Chapters 1 - 3 of Supply Chain Management

1/106

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

107 Terms

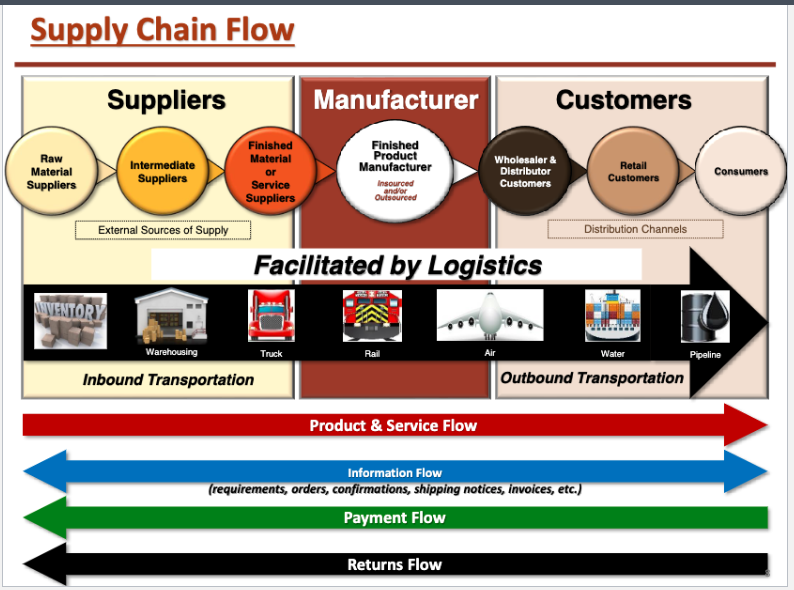

Supply Chain

includes the raw material and parts of a product that distributed through a chain for manufacturing and sales

Structure of Supply Chain

Suppliers, Manufacturers, to Customers

Products and Services are created by

materials

equipment

labor

time

money

resources

Three Links in Supply Chain

the three links in supply chain are

Suppliers

Manufacturers

Customers

every link in the supply chain is

Both a customer of the suppliers and a supplier to their customers

Supply Chain Flow

Tiers in Supply Chain

Tier 1 is direct, the lower the tier number, the more indirect it becomes

Supply Chain Management

the coordination of the network of otherwise independent trading partners who are creating a desired product or service, and then moving it through the supply chain out to customers

represents the active management of all supply chain activities to maximize customer value and achieve a sustainable competitive advantage.

Goals of Supply Chain

Increase Customer Service while simultaneously Reducing Inventory and Operating Expenses

Services in Supply Chain

Facilitating Goods are necessary

SCOR (Supply Chain Operations Reference)

a process reference model as the standard diagnostic tool for supply chain management

helps businesses evaluate and perfect supply chain management for reliability, consistency, and efficiency.

Four Major Components in SCOR

Performance

Processes

Practices

People

5 SCOR Performance Attributes

Reliability

Responsiveness

Agility

Cost

Asset Mangement

What do each trading partner have to do>

Plan

Source

Make

Deliver (Return)

Planning

establishes the parameters within which the supply chain will operate.

Companies need a strategy when it comes to managing the resources necessary to address how a product or services. Resources = Capacity, people, and money

Planning Includes: Marketing and Distribution Channels

Sourcing

the process of identifying the suppliers that provide the materials and services needed for the supply chain to deliver the final product

Making

the series of operations performed to convert raw materials and components into finished products

A finished product has to be

Tested

Packaged

Scheduled

Quality Management

Quality Levels

Production Output

Worker Productivity

Delivering

this is known as logistics phase; oversees the planning and execution of the forward flow of goods and related information to meet customer requirements

Return

this is known as the reverse logistics. the part of supply chain management that deals with moving goods back to the point of origin

Enabling

facilitates a company’s ability to manage the supply chain and spread throughout every stage.

Foundations of Supply Chain Management

Operations Management: managing internal resources

Supply Chain Management: managing all of the supplies and suppliers that are needed to run the business

Logistics Management: managing all the movement and storage of products and materials within the supply chain.

