Melk 3

1/104

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

105 Terms

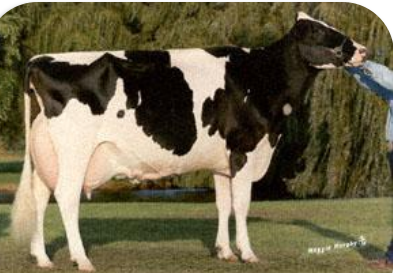

Holstein-Freisian

Origin: The Netherlands

Distinguished by their black and white markings

Largest dairy breed in the U.S. by population

Highest average milk production of all the dairy breeds (lower fat and protein content than Jerseys and Guernseys)

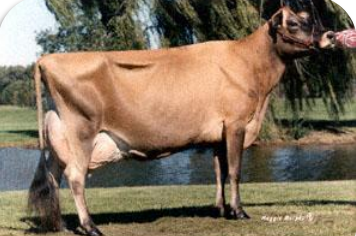

Jersey

Origin: Island of Jersey

Smallest of all the dairy breeds

Second most common breed in the U.S.

Known for their feed efficiency and high components of fat and protein

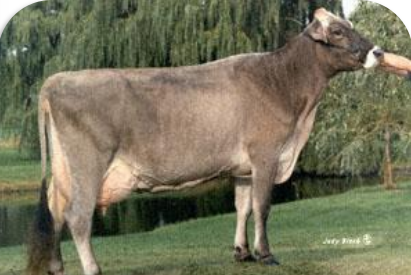

Brown Swiss

Origin: Switzerland

Colors can range from nearly white to very dark brown

Most resilient breed

High milk yield (lower fat content than Jerseys and Guernseys)

Guernsey

Origin: Island of Guernsey

A shade of fawn with white markings

Capable of producing milk with high fat and protein content

Golden Guernsey milk has a yellow tint from beta-carotene

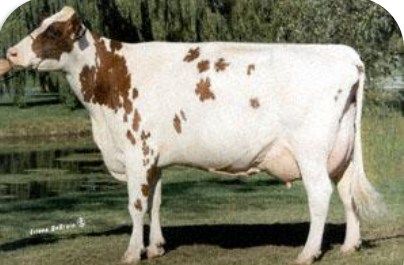

Ayrshire

Origin: Ayr, Scotland

Color varies from light to deep cherry red, mahogany brown, or a combination of these colors with white, some are all white

Considered intermediate among all of the dairy breeds for milk production

Milking shorthorn

Origin: Northeastern England in the Valley of the Tees River

Can range in colors from either red, red and white, white or roan

Most versatile of all breeds

Originally used for meat, later developed more for the milking industry

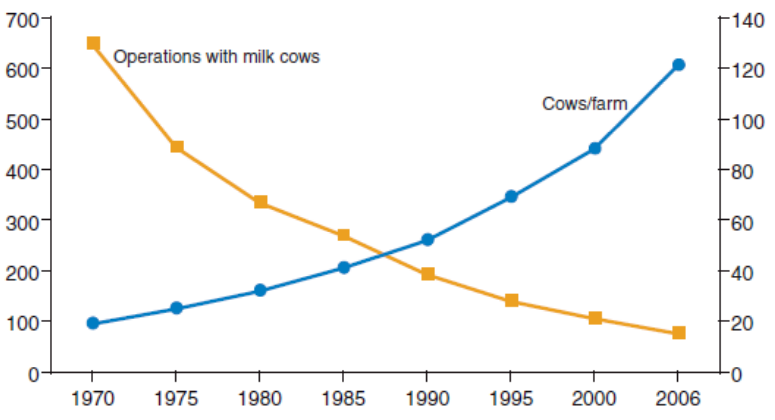

Herd side trends

Decreased from 23 million to 9.2 million in the US between 1935 and 2024

Due to efforts placed on improving genetics relating to milk yield, dairies do not need as many cows to sustain dairy demands

Where are the dairies located in the US

California, Wisconsin, Idaho, Texas, and New York

The majority of dairies are located around highly populated areas because milk is highly perishable

