metals: light gauge steel framing

1/24

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

25 Terms

light gauge steel framing members

steel components are cold-rolled from steel sheet

light gauge steel framing uses

for structural, loadbearing framing and

exterior wall framing (subject to wind loads)for interior non-load bearing walls

c-studs and joists

wall studs, floor joists, roof rafters, etc.

depth: 1-5/8 to 12 in.

width: 1-1/4 to 2-1/2 in.

metal thickness” 0.018 to 0.097 in. (18 to 97 mils)

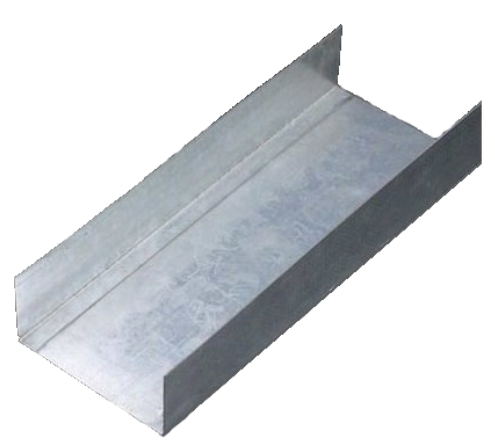

tracks

top and bottom of wall framing; ends of floor framing

analogous to wall plates and rim joists in light wood frame construction

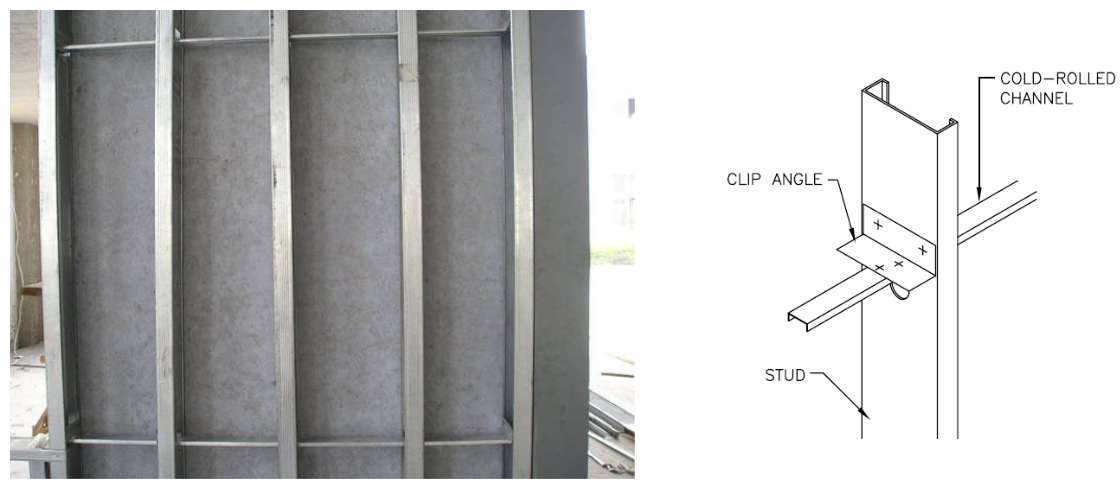

channels

bridging, blocking, and other reinforcing and bracing

also called cold-formed channels

standard sizes:

depth: ¾ to 2-1/2 in.

width: ½ in.

furring

used for bridging, backing, furring

also called hat channels

standard sizes

depth: 7/8 or 1-1/2 in.

width: 1¼ in. at raised surface, 2½ in. at base

L-headers

used for simplified header construction in bearing wall openings.

break-formed angles (sheet metal bent in fabricator's shop to the specified size)