Integration: managing all of the enabling systems

Elements of Operations Management

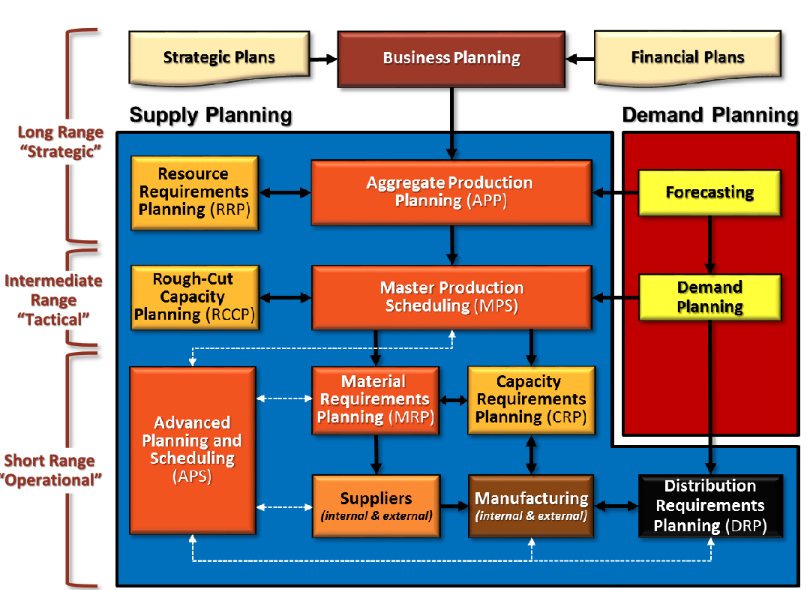

Forecasting & Demand Planning

Planning Systems

Inventory Managment

Manufacturing / Process Management

Forecasting & Demand Planning

forecasting the demand of a product or service so it can be delivered efficiently and satisfy customer needs

Planning Systems

the process of tools used to manage a company’s resources

Inventory Management

techniques used to plan and control the desired levels of items needed to support production

Manufacturing / Process Management

using LEAN Manufacturing to improve the flow of materials / waste. using Six Sigma to improve quality compliance

Elements of Supply Management

Purchasing

Strategic Planning

Supplier Relationship Management

Elements of Logistics Management

Warehousing

Distribution

Transportation

International Trade Management

Customer Relationship Management

Service Response Logistics

Integration Elements

Enabling Systems

Supply Chain Risk and Security Management

Performance Measurement

Project Management

Supply Chain Capability Models

Efficient Model (Supply Push)

Responsive Model (Demand Pull)

Efficient Model (supply push)

produce

a large amount of product

ASAP

lowest possible cost

Supply Push Business Model

Make to Stock

Responsive Model (Demand Pull)

configured to be

fast and flexible

respond quickly to dynamic market demand

Demand Pull Business

Make to Order

Demand Driven Supply Chain

Demand drives all the remaining supply chain activities

Supply - Driven Supply Chain

Supply Drives all the remaining supply chain activities

Examples of Supply - Driven Supply Chain

crude oil

natural gas

bananas

steel, copper, aluminum

two essential building blocks for supply chain planning activities

forecasting

demand planning

Forecasting

an estimate of future demand of products and is developed through data analysis and judgement

Demand Planning

the process of forecasting the demand for a product or service so it can be produced and delivered more efficiently and to the satisfaction of customers

Two Different Demands

Independent Demand: Demand for a finished good

Dependent Demand: Demand for a component

Forecasting Horizon

Short Term: less than three months; mainly used for tactical decisions like purchasing and production schedule

Medium Term: three months to two years

Long Term: greater than 2 years

Considerations of Forecasting

it is inaccurate

basis for most “downstream” supply chain planning decisions

Two Forecasting Techniques

Qualitative: based on opinion

Quantitative: based on math and data

Qualitative

used when there is data is limited, unavailable, or not currently relevant

best for long range forecasts

depends on skill

five qualitative techniques

personal insight

jury of executive opinion

Delphi Method

Historical Analogy

Customer Survey

Personal Insight

the forecast is based on the insight of the most experienced, most knowledgeable, or most senior person available.

Jury of Executive Opinion

people who know the most about the product and the marketplace would form a management panel to discuss and determine the forecast.

Delphi Method

collecting opinions and feedback from experts anonymously

Historical Analogy

based on the identifying a sales history that is comparable to a present situation, such as the sales history of a similar product

Customer Survey

customers are directly approached and asked to give their opinion about a particular product

Quantitative Forecasting Techniques

TIME SERIES

Naive Forecasting

Simple Moving Average

Weighted Moving Average

Exponential Smoothing

Linear Trend

CAUSE AND EFFECT

Simple Regression

Multiple Regression

Time Series

to collect and study the past data of a given time series in order to generate probable future values for the series

Naive Forecasting

sets the demand for the next time period to be exactly the same as the demand in the last period.

Simple Moving Average Forecasting

gets the average of sales.

