TPM MODULE 2

1/102

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

103 Terms

MAINTENANCE

all activities that maintain facilities and equipment in good working order so that a system can perform as intended

GOAL OF MAINTENANCE 1

To keep production systems in good working order at minimal cost

GOAL OF MAINTENANCE 2

Reasons for maintenance: To avoid production or service disruptions, To not add production or service costs, To maintain high quality, To avoid missed delivery dates

HIDDEN LOSSES (VISIBLE COST)

Labor

Materials

HIDDEN LOSSES

Breakdowns

Operability

Restart Losses

Poor Integrity

Plan Trips

Reduced Throughput

Poor Quality

Low Morale

HOW MAINTENANCE IS PERFORMED

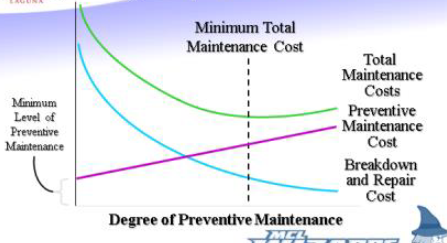

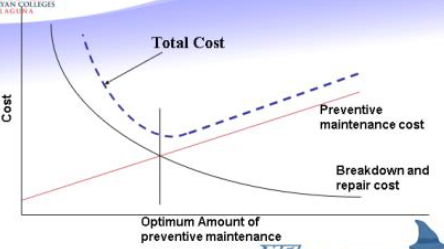

Preventive maintenance cost less and faster the more we move to the left

Competence is higher as we move tot he right

TRADEOFF BETWEEN REPAIRS AND PM

TOTAL MAINTENNCE COST

REPAIR PROGRAMS OBJECTIVE 1

Get equipment back into operation as quickly as possible.

REPAIR PROGRAMS OBJECTIVE 2

Control cost of repairs crews

REPAIR PROGRAMS OBJECTIVE 3

Control cost of the operation of repair shops

REPAIR PROGRAMS OBJECTIVE 4

Control the investment in replacement spare parts.

REPAIR PROGRAMS OBJECTIVE 5

Control the investment in standby or backup machines.

REPAIR PROGRAMS OBJECTIVE 6

Perform the appropriate amount of repairs at each malfunction.

BREAKDOWN PROGRAMS 1

Standby or backup equipment that can be quickly pressed into service

BREAKDOWN PROGRAMS 2

Inventories of spare parts that can be installed as needed

BREAKDOWN PROGRAMS 3

Operators who are able to perform minor repairs

BREAKDOWN PROGRAMS 4

Repair people who are well trained and readily available to diagnose and correct problems with equipment

REPLACEMENT TRADE OFF DECISIONS 1

Cost of replacement vs cost of continued maintenance

REPLACEMENT TRADE OFF DECISIONS 2

New equipment with new features vs mtce

REPLACEMENT TRADE OFF DECISIONS 3

Installation of new equipment may cause disruptions

REPLACEMENT TRADE OFF DECISIONS 4

Training costs of employees on new equipment

REPLACEMENT TRADE OFF DECISIONS 5

Forecasts for demand on equipment may require new equipment capacity

INCRASING REPAIR CAPABILITIES 1

Well-trained personnel

INCRASING REPAIR CAPABILITIES 2

Adequate resources

INCRASING REPAIR CAPABILITIES 3

Ability to establish repair plan and priorities

INCRASING REPAIR CAPABILITIES 4

Ability and authority to do material planning

INCRASING REPAIR CAPABILITIES 5

Ability to identify the cause of breakdowns

INCRASING REPAIR CAPABILITIES 6

Ability to design ways to extend MTBF

Repairs often performed on an emergency basis to:

Minimize interruptions to production

Correct unsafe working conditions

Improve product/service quality

In emergency situations:

Specialists may work overtime

Supervisor/engineers are nearby to collaborate

Standby machines may be quickly put in operation

EQUIPMENT BREAKDOWN ACTION 1

Fast repair of the malfunction equipment

EQUIPMENT BREAKDOWN ACTION 2

Development of a program to eliminate cause of the malfunction and need for such repairs in the future

PROGRAMS TO ELIMINAT BREAKDOWNS 1

Modification/redesign of malfunctioning machine; and part or product being processed

PROGRAMS TO ELIMINAT BREAKDOWNS 2

Training of operators to improve machine care

PROGRAMS TO ELIMINAT BREAKDOWNS 3

More frequent preventive maintenance/inspection

EXTENT OF REPAIRS 1

Do just enough repairs to get equipment running again.

