Product Testing: Stability

1/50

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

51 Terms

Why do we need to do stability testing?

Pharmaceutical products deteriorate upon storage

All products have a shelf life / expiry date, which you need to know as a pharmacist

How do we formulate medicines?

To minimise degradation

Possible routes of degradation

Oxidation

Photodegradation

Heat

Solvent degradation

Acid and base catalysis

Temperature and degradation

Increase in temperature = increase in rate of degradation

Can refrigerate (2-8oC) a product if unstable at room temp

Or freeze (<-15oC)

Temperature and degradation

What is the problem with freezing medicines?

If heat is used for thawing = degradation

As the product melts = we end up with interfaces = proteins stick to interfaces, unfold and lose activity

Some drugs e.g. amoxicillin less stable when frozen than in the fridge » as changes solubility

Biopharmaceuticals and vaccines can be degraded by freezing

Temperature and degradation

Where is the most risk of exposure to elevated temps

Transport and storage in vehicles

What is chemical degradation?

Any process where covalent bonds are broken

So chemical structure changes

What can undergo chemical degradation?

Both the active drug AND excipients

There may be risk of the API reacting with the excipients

What group of chemicals are most drugs?

What is the problem with this?

Most drugs are esters or amides

If water is present, these can hydrolyse to alcohols and carboxylic acids

How can we prevent hydrolysis of drugs that contain esters and amides?

Changing the solvent / the dosage form

Can replace water with another solvent

We can choose this solvent based on the dielectric constant (a measure of polarity) » influences how fast charged species react

Need to consider toxicity of solvent and compatibility with the drug (ensure it doesn’t react with the drug)

Using a solid dosage form instead

Solid dosage forms more stable than liquid dosage form » as in a solution, every single molecule of drug is surrounded by water

But: reactions can occur in water absorbed onto the surface of the particle

E.g. poorly stored aspirin tablets smell of acetic acid (vinegar)

Freeze-dried powders and then reconstituted just before use

For drugs that are very unstable e.g. penicillin

Formulate as a suspension

Suspensions more stable than solutions

Drug molecules in the centre of the particle protected from water

Drug molecules on the surface may react with water

Why should you not store medicines in the bathroom?

Steam = water adsorbs to the surface of particles = hydrolysis

How can we prevent hydrolysis of drugs that contain esters and amides?

Changing the solution itself

Why is pH of the solution important?

A catalyst speeds up a reaction without being consumed itself » so a small amount of catalyst can cause a lot of degradation

H3O+ and OH- (from the dissociation of water) can catalyse hydrolysis processes

» so the drug will degrade faster at acidic or basic pH values

How can we prevent hydrolysis of drugs that contain esters and amides?