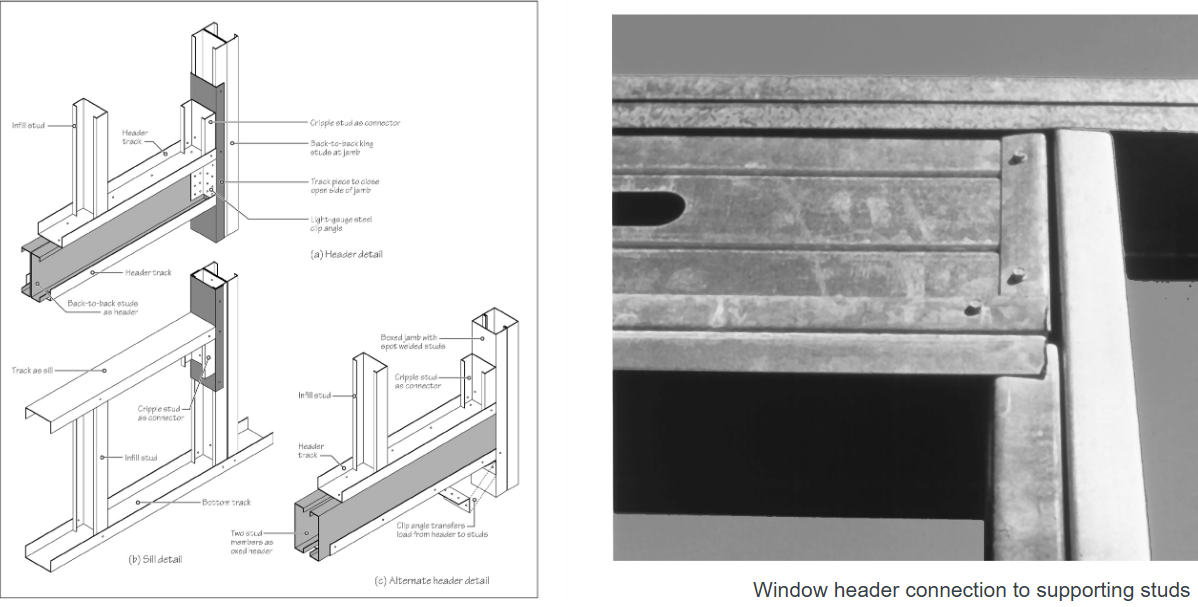

header (top), jam (sides), sill (bottom)

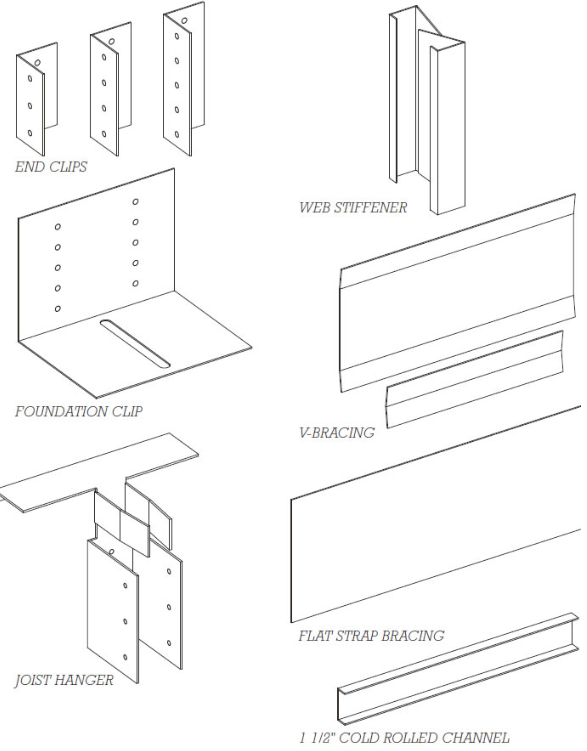

framing accesories

various sheet metal clips, stiffeners,

bracing, and hangers are used to make

connections and reinforce framing

slip track

top track with extended legs and slotted holes

allows fastening of nonloadbearing studs to track while permitting deflection in the track

deflection in the slab above does

not impart unintended loads into

the wall framing.

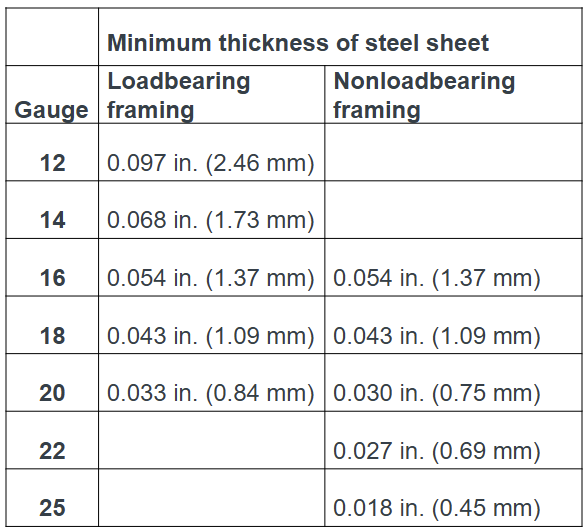

sheet metal thickness

thicker members are stronger and stiffer, but also heavier and more expensive

traditionally expressed as gauge (or gage), with lower numbers corresponding to thicker metal

