OMIS 4300 Exam 2 - Woosley

1/75

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

76 Terms

Capacity planning

The process of determining the production capacity needed by an organization to meet changing demands for its products.

Capacity

The upper limit or ceiling on the load that an operating unit can handle.

Capacity Needs Include?

Equipment

Space

Employee Skills

Strategic capacity planning

The goal to achieve a match between the long-term supply capabilities of an organization and the predicted level of long-term demand.

Design capacity

The maximum output rate or service capacity an operation, process, or facility is designed for.

Effective capacity

Design capacity minus allowances such as personal time, maintenance, and scrap.

Actual output

The rate of output actually achieved; cannot exceed effective capacity.

Determinants of Capacity

- Facilities

- Product and service factors

- Process factors

- Human factors

- Policy factors

- Operational factors

- Supply chain factors

- External factors

Service capacity planning

The planning process that presents challenges related to the need to be near customers and the inability to store services.

Demand management strategies

Strategies used to offset capacity limitations and achieve a closer match between supply and demand.

Outsource

To obtain goods or services from an external supplier rather than producing them internally.

Bottleneck operation

An operation in a sequence whose capacity is lower than that of other operations, slowing the entire process.

Economies of scale

If output rate is less than the optimal level, increasing the output rate results in decreasing average per unit costs

Reasons for economies of scale

Fixed costs spread over more units, decreasing construction costs, and reduced processing costs due to standardization.

Diseconomies of scale

If the output rate is more than the optimal level, increasing the output rate results in increasing average per unit costs

Reasons for diseconomies of scale

Increased distribution costs, complexity, inflexibility, and additional bureaucracy.

Cost-volume analysis

Focuses on the relationship between cost, revenue, and volume of output.

Fixed Costs (FC)

Tend to remain constant regardless of output volume.

Variable Costs (VC)

Vary directly with volume of output.

Break Even Point (BEP)

The volume of output at which total cost and total revenue are equal.

Sensitivity analysis

Determining the range of probability for which an alternative has the best expected payoff.

Projects

Unique, one-time operations designed to accomplish a specific set of objectives in a limited time frame.

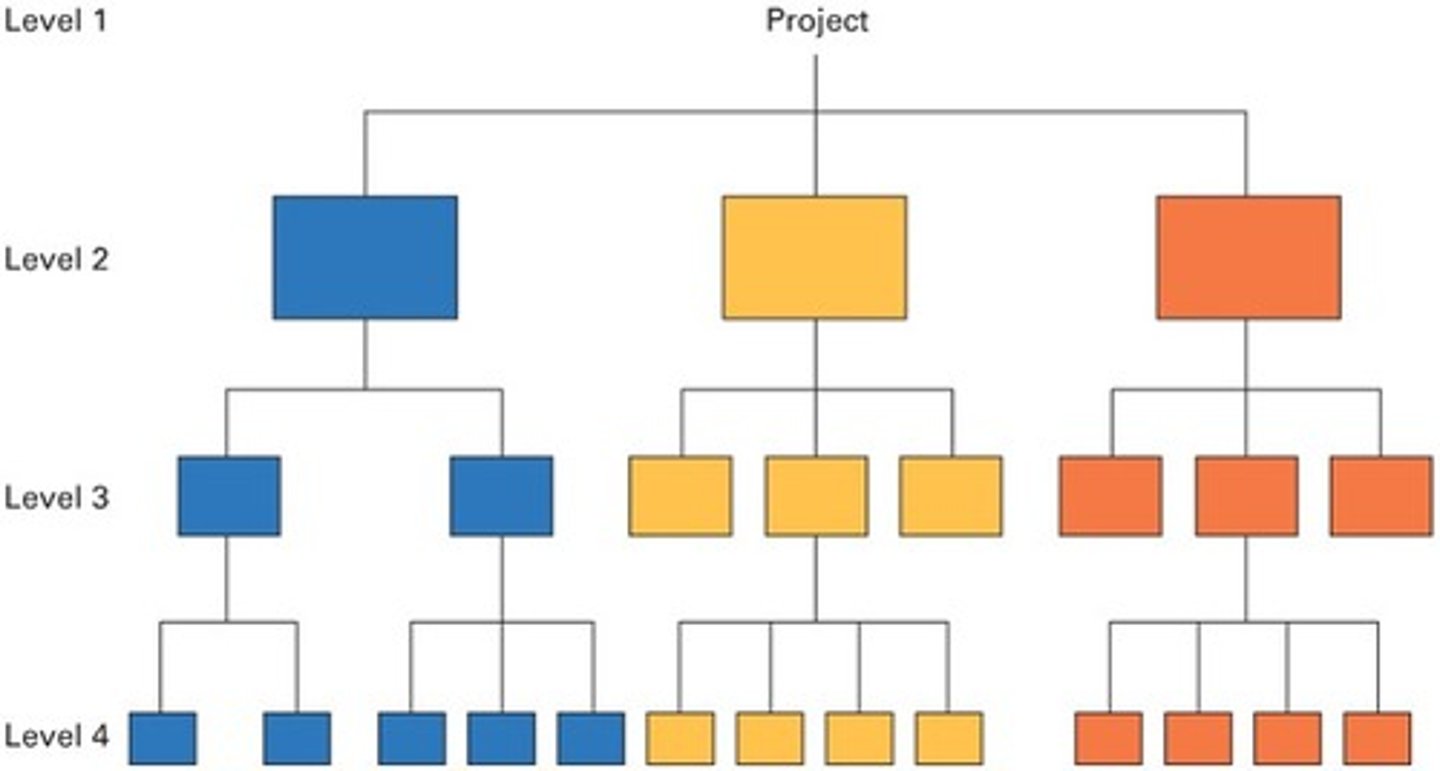

Work Breakdown Structure (WBS)

