Lesson 13: Unit Load Material Handling Interactions Part B

1/29

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

30 Terms

What is the effect of stiffer pallets on unit loads during shipping?

Stiffer pallets result in more stable unit loads and better protect vibration-sensitive products.

What is the Effective Bearing Area in the context of pallets?

The Effective Bearing Area is the area of the pallet deck that effectively supports the product, which is less than the pallet's footprint.

How is compression stress calculated in relation to the Effective Bearing Area?

Compression stress is calculated as force divided by area.

What happens to the compression stress on packaged products when using rigid vs. flexible pallets with gaps?

Rigid pallets result in lower compression stress (5.2 psi) compared to flexible pallets (11.9 psi), leading to a 228% increase in stress.

What are the consequences of unsupported corners of corrugated boxes on their strength?

Unsupported corners compromise the strength of the box, leading to reduced compression strength.

What is the impact of overhang and interlock stacking on box strength?

Overhang can cause a 30-42% reduction in strength, while interlock stacking can cause a 40-60% reduction.

How does pallet stiffness affect the strength of corrugated boxes?

Boxes can be 35% stronger on stiffer pallets due to better support.

What is the financial impact of using different pallet and box configurations?

Using a stiffer pallet can result in savings of $1.84 per unit load.

What are the additional benefits of using stiffer pallets?

Stiffer pallets improve recyclable pallet core quality and could reduce product damage during shipping.

What is the relationship between pallet stiffness and compression stress concentrations?

Lower pallet stiffness increases compression stress concentrations at the interface between the pallet deck and packaging.

