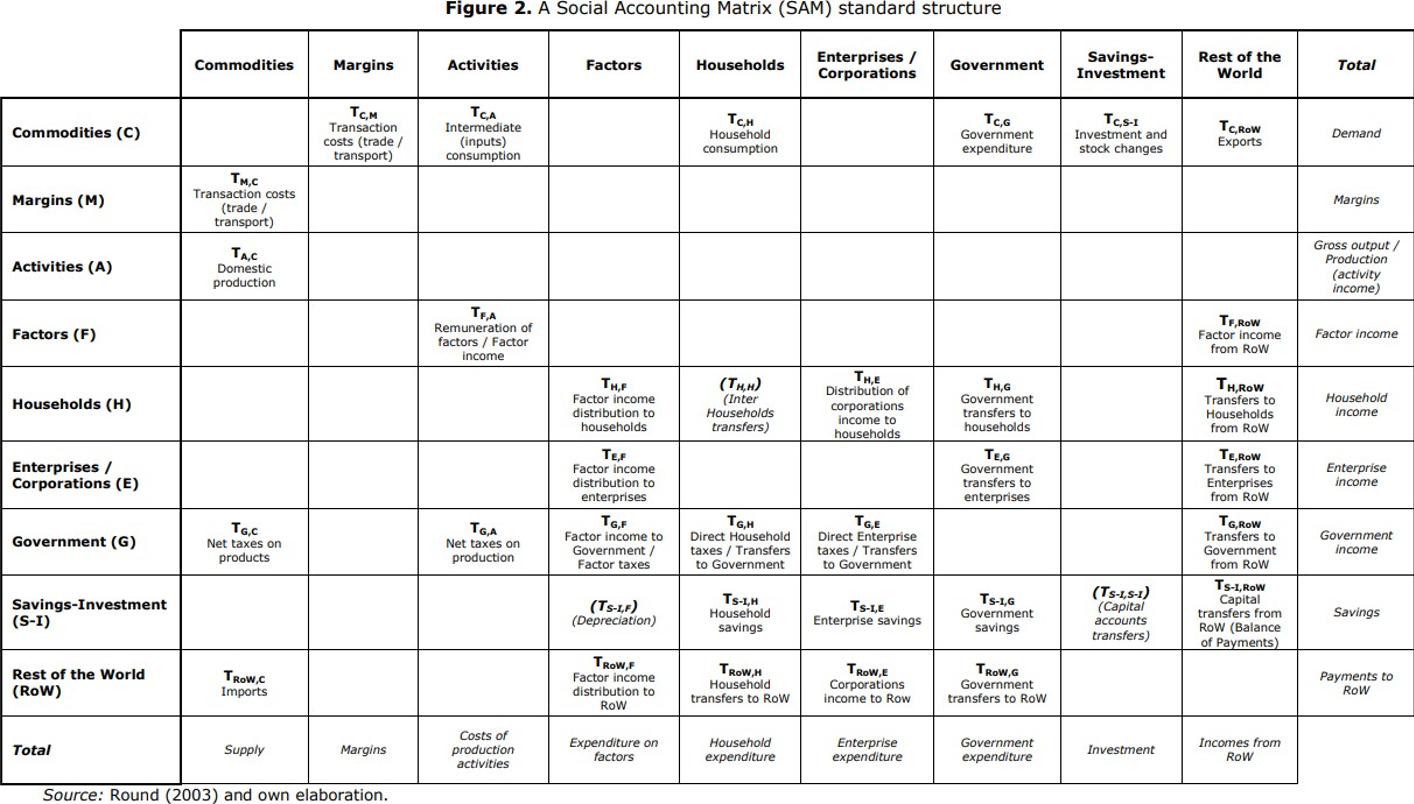

social accounting matrix

looks at all the interactions/relationships you want to study

Contingent Valuation Method

Method of discovering dollar amount people would be willing to pay for goods or services not typically paid for

willingness to pay

how much consumer is willing to pay for goods or services

Surveys used to gauge valuation of goods/services as cost or tax

utility difference model

states there is a threshold to the difference in utility (benefit) b/w two alternatives that a consumer can discern

identify

monetize

compare

main steps in a cost benefit analysis

cost benefit analysis

Used to evaluate price/expense and benefits of project

Used to secure max return on investment

Done before project is carried out

All costs evaluated based on time: direct, indirect, intangible

goal scope and definition

life cycle inventory

impact assessment

interpretation

4 phases of an LCA

functional unit

-As per ISO 14044, FU is “the quantified performance of a product system for use as a reference unit”.

