Session #2: Alginate Impression Material & Dental Stone

1/36

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

37 Terms

What is the purpose of impression materials

Used to make accurate replica of hard + soft oral tissues

Impression= negative reproduction of tissue

Dental stone/other material=positive cast

Impression vs. cast

Impression= carried to mouth in unset condition in tray & applied to area under tx

When set, it is then removed from mouth with tray

Cast= made by filling impression with dental stone/other model material

What is important for impressions

Accuracy, detail, quality of final replica= vv imp

Clinical impression technique & production of cast vary with each impression material

Desirable Qualities of impressions

Pleasant odor, taste, colour

Absence of toxic + irritant constituents

Adequate shelf life

Economically feasible with results obtained

Easy to use

Setting characteristics that meet clinical requirements

Satisfactory consistency + texture

Readily wets oral tissues

Elastic properties= easy removal + recovery

Adequate strength to prevent breaking/tearing upon removal

Dimensional stability over temp + humidity ranges

Compatibility with cast + die materials

Accuracy in clinical use

Readily disinfected w/out loss of accuracy

Impressions- Setting Mechanism

Irreversible

Most of the case

Reversible

Hydrocolloid

No longer acceptable bcs in past, reused material on clients

Impressions- Mechanical Properties

Elastic

Needs to be resilient, want it to be able to deform + take it out and retain its original dimensions after it is removed

Inelastic

What are some impression materials

Elastomeric materials: ***For high accuracy impressions, copies vv thin pits & fissures and gingival sulcus

Polysulfide

Polyether

Condensation silicone

Addition silicone

Hydrocolloids

Reversible

were available

Irreversible

typical alginate

Impression plaster

Impression compound

Zinc Oxide-Eugenol (ZOE) impression paste

Hydrocolloids

Reversible (Agar)

Gel/jelly type material

Physical change induced by temp

Irreversible (Alginate)

What are hydrocolloids

Substance that is microscopically dispersed uniformly throughout another substance

Tiny particles

Consist of 2 separate phases

Dispersed phase (powder)

Dispersion phase (water-hydrocolloid)

Size of colloid particles range from 1-20nm

Vv small particle = more reactive

Smaller also tend to form clusters-harder to mix

***Alginate= only one u use water for other pastes just hand mix

When taking impressions

What is the composition of alginate

Potassium alginate= dissolve in water + react with calcium ions

Calcium sulfate= react with potassium alginate to form insoluble calcium alginate gel

Sodium phosphate= react with calcium ions, provide WORKING TIME bfr gelation

Potassium titanium fluoride= counteract inhibiting effect of hydrocolloid on fluoride, silicates, borates setting on gypsum

Prevents fluoride, silicates, borates from preventing setting of hydrocolloid

Diatomaceous earth: control consistency of mixed alginate + flexibility of set impression

Zinc oxide: filler particles

Controlling setting time

Best regulated by amnt of retarder added during manufacturing process

Manufacturers make both fast setting (1.5-3 min) & normal setting alginate (3-4.5min)

Higher water temp-= shorter setting time

HEAT IS CATALYST FOR CHEMICAL RXNS

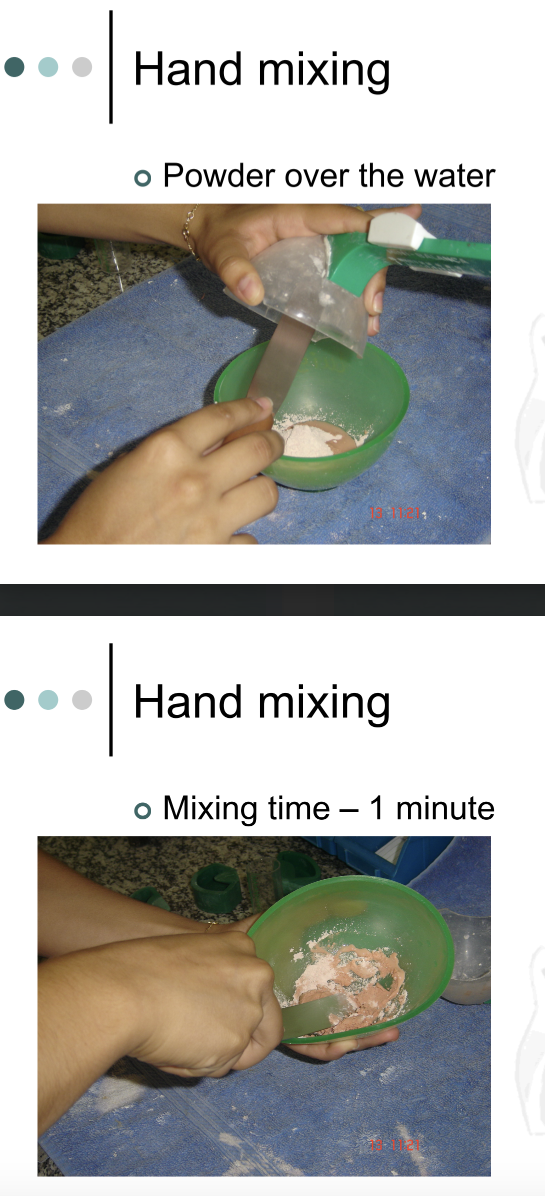

Mixing alginate

Pre-measure powder + water

Add + incorporate powder slowly to water

Avoid incoporating excessive air bubbles

Mix= vigorously + wipe against bowl

All powder must be incorporated

Critical Q: Why is it esp imp to add water to rubber mixing bowl bfr adding powder when mixing alginate impression material

Prevents Clumping:

If the powder is added first, water cannot evenly coat the particles, leading to dry clumps that are difficult to mix.

