unit 3 xray circuit

1/72

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

73 Terms

The 4 condition necessary for X-ray production

source of electrons

Acceleration of electrons

Focusing of electrons

Deceleration of electrons

Source of electrons

cathode filament

Happens when he rotor button is first depressed which will start to heat up the filament and create thermionic emission (boiling off of electrons)

This is determined by the mA selection because it has to do with how many electrons are being created, rotor eventually starts to spin and gets up to speed and wills start to heat up

Acceleration of electrons

potential difference between cathode and anode

When you fully depress your rotor switch and your exposure is made, it is the potential difference going on between cathode and anode

This will force all the electrons over the little gap between the cathode and anode

Focusing of electrons

focusing cup

Part of the cathode

A way of directing or focusing electron stream to a specific spot on our anode

Deceleration of electrons

anode

Specifically at the target area of the anode

Creates x-ray photons

When the electrons strike the material (the tungsten of the anode) is when x-rays are created

The three components of the x-ray tube

anode: from the anode disc all the way back, + side

Cathode: - side

Induction motor: on anode side but separate components

Cathode

thermionic emission: boiling off of electrons

Our source of electrons that we need to create X-rays come from the cathode

Negative side of the xray tube

Source of electrons

Produces a thermionic cloud is produced (of electrons) travel across the x-ray tube and interacts with the anode to create x-rays

