BE 450 PPT 5 Composites

1/73

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

74 Terms

composite

engineered or natural materials made from 2 or more constituent materials

composite

have significantly different physical or chemical properties which remain separate and distinct on a macroscopic level w/in the finished structure

attractive

composites provide the "best of both worlds" since they draw on the ____________ properties from each component

fiberglass

composite examples: strength of the small diameter glass fibers (ceramic) combined with ductility of the polymer matrix

bone

composite examples: hydroxyapatite (ceramic) and collagen (polymer)

high, low

composite major advantage: can obtain a more desirable combination of properties - _______ strength, ______ density

discontinuous

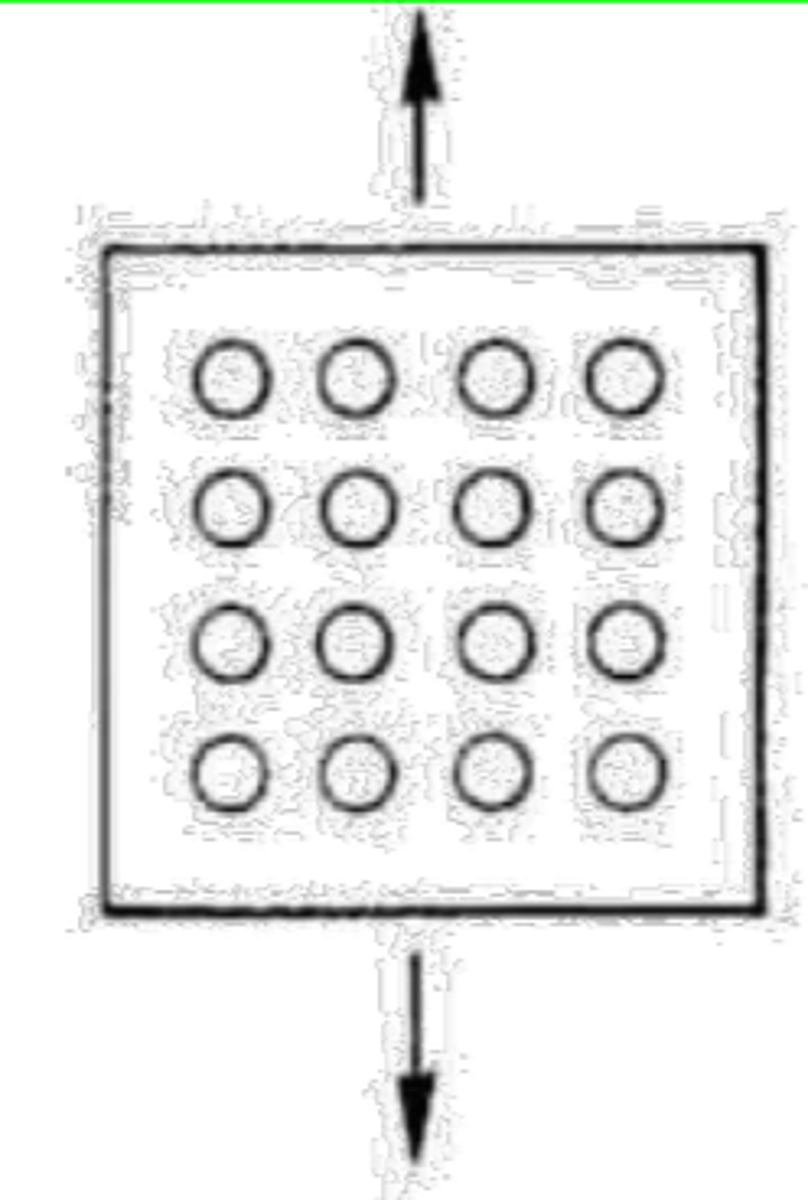

composites consist of 1 or more ________________ phases embedded w/in a continuous phase

continuous phase

matrix, provides environmental protection and transfers stress to the other phase

discontinuous/dispersed phase

usually harder and stronger than the other phase, surrounded by matrix, termed reinforcement or reinforcing material