Changing the solution itself

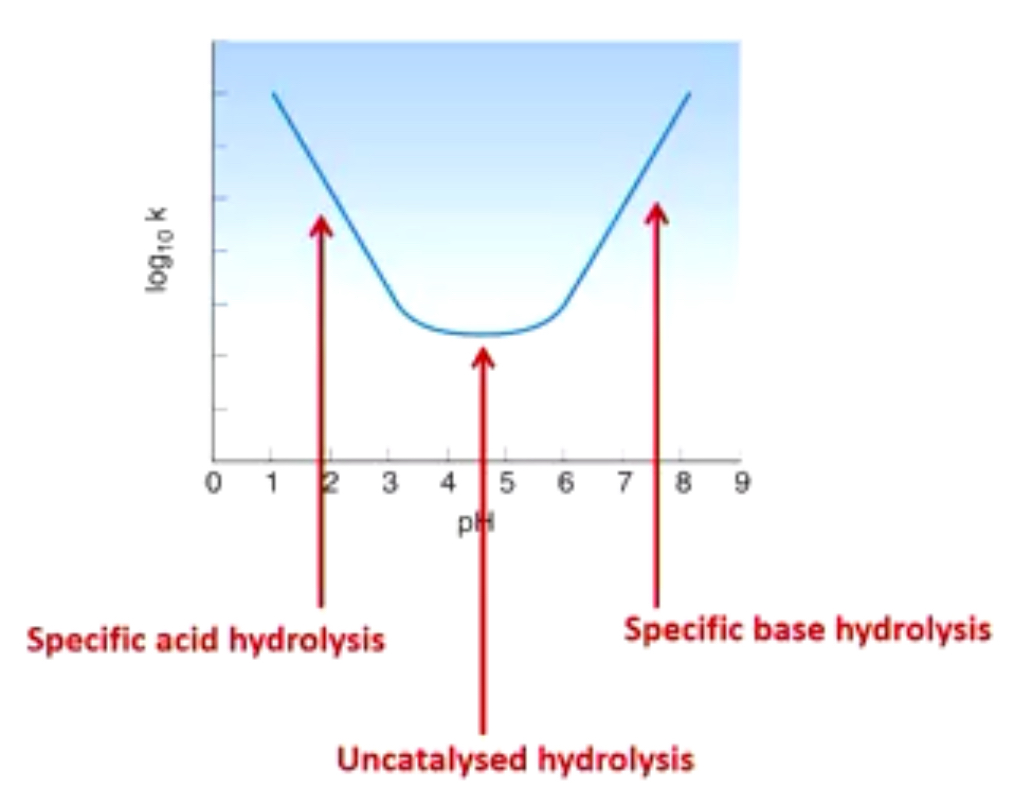

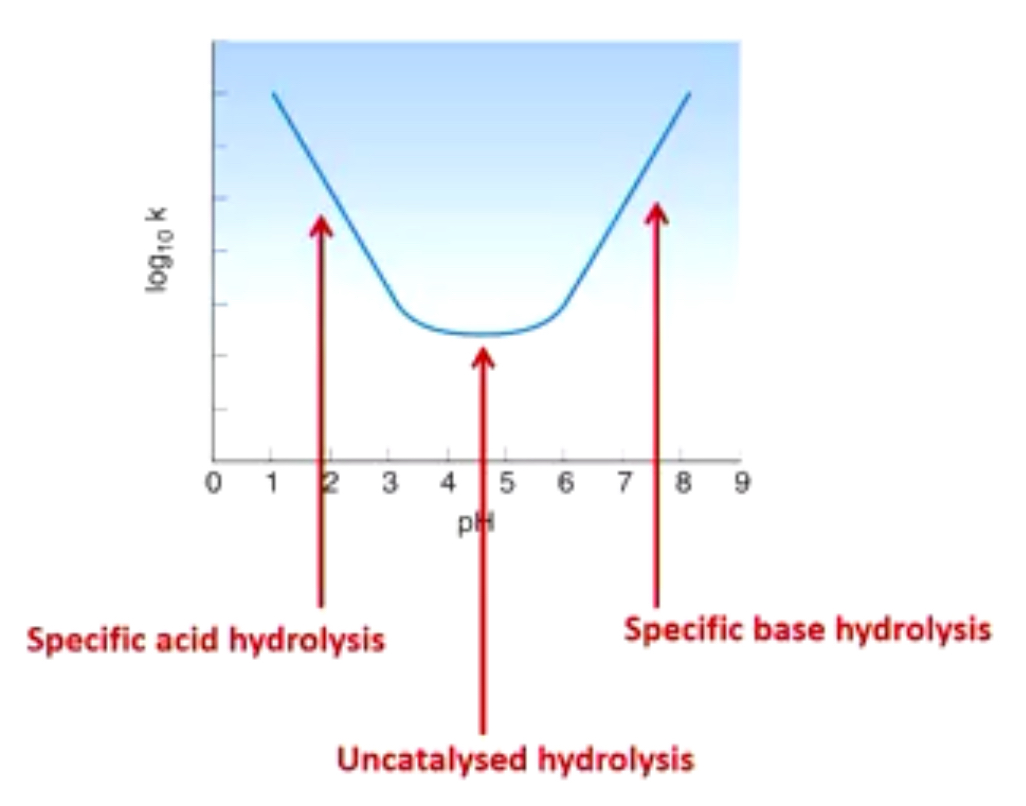

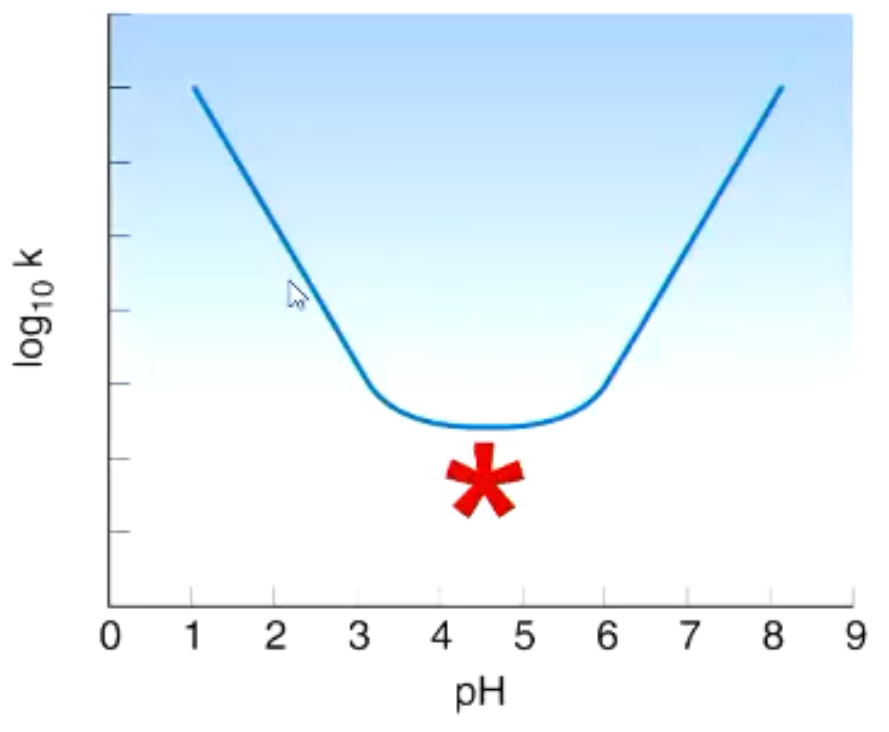

Graph of pH and degradation rate

Specific acid hydrolysis: hydrolysis catalysed by presence of H+

Specific base hydrolysis: hydrolysis catalyse by presence of OH-

How can we prevent hydrolysis of drugs that contain esters and amides?

Changing the solution itself

Why is this graph important?

Tells us the pH range where degradation rate is slowest (uncatalysed hydrolysis)

Tells us when we need to add a buffer

How can we prevent hydrolysis of drugs that contain esters and amides?

Changing the solution itself

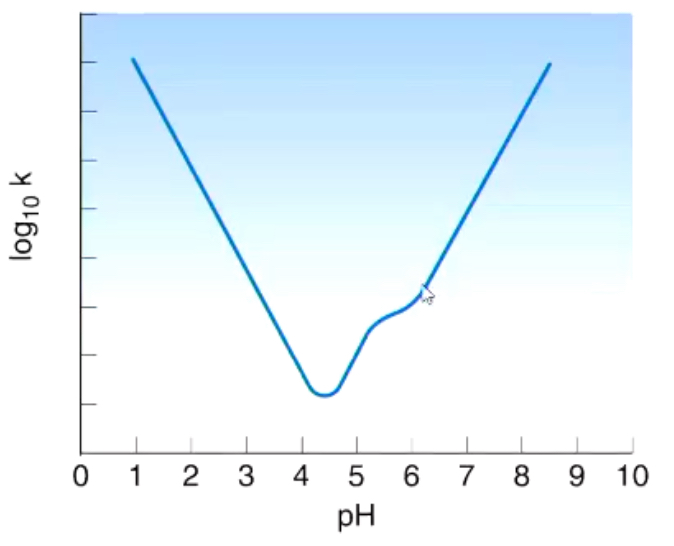

What is this curve showing?

Many drugs ionise

And the neutral and charged forms of the drug degrade at different rates » hence, there is a point of inflection

How can we prevent hydrolysis of drugs that contain esters and amides?

Changing the solution itself

Specific vs General catalysis

Specific catalysis: H3O+ and OH- catalysing degradation

General catalysis: other species catalysing degradation

How can we prevent hydrolysis of drugs that contain esters and amides?

Changing the solution itself

Examples of general catalysis

Ions in buffers

E.g. phosphate or acetate buffer catalyses the hydrolysis of chloramphenicol = incompatible with the drug

Can use borate buffer instead which does not catalyse degradation = compatible with the drug

Light and degradation

Light causes degradation

To protect from light:

Keep medicine in a tinted glass container / opaque outer container e.g. cardboard

To block out UV light (which causes degradation)

Oxygen and degradation

Oxygen causes degradation

To protect from oxygen (oxidation):

We can flush the containers with an inert gas e.g. N2, Ar, CO2 » to expel all the air and oxygen from the container

However:

hard to remove all oxygen

best used for single-use containers as with multi-use, opening and closing allows for gas exchange and oxygen to enter

Oxygen and degradation

When does oxidation occur the fastest?

So how can we further prevent oxidation?