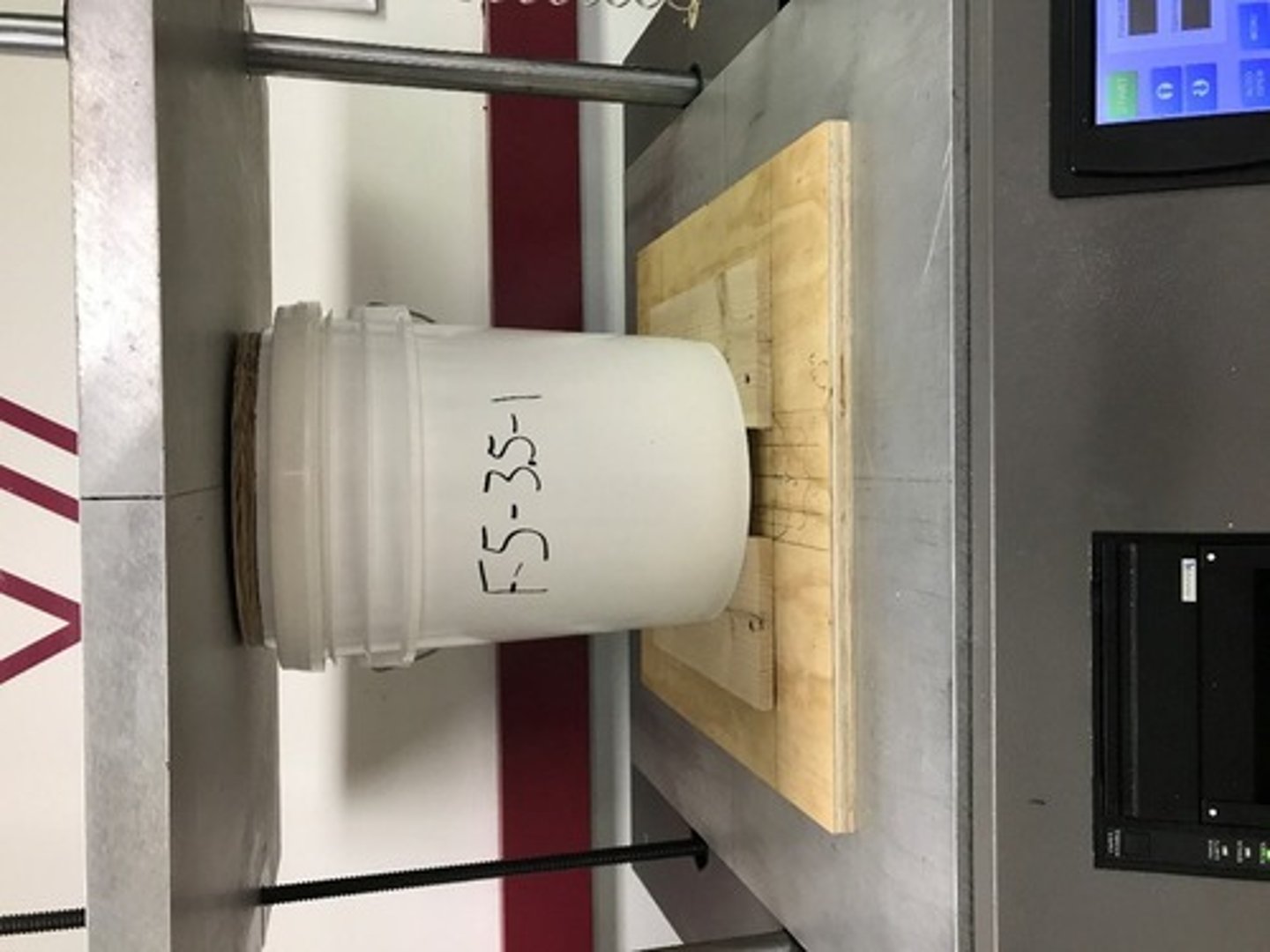

What is the effect of pallet stiffness on the strength of plastic pails?

Pallet stiffness can lead to a reduction in pail strength, with reductions of up to 37% depending on the thickness of the pallet deck.

What are the reductions in strength associated with double and single overhangs on pails?

Double overhang can lead to up to 46% reduction in strength, while single overhang can lead to up to 21% reduction.

How much can compression stress increase with a reduction in effective bearing area?

Compression stress can increase by 400% with a reduction in effective bearing area.

What is the significance of the Effective Bearing Area in load stability?

The Effective Bearing Area is crucial for load stability as it influences the distribution of stress on the packaged products.

What are the implications of using flexible versus rigid pallets on load stability?

Flexible pallets can lead to higher compression stresses and instability compared to rigid pallets.