Ensures Even Hydration:

Pouring water first allows the alginate powder to gradually absorb moisture, leading to a smoother, more uniform mix without air pockets.

Minimizes Air Incorporation:

Adding powder on top of water reduces the chance of trapping air bubbles, which can cause inaccuracies in the impression.

Better Control Over Consistency:

It helps maintain the correct water-to-powder ratio, ensuring optimal working time, setting time, and strength of the final impression.

If done incorrectly (powder first), you may end up with grainy, uneven, or weak impressions that compromise accuracy.

Hand mixing vs. menchanical

Hand= fast set or regular set

Follow instructions precisely for mixing time

Smooth + creamy mixture that does not drip off

Clean handling devices (spatulas + rubber bowls)

Consistent

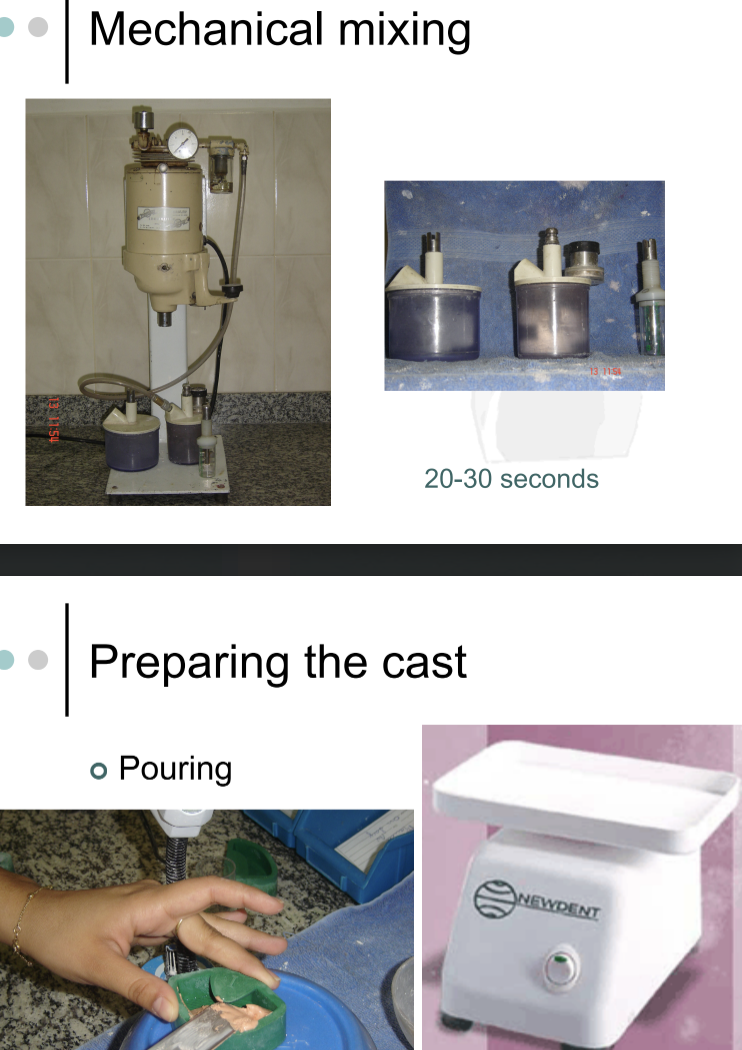

Mechanical mixing devices

Rotating mixture bowl

Mechanical mixer with time-control unit

Vacuum mixed for powder/water mixing

Dynamic mechanical mixer (for 2 paste alginate)