NC Dairy statistics

NC is part of the Southeast US milk deficit region

Most dairies in NC are family owned

Average herd size is 320 head and 500 acres

Ranks in the middle of the US states for milk production and cow population

Slightly below average milk output per cow

Global dairy production

dairy cows produce more than 80% of the worlds milk supply

The US is the leading producer in total milk and milk/cow efficiency

Management decisions are influenced by

Price, supply and demand trends for milk and dairy

products

Markets available for milk

Pricing structure and regulation of milk marketing

Price of milk

Influenced by consumption

Cows produce more milk in May and produce the least in November

Price of milk is the lowest in May and June

Price of milk is the highest in Oct, Nov, and Dec

How is milk utilized

Fluid Products: 29%

Manufactured Products: 71%

Hard Cheese: 43%

Butter and Nonfat Dry Milk: 15%

Soft Dairy Products: 12%

Class I product classification

Fluid: bottled milk, cultured buttermilk, eggnog

Class II product classification

Soft: Icecream, yogurt, cottage cheese, sour cream

Class III product classification

Cheese: Cheese, cream cheese

Class IV product classification

Butter/dry: Butter, nonfat dry milk

Pasteurization

Heating raw milk at a high enough temperature for a sufficient time to remove pathogens (bacteria) and increase shelf life. Has no effect on nutritional value.

Homogenization

Breaks up and disperses milk fat throughout the milk to prevent cream from rising to the top.

UHT milk

Heated to a higher temperature than pasteurized milk, stays fresher longer, has longer shelf life (up to 3 months) because milk is packaged in sterilized, air free packaging.

Fortification

98% of milk sold in the USA is fortified with Vitamins A and D. Some milk is also fortified with extra protein and extra calcium.

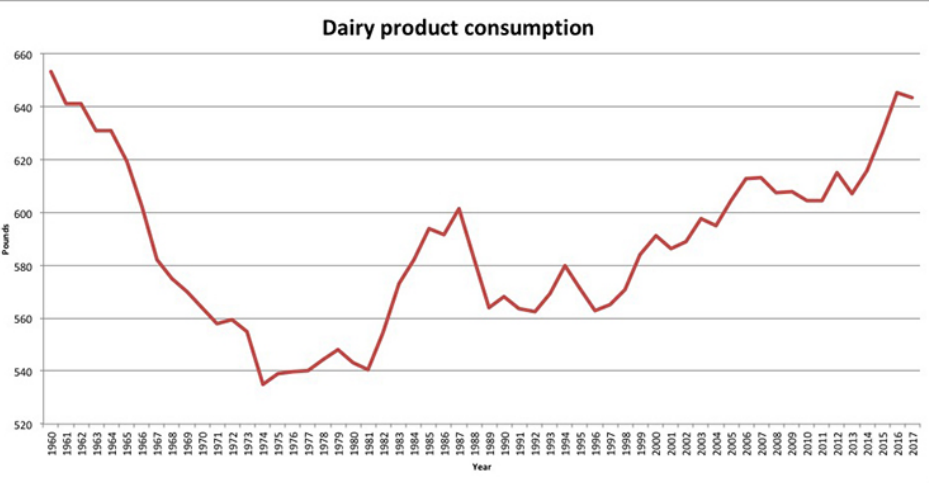

Dairy product consumption from 1960 to 2017

On the rise from the mid 1970s

Whole milk

3.25% fat [contains 150 calories and 8 grams (g) of fat per serving (8 fluid oz)]

May be fortified with vitamin D at a level of 400 International Units (IU) per 1 quart

2% Reduced-Fat Milk

2% fat [contains 120 calories and 5 grams (g) of fat per serving(8 fluid oz)]

Vitamins A and D are removed with the milk fat. For this reason, these vitamins must be added to 2% reduced-fat milk so that it contains at least 2,000 IU of vitamin A and 400 IU of vitamin D per 1 quart.

1% Lowfat Milk

1% fat [contains 100 calories and 2.5 grams (g) of fat per serving (8 fluid oz)]

Vitamins A and D must be added to a level of at least 2,000 IU of vitamin A and 400 IU of vitamin D per 1quart.

Fat-Free Milk

0% fat [contains 80 calories and 0 grams (g) of fat per serving (8 fluid oz)]

Vitamins A and D must be added to a level of at least 2,000 IU of vitamin A and 400 IU of vitamin D per 1quart

Evaporated Milk

6.5% fat is made by removing about 60% of the water from whole milk.