EXTENT OF REPAIRS 2

Repair the malfunction and replace some parts that are worn.

EXTENT OF REPAIRS 3

Perform a major overhaul of the equipment

EXTENT OF REPAIRS 4

Replace the old equipment with new.

Determining the size of repair crews 1

This is one repair-capacity decision

Determining the size of repair crews 2

Queuing analysis is often used

Determining the size of repair crews 2

Computer simulation is used when the assumptions of queuing formulas do not apply

Determining the number of standby machines to have

Trade-off between cost of lost production time and cost of machine storage, handling

Advantages of Letting Workers Repair their own Machines

Greater variety may make job more satisfying

May be more sensitive to potential malfunctions

Increase flexibility

Can make minor repairs faster

Can avoid minor repairs by cleaning, lubricating, adjusting and servicing machines

Operate machines more carefully

Reasons for PM Program

Reduce the frequency and severity of interruptions due to malfunctions

Extend the useful life of equipment

Reduce the total cost of maintenance by substituting PM costs for repair costs

Provide a safe working environment

Improve product quality by keeping equipment in proper adjustment

Implementing Preventive Maintenance

Reduce the frequency and severity of interruptions due to malfunctions

Extend the useful life of equipment

Reduce the total cost of maintenance by substituting PM costs for repair costs

Provide a safe working environment

Improve product quality by keeping equipment in proper adjustment

PM and Operation Strategies

PM program is essential to the success of a product-focused positioning strategy

On production lines, there are little if any in process inventories between adjacent operations. If a machine breaks down, all downstream operations will soon run out of parts to work on

Problems with Preventive Maintenance

Scheduled replacement or adjustment of parts/equipment with a well-established service life. Typical example – plant revamping

Sometimes misapplied, Replacing old but still

good bearings, Over-tightening electrical lugs in switchgear

Automation and the Prominence of PM

Many operations are slowly moving toward workerless production. We are seeing a shift from large to smaller production workforces

Along with this, we are seeing a shift from small to larger PM workforces. Production workers displaced by automation will need to be retrained to become PM workers

Scheduling PM Activities

PM and production are increasingly viewed as being equally important

In some plants, two 8-hour shifts are devoted to production and one 4-hour mini-shift is devoted to PM. In other plants, three shifts are used for production, but time allowances are factored into production schedules for PM activities

Maintenance Scheduling

Scheduling refers to timing and sequences of operations.

It is an important segment of the production planning & control activity as well as the service operations like plant maintenance

Importance of Scheduling 1

Facilitates optimum use of highly paid maintenance staff

Importance of Scheduling 2

Equipment can be utilized effectively

Importance of Scheduling 3

Eliminates undue interruptions in the production flow

Importance of Scheduling 4

Eliminates chances of sudden breakdown

Importance of Scheduling 5

Facilitates proper sequence in maintenance service

Determining the Frequency of Performing PM

First, compute the expected number of breakdowns for each PM policy.

Next, compute the expected breakdown cost, preventive maintenance cost, and total cost for each PM policy.

Finally, identify the policy that minimizes the total cost per unit of time (say, per week).

PM Database Requirements

Detailed records, or an ongoing history, must be maintained on each machine: Dates and frequency of breakdowns, Descriptions of malfunctions, Costs of repairs

Machine specifications/checklists for PM inspection. Computers generally used to maintain a database. Also, data can be kept in plastic pocket on a machine

Modern Approaches to PM

PM at the source - workers have the fundamental responsibility for preventing machine breakdowns by conducting PM on their own machines

Workers listen for indications of potential equipment malfunction. Maintenance-related records maintained by workers

Use of quality circles

Decision Analysis in PM (3 decisions in particular) 1

Determining the number of spare parts to carry

Decision Analysis in PM (3 decisions in particular) 2

Determining how often to perform PM on a group of machines

Decision Analysis in PM (3 decisions in particular) 3

Planning and controlling a large-scale PM project

Large-Scale PM Projects

Large-scale projects occur commonly in maintenance departments.

Banks of machines, whole production departments, and even entire factories are shut down periodically to perform PM.

The number and diversity of the PM tasks that must be performed can be great. PM is a useful way to plan and control large-scale maintenance projects.