Convenience, speed, reduction of human error

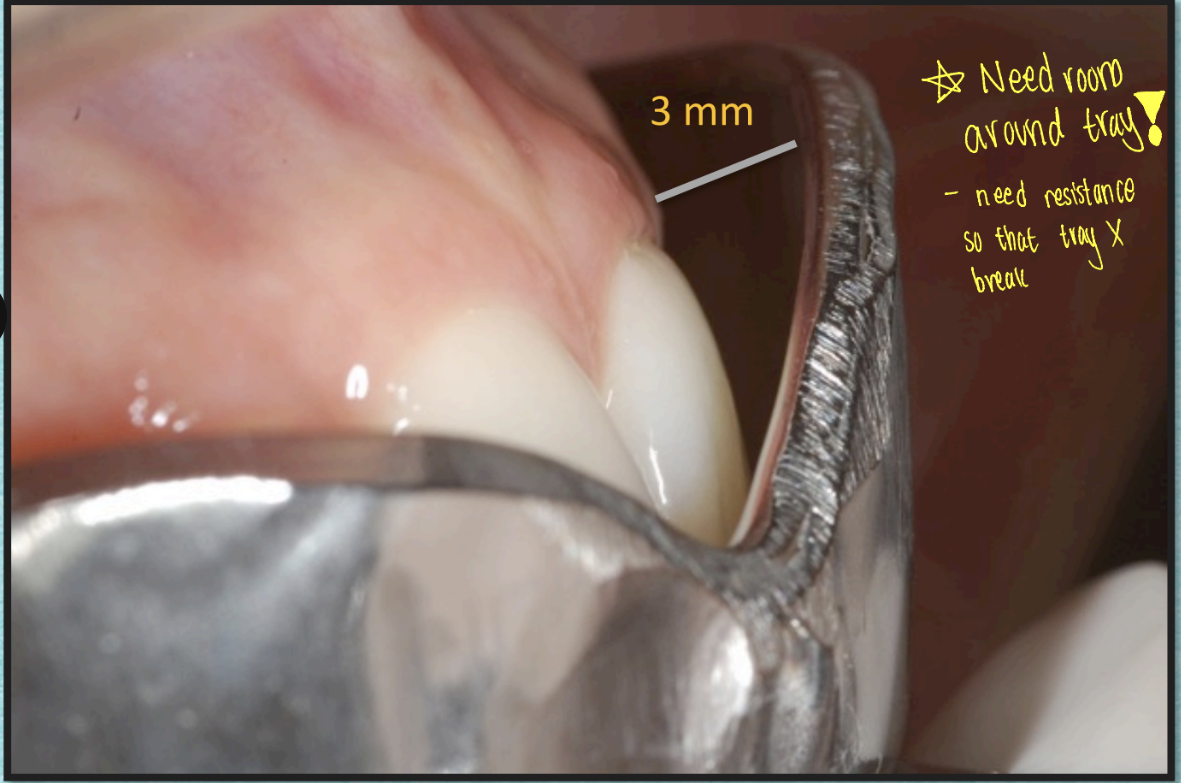

Taking alginate impression

Alginate must be retained on tray

Perforated metal trays= preferred

Alginate tray adhesive (don’t rlly need)

Alginate= weak material

Thickness of alginate b/w tray + tissue ~3MM

Need to store alginate where there isn’t much moisture

Removing alginate impression

Wait 3 min after gelation

Remove along vertical path with snap

Avoid torquing or twisting impression

Break air seal with minimal handle

Alginate strength

Follow manufacturer direction

Deviation can have adverse effect on gel strength

Water/powder ratio

Insufficient spatulation

Overmixing

Alginate shelf life

Storage temperature

Moisture contamination

Individually sealed bags

Less chance of contamination

Correct water/powder ratio ensured

Alginate properties-Dimensional stability

Syneresis-shrinking of alginate in air

Imbibition-expansion of alginate immersed in water

Ideal: 100% relative humidity=best storage environment to preserve normal water content of impression

Cover in wet paper towel & seal in bag

If pouring impression must be delayed

Should be rinsed in tap water, disinfected, wrapped in wet paper towel, placed in sealed plastic bag

Critical Q: How can distortion of hydrocolloid impression be minimized during storage

1. Immediate Pouring (Best Practice)

Pour the impression as soon as possible (within 10–15 minutes) to prevent dimensional changes due to water loss (shrinkage) or absorption (swelling).

2. Proper Moist Storage (If Delayed Pouring is Needed)

Store the impression in a 100% humidity environment by:

Wrapping it in a damp (not soaking) paper towel

Placing it in a sealed plastic bag or a covered container

This prevents dehydration (shrinkage) and excessive water absorption (swelling).

3. Avoid Immersing in Water

Never store the impression submerged in water, as it will absorb water and expand (imbibition), leading to distortion.

Alginate properties-Compatibility with Gypsum

Alginate impressions produce

Insoluble calcium alginate - gypsum retarder

Sodium sulphate - gypsum retarder

Polysaccharide - gypsum retarder

***Gympsum retarder= chemical added to material to slow down rxn

Surface of gypsum models prepared from alginate

***gypsum models made from alginate impressions may have surfaces that are too weak or easily damaged, making them unsuitable for use as dies or working casts in dental procedures.

Excess water on alginate surface= rough stone

Dried alginate surface= adherence of surface to cast

Surface of alginate should be shiny but should have no visible water when pouring

Alginate properties-Disinfection

Rinse impression thoroughly

Disinfect on exposed surface

Wrap impression in disinfectant-soaked paper towel & place in sealed plastic bag for 10 minutes

Rinse & remove excess water

Disinfect quickly to prevent dimensional change

Current protocol

Household bleach (1-10 dilution)

Iodophors

Synthetic phenols

Alginate properties-Accuracy

Most alginate impressions not capable of reproducing finer details observed in impressions with other elastomeric impression materials

But alginate materials= sufficiently accurate to make impressions for removable partial dentures