Oxidation is accelerated at high pH

So we can formulate at low pH

» However, there is a trade off between minimising oxidation and minimising hydrolysis

Metal ions e.g. Cu2+ and Fe3+ catalyse oxidation

These are present in trace amounts in all formulations

However they are not used up so can cause a lot of degradation

We can add a chelating agent, like EDTA, to bind to the metal ion and prevent catalytic activity

Add an an antioxidant

Reacts with O2 and removes it from the formulation

Stops free radical reactions

E.g. ascorbic acid (water soluble)

E.g. a-tocopherol (oil soluble)

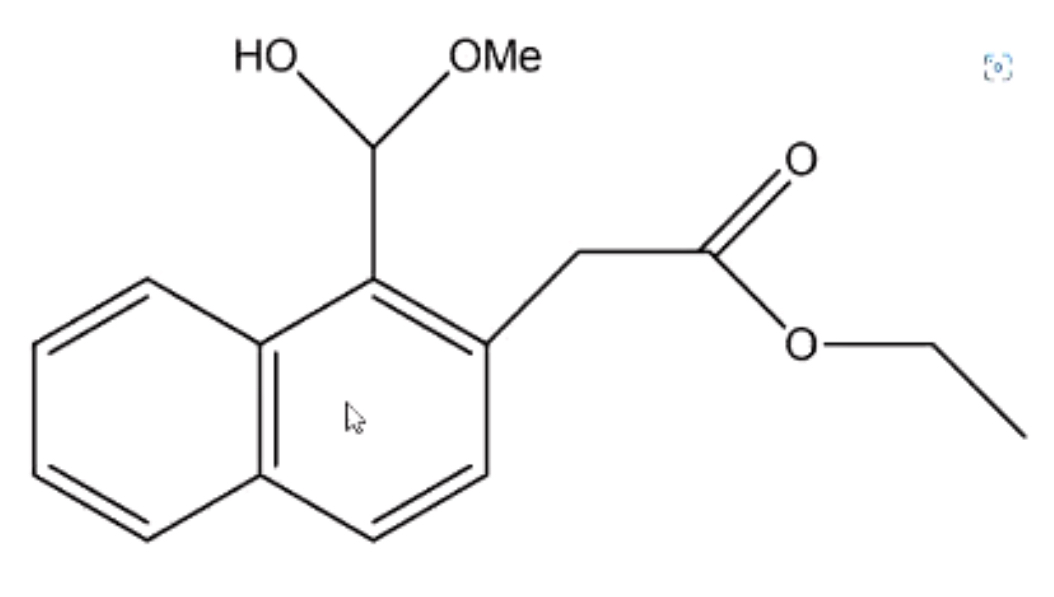

EQ:

What degradation might this drug undergo?

Hydrolysis

Oxidation (of OH group to a ketone)

Heat degradation

EQ:

What does the region marked * on the diagram correspond to?

Uncatalysed hydrolysis

Physical Stability

Problems of containers for liquid dosage forms?

Sorption of drug to container » leads to loss of drug

Shedding of particles from glass container » poor appearance, poor mouth-feel (affects adherence)

Extraction of materials from container into liquid » toxicity, change of pH

Evaporation of volatile components e.g. peppermint » poor taste

Physical Stability

2 types of sorption that can occur

Adsorption: particles of drug adhere to the walls of the container

Absorption: molecules of drug taken up inside the wall of the container

» both cause the loss of drug from the solution

Physical Stability

When is sorption more likely to occur?

Non-polar molecules have a high affinity for plastics and rubbers

e.g. Diazepam in solution sorbs to plastic packaging

pH can affect sorption » unionised form of the drug is less polar so more sorption to plastics and rubbers

Physical Stability

How can we prevent problems to do with containers for liquid dosage forms?

Shedding of glass particles » use a plastic container

If drug is hydrophobic and will stick to walls of a plastic container (non-polar) » use a glass container (polar)

Evaporation of volatile compounds » don’t use rubber caps/lids

Physical Stability

Physical instability of solutions

Precipitation of the drug = loss of efficacy, inaccurate dosing

Precipitation of its degradation products = poor appearance

Physical Stability

Physical instability of suspensions

Caking

Ostwald ripening » even if drug is poorly water soluble, little bits of the drug may dissolve and may precipitate out

» can lead to inaccurate dosing, poor appearance, grittiness

Physical Stability

Physical instability of emulsions

Creaming » dispersed phase droplets accumulate at the top

Cracking » emulsion breaks into 2 separate phases

» poor appearance (affects adherence)

Reduction in viscosity

» difficult application

» non-homogenous product

» increased risk of creaming and cracking

Physical Stability

Effect of changes in physical property

Compromises appearance » can reduce adherence

Compromises efficacy » inaccurate dosing, less drug present

What do we mean by preformulation?

Understanding the properties of the drug

We do this using qualitative measurements of the drug’s susceptibility to oxidation, hydrolysis and light degradation

Stability Testing: Preformulation

How do we measure the drug’s susceptibility to oxidation?

Heat solutions of the drug with / without oxygen flushing

Then look at chemical structure of the drug for degradation

Stability Testing: Preformulation

How do we measure the drug’s susceptibility to hydrolysis?

