Textiles - Specialist technical principles

1/143

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

144 Terms

What should a designer consider when selecting materials?

functionality, aesthetics, environmental factors, availability, cost, social factors, cultural factors, ethical factors

Examples of strengthening materials:

using interfacing on a skirt/trouser waistband or a neckline to stop the fabric stretching, using interfacing in a collar or cuffs to stiffen them and hold their shape, using interfacing behind buttons and button holes and pockets to strengthen the fabric or using a tightly woven fabric such as webbing from synthetic fibres.

Why are fabrics reinforced?

to be strengthened so they don't lose their shape or break during use

What is interfacing?

a woven or non-woven fabric used as an extra layer to give additional strength and help to keep the shape of a textile product

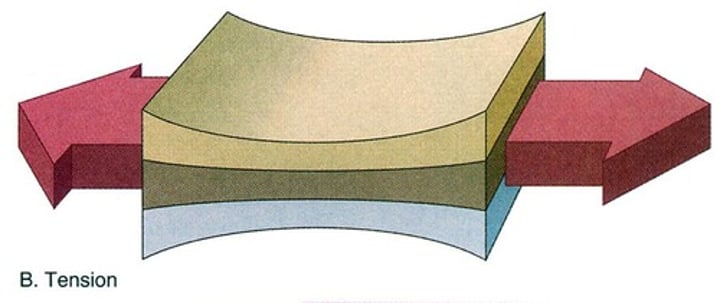

What is tension?

pulling or stretching force

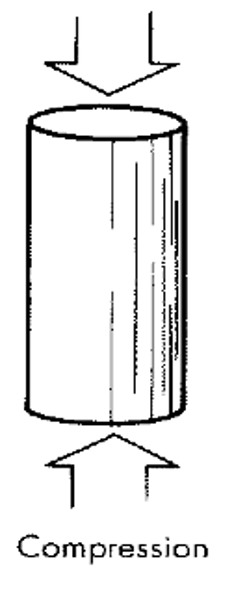

What is compression?

pushing forces that squeeze an object

What is shear?

force directed parallel to a surface

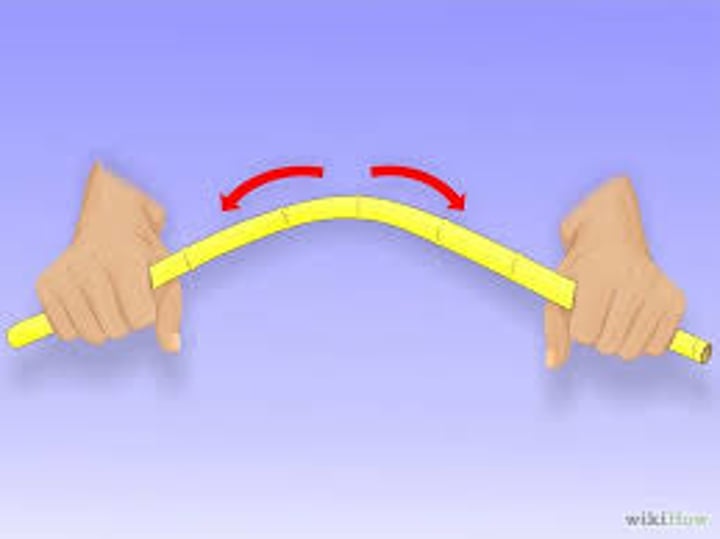

What is bending?