Weighted Moving Average

gets the average of sales but not al time periods are valued similarly.

Formula for Weighted Moving Average

(M1 x W1)+(M2 x W2)+(M3 x W3)+(M4 x W4)+(M5 x W5)+(M6 x W6)

Exponential Smoothing

more sophisticated version of weighted moving average that includes

actual demand

last periods forecast

smoothing factor (between 0 and 1)

Formula for Exponential Smoothing

(Actual x Smoothing) + (Forecast ( 1 - Smoothing )

Linear Trend Forecasting

imposes a best fit line across demand data of an entire time series

Cause and Effect Forecasting

assumes there are one or more factors that predict future demand

Simple Linear Regression

attempts to model the relationship between a single independent variable and a dependent variable (demand) by fitting a linear equation to the observed data.

Multiple Linear Regression

attempts to model the relationship between two or more independent variables and a dependent variable (demand) by fitting a linear equation to the observed data

Fundamentals of Forecasting

Your Forecast is most likely wrong

the more “granular” the forecast, the less accurate it is

it is easier to forecast next month more accurately than it is to forecast next year

Simple Forecast Methods Trumps Complex Ones

A correct forecast does not prove your forecast method is

correct

If you don’t use the data regularly, trust it less when forecasting

All trends will eventually end

Forecasts are Bias

Technology is not a solution for better forecasting

Forecasting is an art and science

Optimal Demand Planning Requires

comprehensive modeling capabilities

the flexibility to shift methods as product life cycles progress and market conditions change

Forecast Error Value and Percentage

Forecast Error Value: A - F

Forecast Error % : (A-F) / A x 100

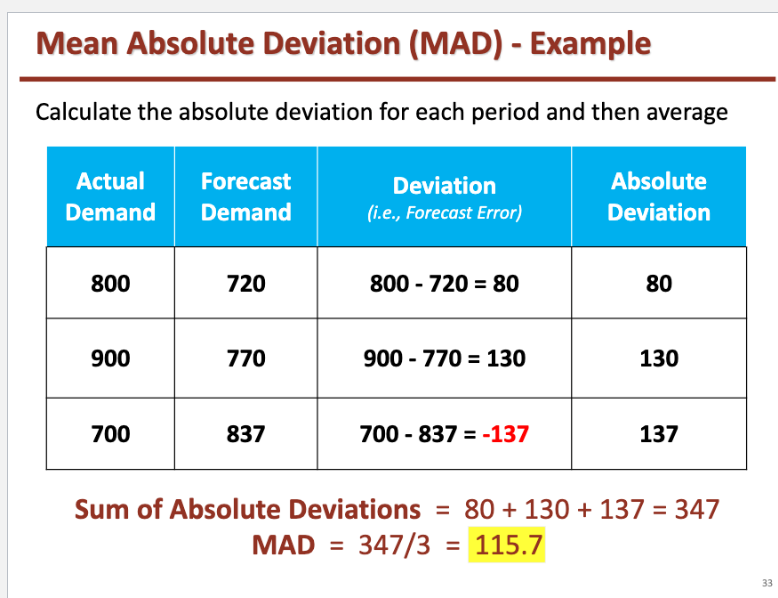

MAD (Mean Absolute Deviation)

size of the forecast error in units

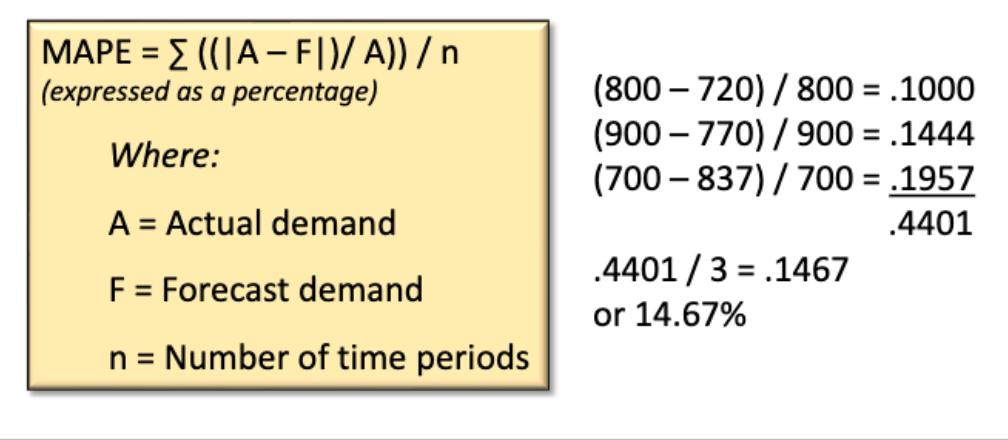

MAPE: Mean Absolute Percent Error

measures the size of the error in percentage terms. It is calculated as the average of the unsigned percentage error.