-Quantifies the function of a system in terms of the service offered.

-Not a ratio; must be quantifiable and additive, such that the impact of two FUs is double that of one FU

system boundary

determines which unit processes to be included in the LCA study

Identification of key parameters and potential improvement options using sensitivity analysis and uncertainty analysis: IDENTIFY HOT SPOTS

What is the role of interpretation in LCA?

midpoint categories

weighs and aggregates the emissions into midpoint impact categories (I.e. GHG in CO2eq)

•you’re still at the level of individual impacts

endpoint categories

aggregates impact categories into damage categories (human health, ecosystem quality, resources)

•when you get a result which is one datapoint and is a daily (# of deaths/day your process causes)

•takes elementary input and multiplies by CF to get kgCO2eq (midpoint)

How do you use midpoint and endpoint characterization factors?

What the ISO standard says about allocation

“Where physical relationship (i.e. kg, m3, etc.) cannot be established or used as the basis for allocation, the inputs should be allocated between the products and the functions in a way which reflects other relationships between them. For example, environmental input and output data might be allocated between co-products in proportion to the economic value of the products.”

system expansion

preferred method of allocation?

???

other methods of allocation that can be used

through system expansion to account for the avoided production of other materials/energy that the coproduct provides

How is allocation used when there is a coproduct to the main product?

system expansion

seeks to capture change in environmental impact as a consequence of a certain activity and there by generate information on consequences of actions

attributional LCA

ALCA

defined by its focus on describing the total environmental

impacts of one system

uses average data

consequential LCA

CLCA

defined by its aim to compare between two products or processes, or a change in initial product or formulation

uses marginal data

reference flow

the products needed to fulfill the function of the FU

system

a group of dynamically interacting elements, organized to achieve one or more functions

unit process

Smallest element in LCA analysis, obtained as an expression after identification of processes and elements required to fulfill the function, for which both inputs and outputs are quantified

elementary flows

Flows that link unit processes to the environment

Can be categorized into two types: input and output

input elementary flows

Flows corresponding to the use of natural resources, such as extracted raw material, energy and land us

output elementary flows

Flows exiting a unit process in the form of emissions to water, air or soil

primary energy demand

the sum of all energy used across the lifecycle for the Functional Unit

nonrenewable energy demand

petroleum, coal,gas, uranium, etc.

midpoint

refers to the fact that this point is on the impact pathway between inventory results and damages

normalization

converts complicated units into fractions of building product's scores per impact category

grouping

§A qualitative/semi-quantitative process that helps prioritize results by sorting/ranking

weighting

§Combines multiple scores for different midpoint or damage categories into a single score for each scenario compared….“Single Score Method”

???

How can you interpret midpoint and endpoint impact graphs to understand process contributions?

biorefinery

A concept where biomass is used to produce multiple raw materials, products, and energy to replace the typical petroleum refinery concept

BTX

Benzene, Toluene, and Xylene

the raw material for most chemicals used in the world today.

sustainable forestry

forestry practices that mimic natural patterns of disturbance and regeneration

•Sustainable Harvest Practices – take into consideration long-term regeneration of forests

forest stewardship council

what is FSC?