act on an angle to an object and makes it bend

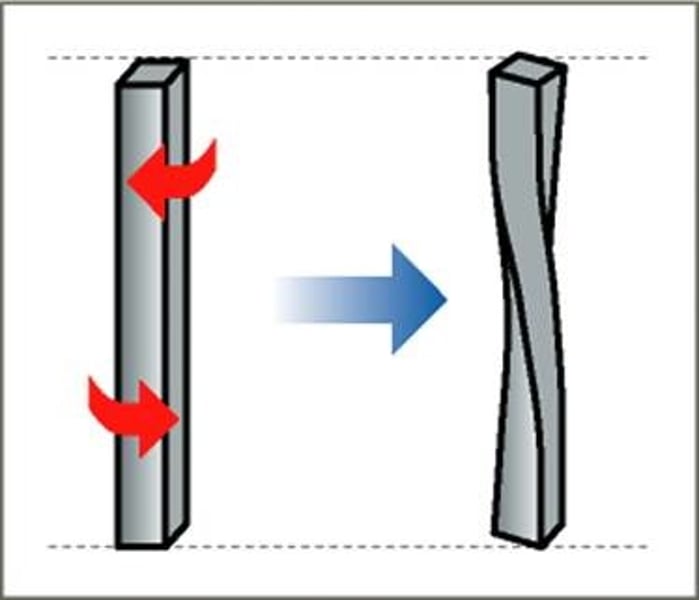

What is torsion?

a twisting force

What is mining?

Extracting ore or minerals from the ground

Positives of mining

employment, income, cheap materials

negatives of mining

pollutes water supplies and threatens indigenous populations

What is deforestation?

the action of clearing a wide area of trees.

what is land dredging?

miners digging at high pressures into the ground

what is river dredging?

moving along a river using a suction hose to collect gravel and mud

What is drilling?

The process of boring down into the earths crust to extract oil or gas

effects of drilling

distruption to the wildlife, chemicals are disposed into sea and ruin marine life

problems with growing cotton

they need a lot of chemical fertilisers and insecticides and can harm workers health, they use large quantities of water that can be used as drinking water

problems of farming

leads to deforestation of land for cotton crops and causes changes to the landscape and destroys habitats

effect of transporting textile materials

products from where they are made are transported to the country where they are sold uses fuel and puts pressure on transport systems

effects of textile waste

takes up a lot of landfill waste and toxic chemicals can leech out into surrounding land and waterways

problems with colouring processes

use a lot of chemicals and water - they're effluent and can pollute waterways

effects of the use of chemical finishes

flame retardancy can cause pollution of waterways and land if waste is not disposed of properly

6 Rs

Repair, reuse, recycle, rethink, reduce and refuse

How are synthetic fibers made?

made from petrochemicals from non renewable sources

why are polyester fibres more sustainable than synthetic fibres?

synthetic fibres take many years to decompose and polyester fibres can be recycled or made from recycled plastic bottles

What is Ingeo?

a biodegradable fibre that can replace polyester made from corn starch

benefits of organic cotton

better for the environment and has less impact on workers lives and health but is more expensive

fibres to replace cotton

regenerated fibres such as tencel and modal

how can we reduce carbon emissions?

reducing transport miles - products are made closer to were they are sold and use more sustainable forms of transport/ fuel

how can we reduce the water and chemicals in colouring cotton?

growing cotton fibres already coloured, newer and disperse dyes use little water and don't wash out in laundry

what are regenerated fibres

Fibres manufactured from the cellulose, for example from spruce trees or cotton linters

What is cotton?

natural cellulose from cotton plant

what is wool

natural protein from sheep or other animals

what is silk

natural protein made from cocoon of a silk caterpillar

what is polyester, polyamide and elastane

made from petrochemicals from coal or oil

what fibre type is cotton?

staple

what fibre type is wool?

staple

what fibre type is silk

filament

what fibre type is polyester, polyamide and elastane

filament

what's a filament fibre?

long continous lengths

whats a staple fibre

a shorter length fibre

what is the manufacture of cotton?

flat, ribbon like fibres are cleaned and twisted together

what is the manufacture of wool?

sheep are sheared and fibres are cleaned and twisted together

what is the manufacture of silk?

two triangular shaped filaments are held together with natural gum from the caterpillar

what is the manufacture of polyester, polyamide and elastane?

chemicals are made into a polymer which is melted then spun into smooth continuous fibres

What do fibres need before they can be made into woven or knitted fabrics?

they need to be spun into yarns

how are staple fibres formed?

carded so they lie in the same direction before they are spun into yarn

how are filament fibres formed?

lightly twisted to make a yarn

what's the effect of spinning?

holds the fibres together and adds strength

what happens when fibres are tightly twisted together?

the yarn will be strong and smooth but trap less air so are less insulating than loosely twisted fibres

what happens to filament fibres to be blended with staple fibres?

cut down into staple form

what are seedpods of the plant?

bolls that can burst and become fluffy

What type of fibre is cotton?