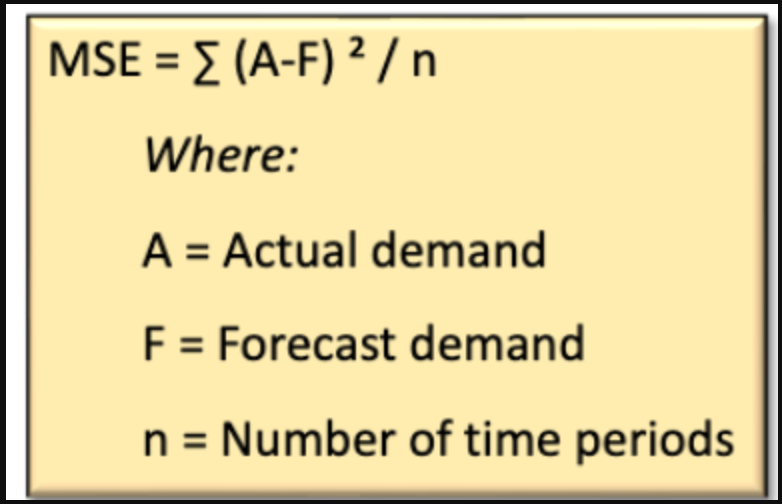

Measures of Forecasting Accuracy (MSE)

magnifies the errors by squaring each

one before adding them up and dividing by the number of forecast

periods.

Forecast Bias

∑ Forecast Error = ∑ Actual Demand – ∑ Forecast Demand

Running Sum of Forecast Errors

RSFE = ∑ et

Where: et = forecast error for period t

Tracking Signal

Running Sum of Forecast Errors / Mean Absolute Deviation

Bullwhip Effect

occurs when small fluctuations in retail demand cause fluctuations in wholesale, distributor and manufacturer demand, resulting in inefficiency and disorganization throughout the supply chain.

How Can the Bullwhip Effect be Alleviated?

Collaboration

Synchronizing the supply chain

Reducing Inventory

Collaborative Planning, Forecasting, and Replenishment (CPFR)

a business practice that combines the intelligence of multiple trading partners who share their plans, forecasts, and delivery schedules with one another in an effort to ensure a smooth flow of goods and services across a supply chain

Supply Chain Planning

the function within SCM that is responsible for determining how best to satisfy the requirements created by a Demand Plan

its objective is to Balance Supply Chain and Demand that benefits the company financially and objectively