phases

__________ of a composite can be metals, ceramics, or polymers

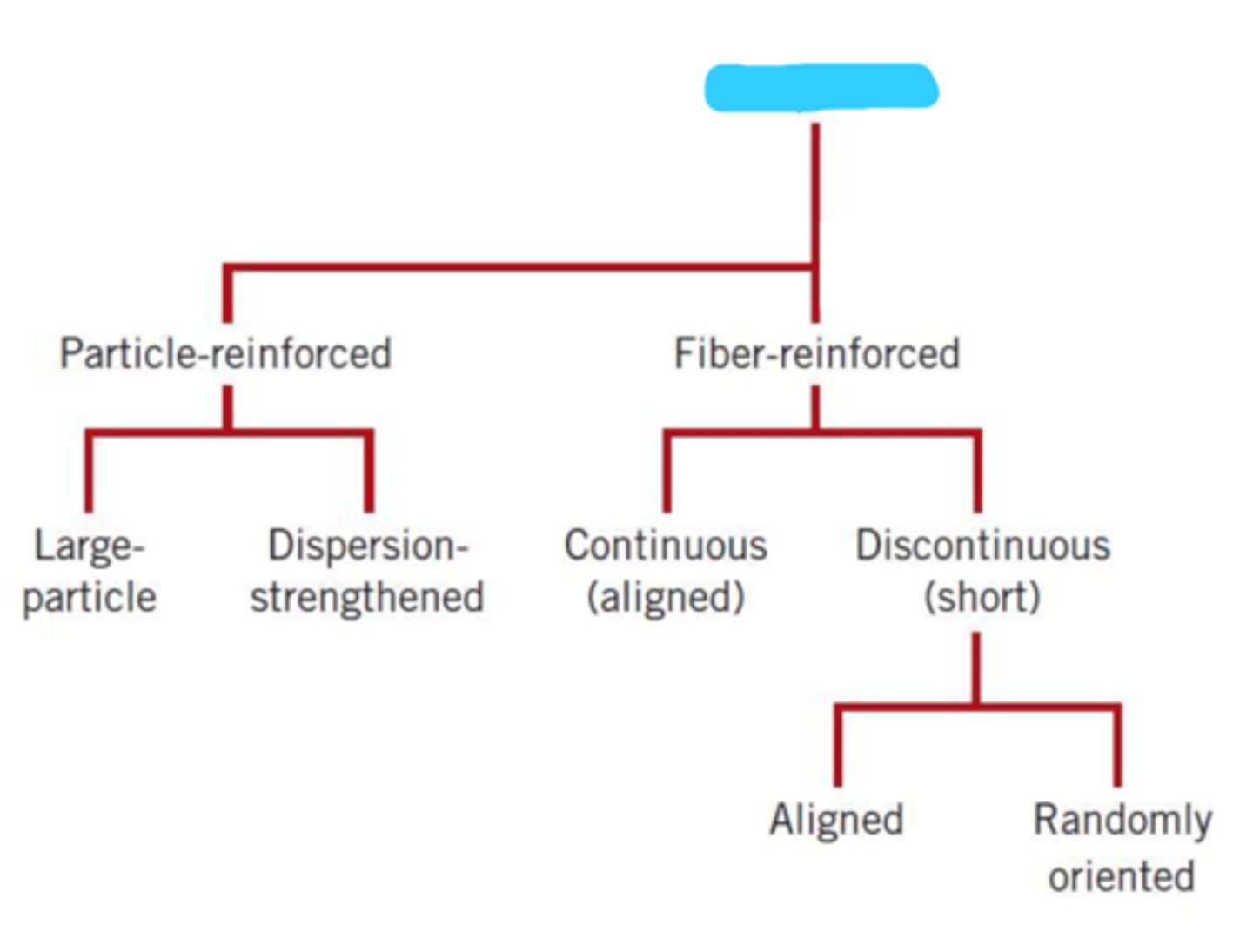

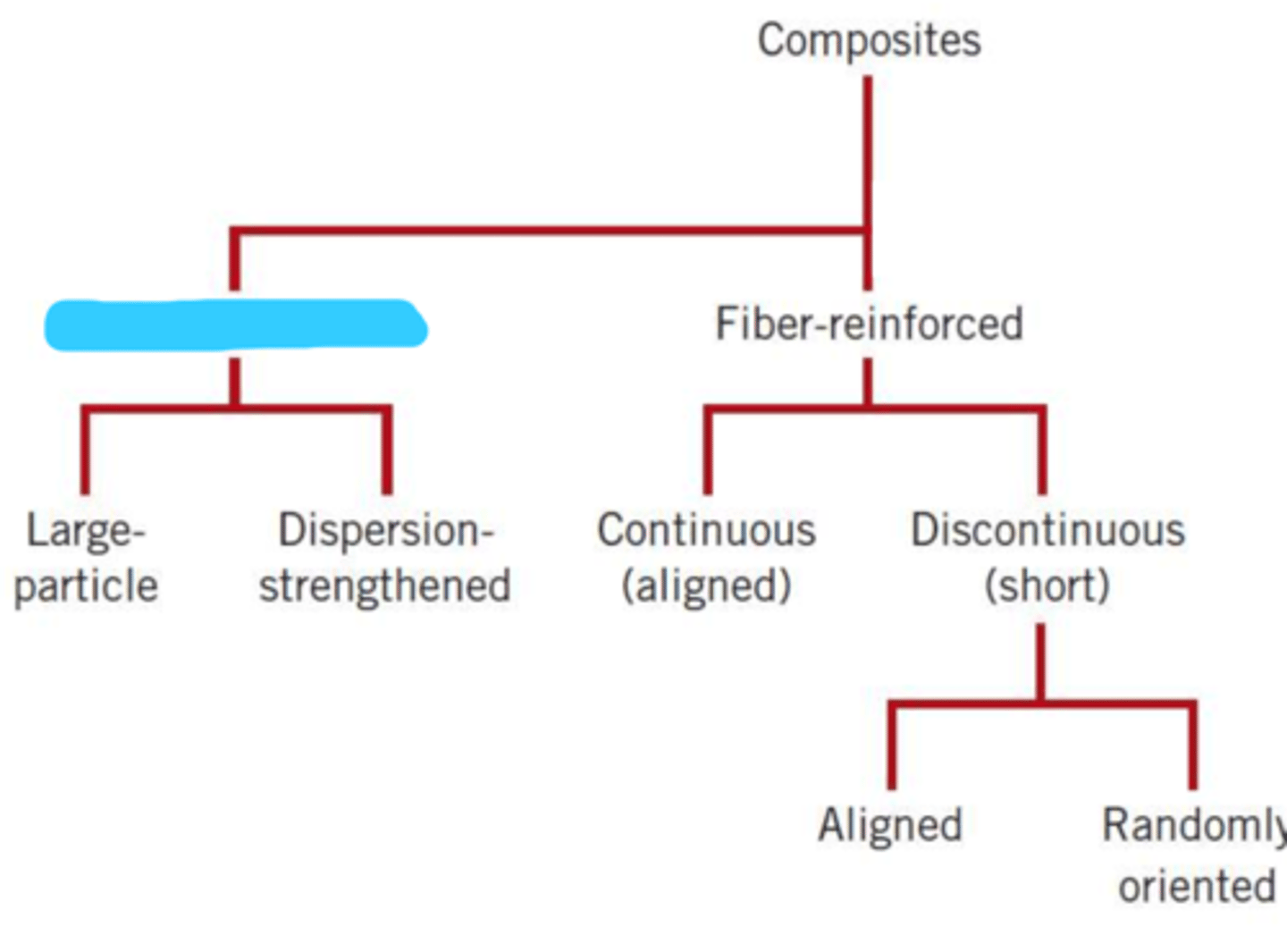

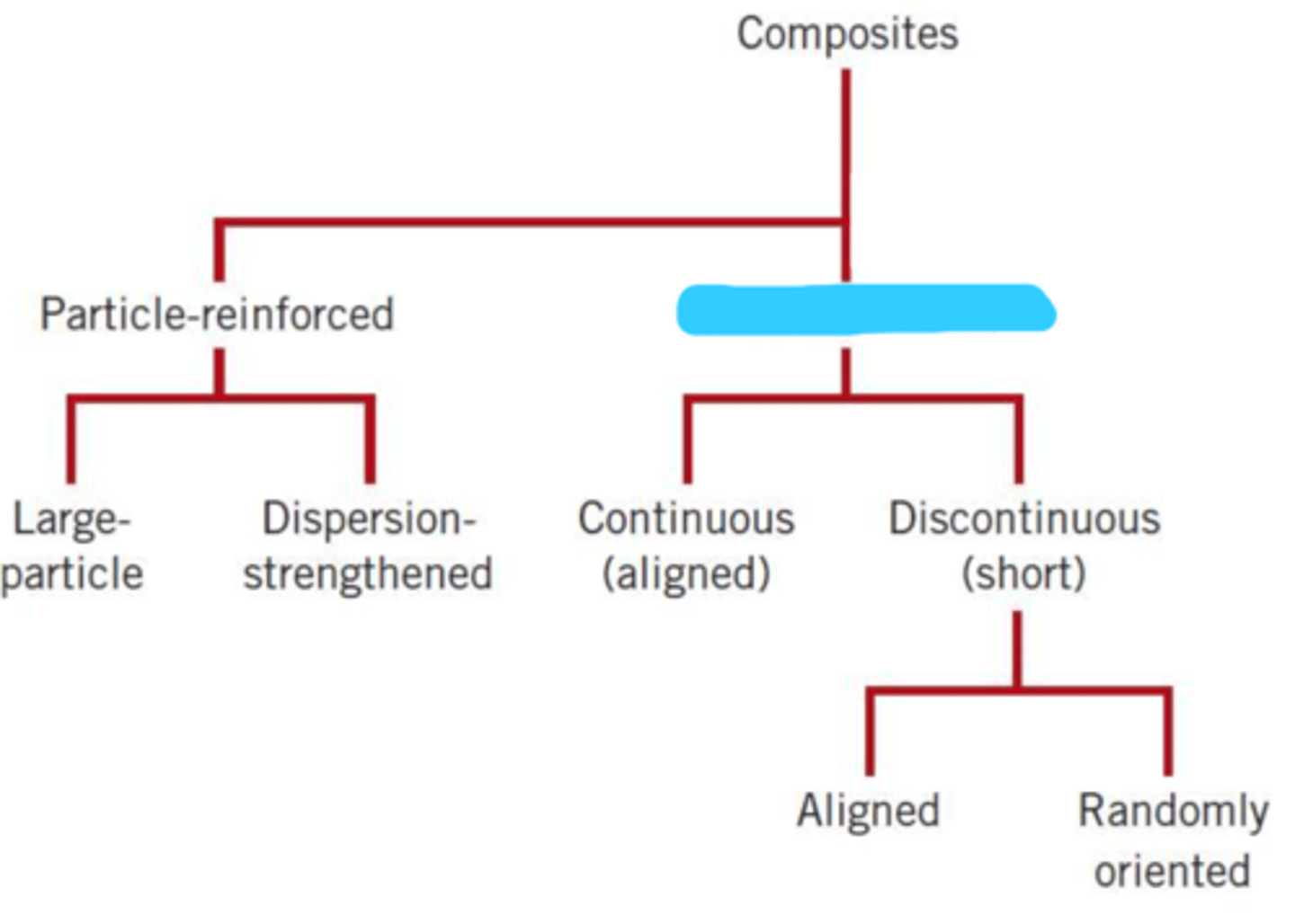

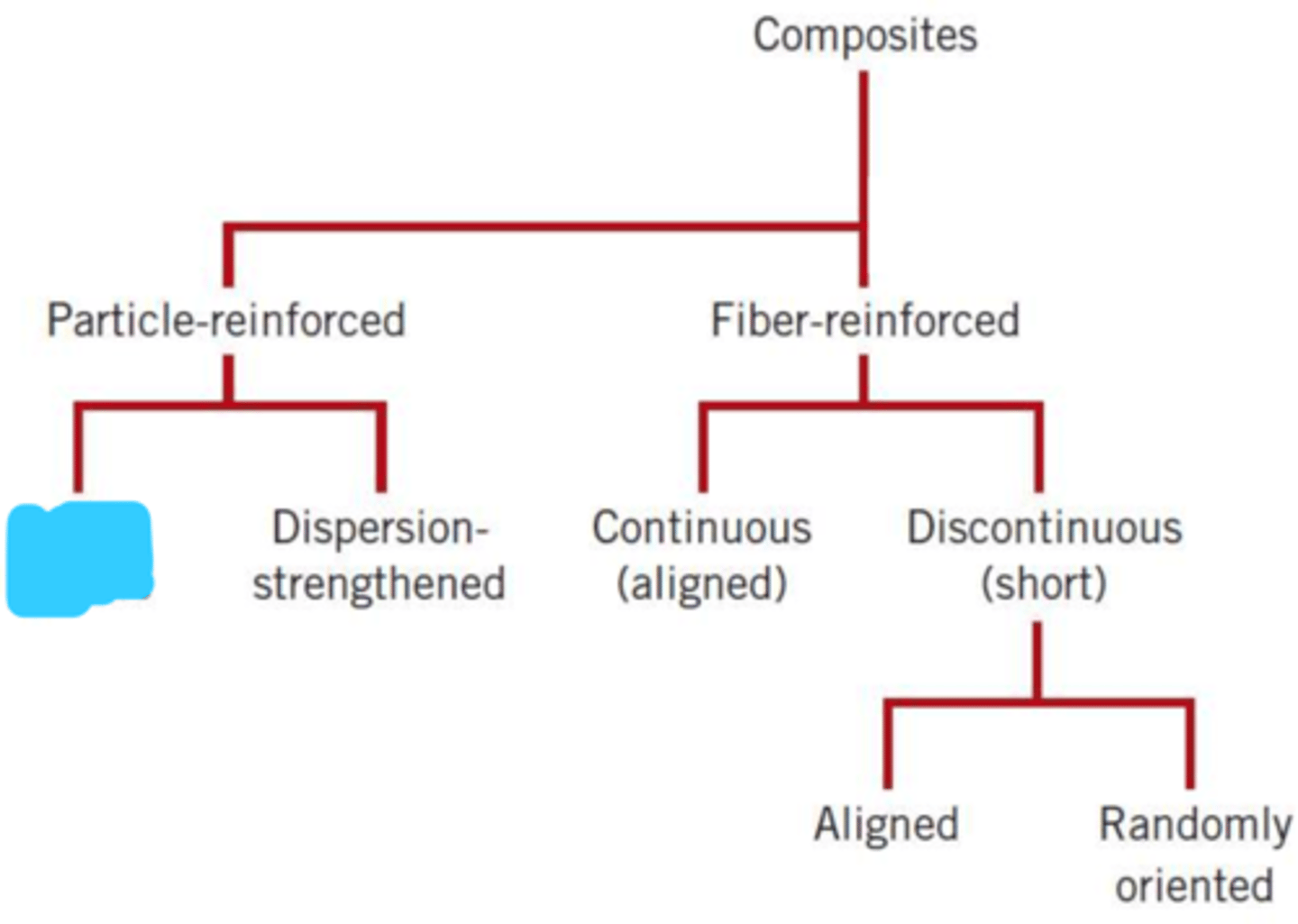

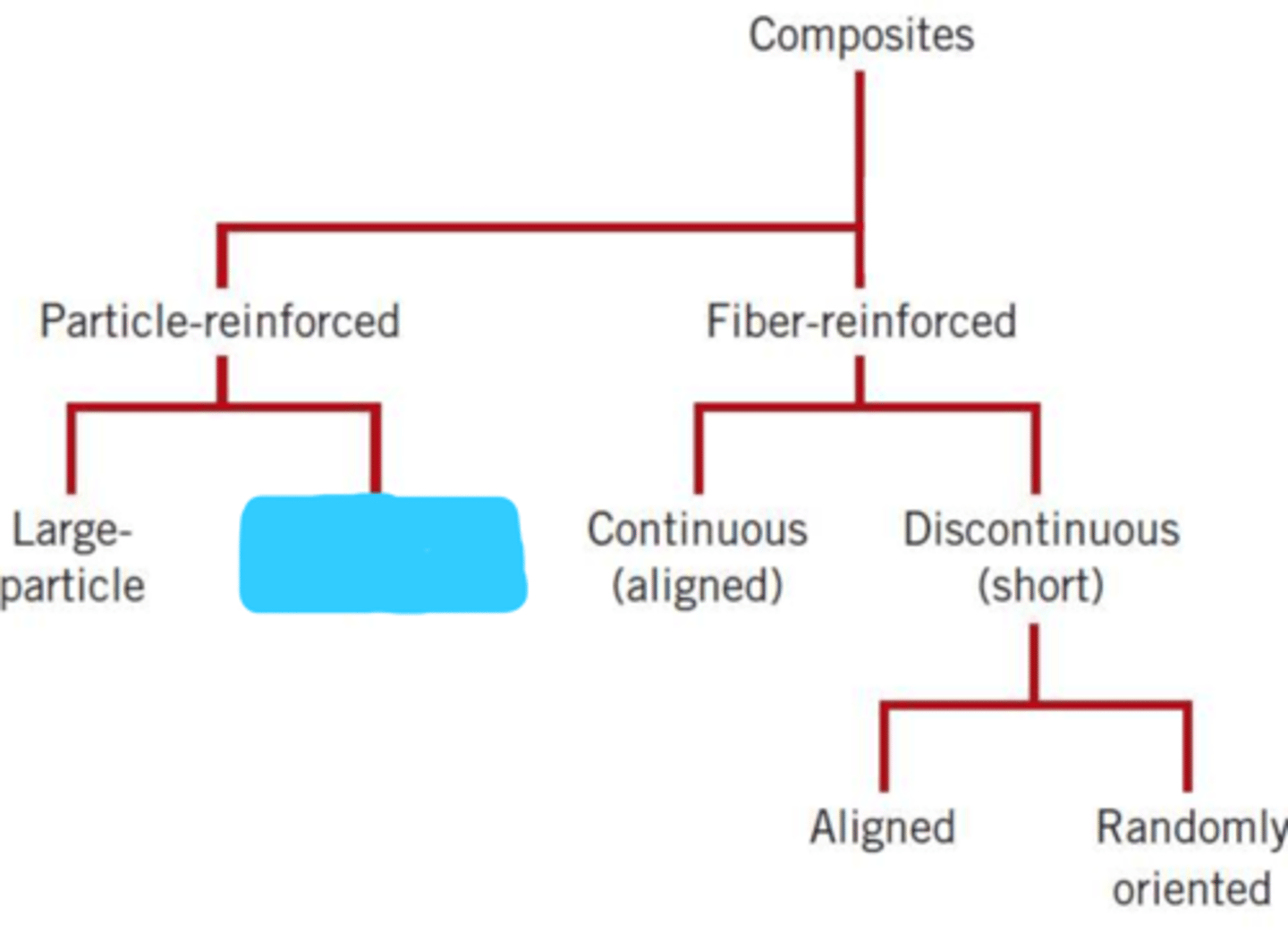