staple

what type of specialised fabrics are used in sportswear?

elastane - gives stretch, polartec fleece for lightweight thermal insulating garments, lightweight, breathable fabrics made from polyester or polyamide microfibres, moisutre management fabrics - coolmax, breathable and windproof, waterproof fabrics - goretex for outdoor sports

types of specialised fabrics used for furnishings:

fabrics with flame retardant finishes for upholstery and curtains, water-repellent fabrics, fabrics with a sanitised finish - hospital bedding, light-resistant fabrics and PVC-coated fabrics for tablecloths

chemicals that give flame retardancy:

proban and pyrovatex from cellulosic fibres that forms an insoluble cross-linked polymer so it wont wash out.

the effect of flame retardant synthetic fibres:

can cause serious burns when they melt

uses of flame retardancy:

important children's nightwear or furnishing fabrics

heat resistant fabrics

kevlar and Nomex in protective clothing for motorcycle and racing car driverss

What is neoprene?

synthetic rubber used in wetsuits, hoses, laptops/tablet covers, etc.

what are microencapsulated fibres?

contain insect and odor repellents

use of interactive fabrics:

contains conductive fibres such as carbon, silver and steel allow fabrics to have wearable electronics such as GPS, solar panels and performance monitors

Define fabric

a flat, sheet-form material and needs to be cut and shaped into products

what should u make sure a fabric is before use?

crease free and clean

Define template

a pattern shape, usually made from paper or card, used to cut out fabric to the size or shape required

What is the grainline?

marking on the pattern template that is placed on the straight grain of the fabric otherwise it won't hang properly in the finished product - must be checked with a tape measure for accuracy

Describe the process of cutting

both slevedges must be placed exactly on top of each other to keep the grain accurate when making double layer, the fabric must be pinned flat to the fabric at regular intervals to stop it moving

How to transfer markings on a template to the fabric?

using tailor's chalk, a tracing wheel and tracing paper or tailor's tack

What is tacking?

a temporary stitching to hold fabrics together until it's ready to be sewn permanently

Things to consider before making a seam:

they must be appropriate for the fabric, type of product and where its hidden or a decorative function

describe a plain seam

its flat and not seen on the outside of the product but the seam edges will need to be neatened to stop fraying.

describe a french seam

sewn twice so all the edges are enclosed and it is not visible on the outside of the product. Its a strong seam useful for fine fabrics as the turnings are hidden but it's bulky on thicker fabrics

describe a double-stitched seam

strong and flat with all the turnings enclosed. it's visible on the outside of the product so is often used as a decorative feature

How do you make a plain seam?

Put your two pieces of fabric with right sides together and the raw edges even.

Stitch along the seam allowance line. Common seam ⅜ inch (1cm), 1/2 or 1/4 of an inch. Always check your sewing instructions as these will vary by designer.

Neaten the raw edges. The edges may be pressed open and finished separately or pressed to one side and finished together

How do you make a french seam?

place fabrics wrong sides together and stitch on seamline. Press seam open and trim one seam allowance to 5mm. fold over seamline. stitch folded edge over

Hoe do you make a double-stitched seam?

Stitch a 5/8" standard seam with the right sides of the fabric together.2. Stitch again about 1/8" from the seam line in the seam allowance. A narrow zigzag stitch may be used for this second row of stitching.3. Trim the seam allowances close to the stitching.