Heat solutions of the drug in water, acid and base

Stability Testing: Preformulation

How do we measure the drug’s susceptibility to light degradation?

Shine artificial daylight lamps on the drug

Stability Testing: Preformulation

What other preformulation test do we do?

Investigate stability of the drug in the solid state

Keep the drug at high temp

Add the drug with possible excipients

Stability Testing: Stress Testing

High temperatures

What does this involve?

Storing the drug at high temperatures

We then calculate the rate of degradation at RT using the Arrhenius equation:

k = Ae-Ea/RT

You then plot a graph of k vs the different temperatures

Calculate equation of the line

Determine what the rate of reaction at room temperature should be

Carry out with the drug alone then repeat with drug + excipients then with candidate formulations (exactly how the patient will take the drug)

Stability Testing: Stress Testing

High temperatures

Advantages

Speeds up the degradation process instead of waiting for years For degradation to happen at room temp

So we get results quickly

Stability Testing: Stress Testing

High temperatures

Limitations

Predicted shelf life at room temp is inaccurate

Different reactions may occur at higher temperatures than room temperature

Degradation products may themselves break down

E.g. if trying to quantify the amount of degradation product (B) but the degradation product (B) breaks down (C), we will not be able to quantify the C as we are only looking for the B

Heating reduces moisture levels in solid products

Underestimate rates of hydrolysis

The stability of the product must be studied in the actual storage conditions to be used

Stability Testing: Stress Testing

Temperature Cycling

What does this involve?

Subjecting liquid products to freeze/thaw cycles (very high then very low temps)

This can cause:

Ageing and particle growth in suspensions,

Cracking in emulsions

Precipitation in solutions

Stability Testing: Stress Testing

Photostability Testing

What does this involve?

Shine an artificial daylight lamp on pure drug

Then repeat with formulated product

Then use same packaging as will be used when drug is released to market

Stability Testing: Long Term Testing

What is long-term testing?

Long-term studies performed under actual storage conditions

After preformulation and stress testing, we should now have a formulation that we are confident is stable

Long-term testing is used to validate this to show a regulator that the drug is ready to be released to market

Stability Testing: Long Term Testing

What do we do during long-term testing?

Use worst case scenarios of temperature and humidity E.g. in particular regions of the world, how hot and how humid does it get

Use packaging that is intended to be used in the market

Samples are removed for 12 months

We then assay for both the drugs and excipients

Might also need pH tests, microbial tests and physical characteristic tests

Stability Testing: Long Term Testing

Requirements for long-term testing?

Use same packaging for testing as will be used for the product

Test at least 3 batches of the product

Store liquid formulations inverted to ensure that the contents interact with the cap of container

Sample every 3 months in year 1, every 6 months in year 2 and then annually until the end of the proposed shelf life

Stability Testing: Long Term Testing

How big are the samples used?

Batches of at least pilot scale

Stability Testing: Long Term Testing

What are we looking for when we sample every 3 months/6 months/annually?

Oral solutions, suspensions, emulsions:

Precipitation

Clarity (solutions)

pH

Viscosity

Extractables

Microbial contamination

Suspensions:

Dispersibility

Rheological properties

Size and distribution of particles

Emulsion:

Phase separation

Size distribution of dispersed phase

Stability Testing: Long Term Testing

Criteria for results

Degradation must leave >90% of stated dose left » use statistical tests

Appearance, smell and taste must be acceptable

Test at least 3 batches, calculate shelf lives and take the shortest shelf life

When do we NOT need to control humidity in stress testing / long term testing?

For aqueous products in glass containers

Purpose of pre-formulation and stress testing summary

Preformulation: tells us which degradation will pose the biggest problem

Stress testing: tells us the rate of degradation and quick information about the stability of the drug

EQ:

Explain the differences between the four global climactic zones. Why is it important to study product stability in all the zones where the product will be sold?

The four zones differ in their average temperatures and relative humidities.

It is important to study product stability in all the zones where a product will be sold in order to ensure that it is stable in that set of conditions: temperature and relative humidity (RH) will affect degradation rates and processes.

EQ:

What is caking, and why is it problematic in a pharmaceutical suspension?

Caking arises when particles in a suspension sink very slowly

This results in minimal liquid trapped within the particle

So the particles are very difficult to disperse upon shaking

This means most of the drug will be stuck at the bottom of the container

Leading to inaccurate dosing

EQ:

Why do we test multiple batches of a product during long-term stability testing?

There will be batch to batch variability - not all batches will be identical

So we need to test several batches to ensure we have a good overall understanding of how the formulation will behave