The milk is then homogenized, fortified with vitamin D to a level of 25 IU per 1 fluid ounce, canned and heat sterilized.

Evaporated Fat-Free Milk

0.5% fat or less is a concentrated, fortified (vitamins A and D) fat-free (skim or nonfat) milk that is canned and sterilized

Sweetened Condensed Milk

8% fat or less is a canned milk concentrate of whole milk to which sugar has been added. The sweetener used (usually sucrose) prevents spoilage.

Sweetened condensed fat-free milk contains no more than 0.5% milk fat.

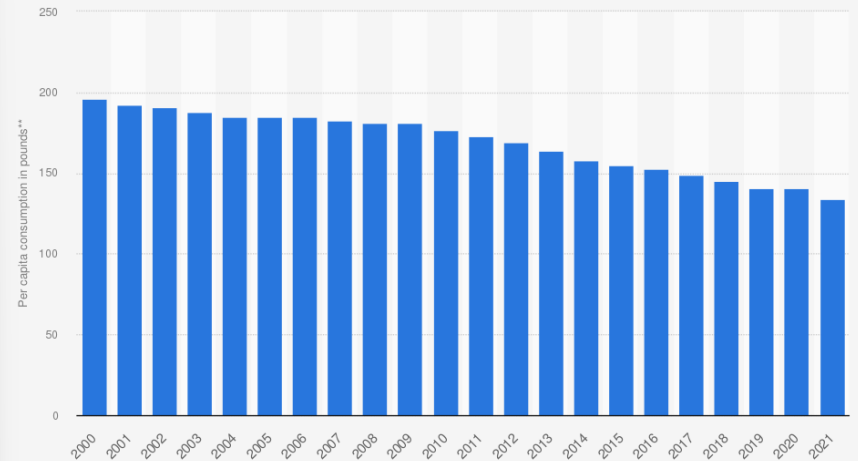

Per capita consumption of fluid milk products in the US from 2000 to 2021

Decreased

Butter and cheese consumption has risen

Butter

Must contain more than 80% fat and may contain some solids non fat (protein, minerals, etc) and water, the rest of the milk solids and water are used to produce non-fat dry milk and condensed skim milk

More products are produced when milk production is highest—surplus milk is used to make these products

Grade “A” Raw Milk

Must be cooled to 45 degrees F or less within 2 hours of milking

Blend temperature after the first and subsequent milking cannot exceed 50 degrees F

Each farmers milk cannot exceed 100,000 bacterial count per milliliter before it is mixed with other producers

Bacteria count from several producers cannot exceed 300,000 bacterial count/ mL before it is pasteurized

Each producers milk cannot exceed 750,000 somatic cells per milliliter

Can be no detectable antibiotics

Inspections on the farm are made regularly and the permit to sell Grade A milk can be suspended if violations are found and not corrected.

Grade B Milk

Produced under standards that allow it to be used for manufacturing of dairy products but not for fluid milk

Standards are not as strict as for Grade A milk

Grade B milk is safe and wholesome in manufactured products

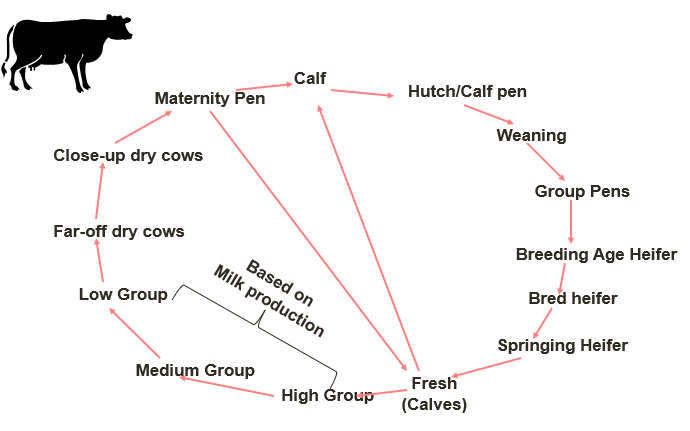

Typical dairy herd for 100 milking cows

92 healthy cows

4 cows that have recently calved

4 cows with special needs

Calving

Year-round calving is most common in the US to promote a steady flow of milk for sale

Some seasonal calving utilized to reduce milking and calving in the coldest months or to support grazing-based systems