Service Organizations

Maintenance issues are not limited to manufacturing

Transportation firms (airlines, railways, haulage, dispatch companies, etc) must maintain vehicles in good operating condition

Highways Department must maintain roads

Office personnel are reliant on computers, printers, copiers and fax machines working properly

As services become increasingly automated, service firms face more and more maintenance issues

TRENDS IN MAINTENANCE 1

Production machinery is becoming more and more complex and maintenance personnel must keep pace

TRENDS IN MAINTENANCE 2

Special training programs to maintain worker skill level

TRENDS IN MAINTENANCE 3

Subcontracting service companies

TRENDS IN MAINTENANCE 4

Production workers maintain own equipment

TRENDS IN MAINTENANCE 5

Computer assistance in maintenance

OVERALL EQUIPMENT EFFECTIVENESS 1

The goal of Total Productive Maintenance (TPM) is to increase equipment effectiveness so that each piece of equipment can be operated to its full potential and maintained at that level.

OVERALL EQUIPMENT EFFECTIVENESS 2

To maximize equipment effectiveness, you need a measurement tool that can help you understand your equipment problems so that you can take steps to eliminate them.

OEE (OVERALL EQUIPMENT EFFEECTIVENESS) 1

is a “best practices” way to monitor and improve the efficiency of your manufacturing processes: (a) machines, (b) manufacturing cells, (c) assembly lines

OEE (OVERALL EQUIPMENT EFFEECTIVENESS) 2

is a crucial measure in TPM that tells you how well your equipment is running.

OEE (OVERALL EQUIPMENT EFFEECTIVENESS) 3

It is a composite metric that takes into account three factors

THREE FACTORS OF OEE

AVAILABILITY

PERFORMANCE

QUALITY

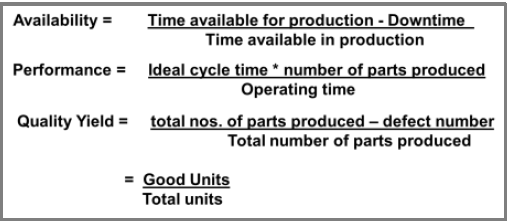

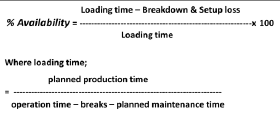

AVAILABILITY

the time the machine is actually running

Refers to the percentage of time the equipment is available for production. Downtime due to breakdowns, maintenance, and changeovers are considered losses.

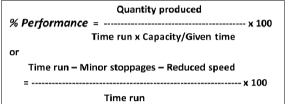

PERFORMANCE

the quantity of products the machine is turning out

Refers to the percentage of the actual production rate compared to the theoretical maximum rate. Factors that affect performance efficiency include operator performance, equipment speed, and defects.

QUALITY

the quantity of good output

Refers to the percentage of good quality products produced compared to the total number of products produced. Defects and rework are considered losses

TYPE OF EQUIPMENT LOSSES

BREAKDOWN LOSSES

MINOR STOPPAGE

QUALITY DEFECT AND REWORK LOSSES

START UPS AND YIELD

SET UP ADJUSTMENT LOSSES

BREAKDOWN LOSSES

Caused by equipment defects which require any kind of repair. (Examples: Tooling failures, Unplanned maintenance, General breakdowns, Equipment failure)

Losses consist of downtime with labor and spare parts required to fix the equipment. Magnitude is measured by downtime

MINOR STOPPAGE LOSSES

Caused by events such as machine halting, jamming, idling, misfeeds, blocked sensors, etc.

Generally, these losses cannot be recorded automatically without suitable instrument

QUALITY DEFECT AND REWORK LOSSES

Caused by off-specification or defective products (e.g. Rework, Scrap)

Losses consist of labor required to rework the products and the cost of the material to be scrapped

Measured by the ratio of quality products to total production

Sometimes designated as “quality defects in process” in order to distinguish from defective products during start-up and adjustment operations

CALCULATING OEE

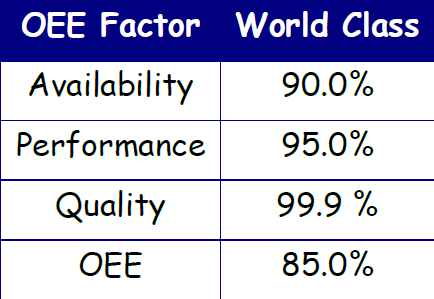

WORLD CLASS OEE

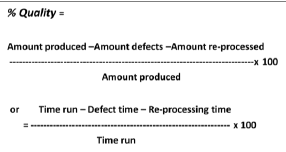

AVAILABILITY FORMULA

PERFORMANCE FORMULA

QUALITY FORMULA