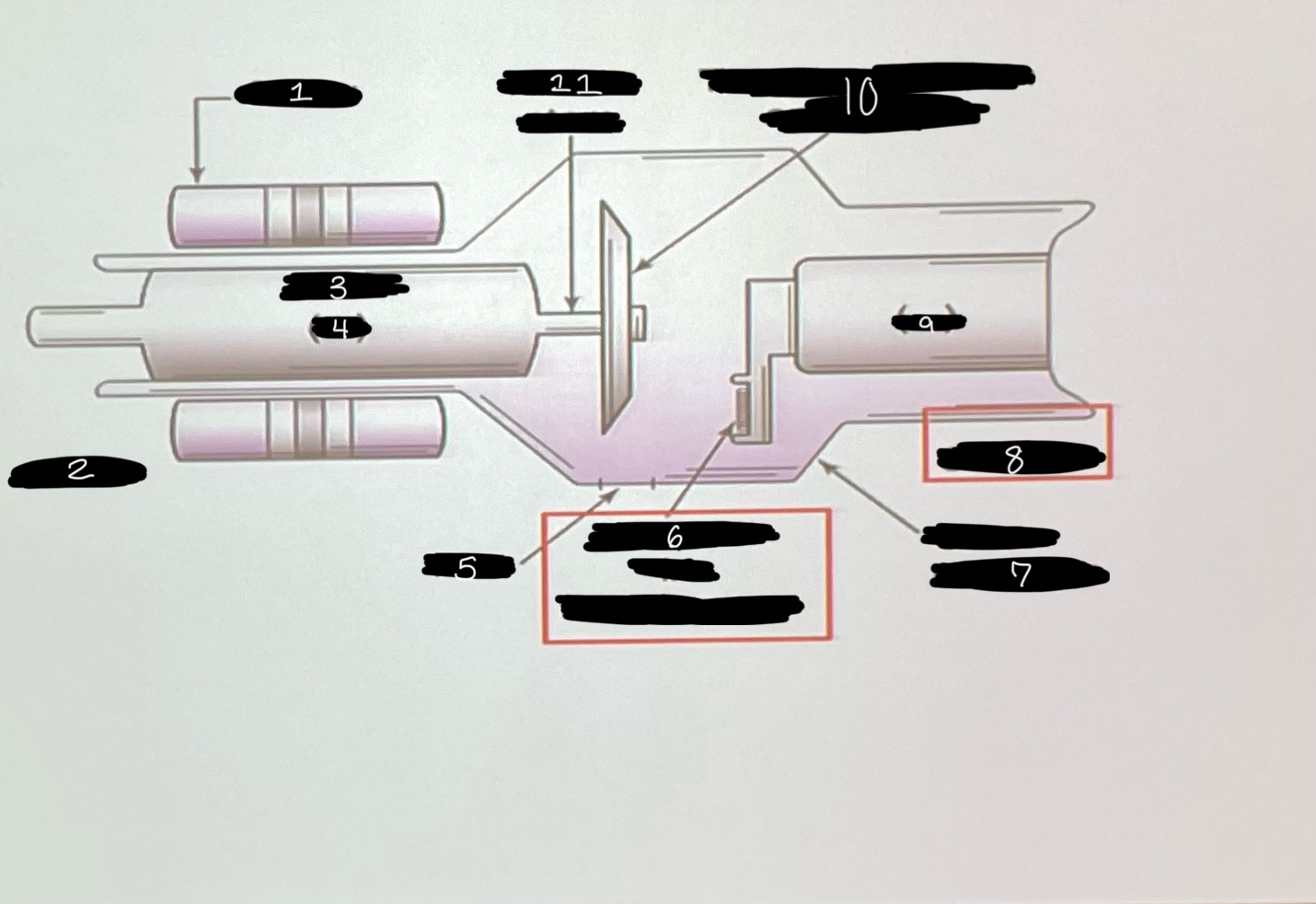

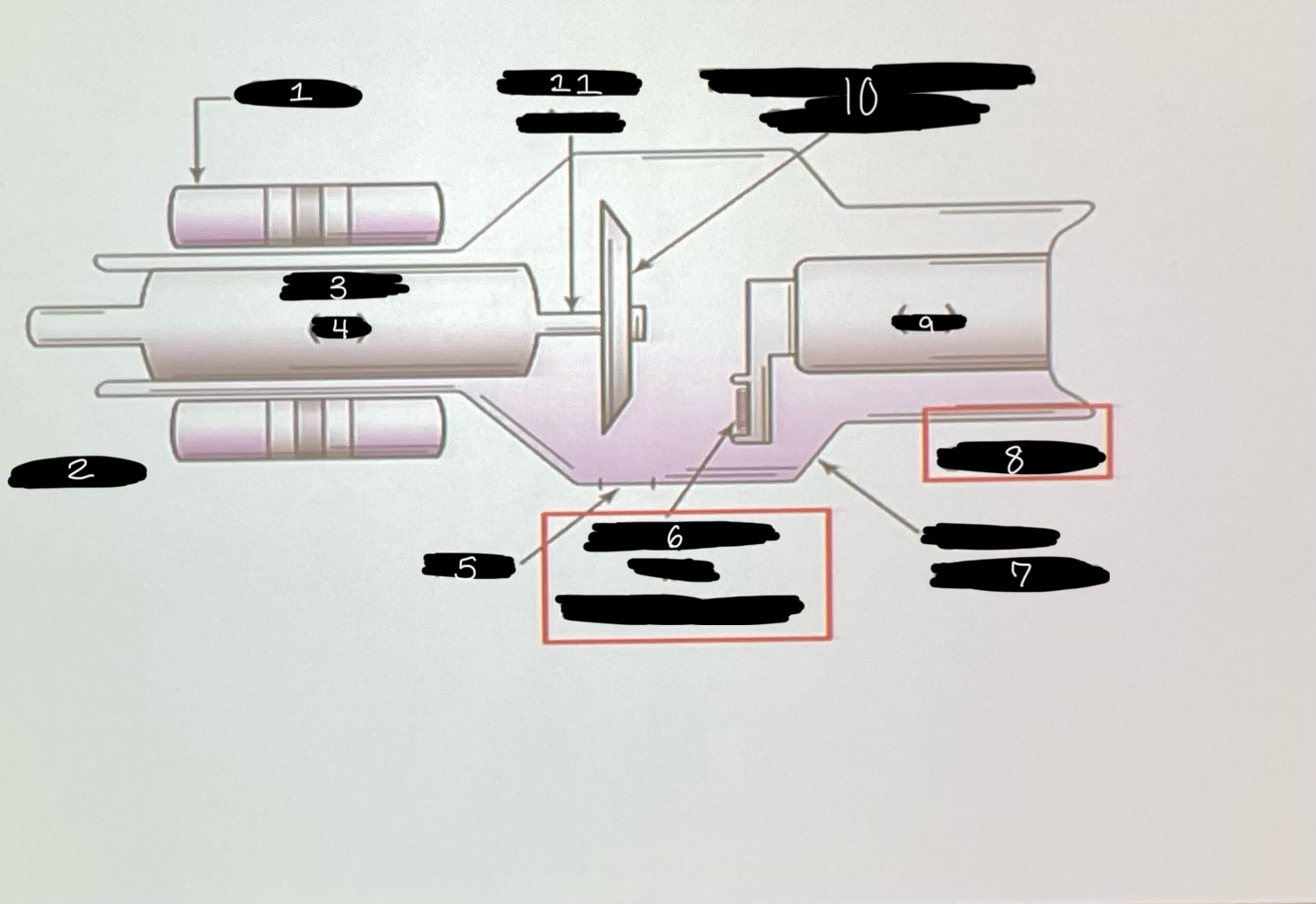

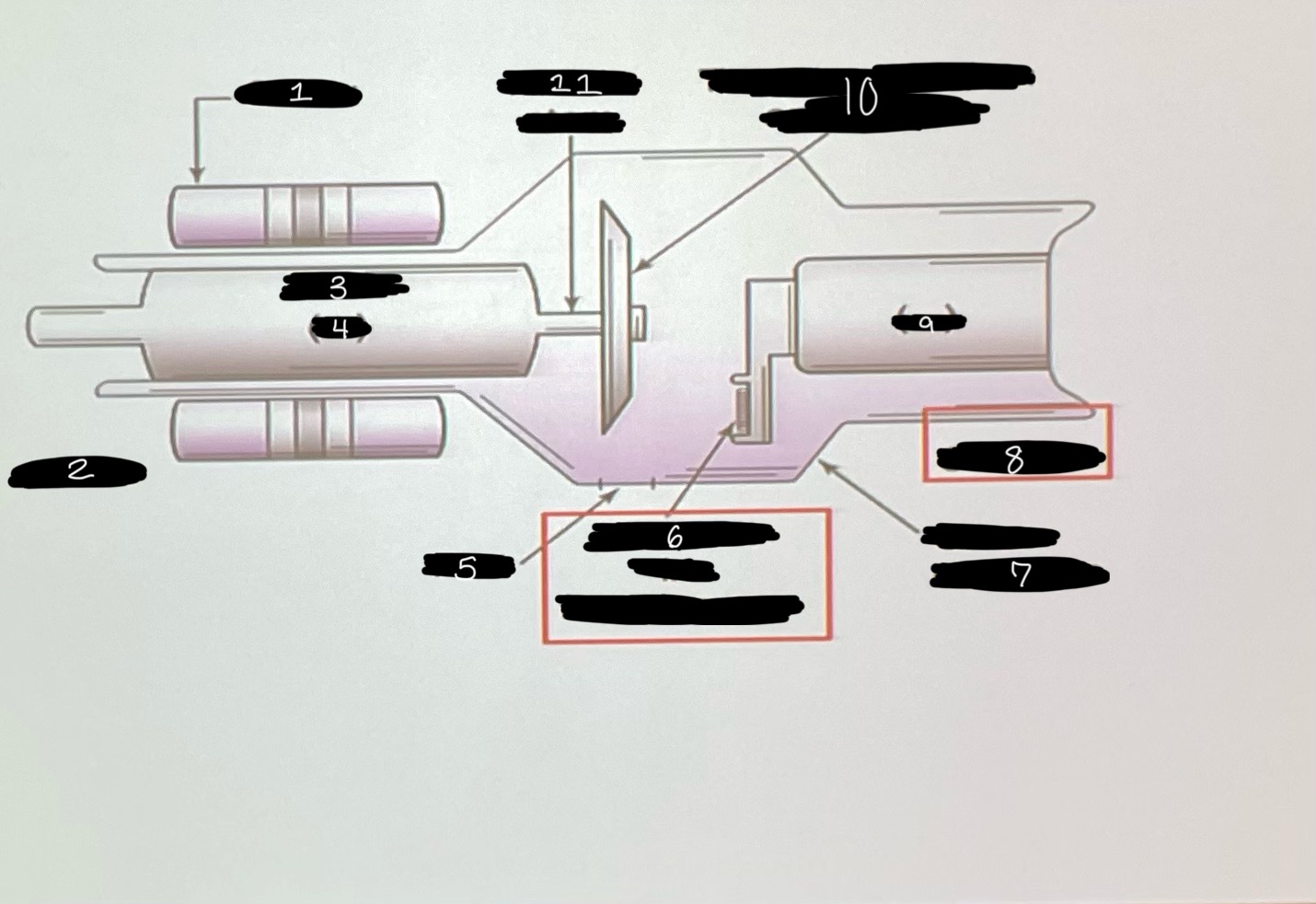

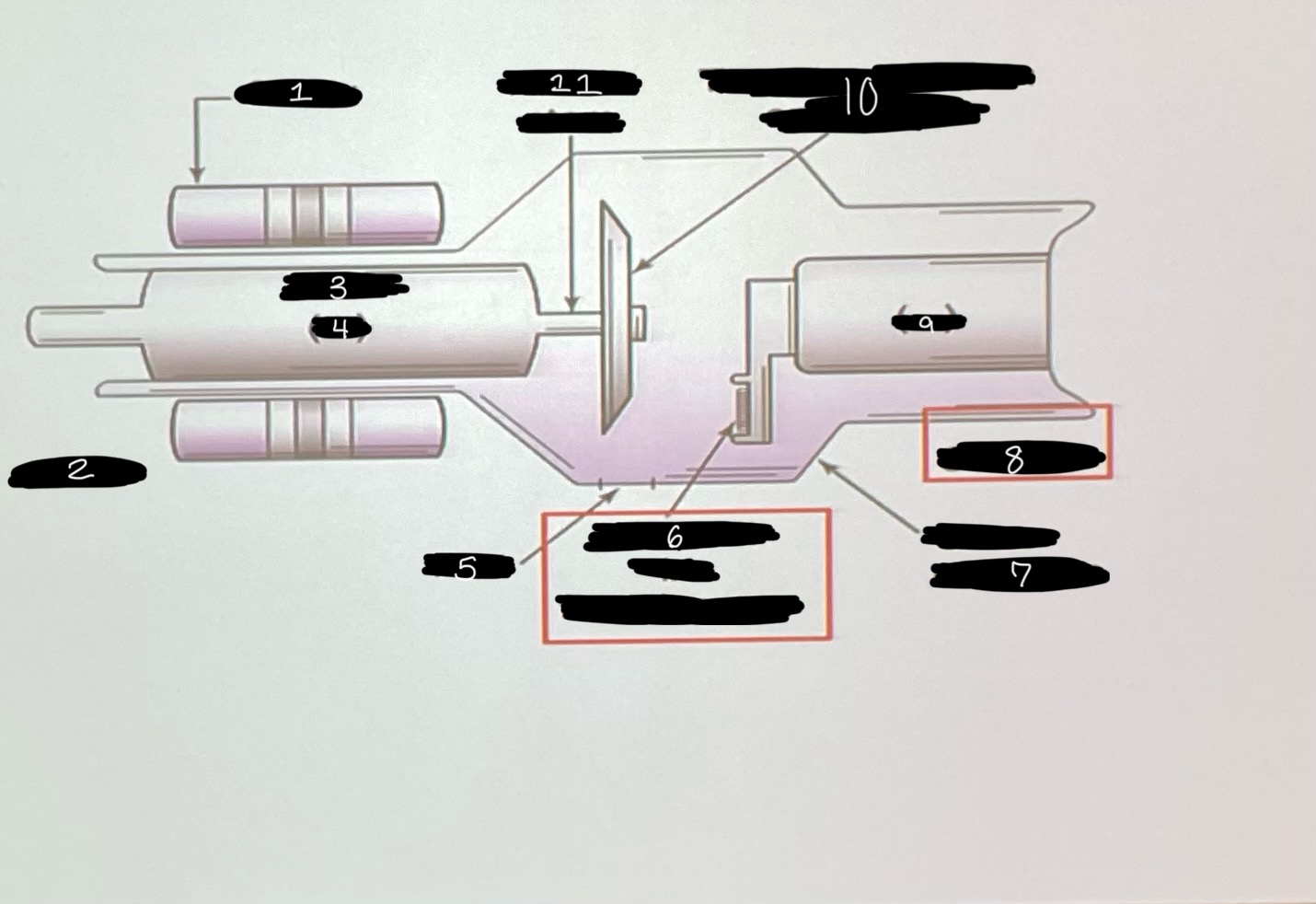

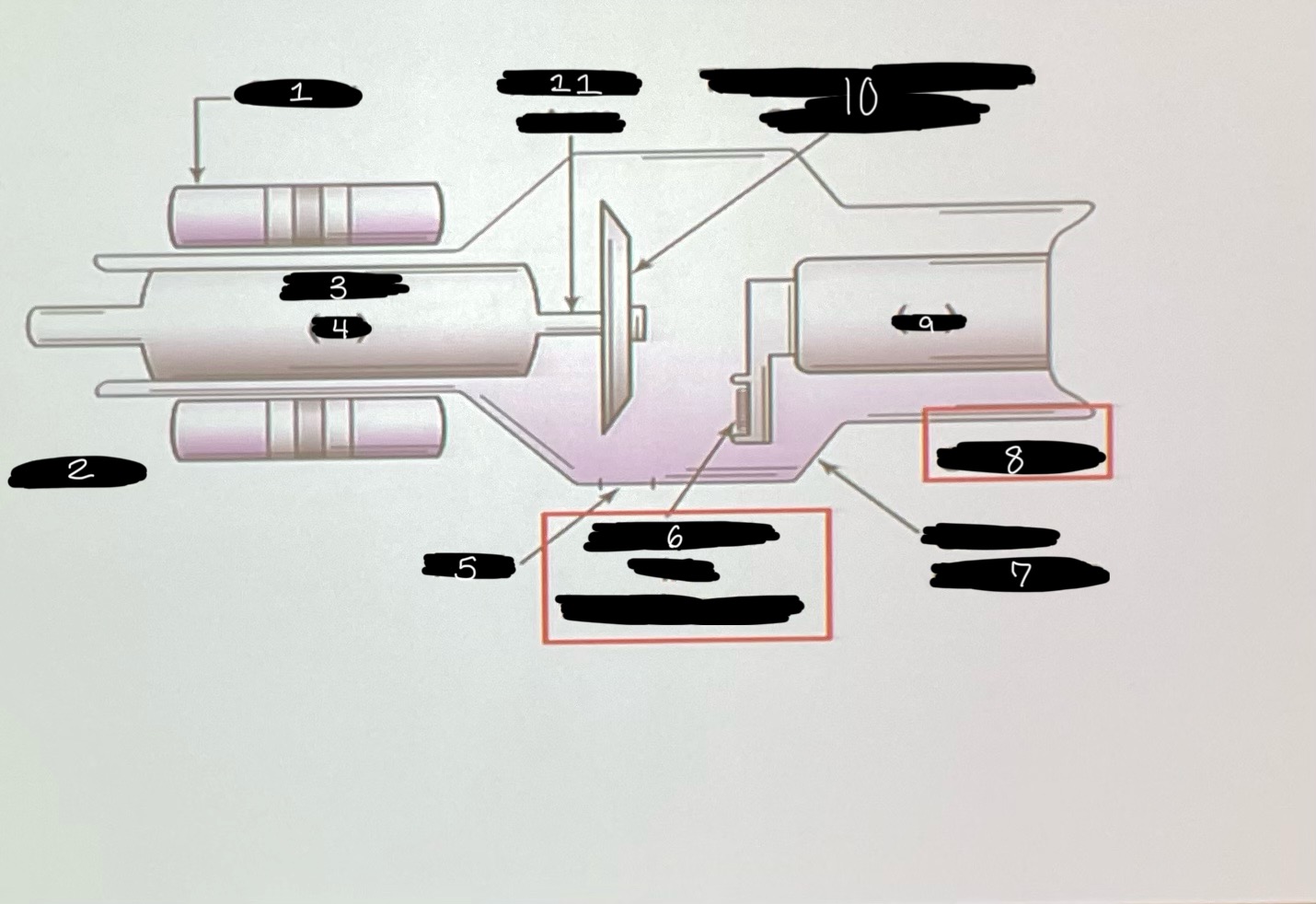

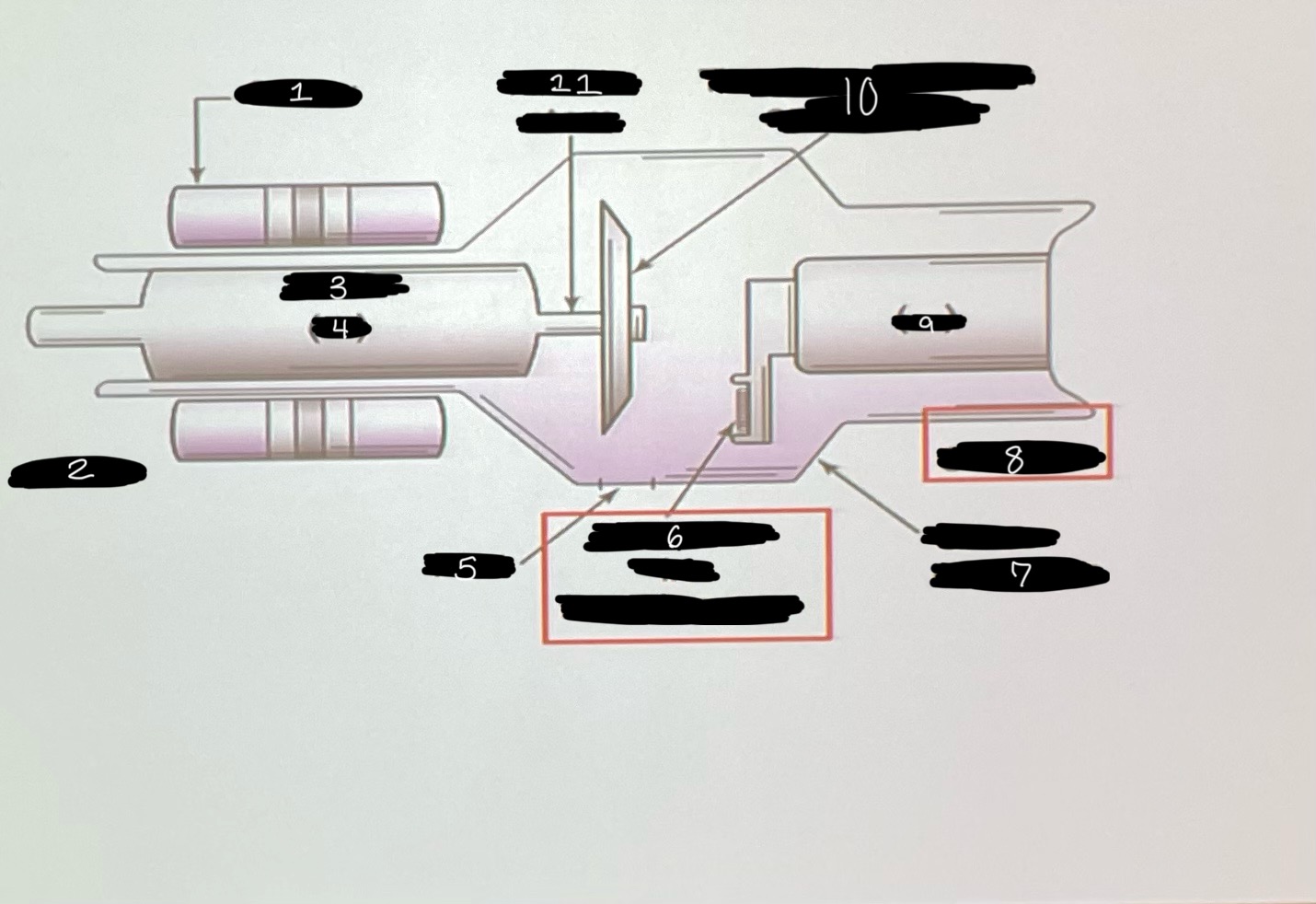

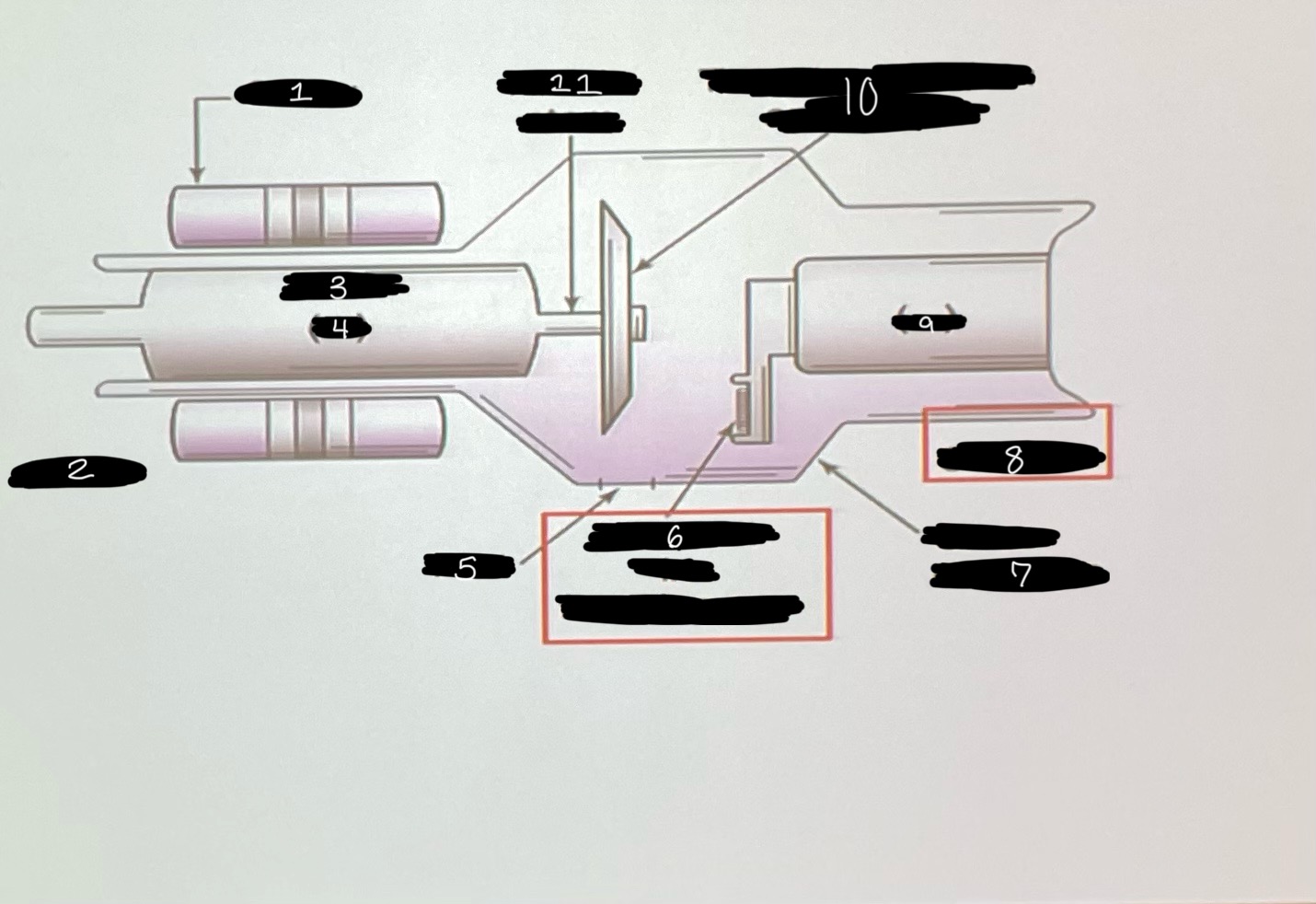

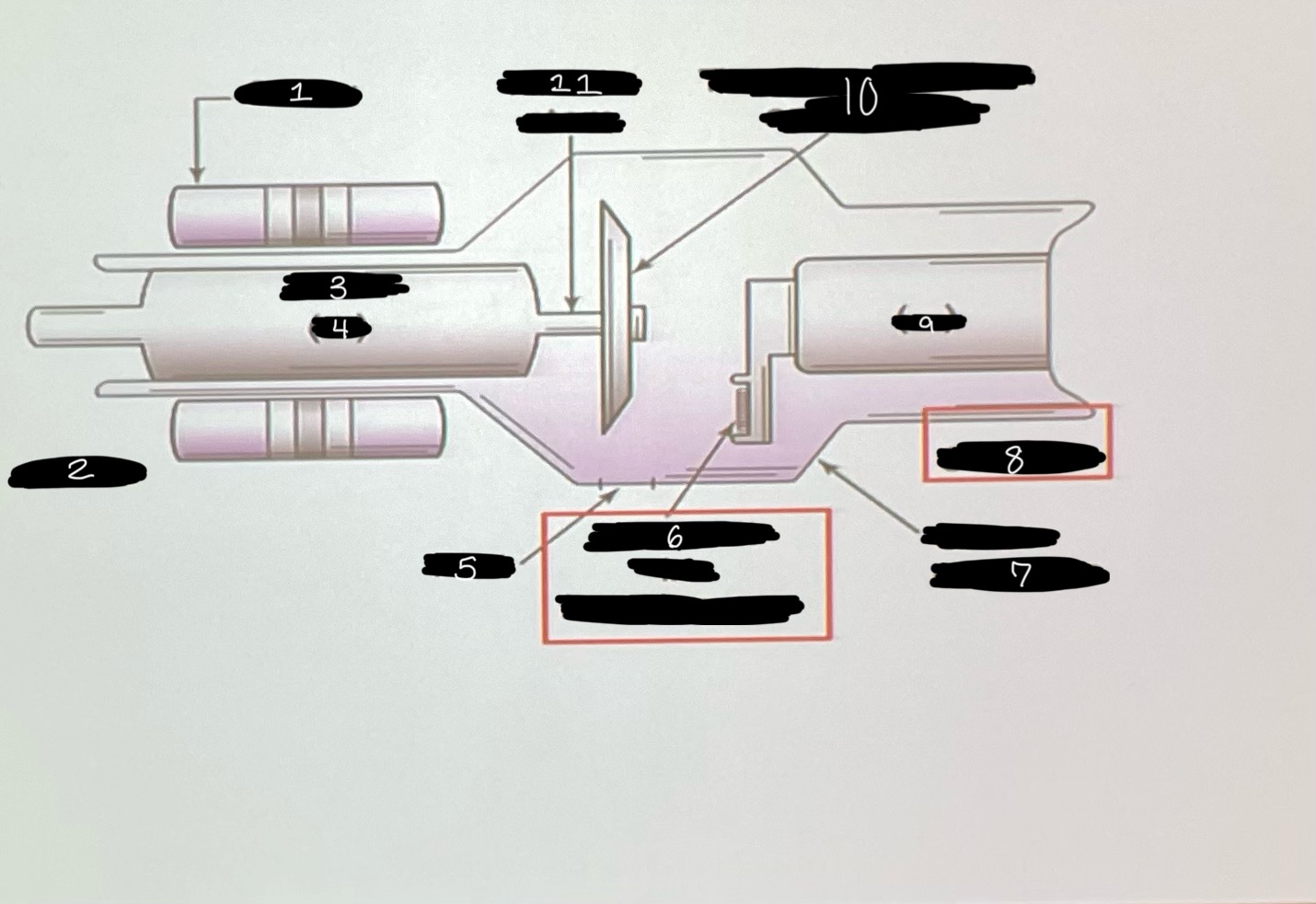

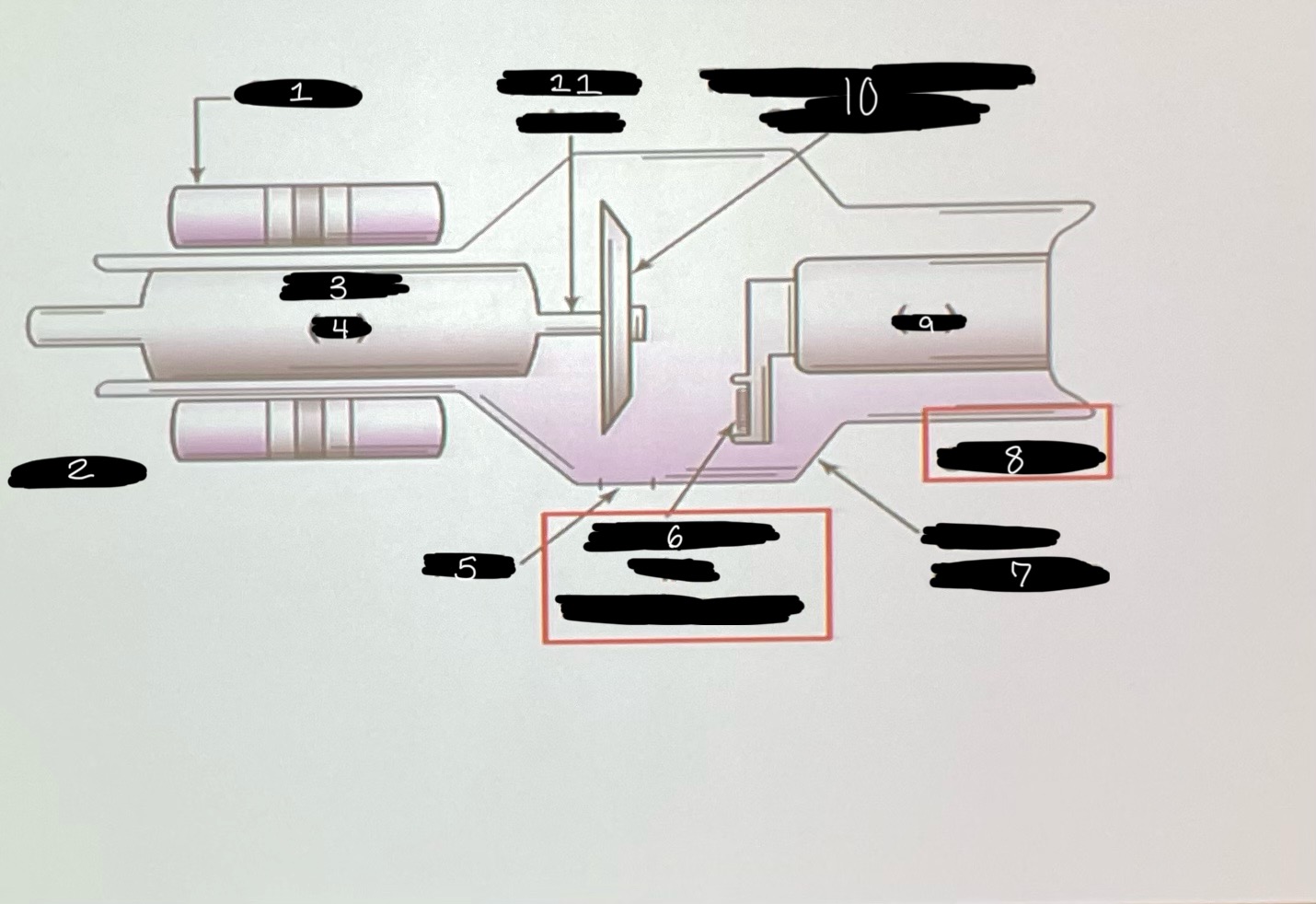

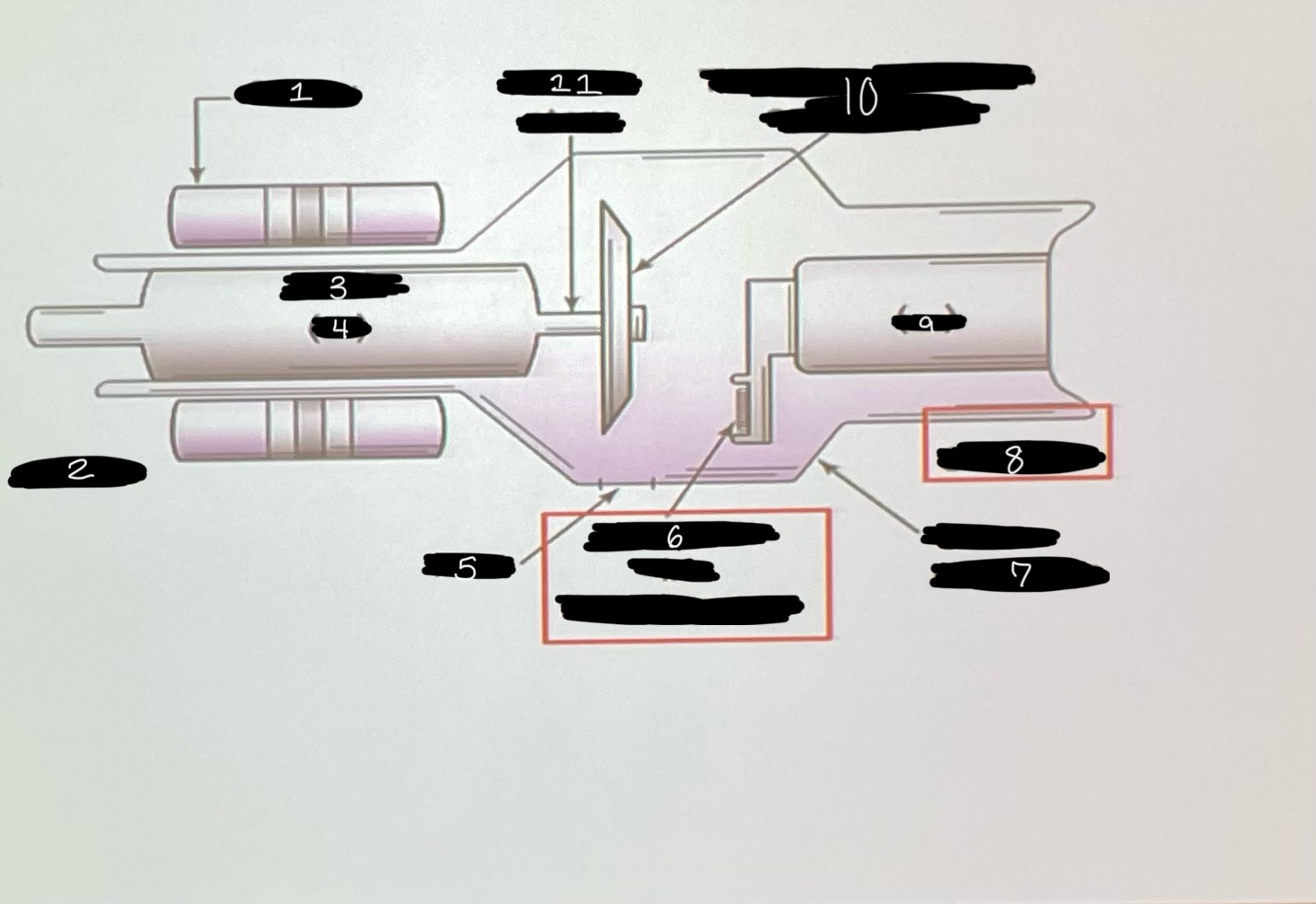

What is 1?

stator

What is 2

anode

What is 3

rotor

What is 4

(+) side

What is 5

port

What is 6

filament in focusing cup

What is 7

glass envelope

What is 8

cathode

What is 9

(-) side

What is 10

tungsten/rhenium anode disk

What is 11

anode stem

The purpose of the focusing cup is to…

focus electrons towards the target

The focusing cup is part of the

X-ray circuit secondary, high potential difference

Where is the focusing cup and filament connected in the tube?

focus cup is in secondary circuit

Filament is in the filament circuit