cutting light gauge sheet metal

tin snips (aviator's snips): quiet,

clean, slower than power methodspower shears

power saw with abrasive or

carbide-toothed bladetorch cutting

brake lathe

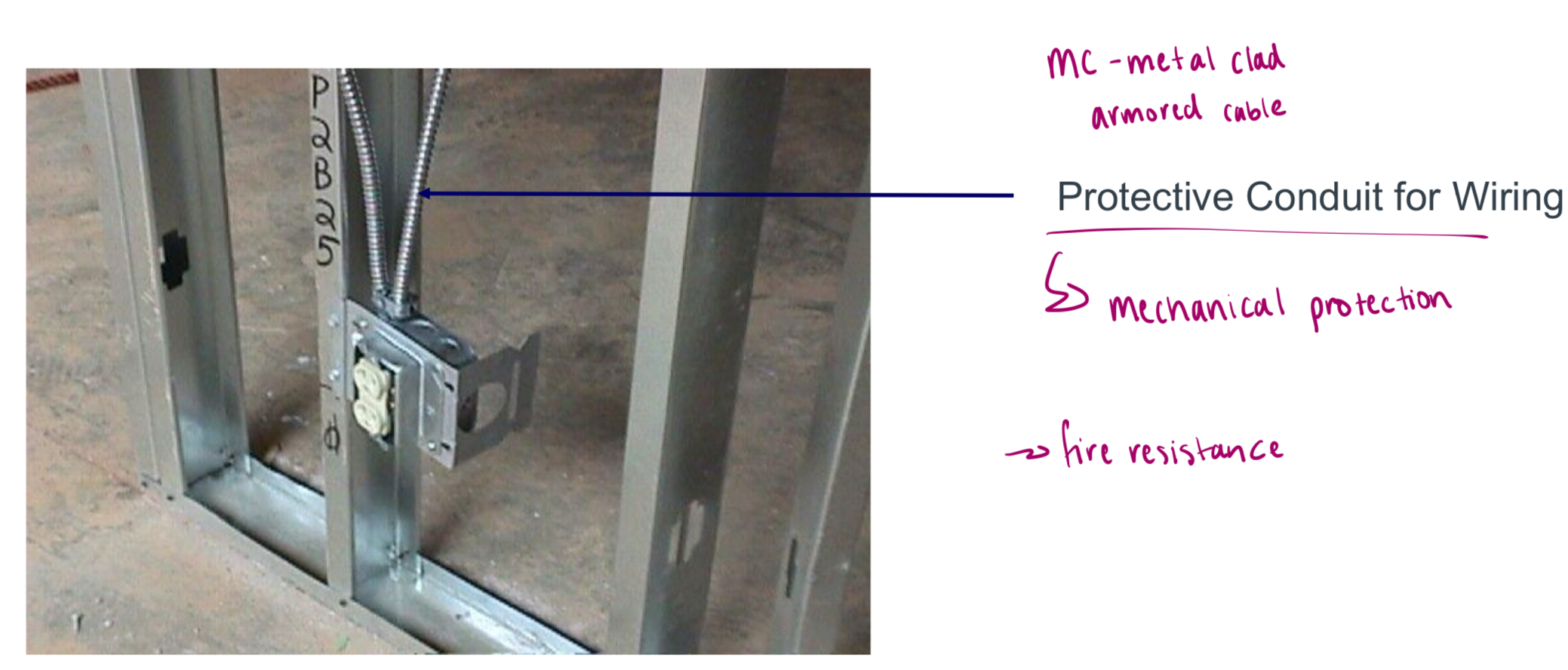

fastening

self-drilling, self-tapping screws are most common

crimping tools mutually deform parts to be joined

nail-like pins are power-driven

welded joints can have higher strengths but are more labor intensive to make than mechanically fastened joints