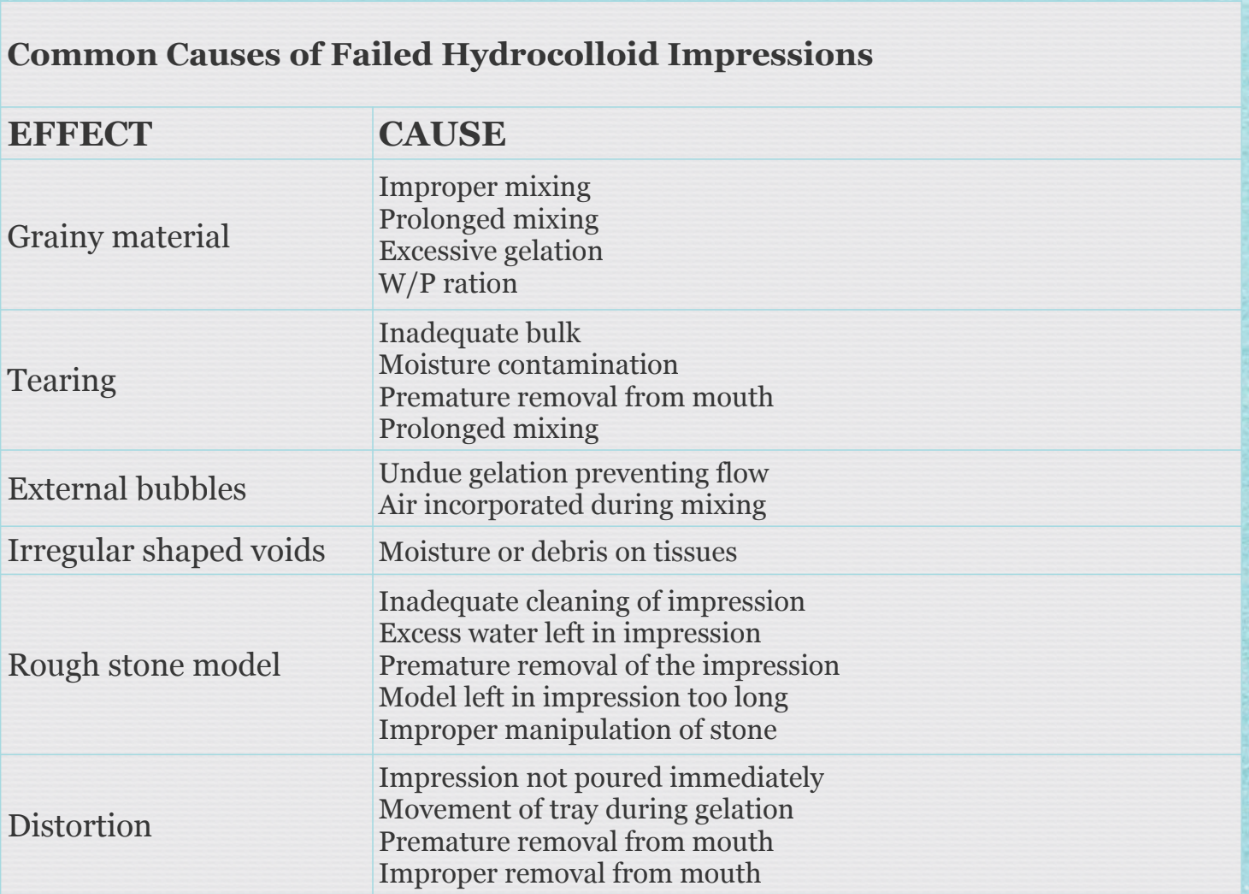

Alginate properties-Common cause of failed hydrocolloid impressions

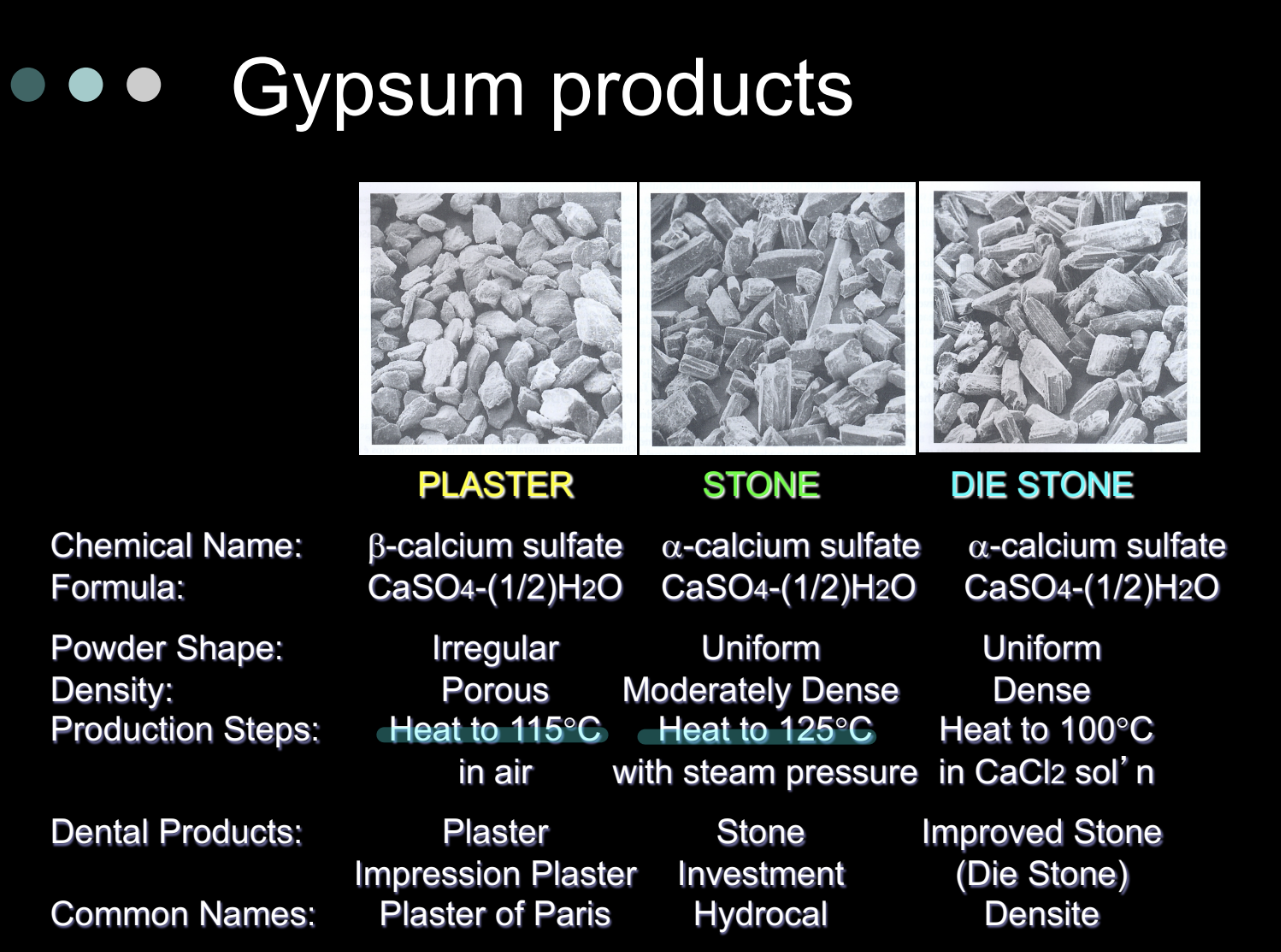

Gypsum products in dentistry

Plaster, stone (cast stone), improved stone (die stone), specialty stones, investment materials