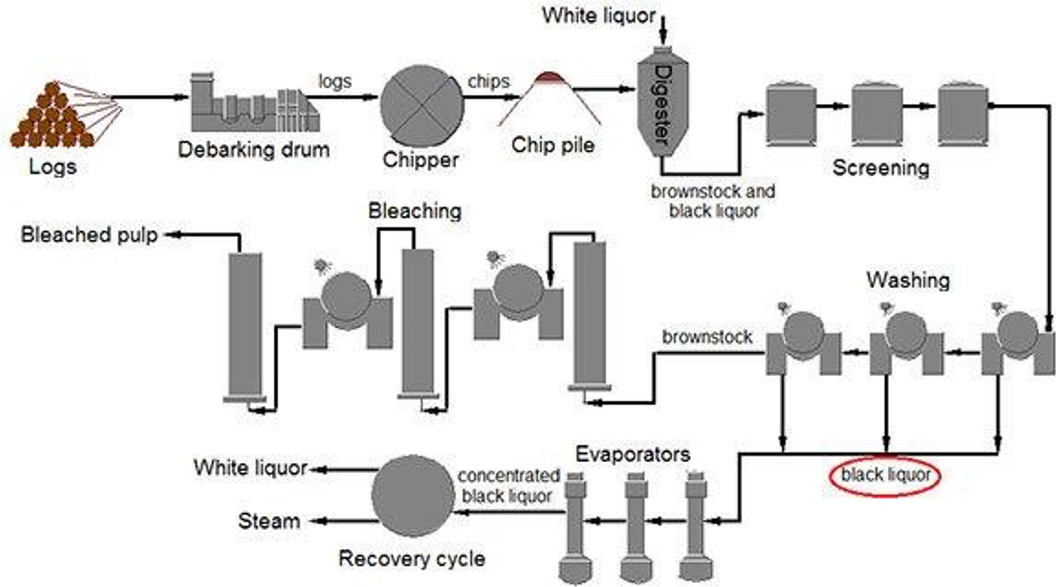

•Wood extraction: removing bark, cutting into chips, screening oversized chips

•Separated bark is used to produce syngas (a mixture of hydrogen gas and carbon monoxide)

•Wood chips are cooked in a digestor; dissolve lignin and create cellulose pulp

•Pulp is screened off; black liquor is concentrated by evaporation

•Concentrated black liquor is burned to produce energy (steam)

•Green liquor dissolved in water and then forms white liquor

•The cellulose fiber is further screened, heated, and bleached to get a high whiteness level

•Bleached pulp is sent to a pulping machine where screening, dewatering, drying and sheet formation occur.

main processes at a pulping mill (detailed)

debarking

digester

screening

washing

either evaporating or bleaching

main processes at a pulping mill (simple)

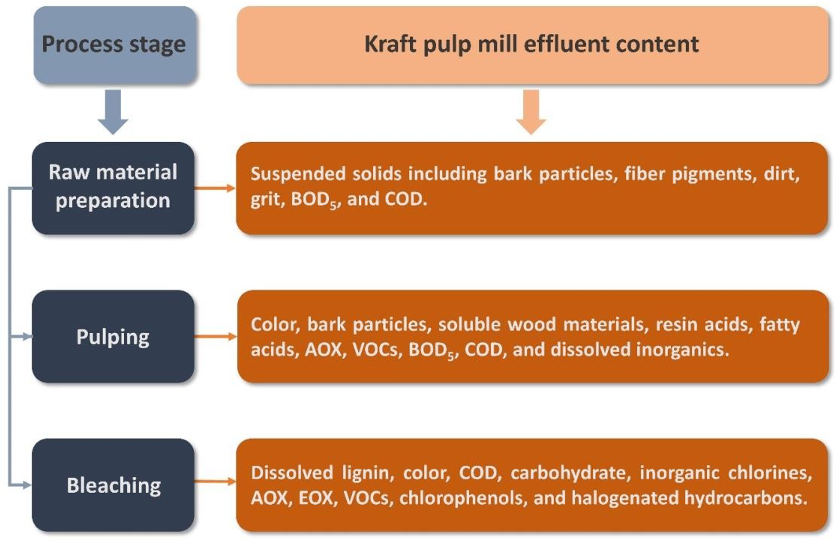

What are the main effluents at a pulping mill?

cellulose (30-50%)

lignin (15-35%)

hemicellulose (25-35%)

main components of wood?

fibers: pulp, biofibrils, and biocomposites

extractives: renewable diesel or biochemicals

lignin, cellulose, hemicellulose: biochemicals

logs: for sawn goods and plywood

bark and branches: for renewable diesel and energy

product streams that come from each component of wood

there is a natural recycling process that a pulping plant relies on:

Lignin supplies energy for recovery boilers and process steam

Sulfur and inorganic materials (green liquor) is not recovered to replenish the cooking medium (white liquor)

interrupting this to harvest lignin/tall oils could disrupt the natural cycle

What is the importance of recycling energy and chemicals at a pulping plant?

sustainable paper has a natural/raw look and feel, and is not as strong as high gloss or coated paper