Gestation in cattle is approximately 282 days

Newborn Calf Management

Birth weight: 60-100 pounds

Colostrum feeding - hand feeding compared to beef nursing

Weaning from dam - within first day

Navel dipping

Identification

Calves

Should receive colostrum, via bottle, within an hour of birth

After colostrum, calves are fed reconstituted milk-replacer and until weaning (30-60 days of age)

Calves are raised in hutches or specialized calf facilities

Dairy (heifer) Replacements

Goal 1: first calf by 2 years of age

Selected females will be bred at about 15 months of age

After a heifer has a calf and enters milking herd, she’s often called a 1st calf heifer

Goal 2: 12 month calving intervals

Rebred by 90 days post-calving

Full maturity reached at about 4-5 years

12 Month Production Cycle

Lactation is initiated by calving

Standard lactation period: 305 days

Peak production reached at 45- 60 days

Dry period: 60 days

Cessation of milk production and rebuilding of body stores and mammary gland

Lactation is reinitiated by calving

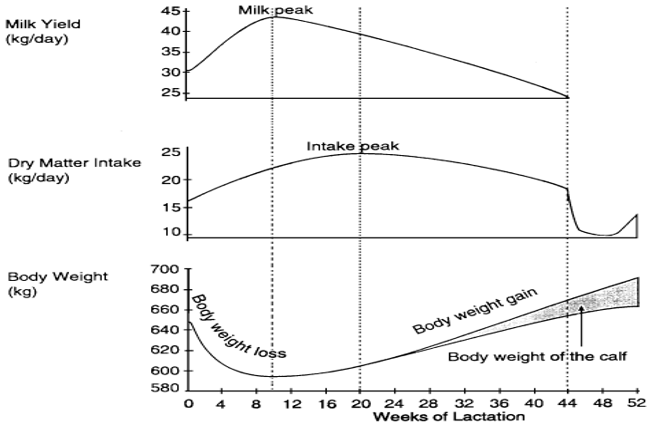

Early Lactation

14 – 100 days

Achieve peak (60 days for Holstein)

Milk yield increases more rapidly than dry matter intake

Mid- Lactation

100 – 200 days

Goal is to maintain peak milk productions as long as possible.

Late Lactation

200 days after calving and end when the cow dries off (day 305)

Cow gains weight to replenish body condition

What makes a great commercial dairy cow?

High milk yield, good components and feed efficiency

Avoids metabolic disorders and maintains body condition

Shows heat and conceives when bred

Stands and walks comfortably and hooves rarely need trimming

Has live calves without assistance

Resists mastitis and avoids injury

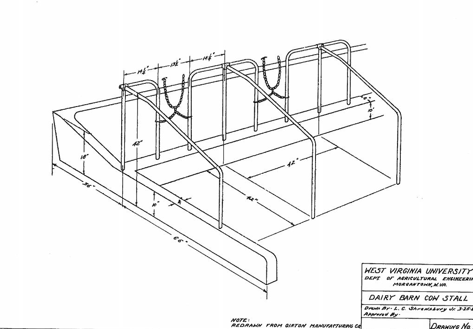

Stall Barns

One or two rows of cows in stanchions, tie stalls, or comfort stalls

Cows may be faced inward toward center of barn, or outward toward the wall

Time spent laying down is dramatically decreased in this stanchion barn with concrete stall platforms, reducing cow performance

Older facilities were not designed for cow comfort, but instead focused on worker comfort and cow cleanliness