The top portion gets us the kVp power, the kVp is the voltage difference that is happening and that is the difference between the electro volt charges that is happening in the negative charge that is happening cathode and the positive charge in the anode. Specifically the coursing cup of the cathode, the negative charge within the focusing cup is what will shoot the electrons across the x-ray tube

The filament itself is connected to the filament circuit because that is how we get our mA. All the voltage changes give us the number of electrons that we need

What are the 2 components of the cathode?

focusing cup and filament

What is the focusing cup?

shallow depression

Made of nickel

Surrounds each of the filaments on the back and both sides

Receives strong negative charge from the secondary side of the circuit, that strong negative charge is going to force or expel the electrons that are being created but the filament , this force is done through electrostatic repulsion

The negative charge from the focusing cup is greater than the negative charge of the electrons and forces them together into a stream to be boiled off

Size, shape, and charge will tell how efficient t it is

Can’t change them, they are Preset in the tube

Filaments are what type of structures?

filament type

When we have 2 filaments (most tubes do) focal spot=filament size (large to small filament)

What is dual focus arrangement

2 filaments

Small coil when imaging small body parts (we can create/ hold less electrons that if we use the large one)

Filaments are coils of wire, they are a lot smaller (7-15 mL) (1-2 mL wide)

When the cloud of electrons that are being created in the filament is shot to the xray tube, what hits the tube is 1/20th of the size of the initial stream. So it really focuses them down and close to each tower

Made of tungsten and with 1-2% thorium (Thoriated tungsten) added to them (increases the amount of thermionic emission that can occur and it helps to extend tube life so it helps reduce the vaporization)

Tungsten is used in the focal spot of the anode, causes high atomic number and high melting point, and doesn’t vaporize (break apart) easily

What is the number one cause of filament in most equipment?

breaking down of tungsten

What effect does doubling the mA on the console have on the xray tube?