What are the characteristics of more sustainable paper vs. high gloss / coated paper?

clay coated news backboard

solid bleached sulfate

folding box board

natural kraft, unbleached

duplex paper

different paper types? (5)

clay coated news backboard

Made from recycled newsprint, paper, and corrugated

Low cost folding cartons

High water adsorption

Low cost, used in cereal cartons and other similar materials

Contains clay coating – creating difficulties when recycling

solid bleached sulfate

High quality paperboard

Used in boxes for retail from bleached pulp fibers

Can be coated on both sides

Used in cosmetics, baked items – high end appearance

High bleaching amount, virgin fibers, high cost

folding box board

•Paperboard from multiply pulp

•Smooth surface, high printing ability

•Durable, high stiffness

•Can use recycled paper

•Requires more energy to recycle due to multiple layers

natural kraft, unbleached

•More natural look and feel

•From wood pulp or recycled sources

•Often uses clay coating for water barrier or with Polyethylene for strength

•Not as strong as other paperboard, can be recycled if uncoated

duplex paper

•2 pieces of paper fused together

•Exterior often coated to be glossy / water resistant

•Used to make cartons for higher value products / pharmaceuticals

• High-quality paper often includes highly bleached/glossed paper that reduces recyclability

•Coatings reduce recyclability and increase chemical usage

what makes certain paper types more/less sustainable than others?

high energy requirements and GHG emissions

high oxygen and water vapor permeability than plastic

many of the barriers used inhibit recyclability by typical processes

What are the challenges of paper packaging and barrier properties?

Perfluoroalkyl Substances

what does PFAS stand for?

PFAS

Used in non-stick coatings on cookware, and paper coatings to increase barrier protection to grease

danger of PFAS

Migration into food/water

Exposure to marine life has longer residence times due to contamination of food chain

jackets

upholstery

carpets

papers

building materials

food contact materials

impregnation agents

cleansers

polishes

paints

ski waxes

polar bears

where is PFAS found? (name 3-5)

Crushing/dissolving

Grinding / fiberizing

Filtration / Separation

Cleaning, Screening

Ink and toner released in flotation process, further cleaned to create white pulp

steps in the paper recycling process? (5)

chemicals used in recycled pulp production

hydrogen peroxide

sodium hydroxide

sodium metabisulfite

???

what makes recycled paper more sustainable?

aerobic

is composting aerobic or anaerobic?

mesophilic bacteria break down cellulose into glucose

thermophilic higher degree bacteria and fungi take over

hyperphilic this is where pathogens and seeds are destroyed. Complex carbs are fully broken down, and some proteins decompose.

slowly return to mesophilic.

Curing, compost is allowed to come back to ambient temperature and is sifted / ground to soil sized particles

process for composting (windrow)?

aerobic process that does not produce harmful gases like landfills (anaerobic process) do

why is compost desired for food waste?

static pile with passive aeration

static pile with aeration

windrow

in-vessel

vermicomposting

biosolid composting

different methods of composting (6)

static pile with passive aeration

warm air (from microbial activity) is directed upwards out of the pile, while cool air is sucked in through the sides

static pile with aeration

Air is forced through the compost pile with blowers (often “reverse aeration where air is brought down from the top of the pile to mitigate against moisture loss)

windrow

long piles of compost continually turned to increase aeration. Pile turning used to set different temperature profiles. (6 weeks)

in-vessel

use of enclosed space or drum for composting. Mechanical agitation is often used to increase aeration

vermicomposting

Use of earth-worms to create rich soil amendment material

biosolid composting

wastewater treatment plants collect solids after filtration.

The solids need to be treated to destroy harmful pathogens.

Composting has been found to be an effective tool for turning biosolids into nutrient rich soil amendment.

Industrial vs. home composting

Contamination of compost with microplastics and PFAS

Slower rate of composting of some “certified” biodegradable products.

Lack of access to industrial composting

challenges of composting a package?

biodegradation

disintegration testing

visual inspection

respirometry test

how is compostability measured?

BPI

Compost manufacturing alliance

TUV OK

how is compostability certified?

BPI

Currently only has commercial composting certification

Compost manufacturing alliance

Uses disintegration testing to certify compostability

TUV OK

European certification for home composting

labels used for composting