Loose housing

Group hosing

Cows rest in common areas on a manure pack

About 60-70 sq ft per cow

Bedding should be deep and more should be added daily

Free-stall housing

Open individual stalls, bedded

Small breeds have different size stalls than large breed cows

Organic bedding

Saw dust

Newspaper

Chopped straw

Manure recycled solids

Compost

Advantages of organic bedding

Low initial investment

Cow comfort

Cow cleanliness

Disadvantages of organic bedding

Cost over time

Increased labor for maintenance

Problems for manure-handling systems

Sand advantages

Low initial investment

Cow comfort

Cow cleanliness

Sand disadvantages

Cost over time

Increased labor for maintenance

Problems for manure-handling systems

Mattresses advantages

Insulating

Good traction

Durable

Easy on manure-handling systems

Mattresses disadvantages

Expensive initial investment

Possible mattress hardening

Ventilation

Critical for cow productivity

Determined by amount of air changes needed for moisture removal\

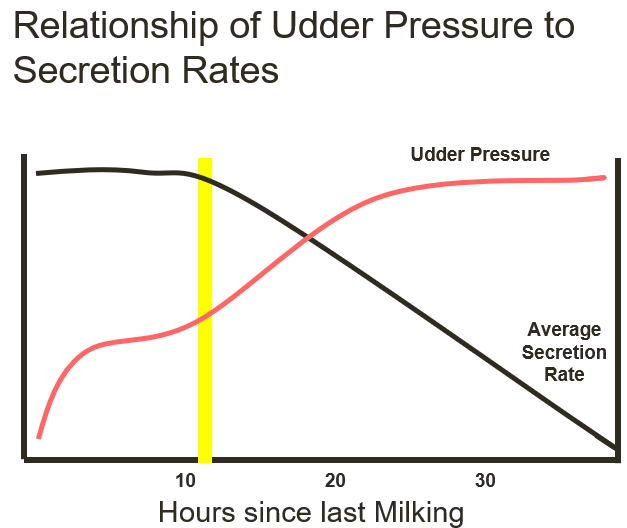

Milking Frequency

2X milking (two times each day) is most common

3X produces 10-15% more per cow per day

Farms make this decision based on herd size/parlor size, feeding program, labor availability, etc.

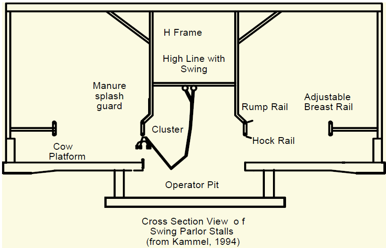

Milking Parlor Issues

Cost

Type and Size of parlor

Herd size & expansions

Labor available

Farm location/design/issues

Single Side opening

Handle cows one at a time so a slow-milking cow does not delay the completion of milking and release of other cows in the parlor.

These parlors are well suited to farms that take special care about observing individual cows and practice individual cow care in the parlor.

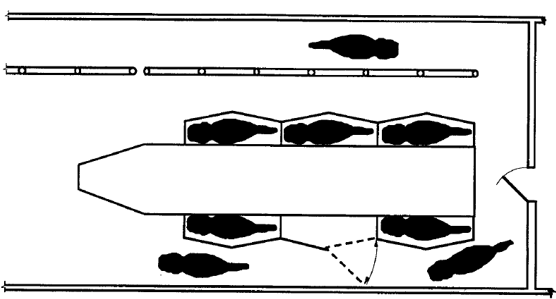

Herringbone

Most common parlor type in the US for ‘small’ parlors (less that double 12). Cows stand on an elevated platform in an angled or herringbone fashion facing away from the operator area

This exposes enough of the back half of the cow to allow access to milk her from the side and room for an arm type detacher and associated equipment.

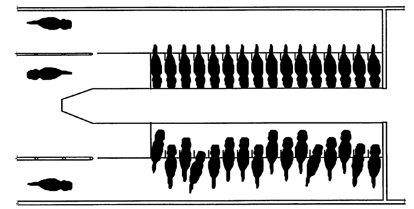

Parallel (Side by Side)

Cows stand on an elevated platform at a 90-degree angle facing away from the operator area.

Access to the udder is between the rear legs, which reduces visibility of the front quarters and can make unit attachment and udder user sanitation more difficult.

Most use rapid exit stall fronts and use dual return lanes. The stall spacing in this parlor type is such that support arms cannot be used. It is also more difficult to balance milking units on the udder in this parlor type.

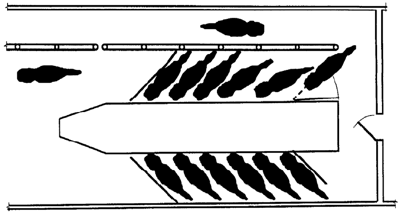

Swing Over (Parabone)

The cows are placed at a greater angle from the operator (about 70 degrees) than in traditional herringbones but less than 90 degrees as in a parallel.