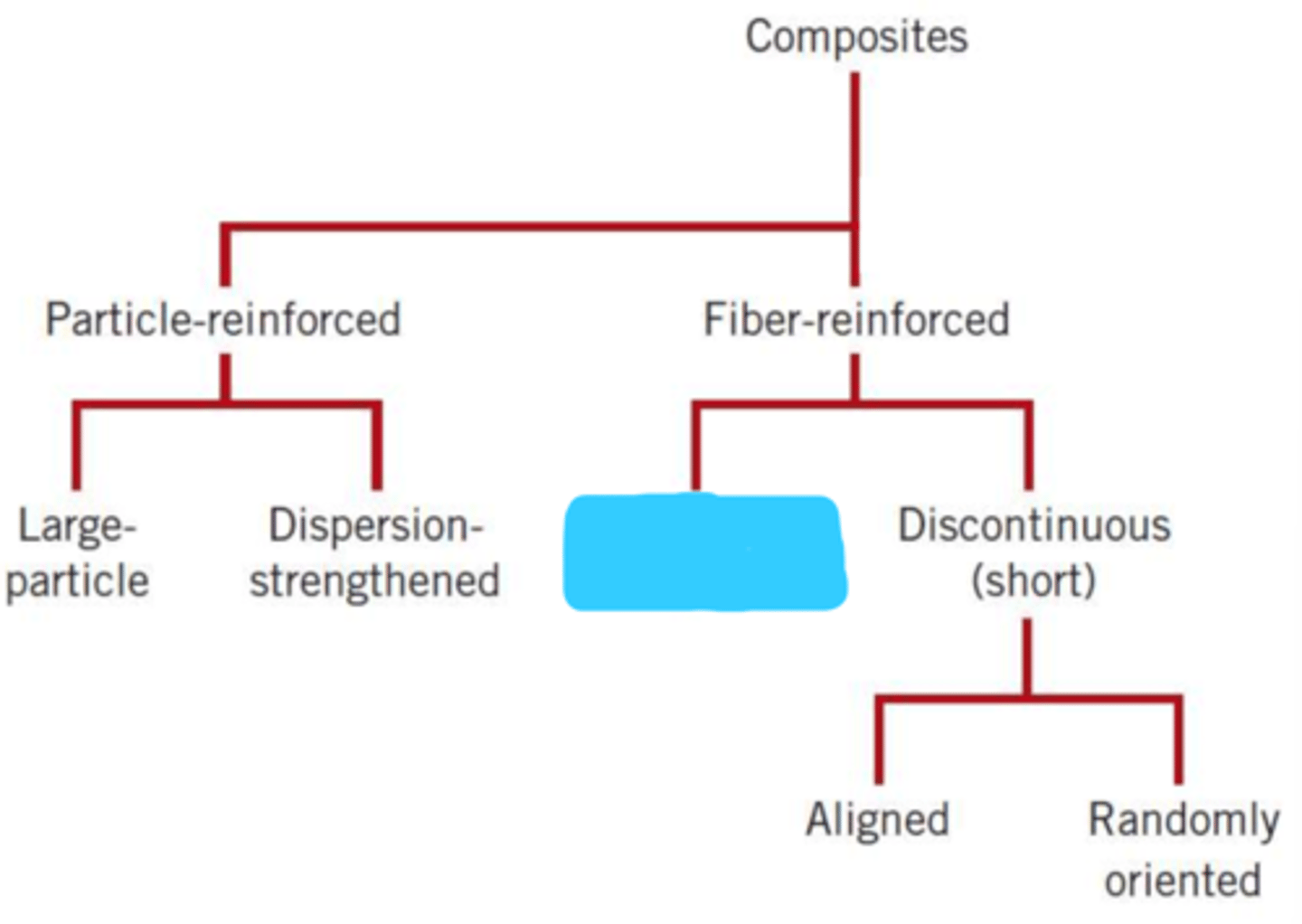

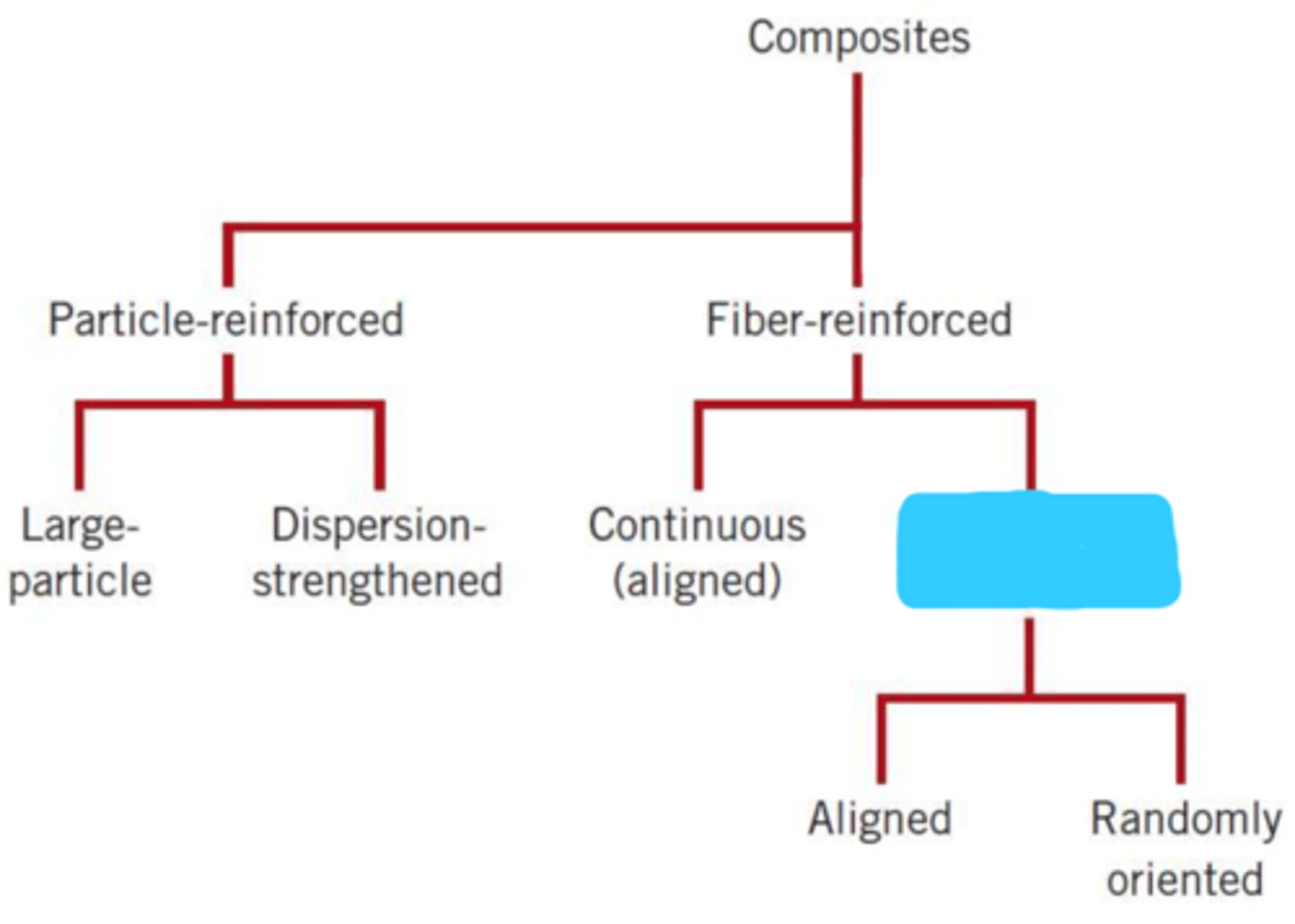

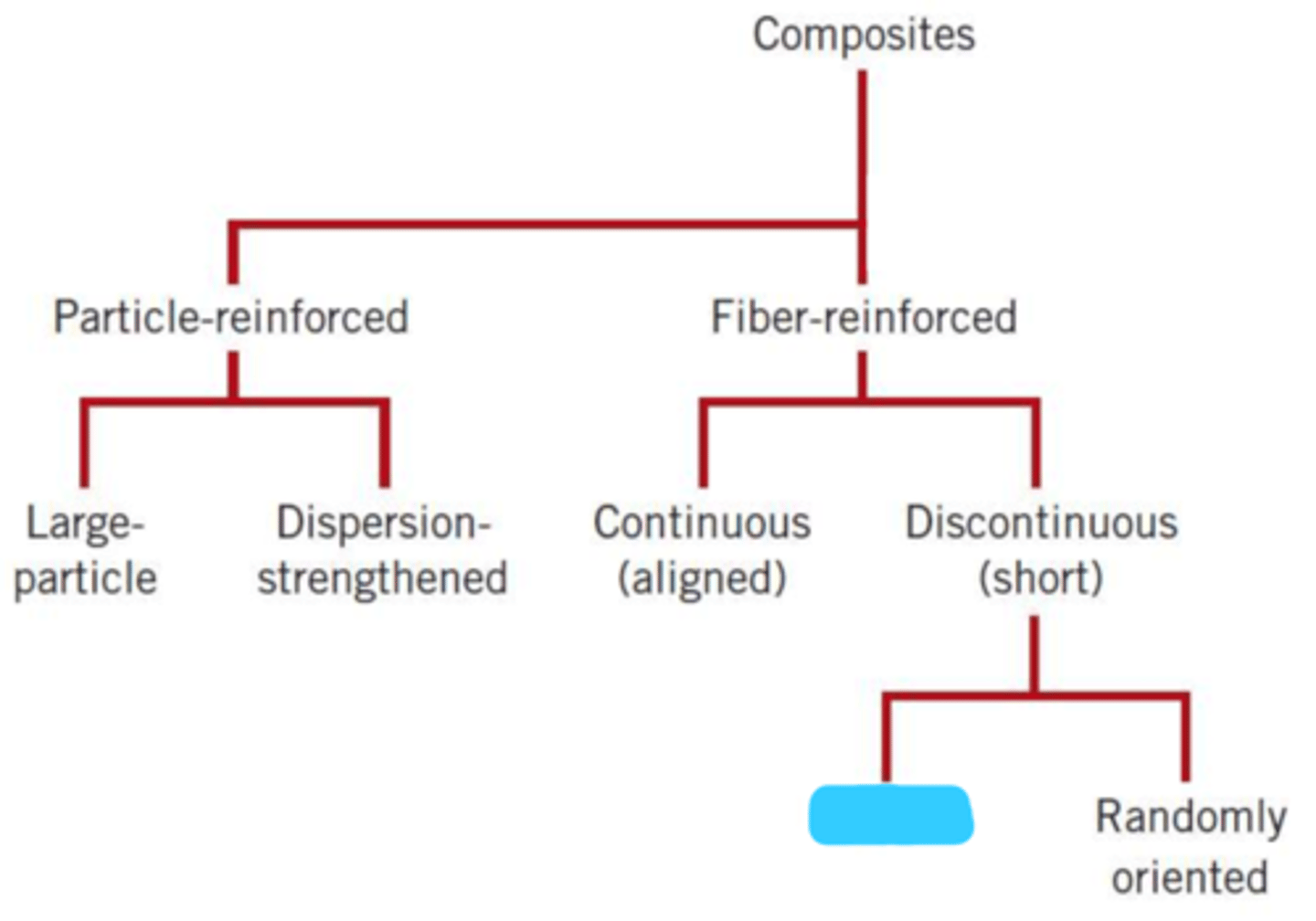

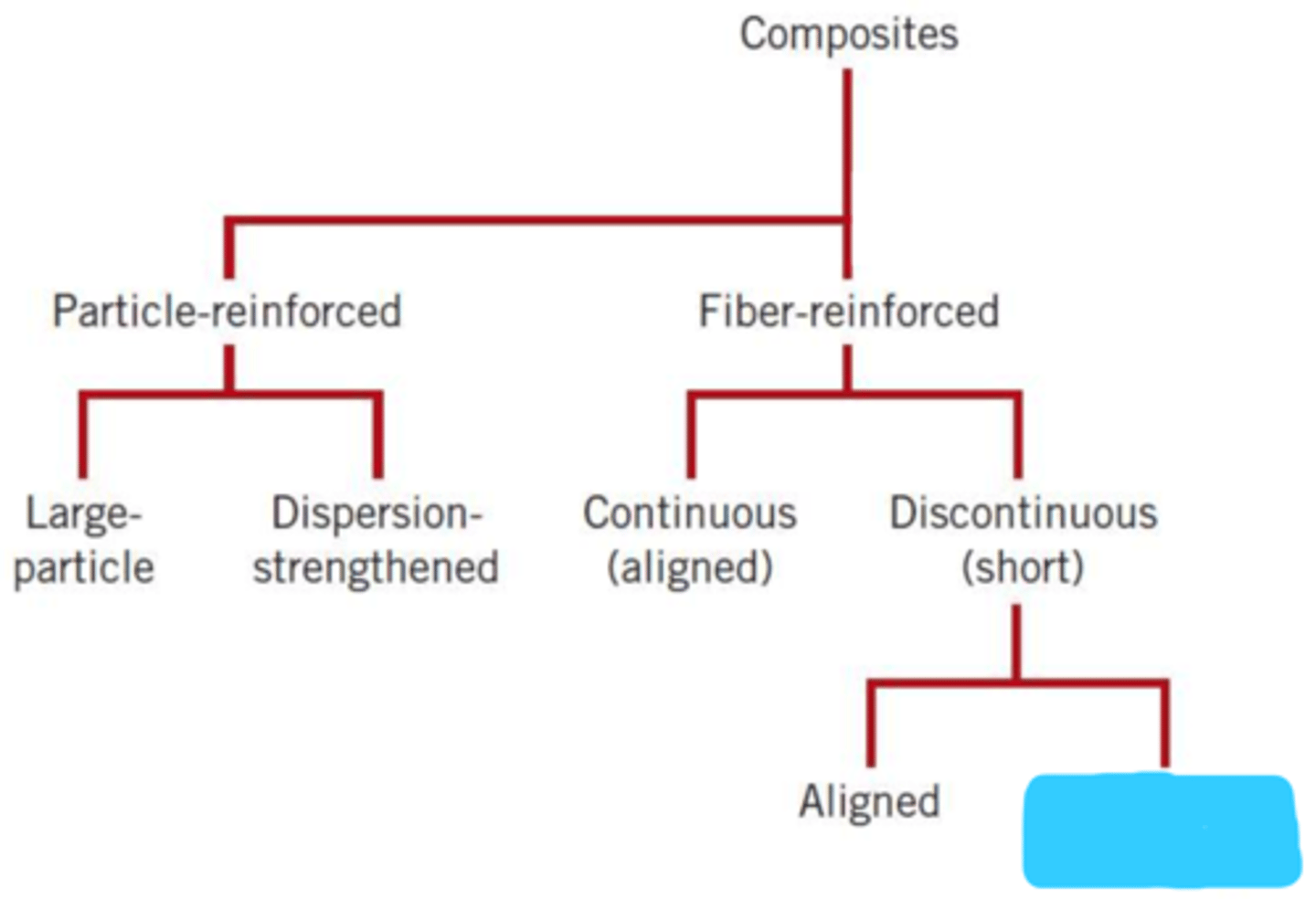

composites

particle-reinforced

fiber-reinforced

large particle

dispersion-strengthened

continuous (aligned)