double e- flowing across the tube

Effect the amount of electrons that are being boiled off and those electrons travel across the tube, electrons travel across and then the xray photons are created in the anode and come out of the tube

Anything flowing across the xray tube should be an electron

Anode

(+) side

Made of anode steam and discs and on top a focal spot/track

Provides the target for the high voltage electrons that left the cathode and are traveling to its electrical and thermal conductors. Conducts all the voltage that has left the cathode and traveling to the anode

When it hits that it conducts all the voltage back into the X-ray generator circuit, we reuse all that power and also it is able to conduct heat

X-ray production is not an efficient process, 1% of that turns into an X-ray and the rest of it is heat

So there is not a lot of heat generated. The anode can absorb that heat and dissipate it so the tube is not overheated

Stationary anode

used now more in dental imaging

Tungsten button embedded in a cooper rod

Doesn’t turn just stays stationary

Primary disadvantage is that there is one spot on the button that is being bombarded with electrons so a lot of heat is produced in one area, and because we are using a higher mA and more electrons to create images now it will wear out faster

Rotating anodes

Use now

Purpose is to spread the tremendous amount of heat that is produced while taking xrays

The stream doesn’t change but where it hits on the anode changes, we went from created a focal spot to now a focal tract (where we focus our electron to be able to spread that heat we are producing around a larger surface)

Greatly increasing the amount of heath that the tube can handle so we can use greater exposure techniques

These rotating anodes are around (5-13cm) in diameter depending on the piece of equipment)

The anode disc and stem are made of?

molybdenum

High melting point so it doesn’t fall apart

High atomic number to reduce ionization

Low thermal conductivity so it wont heat up as quickly and wont make the tube overheat

Slow the migration of heat back into the induction motor

Metal is very light material to help with anode rotation

What material is added to the tungsten target?

rhenium because it adds some give to the target so when it expands because the heat it gives more give to it

What metal is added to the Tungsten filament to increase thermionic emission and extend tube life?

thorium to reduce the vaporization of tungsten

What are the anode materials?

molybdenum

Tungsten

Cooper

Rhenium

Molybdenum

anode disc base and core going back into the steam portion

Melting point of 2600 degrees F

Low thermal conductivity ( high melting point, low thermal conductivity so it wont conduct the heat back into the conduction motor)

Light so it makes the anode easy to rotate

Tungsten

material in the main portion (where electrons strike the anode)

Target material coated in tungsten

Atomic number of 74

High melting point of 6100 degrees F

Low thermal conductivity so it wont make a lot of heat traveling through the whole anode and induction motor

Cooper

part of the shaft, between anode and induction motor that helps to decrease the heat being produced that moves back into the induction motor