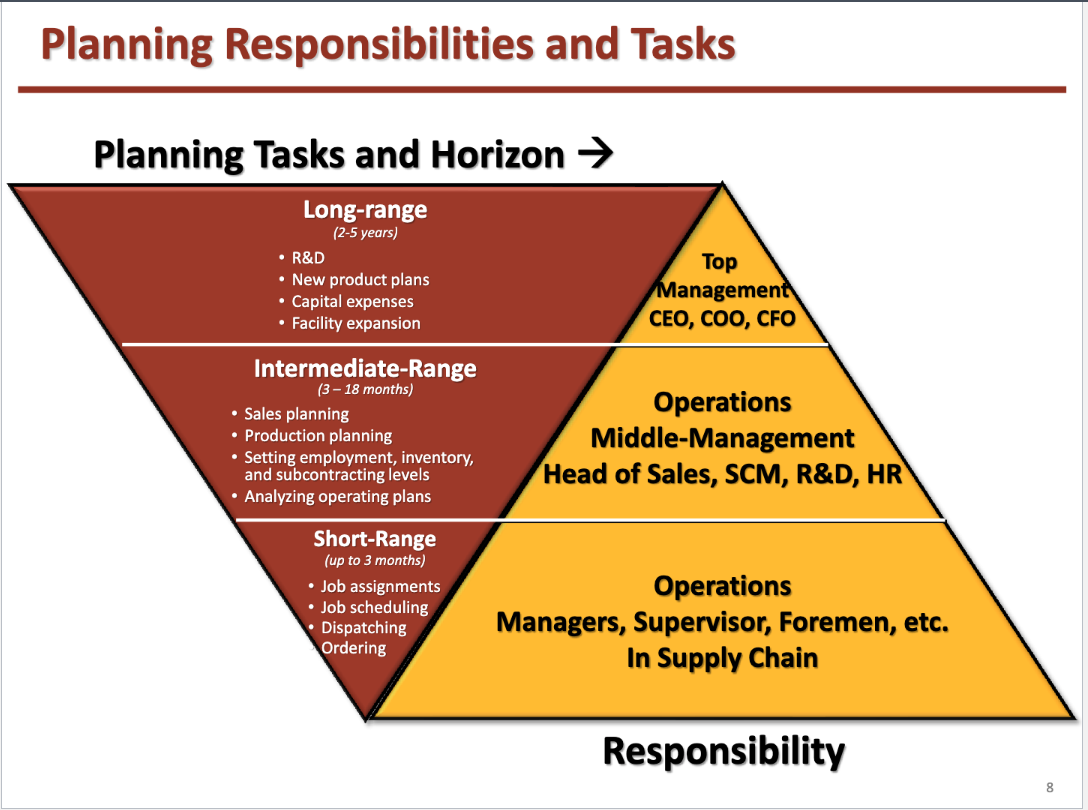

Supply Chain Hierarchy

Supply Chain Levels and Horizons

Long Range: involves planning actions for construction, major equipment purchase

Intermediate Range: shows the quantity and timing of end items to be produced in 3- 18 months

Short Range: detailed planning process of components and parts in 1 - 3 months

Planning Responsibilities and Tasks

Business Planning

provides the companies direction and business goals for the next one to five years.

Whats in a Business Plan

Executive Summary

Business Description

Market Analysis

Products and Services

Marketing Plan

Logistics and Operations Plan

Financial Plan

Aggregate Production Plan (APP)

a planning process that translate annual business plans, marketing plans, and demand forecasts into a production plan for a product family in a plant or facility.

Steps to Develop the Aggregate Production Plan

Determine the demand for each period

Determine the capacity

Identify any constraints

Determine the direct labor and material costs and indirect manufacturing costs

identify and develop strategies and contingency plans

agree on plan

Aggregate Planning - Purpose and Goals

establish production rates that will achieve goals by maintaining, raising, lowering inventories, while keeping workforce relatively stable