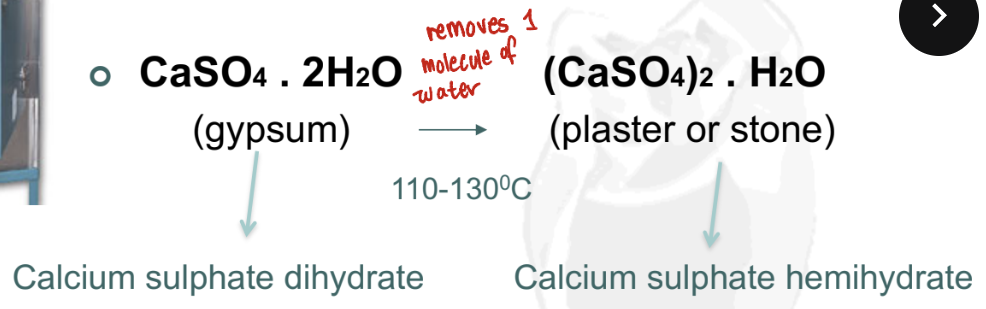

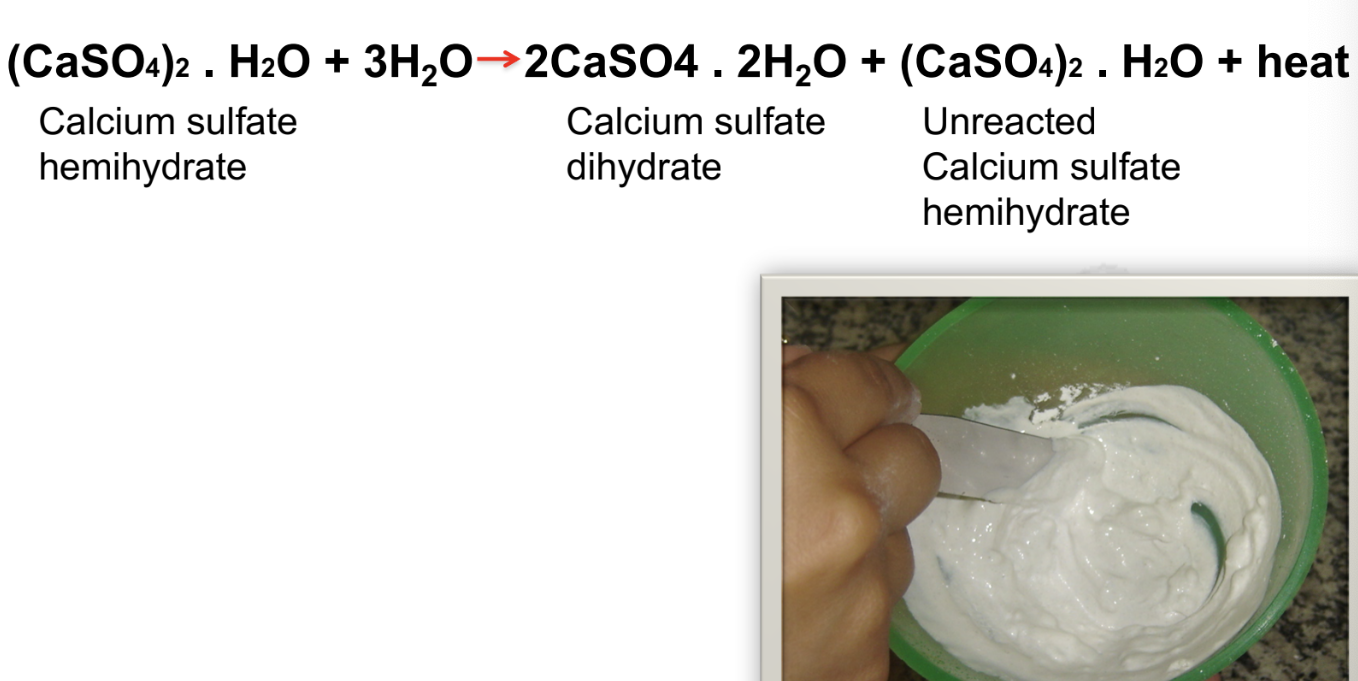

Gypsum = calcium sulphate, naturally occurs as dihydrate (CaSO4 & 2H2O)

What is calcination

Calcination=process of removing water of crystallization from calcium sulphate dihydrate

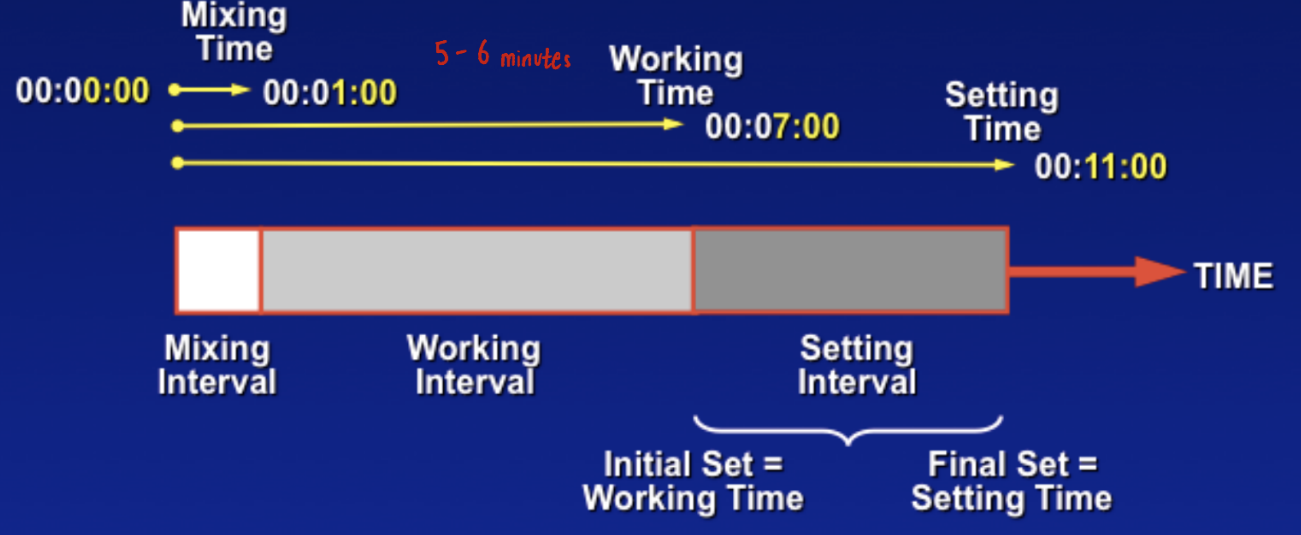

What is the setting mechanism of stone

Mixing time, working time, setting time

What affects setting time

Water to plaster ratio vv imp

Higher ratio= longer setting time

Mixing time, longer mixing time= more speed + NRG applied, shorter setting time

Particle size

Smaller particles in powder = shorter setting time will be

Modifiers for controlling setting time

Accelerators

Potassium Sulfate (K2SO4)-max 3.4%

Slurry water (like if u use murky water with a lot of minerals, the particles will act as nuclei of crystallization-harden plaster)

Sodium chloride- [2%']

Retarders

Sodium borate (Na3BO4)

Sodium chloride (high [ ])

