WELDING PIPE 1

1/27

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

28 Terms

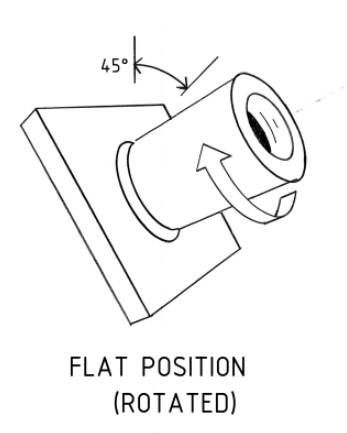

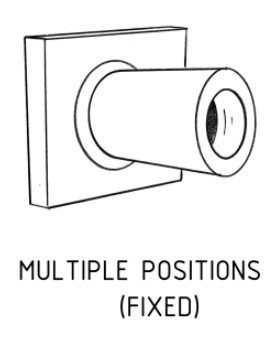

1F

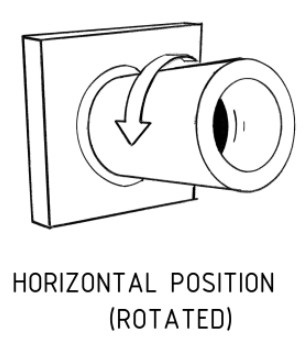

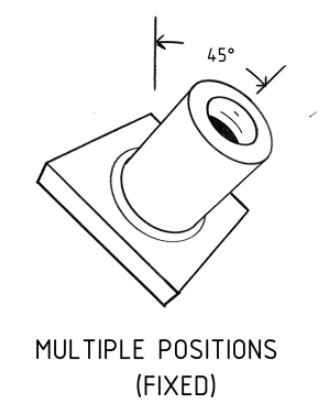

2F

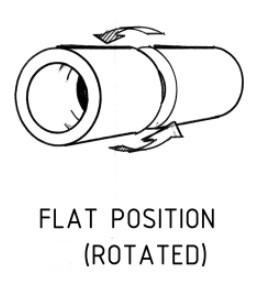

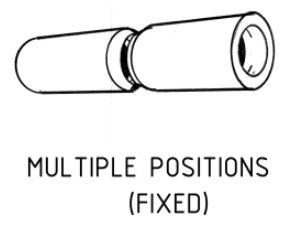

2FR

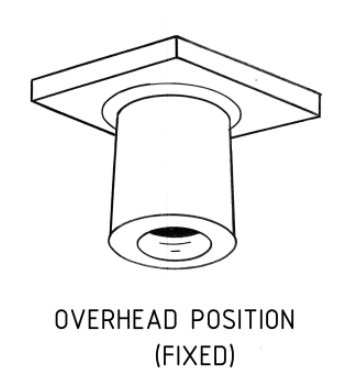

4F

5F

6F

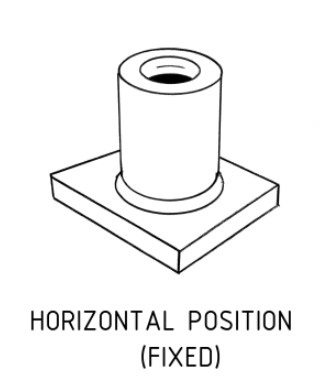

1G

2G

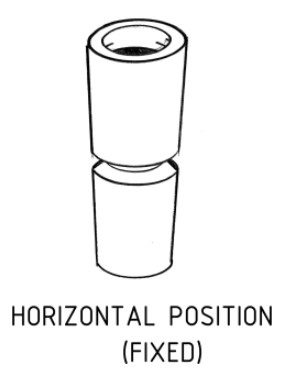

5G

6G

Land

Just under 1/16”

Bevel

37.5*

Minimum Face Distance

5/16”

Maximum Face Distance

3/8”

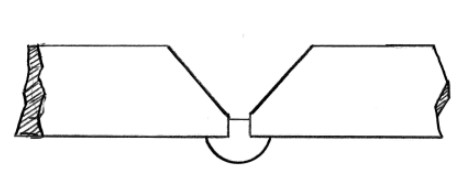

Consumable Insert: Class 1

Consumable Insert: Class 2

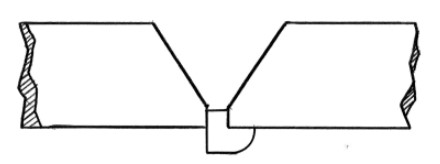

Consumable Insert: Class 4

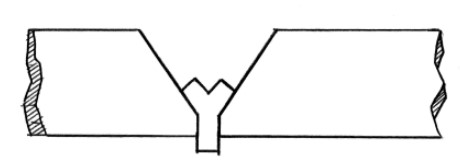

Consumable Insert: Class 3 & 5

Thin-Wall Pipe

1/8'“ to 5/16” pipe wall thickness

ERW

Ideal for welding long seams in pipe because it’s exceptionally fast, economical, and requires no filler metal

Thick-Wall Pipe

More than 5/16” pipe wall thickness

How long should a tack be?

3/4” long tack

Position welding

Uses all welding positions in pipe

Groove welding

Most commonly used for joining pipe

Welded pipe

less expensive to produce than seamless pipe

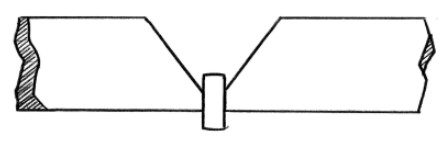

Open Single V-Groove

most commonly used joint design for joining pipe

Pipe up to 3/16” wall thickness

Can be welded without joint preparation

Modified GMAW-S

Welding process with high tolerance for misalignment between pipe sections