Aggregate Production Planning (APP) Strategies

DEMAND ADJUSTMENTS

Influencing Demand

Backordering

Counter Seasonal Product Mixing

SUPPLY ADJUSTMENTS

change inventory levels

change capacity

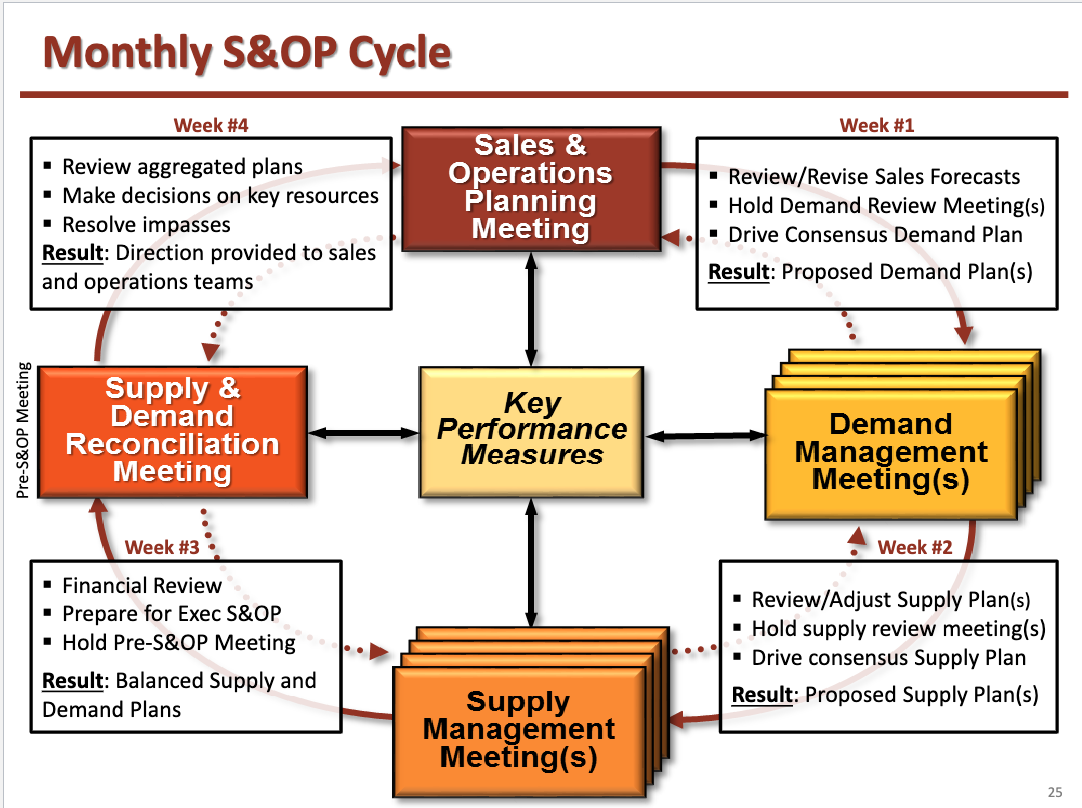

Sales & Operations Planning (S&OP)

A process to develop tactical plans that provides management the ability to strategically direct the business to achieve a competitive advantage on a continuous basis by integrating customer-focused marketing plans for new and existing products with the management of the supply chain

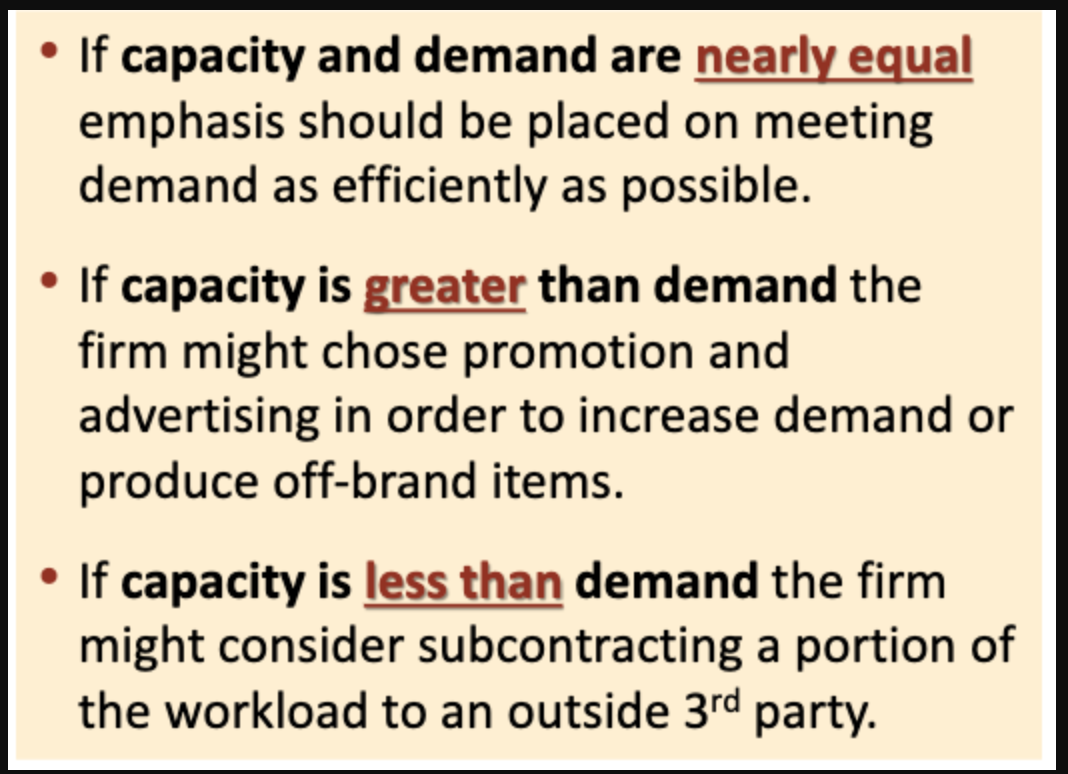

If capacity and demand are…

Monthly S&OP Cycle

Master Production Scheduling (MPS)

represents what the company plans to produce expressed.

it is a statement of production and not a statement of demand

MPS planning horizon is typically 3 to 18 months

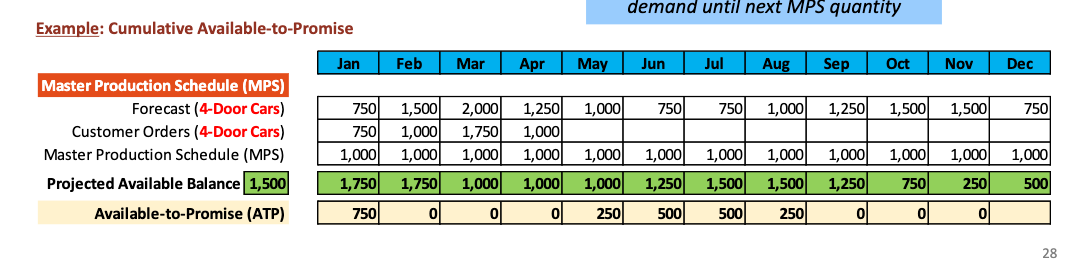

Available to Promise (ATP)