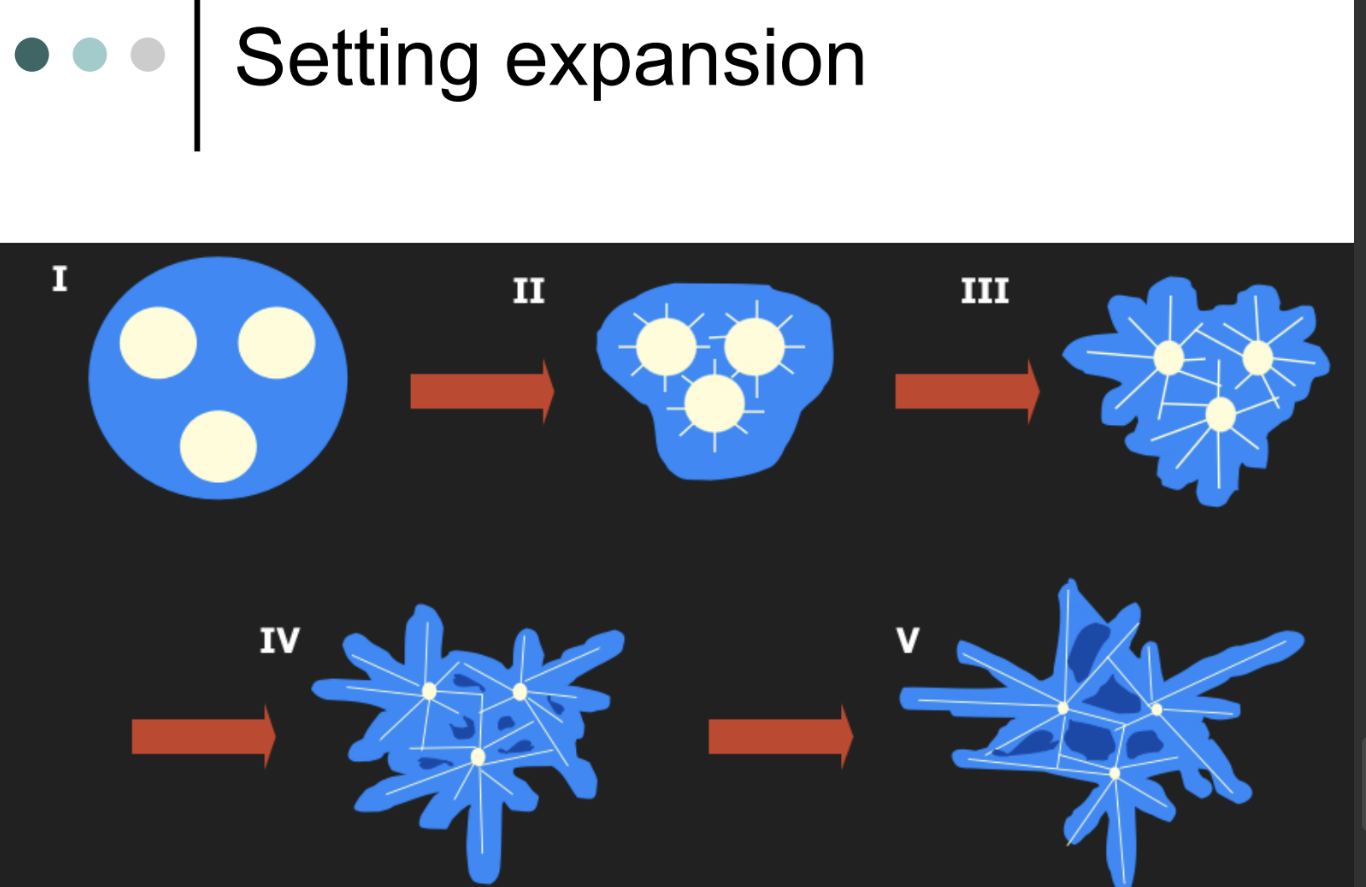

What does setting expansion look like

What are some factors that alter the strength of gypsum

W/P ratio

Mixing time

Accelerators + retarders

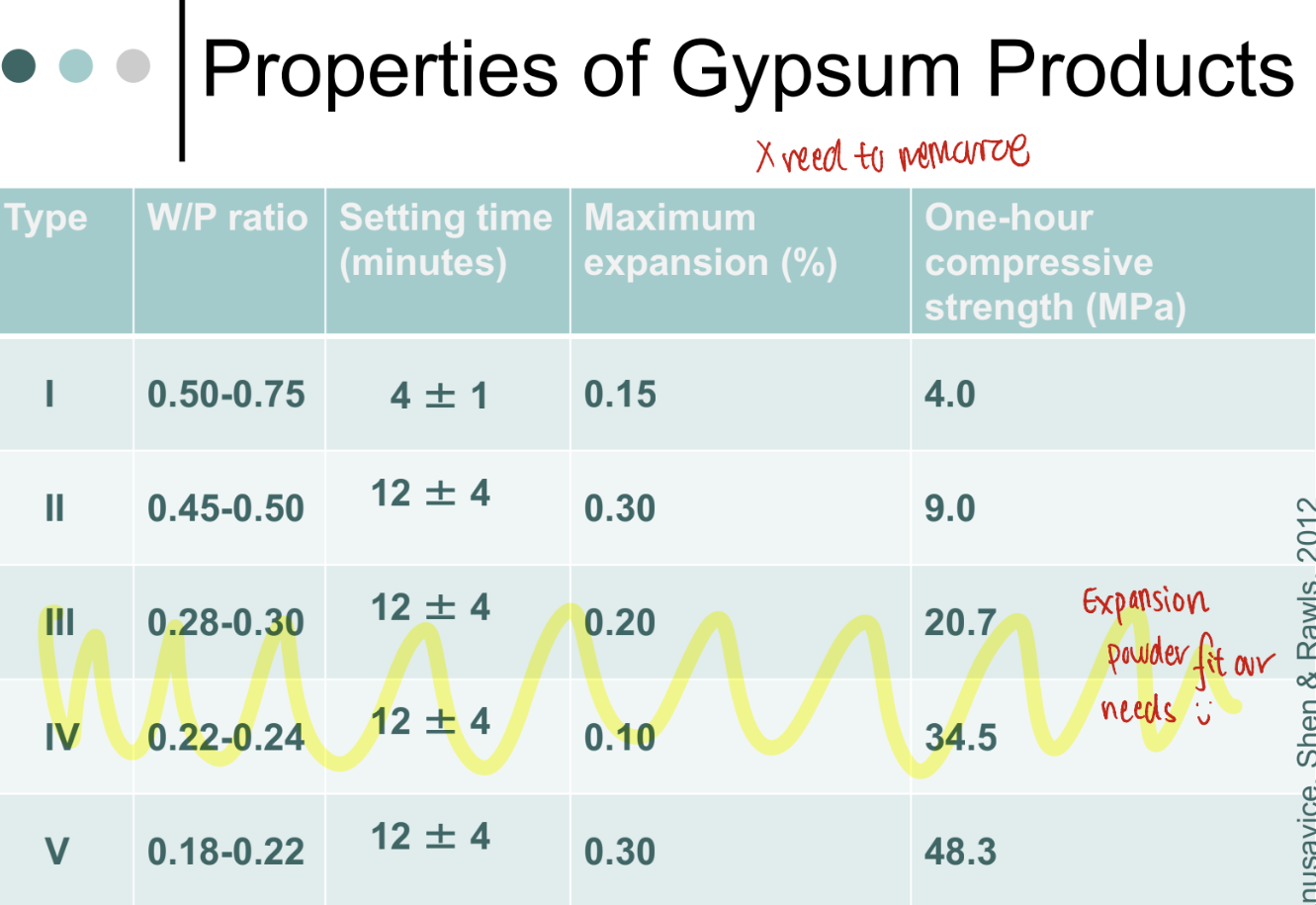

Types of gypsum products

Type I-Impression plaster

Type II-Model plaster

p weak

Type III-Dental stone

The ones we do

Type IV-Dental stone, high strength

Smaller particles

Type V-Dental stone, high strength, high expansion