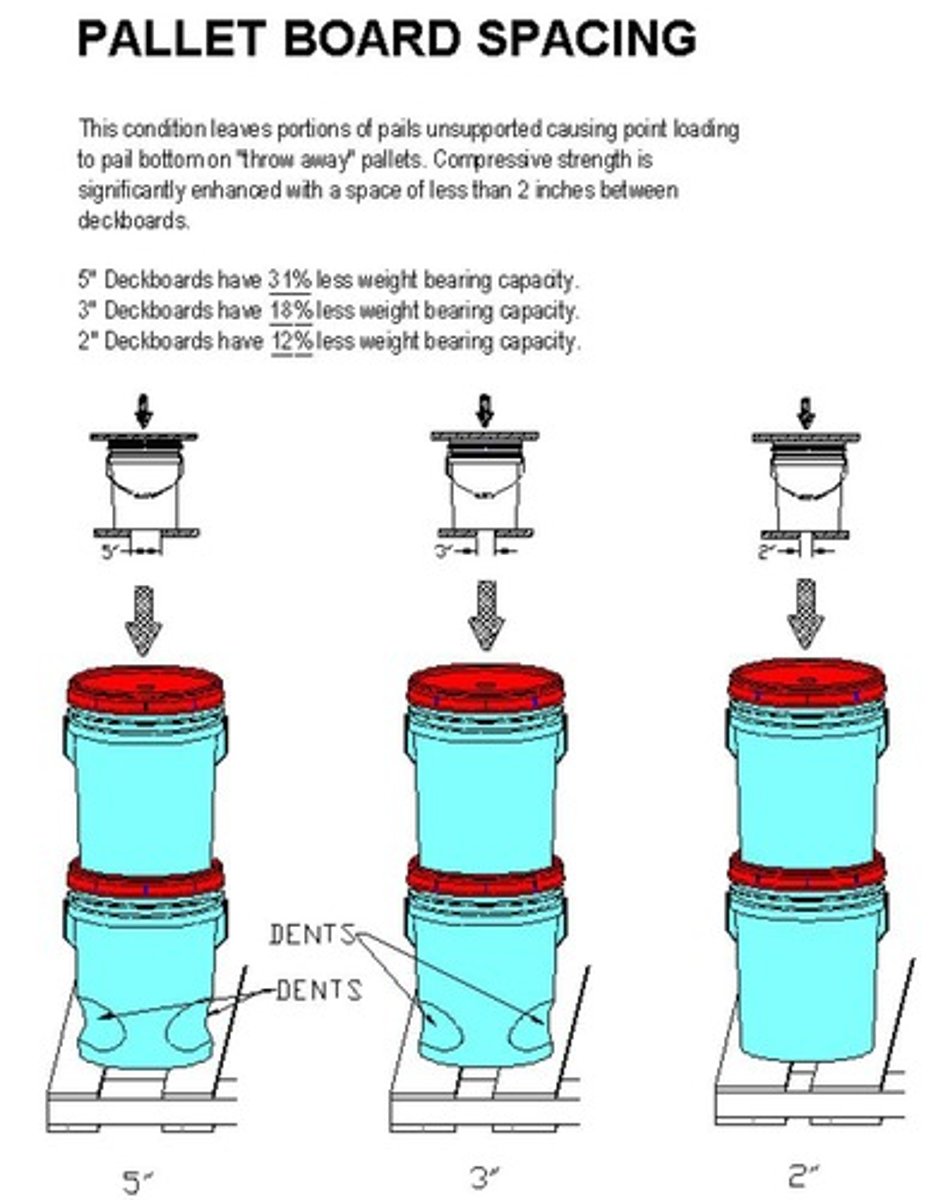

What is the effect of pallet gaps on box strength?

Pallet gaps can cause a 13- 31% reduction in the strength of the boxes.

What is the role of pallet deck stiffness in supporting packaged products?

Pallet deck stiffness affects the distribution of stress and overall strength of the packages.

How does the thickness of pallet deck boards impact pail strength?

Reducing the thickness of pallet deck boards can lead to significant reductions in pail strength, with a difference of ~780 lbs between the thickest and thinnest boards.

What is the relationship between the type of flute in corrugated boxes and their strength?

Different flute types (e.g., B and C-flute) can affect the strength of the boxes when supported by pallets.

What are the findings regarding compression stress experienced by packages on stringers?

The compression stress experienced by packages on stringers can be 500% more than the average compression stress.

How does the design assumption of corrugated boxes affect their performance on pallets?

Corrugated boxes are often designed with the assumption that pallet deckboards are rigid and non-deformable, which may not be true in practice.

What are the potential environmental benefits of using stiffer pallets?

Moving fiber from corrugated boxes to wooden pallets could be more environmentally beneficial.