discontinuous (short)

aligned

randomly oriented

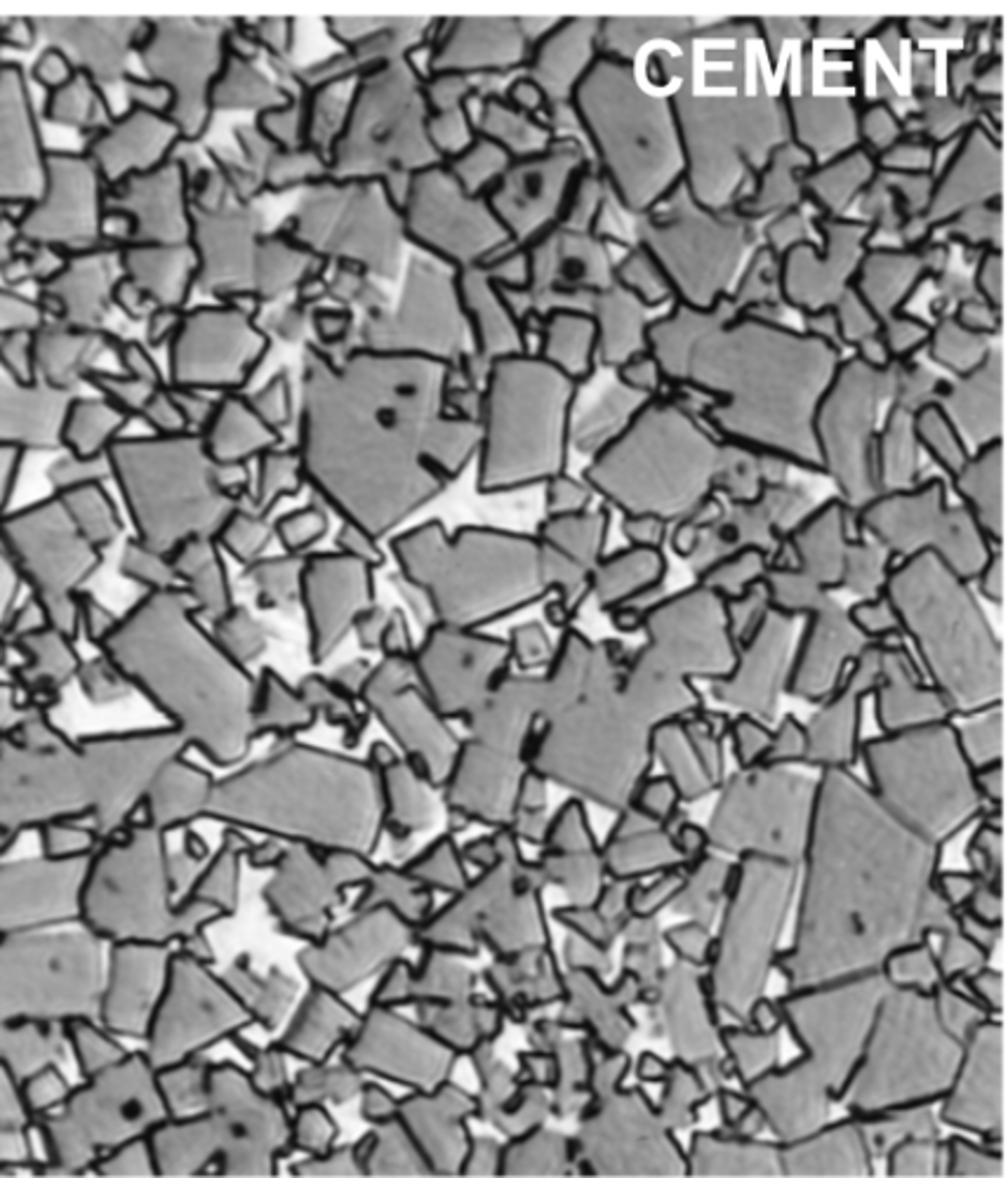

large particles

type of common particle configuration for composites?

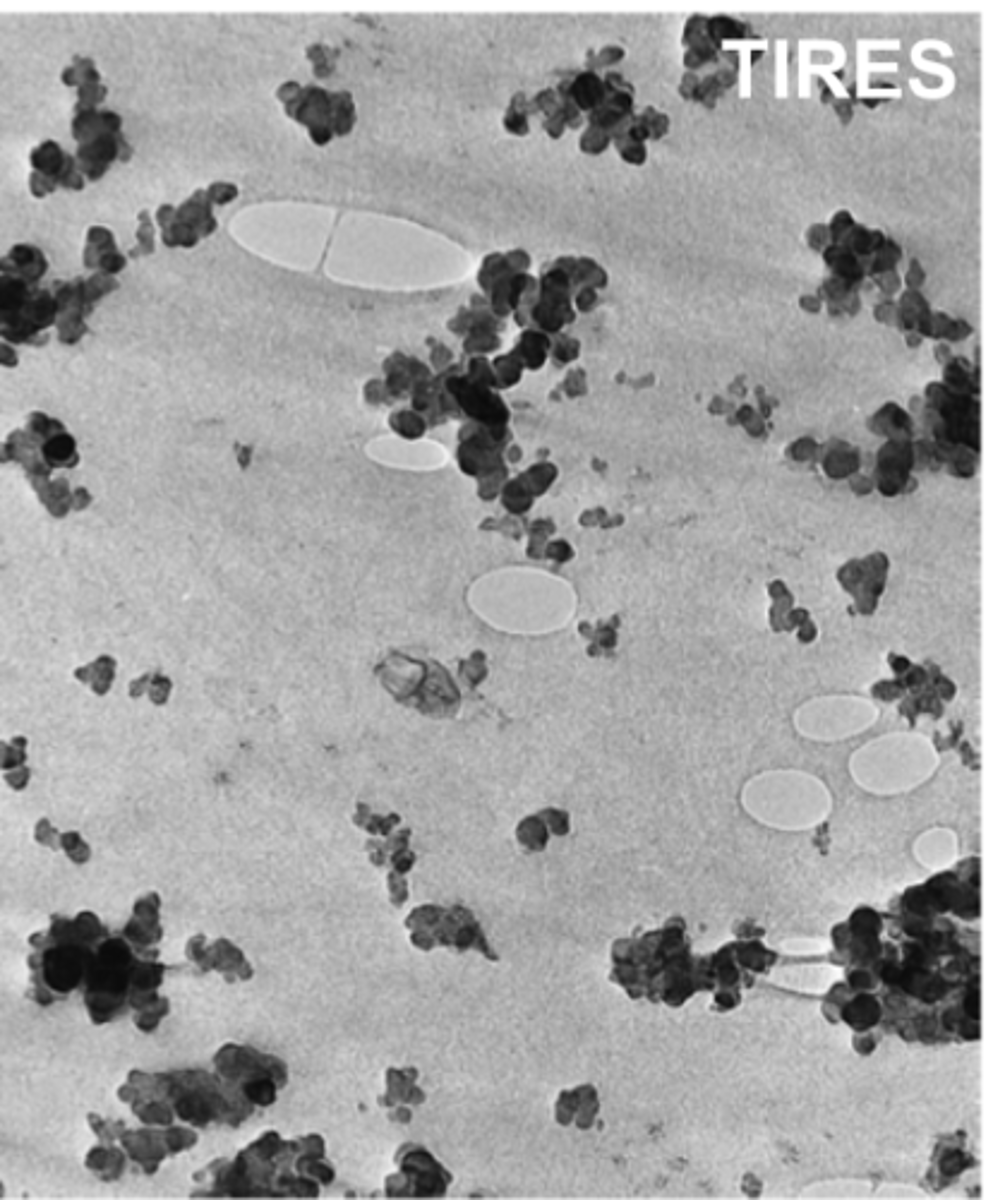

dispersion-strengthened

type of common particle configuration for composites?

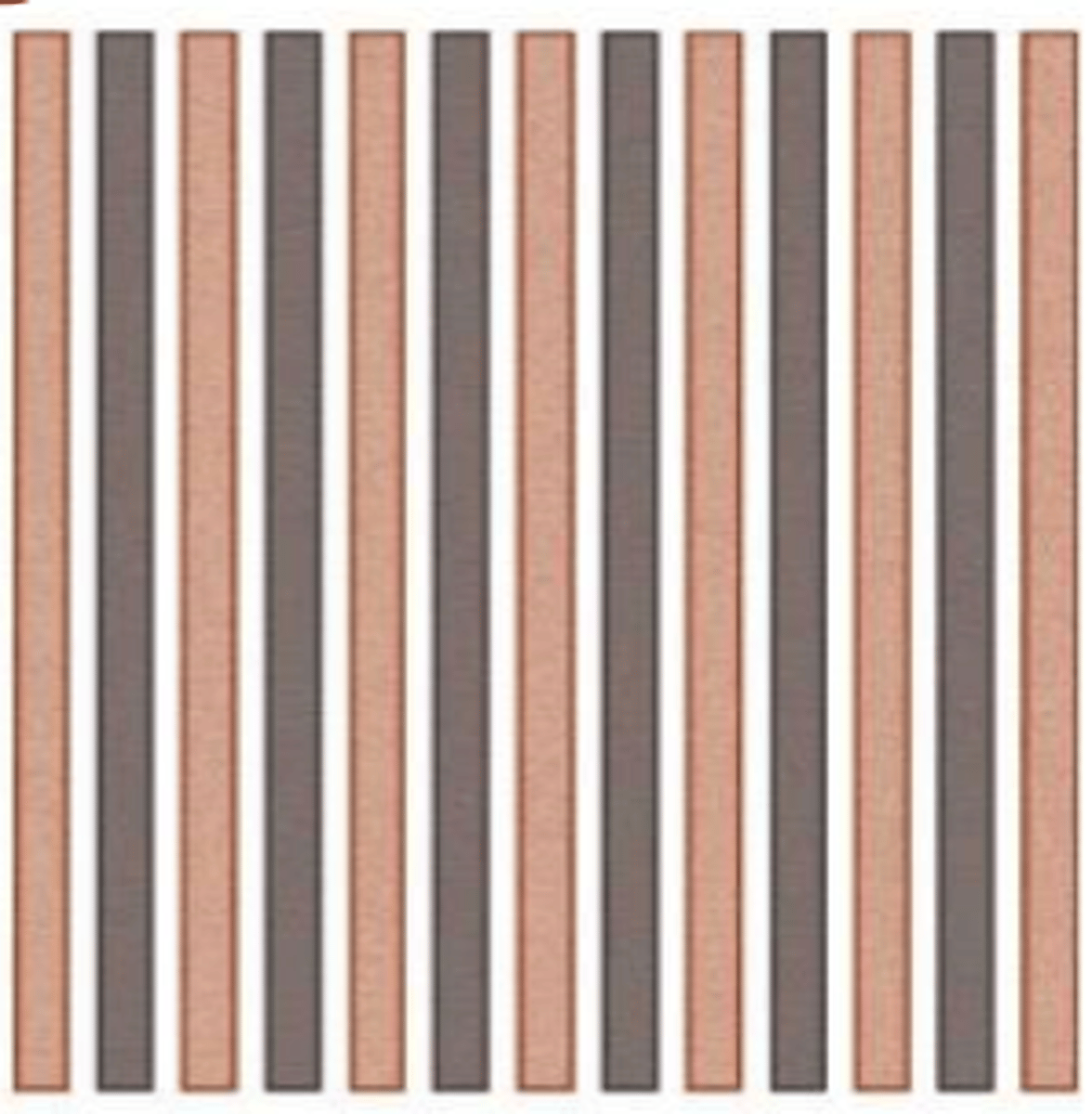

continuous and aligned

type of common fiber configurations for composites?