How to mix gypusm products

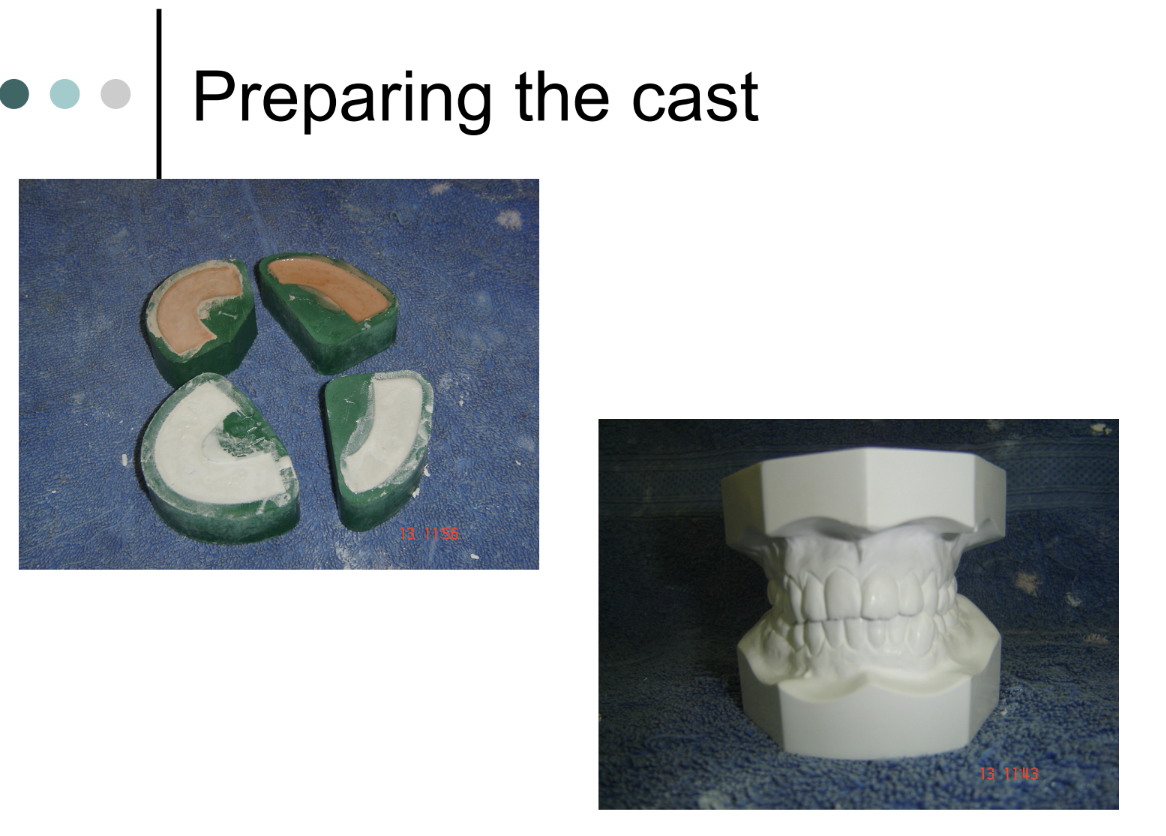

Preparing the cast

How to care of gypsum products

Imp that all gypsum products be stored in DRY atmosphere

If relative humidity 70%+ —> plaster starts setting reaction

Few crystals produced act as nuclei of crystallization & accelerates the setting rxn

How to care of cast

Wait at least 40 min for removal

Avoid contact with water

Do not expose cast to temperature higher than 55 degre