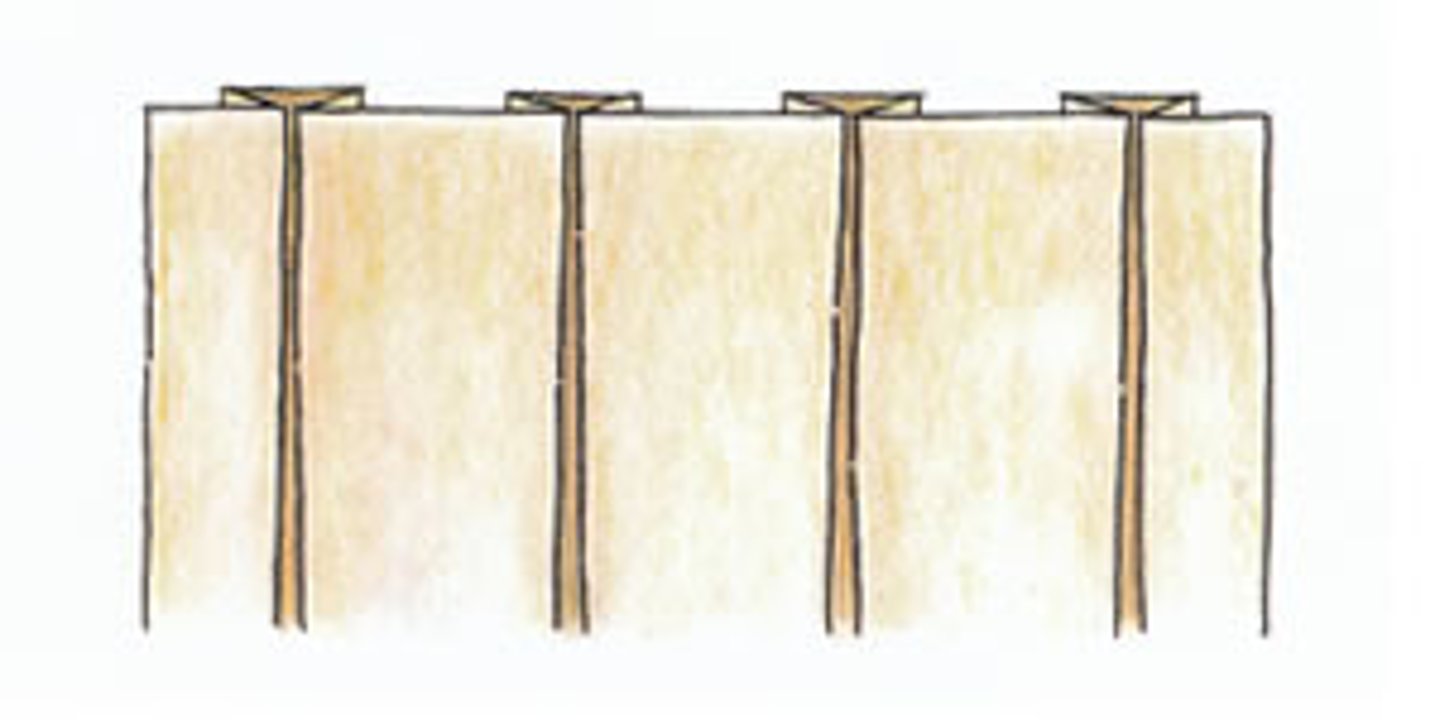

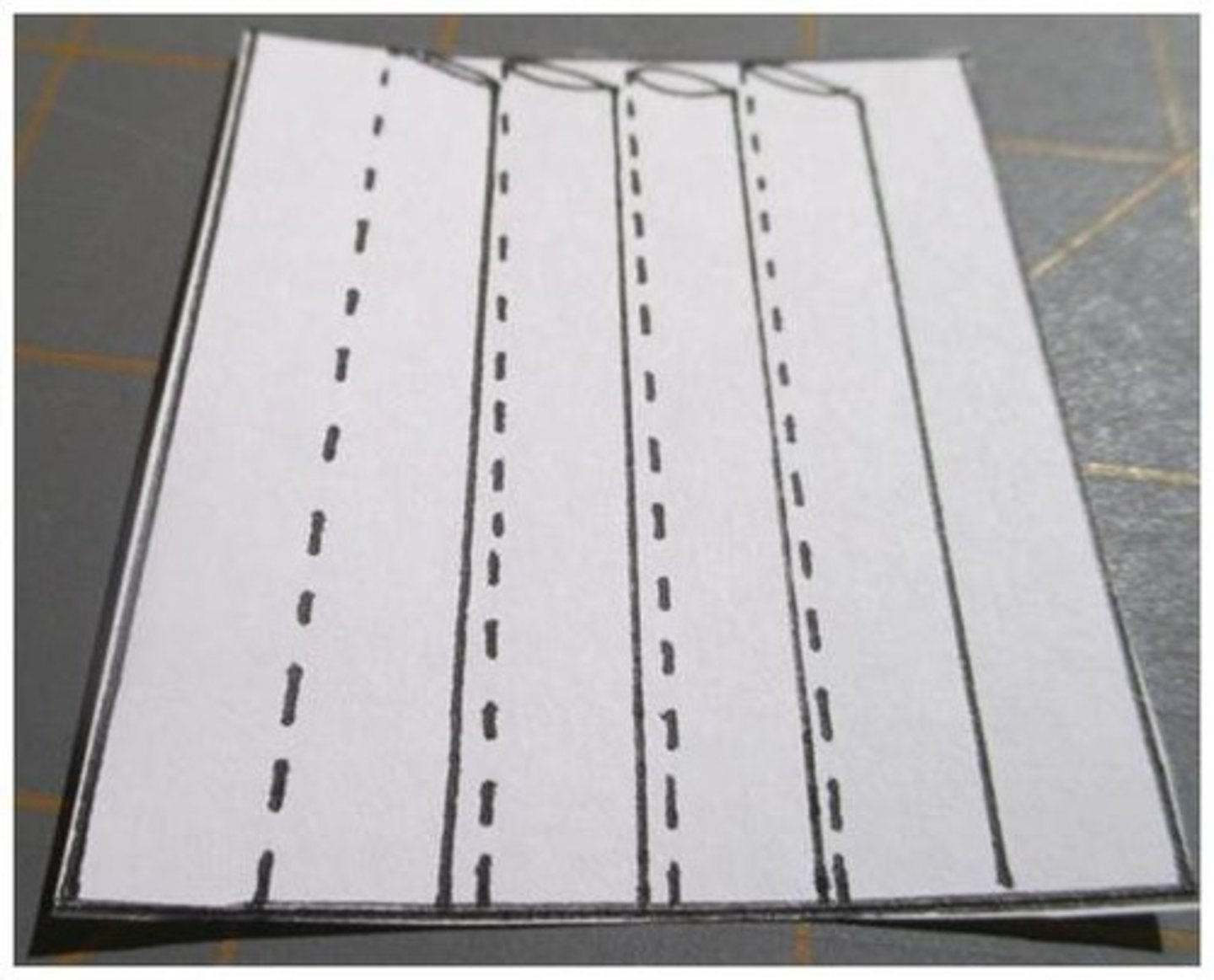

what are pleats?

folds in fabric that are stitched and pressed in place that allow for movement in clothing, add texture and a decorative effect

How are knife pleats made?

folds of the fabric over in one direction facing the same way

How are inverted pleats made?

two knife pleats facing each other

How are box pleats made?

two knife pleats facing away from each other

What are tucks?

narrow and stitched along their length - decorative feature

What is gathering?

fabric is drawn up using thread to reduce the length of the fabric

Uses of gathers?

to shape fabric, add ease and movement in clothing and as a decorative effect

Effect of quilting

adds texture and decoration of a product

process of quilting

consists of layers of wadding sandwiched between two layers of fabric and sewn in a decorative pattern

uses of quilting

to add warmth as the trapped air in wadding acts as an insulator

What is piping?

defines and strengthens an edge and can add decoration

How is piping made?

enclosing a cord in a strip of bias-cut fabric before stitching it into a seam

How are yarns made?

Yarns are made by spinning and twisting fibres together.

What is plying?

yarns twisted with other yarns to make them stronger so they can be used for many purposes

What is a ply of a yarn?

number of single strands in the yarn

What does the fabric width determine?

the amount needed to make a product - the wider, the less needed

what are general purpose threads made out of?

polyester fibres

How are embroidery threads made?

from different fibres and some are designed to make special effects

types of fastenings:

zips, buttons, velcro, poppers, press studs, and hook and eyes

What is one-off production?

A single unique product made by skilled workers such as wedding dresses or made-to-measure suits

What are bespoke/ one off products and examples?

> Tailor made to specific user needs

> Suits and dresses, Artwork, ceramics and jewellery, Architecture

What is batch production?

> Specific quantity of a product is made

> They can be repeated

> Machinery and workforce are flexible and could change to make a different batch

> Uses jigs, moulds and cheaper products

What aids manufacturing systems to change a new product quickly?

computer control is used to track what's made according to consumer's demand