Procedures and equipment developed for milking between the hind legs are used. Milklines are typically mounted as “midlines” or above the head of the operator resulting in a lift from the udder to milk line of about 1 meter

The primary advantage is that fewer milking units are needed and stall designs are simper, both of which reduce the initial cast of the parlor. The main disadvantage is this parlor type is the inconvenience resulting from milk hoses hanging in the operator area and the inefficiencies resulting from switching unit from side to side (especially for a slow milking cow and/or cow requiring special attention. This parlor type is not suited to the use of support arms and automatic detachers are typically mounted above the milkline.

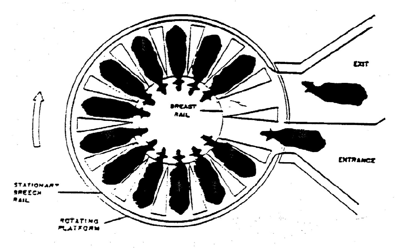

Rotary

Gaining in popularity

Platform on which the cows stand moves around

Milkers stand in one location

Milking Machine Goals

A properly designed, installed, maintained, and operated milking machine will:

Remove milk from the animal quickly and gently

Minimum irritation to the udder, teats, tissues

Support good udder health

Prevent invasion of organisms

Not degrade milk quality from the time of removal to delivery

Be easy to clean and sanitize

Milking Machine Components

Milking units

Vacuum production and control system

Milk transport system

Cleaning and sanitation systems

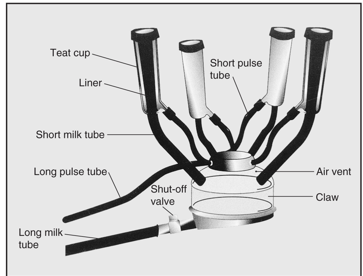

4 Teatcups

A soft rubber liner that is mounted in a metal or plastic shell

The soft rubber liner is the only part of the machine that touches the udder

The Claw

Collect milk from all of the teatcups

The Pulsator

An air valve that creates ‘pulsation’ or the opening and closing of the liner

Connecting tubes

Short milk tube = liner to claw

Long milk tube = claw to milkline

Short pulse tube = shell to air fork

Long pulse tube = air fork to pulsator

Pulsation ratio

% of time milk phase

% of time rest phase

Desirable 50:50 to 70:30

Pulsation rate

no. of cycles per minute - 50 - 60

How the milking machine gets milk out of a cow

Vacuum is applied to the inside of the liner to withdraw milk from each teat and keep the machine attached to the cow

Milking phase: When the pulsation chamber is under a vacuum, the liner is open and milk flow starts

Atmospheric pressure is the applied to the pulsation chamber and the liner closes.

Massage phase: Milk flow stops and the teat is massaged to reduce congestion

Mammary Gland Structure

Udder consists of four separate glands

A teat hangs from each quarter

Bottom of teat closed by sphincter muscle known as streak canal

Can have extra nonfunctional teats

Called supernumerary teats

Removed when calf is young

Teats should be moderately sized and located centrally on each quarter

Sphincter in each teat should be tight enough to prevent leakage

Teats are hairless

Support system

Stroma (connective tissue)

Parenchyma

Glandular; secreting tissue

Alveoli

secreting epithelial cells

the basic milk producing unit

Small bulb-shaped structure with hollow center

Lined with epithelial cells that secrete milk

surrounded by network of capillaries and myoepithelial cell

Contraction of myoepithelial cell stimulates milk ejection

Duct system

lined by epithelial cells

provide storage area for milk and a means for transporting it outside

Lined by two layers of epithelium

Myoepithelial cells are arranged in longitudinal pattern

Shorten to increase diameter to facilitate flow of milk

Lobules & lobes

clusters of alveolar tissue supported by connective tissue

Groups of alveoli empty into a duct

Ducts of lobe empty into a galatophore, which empties into the gland cistern

Mammary Gland Structure/Suspension

3 major supporting structures: Skin, Median suspensory ligament, Lateral suspensory ligament

Intermammary groove formed where lateral suspensory ligament and median suspensory ligament meets