discontinuous and randomly oriented

type of common fiber configurations for composites?

discontinuous and aligned

type of common fiber configurations for composites?

polymeric

most biomedical composites have ______________ matrices

thermoplastic, bioabsorbable

polymeric matrices: mostly _______________ for ease of manufacturing, some ________________

synthetic non-absorbable

2 types of polymeric matrices: polysulfone, PEEK, UHMWPE, PTFE, PMMA, hydrogels

synthetic absorbable

2 types of polymeric matrices: Polyesters, PLA, PGA, PLGA, polydioxanone, poly(glycolide-co-trimethylene carbonate), poly)ethylene carbonate), poly(iminocarbonates), polycaprolactone, polyhydroxybutyrate, poly(amino acids) etc...

carbon fiber

reinforcing fibers: lightweight, flexible, high strength, high tensile strength, poor shear strength, tendon repair, bone scaffolding

polyamide (kevlar)

types of non-absorbable polymer reinforcing fibers: low density, light, high tensile strength, resist impact and abrasion, poor compressive strength

UHMWPE fibers

types of non-absorbable polymer reinforcing fibers: high strength, high modulus, light weight, high energy dissipation ability, resist abrasion and water absorption

UHMWPE fibers

types of non-absorbable polymer reinforcing fibers: low MP makes it difficult for fabrication, used in joint prostheses, dentistry, intervertebral disk prostheses

PET fibers

types of absorbable polymer reinforcing fibers: high tensile and compressive strength, resist abrasion and water absorption, vascular grafts, tendons, ligaments, intervertebral disks

PLA/PGA and PLGA fibers

types of absorbable polymer reinforcing fibers: sutures, ligaments, tendons, orthopedic applications

glass fibers

type of reinforcing fiber: used to reinforce plastic matrices to form structural composites and molding compounds

glass fibers

type of reinforcing fiber: high strength-to-weight ratio, good resistance to heat, cold, moisture and corrosion, good electrical insulation, used in dentistry

ceramics

material typically used as particulates in composites

tension, shear

ceramics in reinforcing particulates: most are weak and brittle in _________ and _________

compressive

ceramics in reinforcing particulates: enhances _______________ strength

reinforcing particulates

includes calcium phosphates, aluminum- and zinc-based phosphates, glass and glass-ceramics

constituent, distribution, interaction

general properties of a composite are strongly influenced by the properties of the _____________ materials, ______________, _______________

synergistic, volume

general properties of a composite may be: _______________, improve based on the _____________ fraction of constituent materials

average

due to the nature of composites, it is obvious that the properties must, in some way, represent an ____________ of the properties of the individual components

geometry

determining material properties of composites: the precise nature of the average is highly dependent on the microstructural _______________

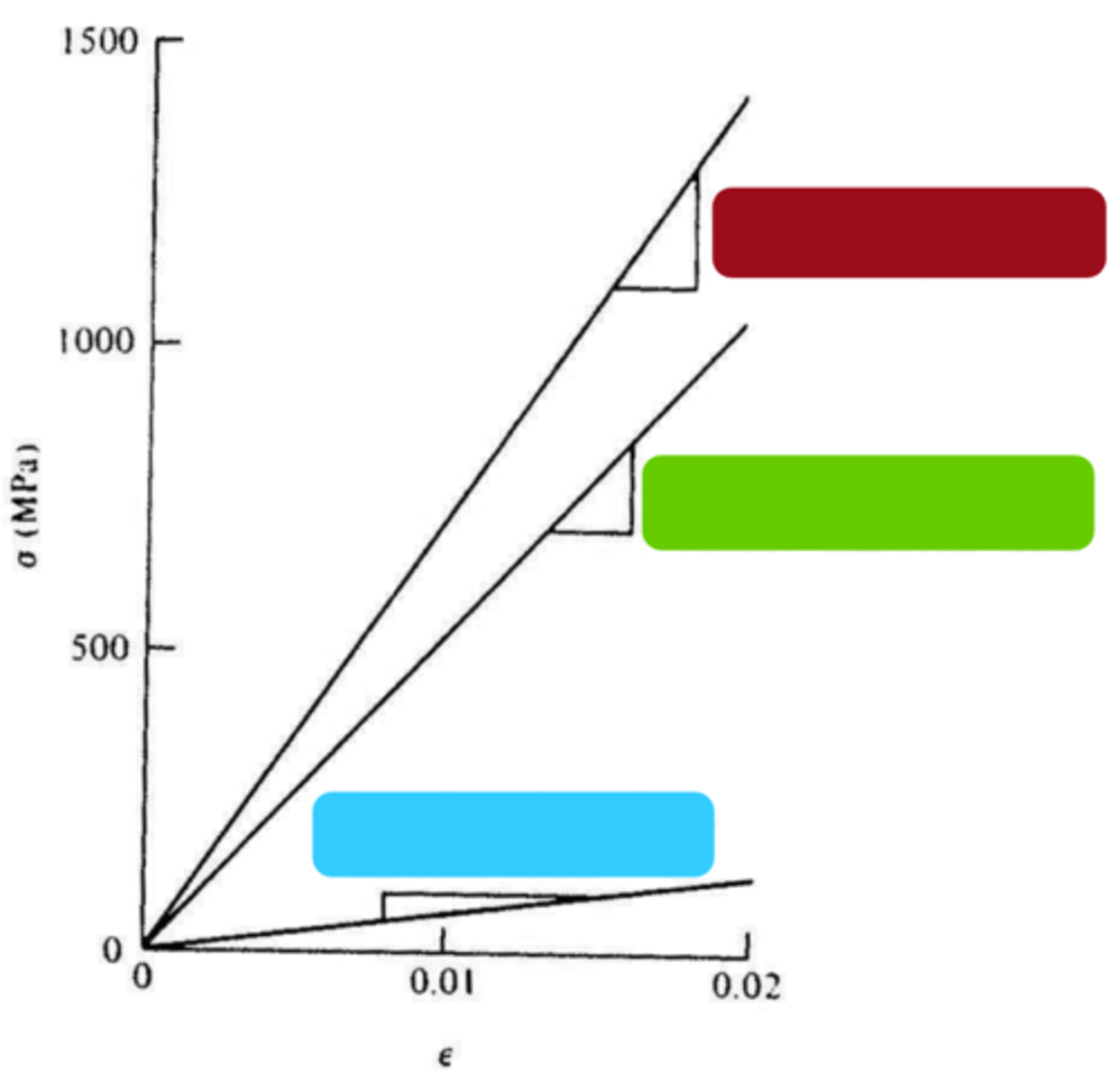

parallel

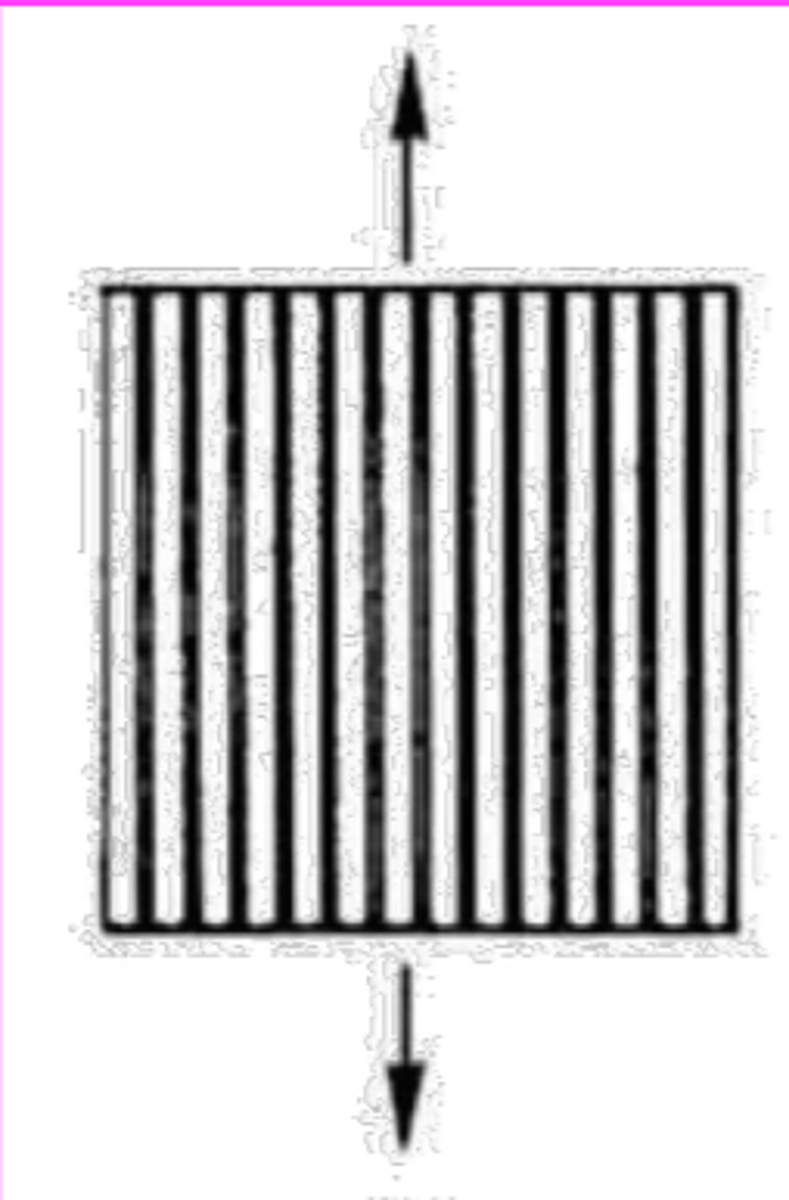

3 idealized composite geometries: a direction ____________ to continuous fibers in a matrix

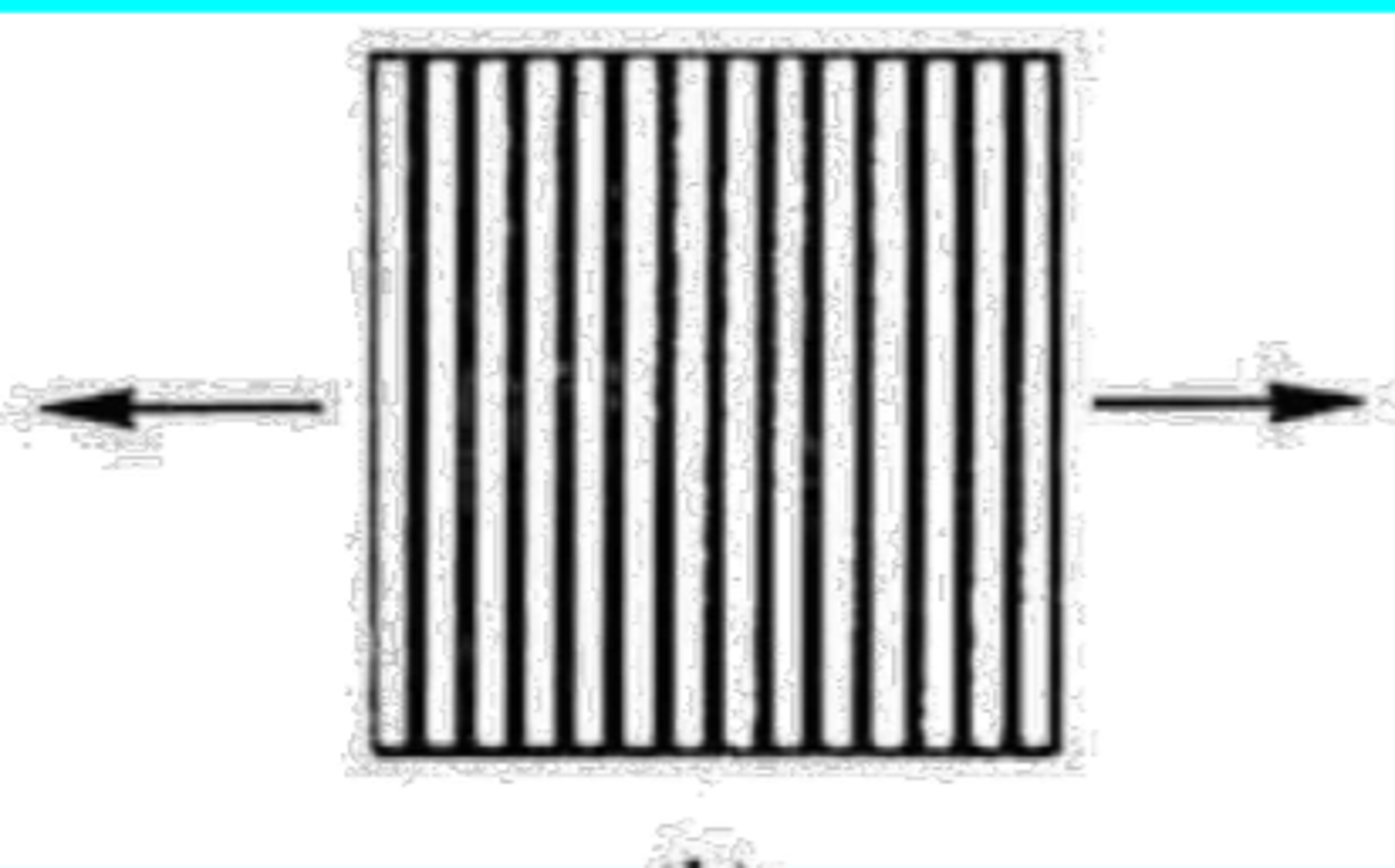

perpendicular

3 idealized composite geometries: a direction ____________ to continuous fibers in a matrix