welding is best suited to thicker sheets that are less susceptible to melt-

through (burn through) than thinner sheets

framing

framing methods parallel wood light frame platform construction

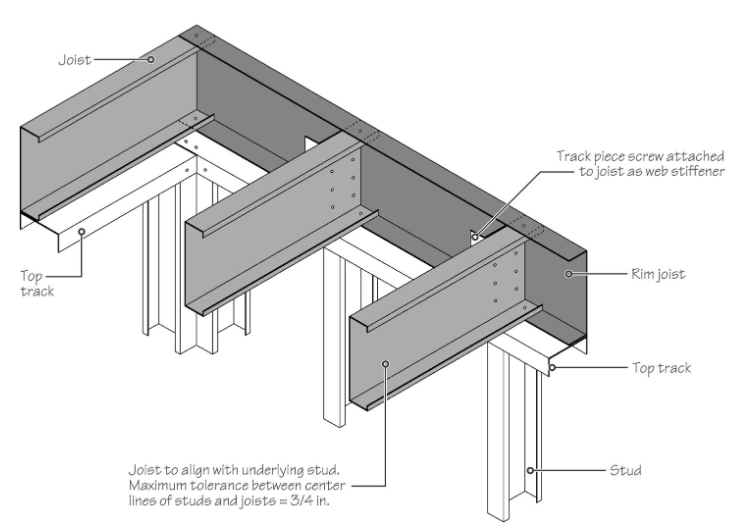

steel joists spaced from 12 to 24 in. O.C. (on centre) are framed into tracks or

channels

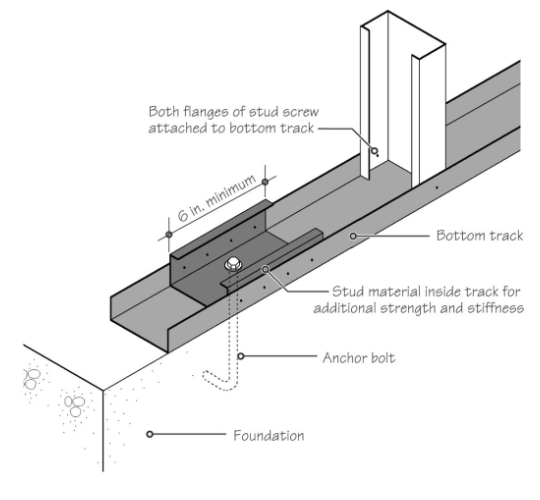

anchorage detail: wall to foundation

in pic

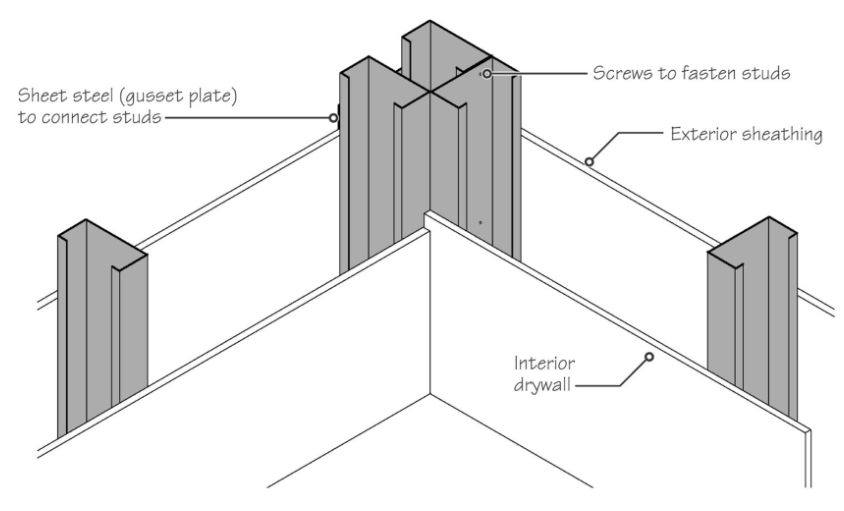

configuration at corner

in pic

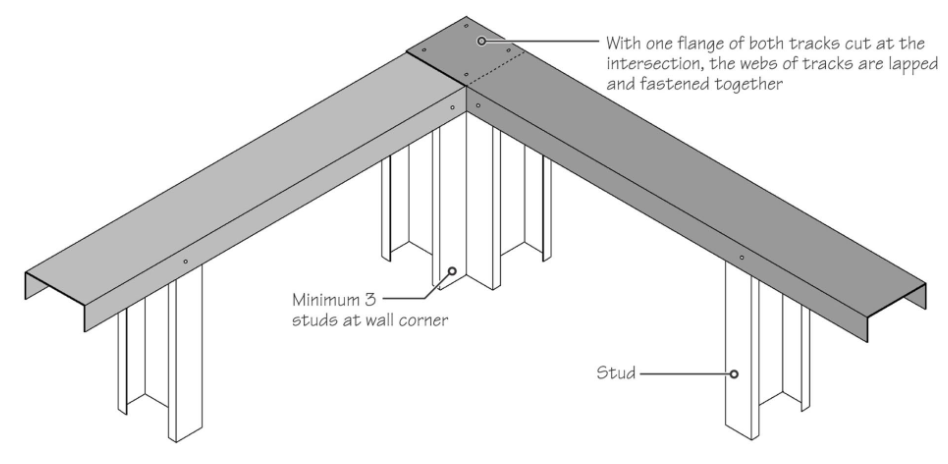

intersecting tracks at top corner

in pic

details: header and sill

in pic

floor joists

in pic

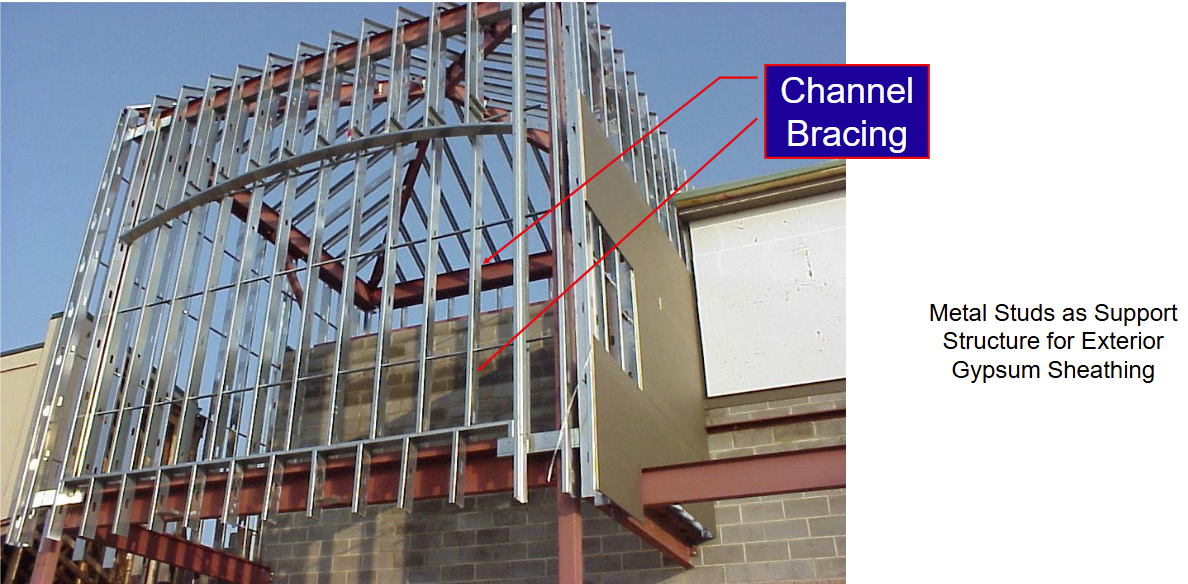

bracing

The slender steel members require bracing at regularly spaced intervals to reduce the tendency to buckle

wall framing details

in pic

exterior wall

steel shelf pic

exterior wall pt. 2

brick veneer pic

exterior wall pt. 3

channel bracing pic

advantages compared to light wood framing

versatile, flexible, simple to construct

noncombustible (not prone to catching fire) and immune to insect attack and mold

dimensionally stable, with consistent

material propertieslighter weight

disadvantages compared to light wood framing

members require more frequent bracing

non-renewable

readily conducts heat, susceptible to corrosion