Skin

Minor role in support

Median suspensory ligament

Separates right and left halves of udder

Connects udder to abdominal wall: Lamellae

Elastic tissue which responds to weight of milk in udder

Lateral suspensory ligament

Inflexible

Surround the outer wall of udder

Attached to prepubic and subpubic tendons

Streak canal

Functions to keep milk in udder and bacteria out of udder

Teat cistern

Duct in teat with capacity of 30-45 milliliters

Separated from streak canal by folds of tissue called Furstenberg’s rosettes

Gland cistern

Separated from teat cistern by the cricoid fold

Holds up to 400 milliliters of milk

Collecting area for the mammary ducts

From this branches the mammary ducts

Myoepithelial cells

Contract to force out milk – oxytocin

Capillary ducts to milk ducts to gland cistern

Epithelial cells

milk synthesis & secretion

Lumen

collect milk components & water

Basement membrane

selective transfer

Terminal duct

milk transport out of alveoli

Capillary system

supply milk precursors and deliver hormones

Lactogenesis

Process by which mammary alveolar cells acquire the ability to secrete milk

Galactopoiesis

Maintenance of actual production/ synthesis of the milk

Agalactia

Absence of milk production

Due to low Prolactin

What stimulates the milk letdown response

Sight

Sound

Smell

Routine

Direct nerve stimulation

Teat washing

Suckling

Circulation

One gallon of milk requires 400 gallons of blood being passed through udder

Ratio may increase in low producing cows

Blood enters the udder through external pudic arteries

Blood exiting udder from veins at the base of udder blood can travel through two routes

Via external pubic veins

Via subcutaneous abdominal veins

Lymphatic System

Helps regulate proper fluid balance within udder and combat infection

Fluid drained from tissue only travels away from udder

Blood capillary pressure

Contraction of muscles surrounding the lymph vessels

Valves that prevent backflow of lymph

Mechanical action of breathing

Lymph travels from udder to the thoracic duct and empties into blood system

Flow rates of lymph depend on physiological status of the cow

Edema

low pressure, passive system fed by a high pressure vascular system!

this situation results in pooling of interstitial fluid if evacuation of lymph is impaired

Frequent milkout to reduce mammary pressure

Diuretics, corticoids to reduce swelling

Quality of raw milk for cheese manufacture

Is largely defined by: Milk composition, Microbial activity of milk, Somatic cell count (SCC), Enzymatic activity of milk, Chemical residues

Somatic Cell Counts (SCC)

Released from the blood to combat udder infection, and thereby, prevent or reduce inflammation (mstitis)

Factors that contribute to increases in SCC of milk include: sub-clinical mastitis, advance in stage of lactation, lactation number, stress and poor nutrition.

Standard Plate Count (SPC)

Measure the bacteria content of raw milk.

the Raw count, the Standard Plate Count (SPC)

Determines the total number of bacteria in a milk sample that can grow and form countable colony forming units on a Standard Methods Agar plate

1 ml of milk added to plate

Then incubated aerobically at 90°F for 48 hours

Raw milk should contain less than 5,000 bacteria/ml.

a SPC of 10,000/ml or less should be achievable by most farms.

The maximum legal limit for SPC is 100,000 bacteria/ml

Preliminary Incubation Counts (PIC)

The PI count is based on the theory that the normal microbial flora of the cow will not grow very well when incubated at this combination of time and temperature.

To determine PI, a sample of milk is incubated for 18 hours at 55°F followed by the SPC procedure.

Microorganisms called psychrotrophs or cold-loving bacteria

Psychotrophic bacteria will continue to grow at temperatures below 45o F.

These organisms and the enzymes they produce are associated with off-flavors, milk spoiling and short shelf-life.

Currently there is not a legal limit for PIC.

A PIC above 20,000 cfu/mL is considered a high level.

Many herds can have a PIC of 10,000 or less just like the SPC if sanitation, cooling and milk procedures are done properly and monitored.

Causes of High Bacteria Counts

Improper cleaning of milking equipment after each milking or neglecting to sanitize equipment before the next milking

Wash water temperature should start at 155-170°F and drain at above 120°F

Using the wrong amount or type of detergent, acid or sanitizer.

Gaskets, teatcup liners, rubber parts and hoses need to be clean, free of cracks and deposits and replaced when needed.

Check your bulk tank cooling system. Slow cooling bulk tank or temperature above 40°F. The bulk tank milk temperature should be less than 40°F within two hours of milking and kept below 45°F during milkings.

Mastitis infections due to Streptococcus agalactiae can lead to a large number of these bacteria being released in the milk. Several cows infected with Strep. Ag. can cause the bulk tank SPC to be elevated