aggregate

3 idealized composite geometries: a direction relative to a uniformly dispersed _____________ composite

isostrain

unidirectional strain, loading parallel to reinforcing fibers

bonded

isostrain: assume the matrix is intimately ____________ w/ the reinforcing fibers

same

isostrain: the strain of both the matrix and the fibers must be the ________

different

isostrain: true even though the E's of each component will tend to be ____________

fibers

red

composite

green

matrix

blue

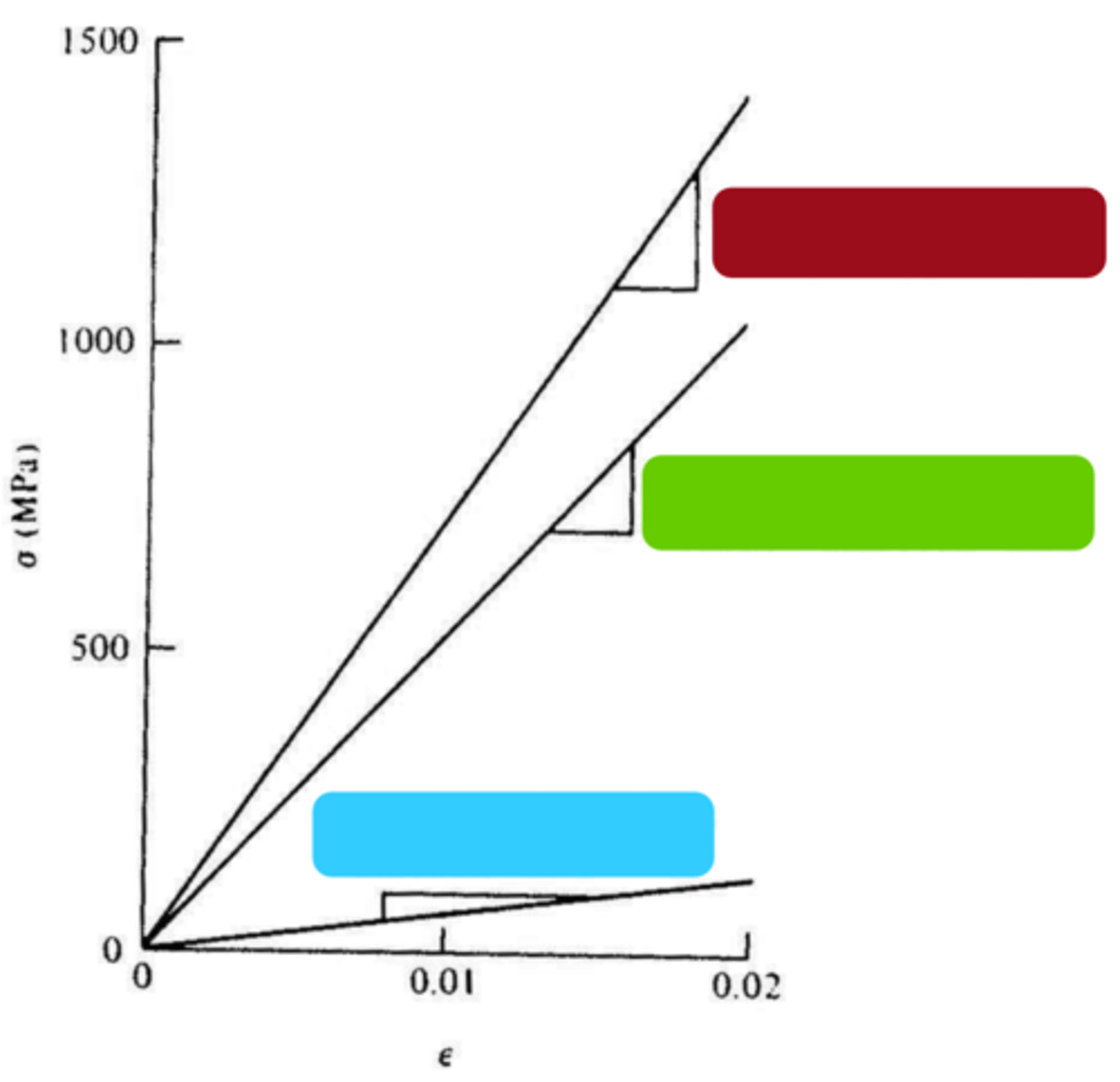

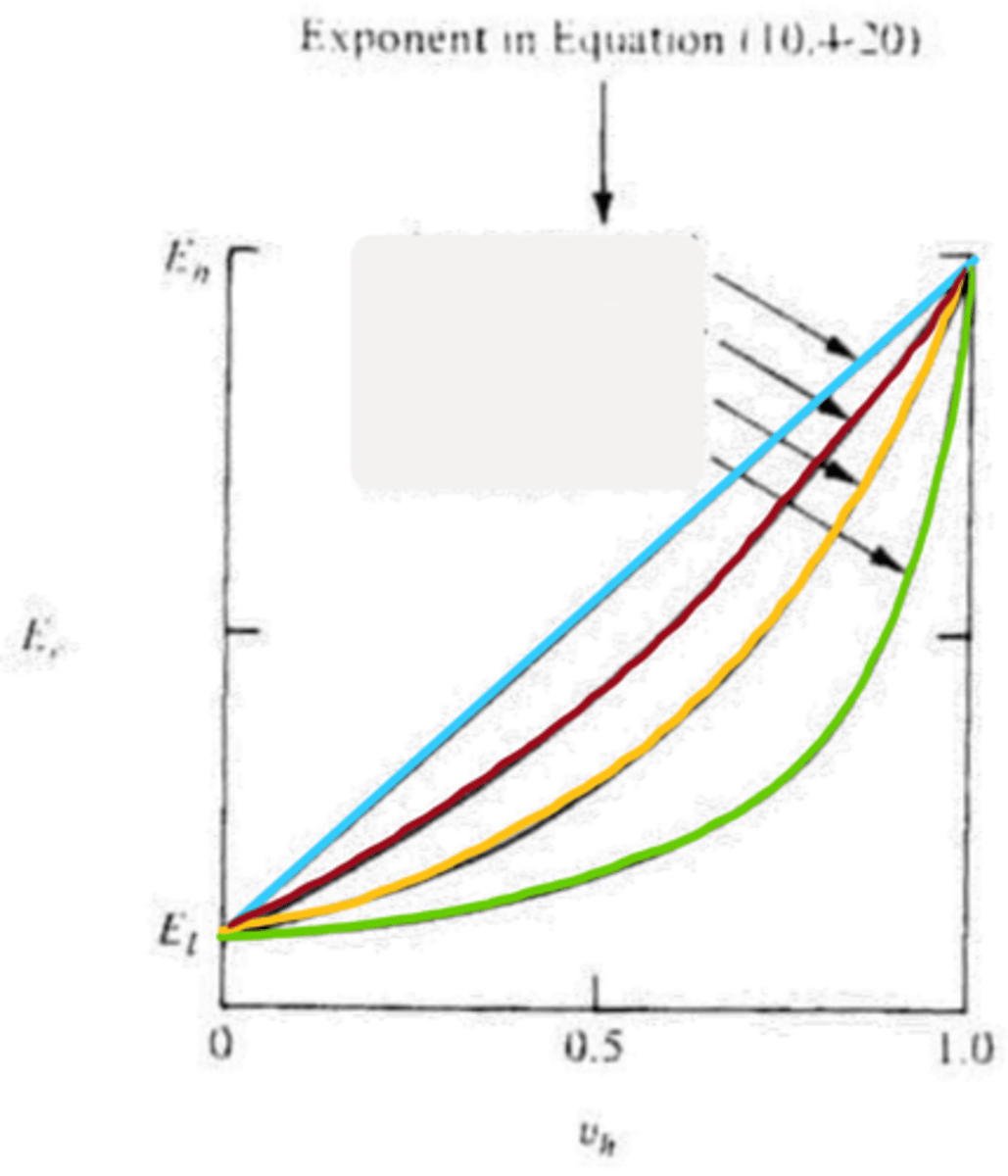

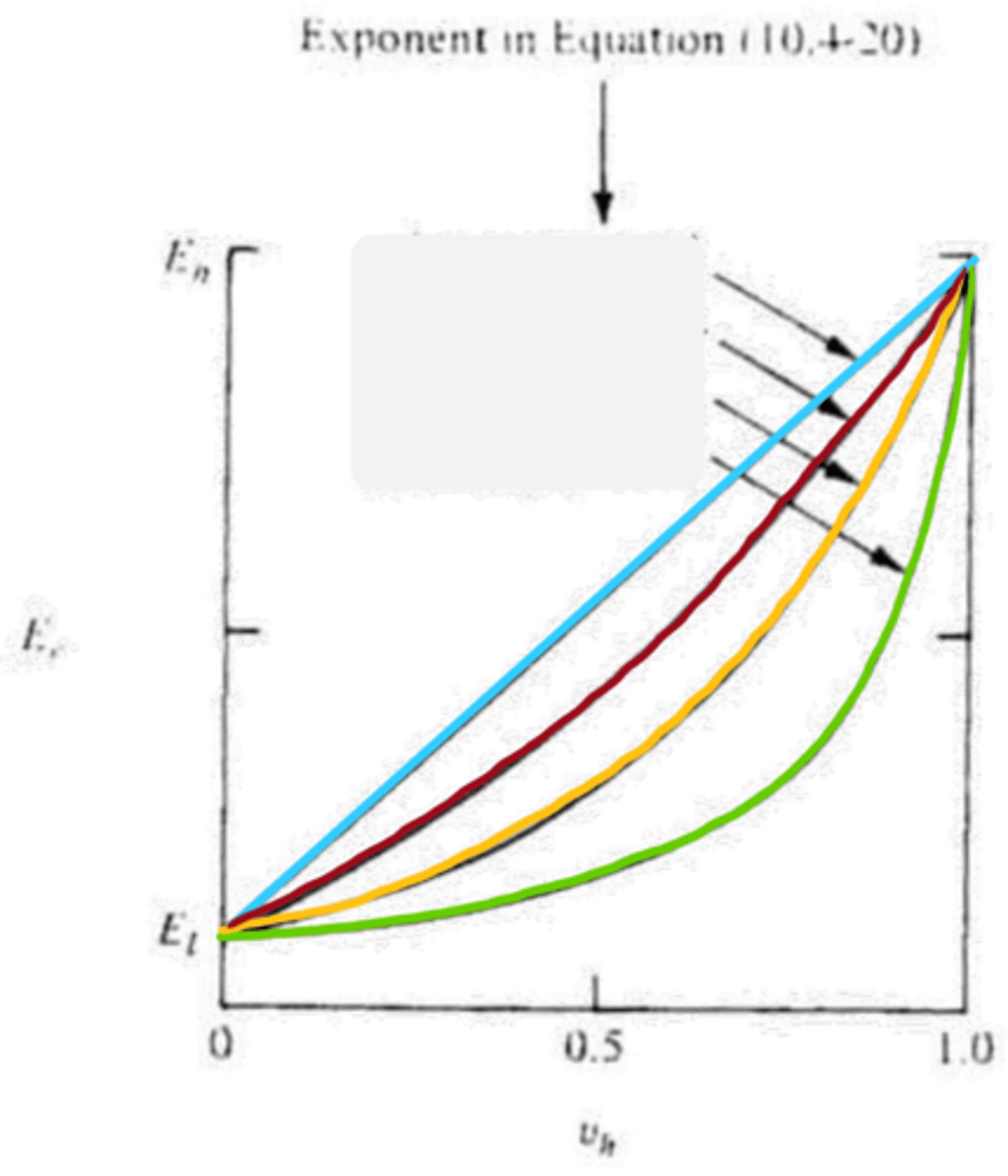

isostress

loading perpendicular to the reinforcing fibers

sum

isostress: the total elongation of the composites in the direction of stress application is the ______ of the elongations of matric and fiber components