A calculation to provide a response to customer order inquiries, based on product availability

It represents the uncommitted portion of a company’s projected available

inventory to support customer order promising

Time Fencing

Firmed Time Period: from current date out several weeks into future

Planned Time Period: the end of the firmed time period to the end of the planning horizon

Basic Production Strategies

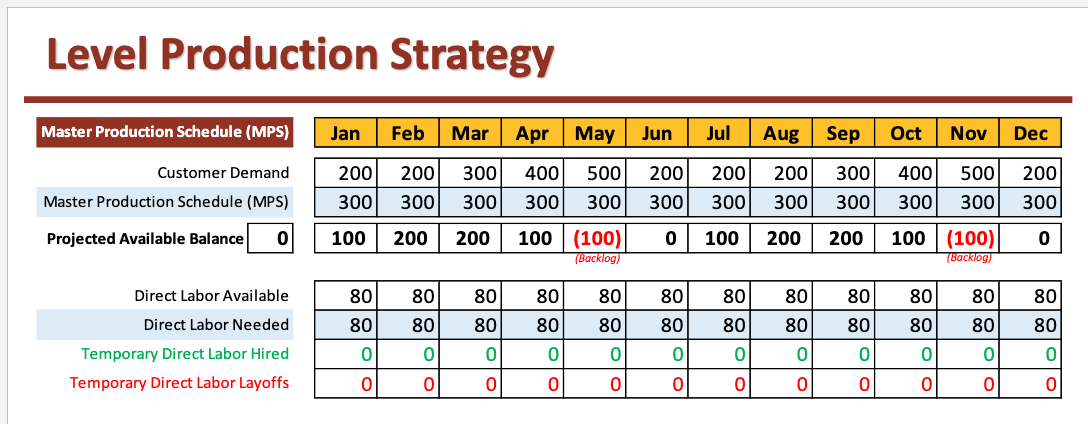

Level Production Strategy

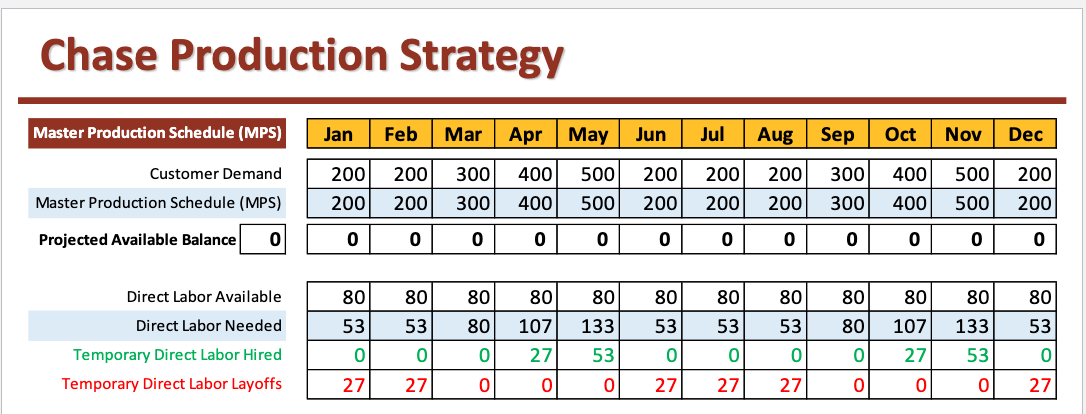

Chase Production Strategy

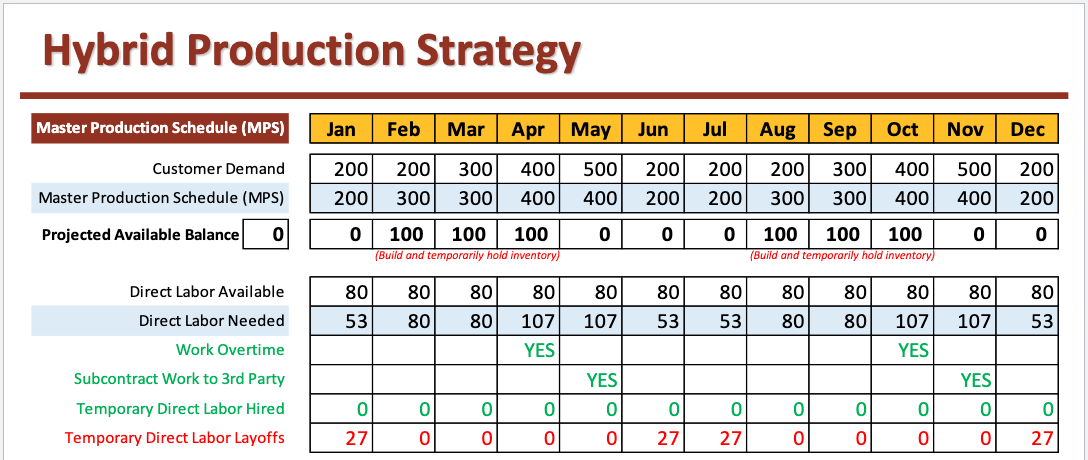

Hybrid Production Strategy

Level Production Strategy

Maintains a constant production rate and allows inventory and backlog to vary according to fluctuating demand

works well with make to stock items

Chase Production Strategy

Adjusts the production rate and capacity to exactly match demand