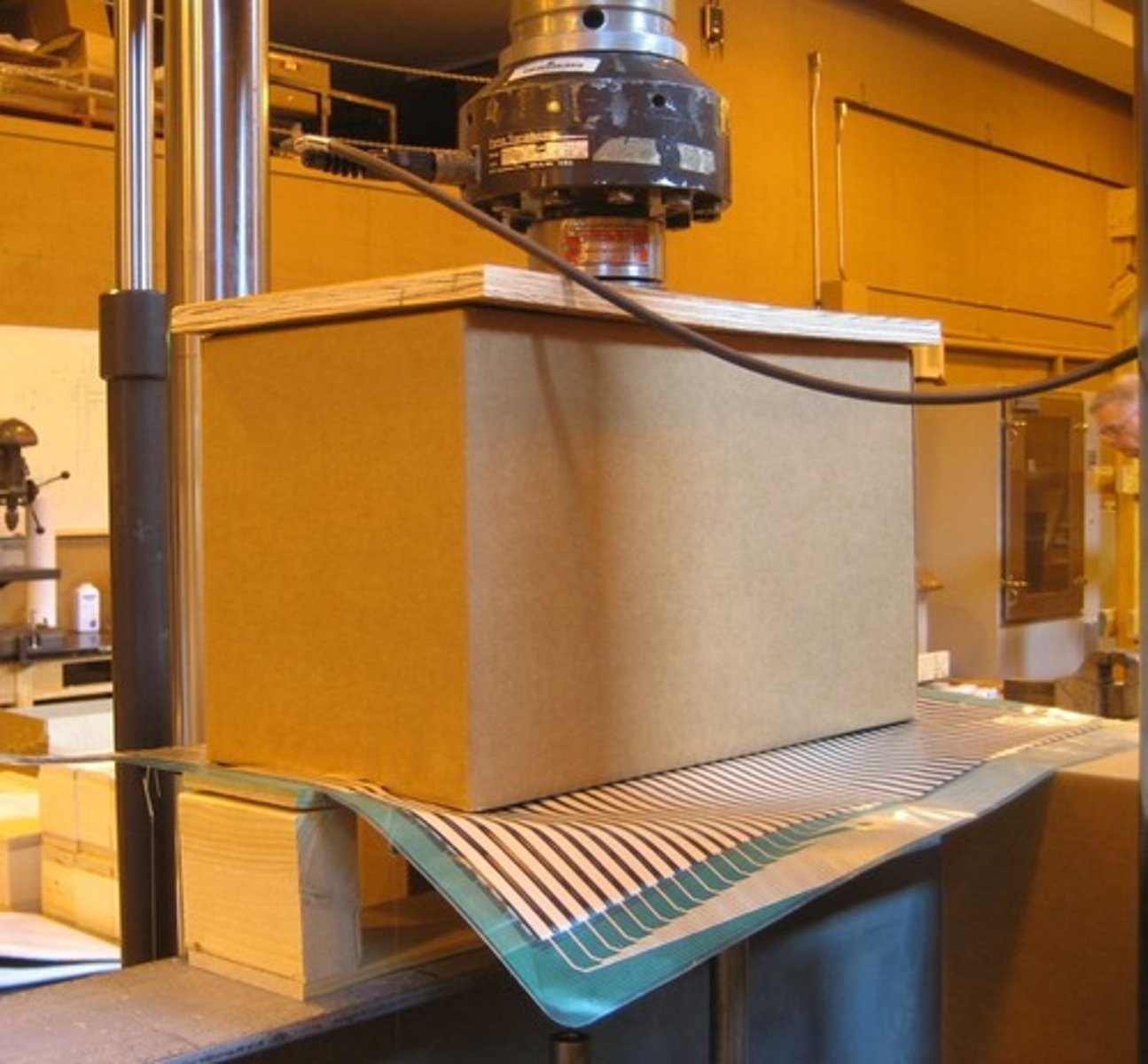

What is the significance of the testing setup in evaluating pallet and packaging interactions?

The testing setup helps measure the effects of different pallet types and configurations on the strength and stability of packaged products.

What are the implications of lower pallet stiffness on the overall unit load costs?

Lower pallet stiffness can lead to increased costs due to higher compression stresses and potential damage to products.

What is the impact of compression stress concentrations on product integrity?

Compression stress concentrations can lead to product failure, particularly in vibration-sensitive items.

Overview of Pallet & Plastic Pail Interactions

Bearing Area

is the area of top and bottom touching the packages

37%

% reduction in strength when decreasing deck board thickness

Increases Pallet Transmissiblity

Lower pallet stiffness

Lower pallet stiffness

reduces the effective bearing area