isostress

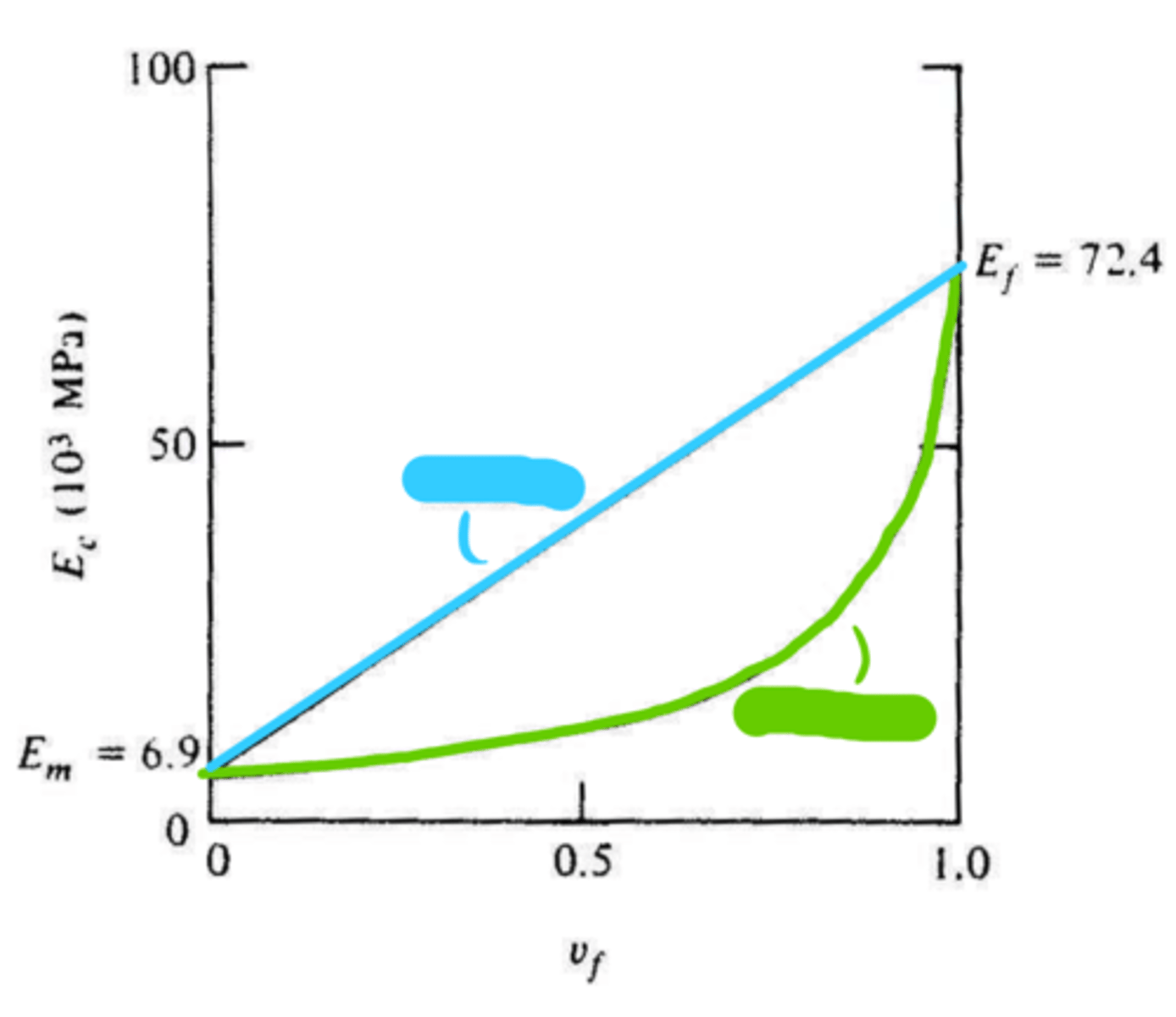

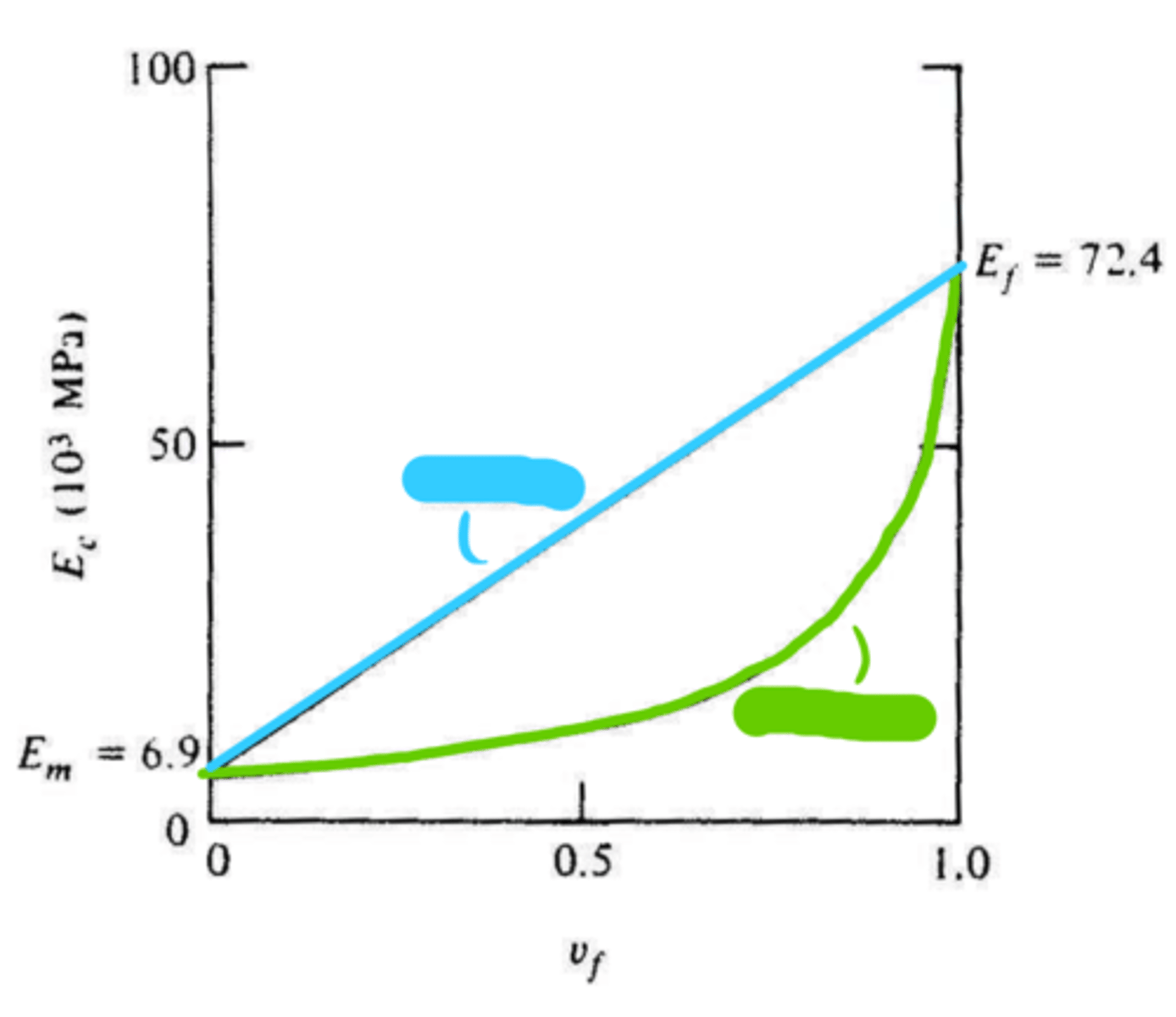

green

isostrain

blue

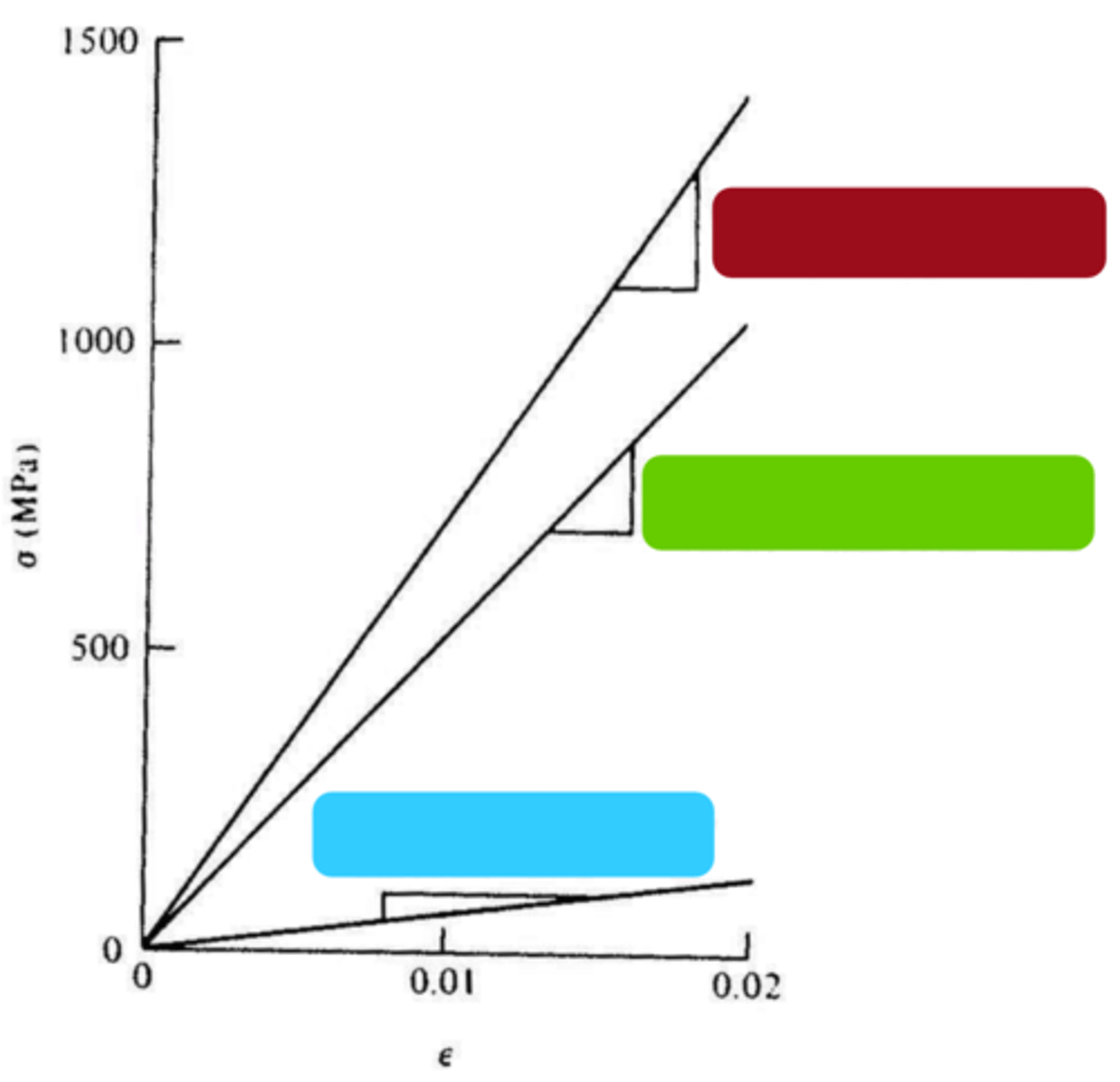

bounds

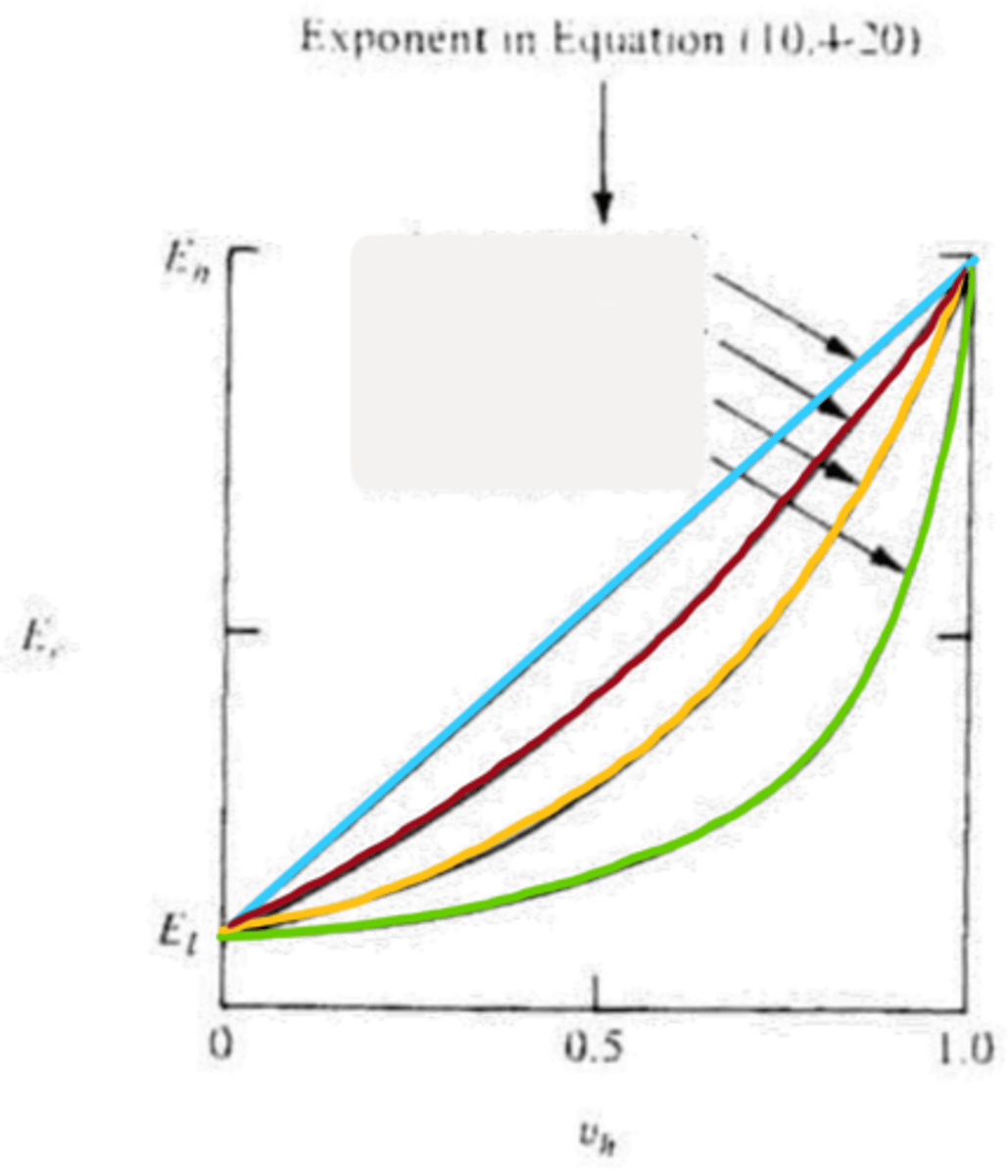

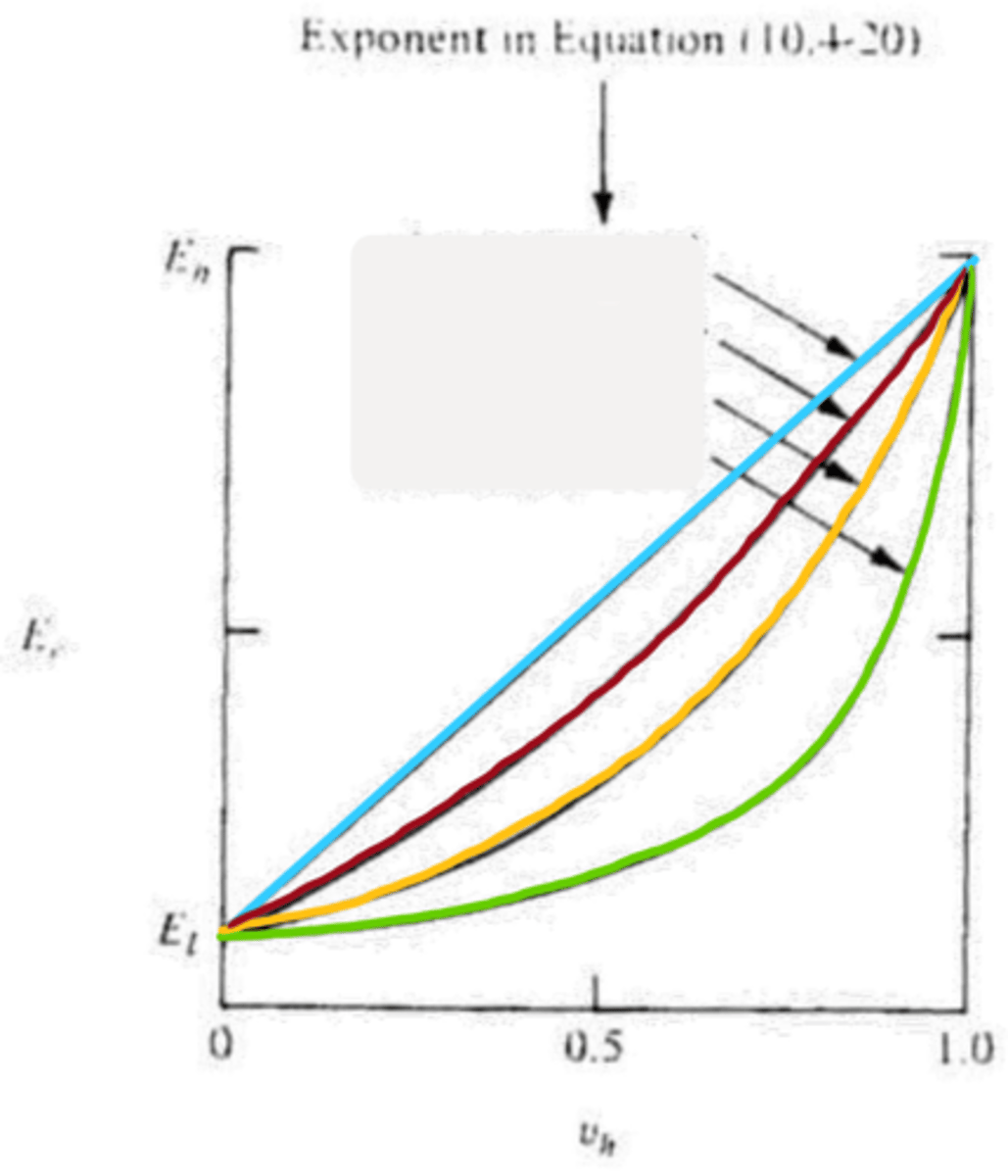

isostress and isostrain serve as upper and lower __________ for particulate composites

n=1

blue

n=-1

green

n=1/2

red

n=0

yellow

higher, lower

n=0: __________ modulus aggregate in a _________ modulus matrix

lower, higher

n=1/2: __________ modulus aggregate in a _________ modulus matrix

bonded

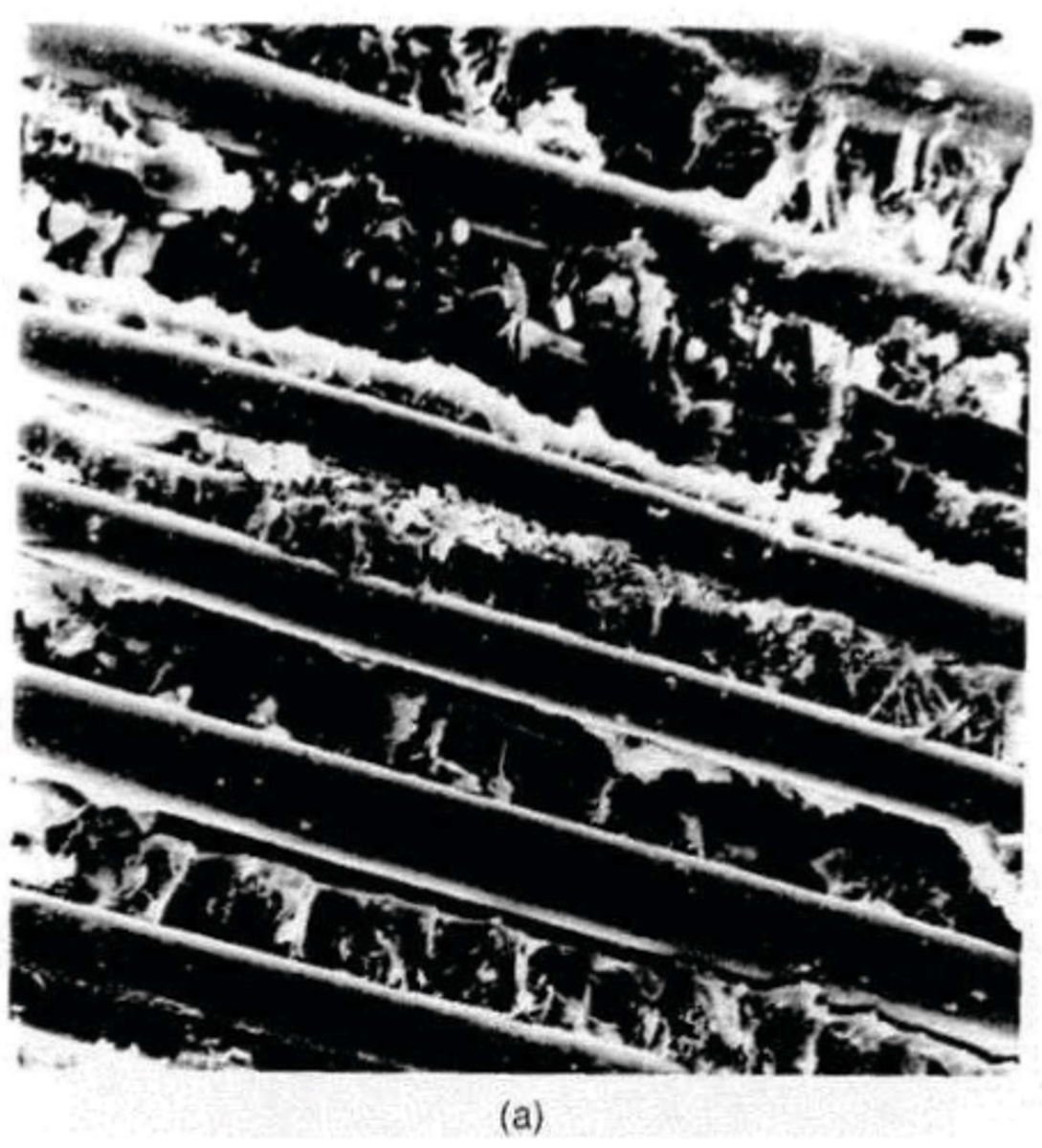

the equations developed for different types of composite materials assumed that the matrix is intimately ___________ w/ the reinforcing fibers

transmit

the interface between the matrix and discontinuous phase must be strong enough to ____________ the stress or strain due to a mechanical load from one phase to the other

communicate

interfacial strength: w/o this strength, the dispersed phase can fail to "________________" w/ the matrix

slipping out

interfacial strength: if matrix and fibers don't "communicate" this could lead to the reinforcing fibers ____________ ______ of the matrix

smooth

poorly bonded: __________ surface of the fibers indicated failure of the matrix to tightly bond to the fiber

rough

well bonded: ___________ surface of the fibers and matrix indicated an integrated tight bond between matrix and fiber

2

composites are made up of _____ phases

continuous, discontinuous/dispersed

2 phases of composites?

structural, direction

composites material responses can be predicted based on: ____________ and material make up and __________ of applied load