works well with make to order (mto) items

Hybrid Production Strategy

Sets a baseline production rate based on a stable core workforce, and then uses other short-term means, such as overtime, subcontracting and part-time labor to manage short- term fluctuations in demand.

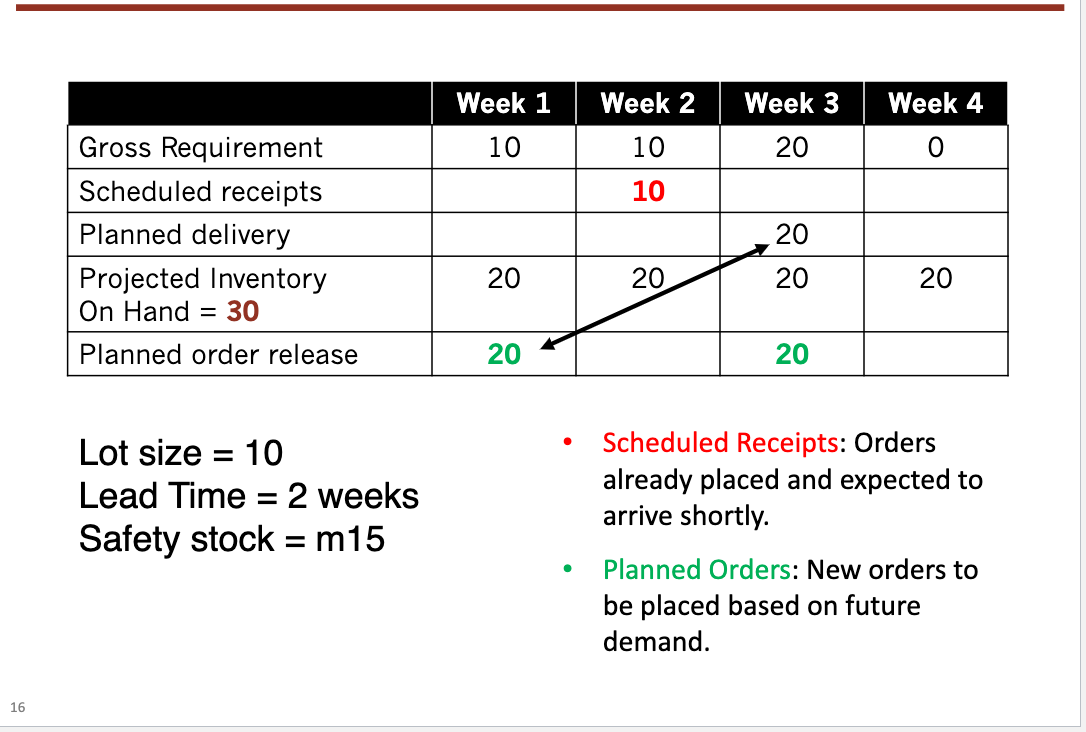

Material Requirements Planning (MRP)

A computer-based materials management tool that calculates the exact quantities, need dates, and planned order releases for all the component parts and materials required to manufacture a product.

MRP requires

Finished Master Production Schedule

Bill of Materials

Item master data for each component

Inventory status of components / materials

planned or scheduled receipts for any of the components and materials needed

Bill of Material (BOM)

An inclusive list of all raw materials, component parts, and sub-assemblies making up the final product (finished good)