Helps conduct electricity

Rhenium

added to the target area where tungsten is to help with the thermal capacity

Allows the expansion to happen

What might you see being used instead of tungsten or they might add to it?

graphite because it has a low density and makes it easy to move

X-ray photons are created at what area in the xray tube?

anode target

High voltage electrons interacting with the tungsten material and creating an X-ray photon

This is where we get our SID from, the SOURCE of our X-ray photon/beam is the anode target)

Where are electrons created?

in the filament and they travel across the xray tube and the electrons interact with the tungsten material in the anode and that interaction creates the xray photon

What does the stator do?

stays still

Is outside the envelope

Group of electromagnetic that have a current that is supplied to them

The current and changing magnetic field induces a current in the rotor (inside the envelope) and the rotor rotates and then allows the anode to rotate

Has the current supplied to it and then induces the rotor to turn which leads to the anode also turning cause they are connected

What do rotors do?

rotate

Inside the envelope

What do bearings do?

inside the envelope

Silver plates spheres that have low friction so we can have that rotation at higher speeds

Need to be in there to make sure its not bouncing around and hitting things

What is the Induction motor

works off the concept of mutual induction

Based off the law that states inducted electrical current flows in the direction such that the current opposes the change that induced it

Has different magnetics and as the current induced in those different magnetics due to the AC that is being supplied to the, it will start to energize the opposite pairs and that constantly changing current will create a magnetic field and that field is what will rotate the rotor or cause it to turn and correct itself

Cable of speeds of 3400 rpm in general purpose tubes and 10000 rpm for specialty tubes

The stator is supplied….

with AC, AC that is supplied to the stator is then induced in the rotor, no contact betWeen them, the envelope separates the 2

How is the speed determined for the rotor/anode?

by the frequency current applied to the stator

The higher the current applied to the stator the quicker/more rotation you will have

These 2 will rotate at the same time

Components of the proactive housing

cooling fan

Oil

Lead layer

Electrical wire and high voltage receptacles

Purpose of the cooling fan

circulates the air inside the tube and helps dissipate the heat out into the air

They spin really fast

Purpose of Lead layer

xray housing is usually steel or aluminum with this lining on the inside

Purpose of this lining is to reduce scatter or leakage radiation

Purpose of oil (dye electric oil)

located in the space between the envelope and the housing

Used to draw the heat away from the X-ray tube and helps dissipate dissipate it and keep it stable

Doesn’t boil at high temps

Provide insulting against electrical shock

Purpose of electrical cables and high voltage receptacle

the cables are coming from the circuit either through the floor or ceiling and they are coming into the tube

Secure the X-ray tube/housing to the rest of the components

Special high voltage receptacles that securely attach the tube to the rest of the circuit

Provide mechanical support and protect from rough handling

Protects from electrical shock because it covers the high voltage wires

Main purpose of the envelope

provides a vacuum within the tube

important because X-rays do not travel in one direction, so when those filament electrons interact with your anode target and your X-rays are created they will travel in different directions so this is why we need to create a vacuum so they can try and stay in the same direction

Typically made of glass or metal

Size of the envelope

30-50cm or 12-20 inch in length

20 cm or 7 ½ inches in diameter

Made of glass or metal (now we mainly use metal)

Materials are picked because there ability to stand the heat that is being created

Down fall of Pyrex glass?

suntans

this tan happens when the tungsten in the filament breaks downs and vaporizes

It deposits itself on the glass and holds onto the glass

What is arching? (When using glass)

the charge the electron created in the filament is now crossing the X-ray tube, this is how tube failure happens

Why do we mainly use metal now?

help provide a constant electrical potential between the stream and avoids the arching problem that happens when the tungsten on the deposits on the glass

Regardless of glass or metal there is always a….

window

it is flat and thinner at this spot compared to the rest of it

Where x-ray photons should exit the envelope

It is 5 cm

It is thinner here because it will reduce the amount of x-rays being absorbed by the glass or meta so it can transmit more

Leakage radiation

the reason why we have vacuums and lead lining

travels in a bunch of different direction, so we have lead lining to reduce the amount of leakage radiation

We can only have 1 mGy per 1 hour at 1 meter from the tube per regulation

ANYTHING THAT ESCAPES THE HOUSING ANYWHERE BESIDES THE WINDOW

Off focus radiation

radiation is not being produced at our focal spot, not being produced at the right spot on the anode

Actual focal spot or actual focal spot size

where electrons are actually interacting with your tungsten anode, this is determined by the size of the filament and the body part being imaged

Dual focus tube, we have a small and large filament

The small filament will have a narrower/smaller area of interaction that the large filament

Effective focal spot

what is being projected towards the body part which is radiation

Origin of the x-ray beam as seen from the patients perspective

X-ray Beam going straight down to the patient

The smaller the origin/focal spot size the sharper the image you will have

Goal is to make this as small or narrow as possible

When we angle the anode we create the line focus principle, which is….

what allows us to have a large actual focal spot size and a small effective focal spot size so we can create sharper images

As long as our target angle is less than 45 degrees we will be able to create a large actual focal spot size and a small effective focal spot size

We want an angle size that is….

smaller

Being able to have a large actual focal spot size so a large area where electrons are hitting our anode spread out that heat, this doesn’t wear an area away as quickly

Larger area for heat to be created

Depending on the angel You can stream line or narrow in our effiective focal spot and strain and that is what will create….

A sharper image because the wider the image is the more it spreads out and as it spreads out we lose the intensity of the X-ray photons on the outside

If we keep the beam narrow in the middle it wont diverge as much and we wont have as great of a difference between the intensity of the beam between the middle to the outside of the beam

Larger actual one so we can spread heat production so we narrow in the beam to create a sharper image

The angle of the target area of the anode is around how many degrees?

7-18 degrees

the most common on is 12 degrees

The smaller you angle…

the larger the actual spot size and the smaller the effective focal size

when given two options always pick the one with the smaller angle=line focus principle

We don’t select this on the tube we select the filament size which will change the electron stream that is being created originally

What is the reason for having a range of 7-18 degrees

anything less than 7 degrees you will have a straight up and down angle and that wont allow the beam to fill a 17×14 or 14×17

Anything less than 7 degrees is….

undesirable because it reduces how much the beam can diverge

Number for single phase

1.0

Number for high frequency

1.45

Number for 3 phase, 6 pulse

1.35

Number for 3 phase, 12 pulse?

1.41