A hierarchical decomposition of the total scope of work to accomplish the project objectives.

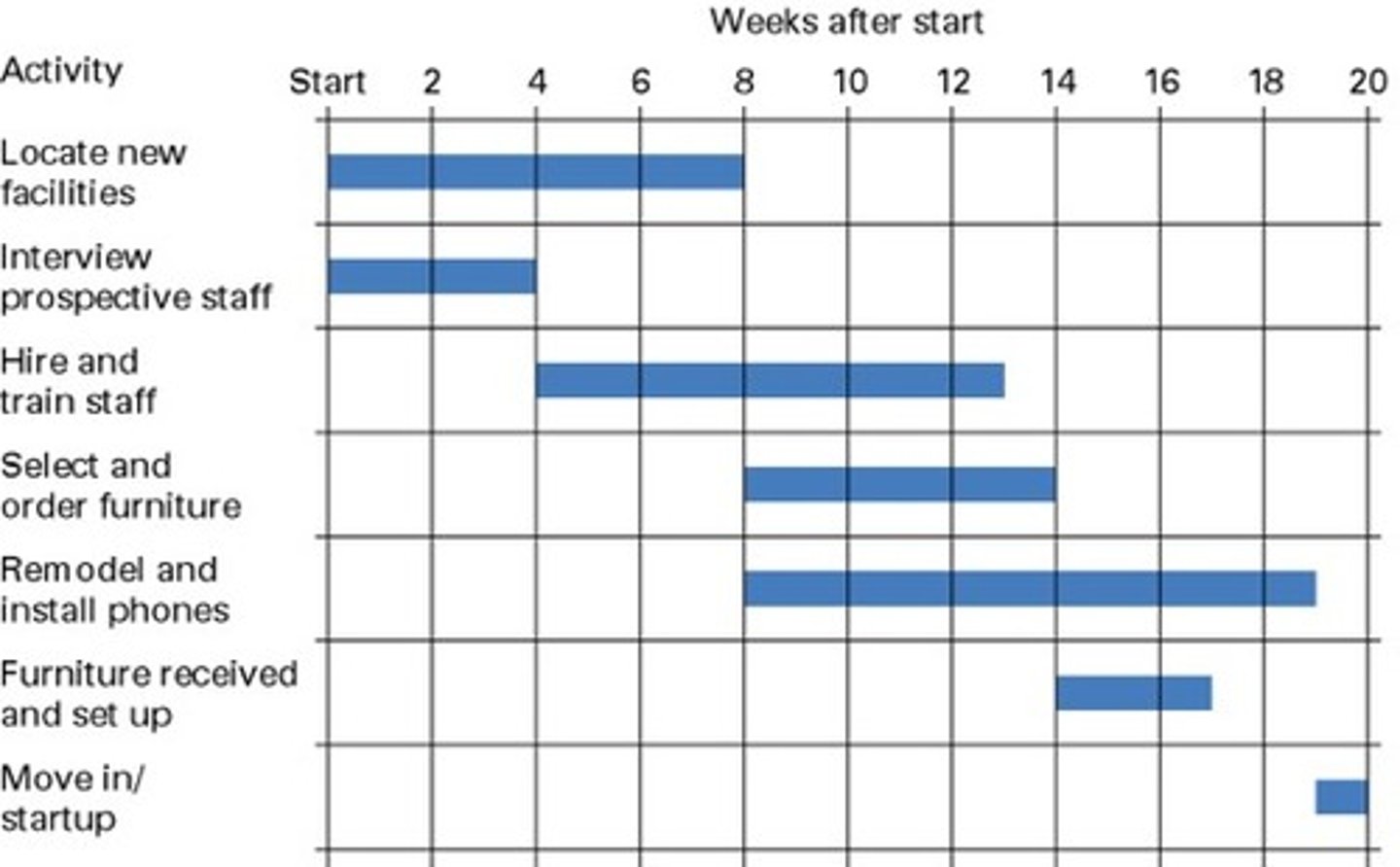

Gantt Chart

A visual representation of a project schedule over time.

PERT

Program Evaluation and Review Technique, used for analyzing the tasks involved in completing a project.

Critical Path Method (CPM)

A project management technique used to determine the longest stretch of dependent activities.

Network diagram

Diagram of project activities that shows sequential relationships by use of arrows and nodes.

Activity on Node (AON)

Network convention in which nodes designate activities.

Early Start (ES)

The earliest time an activity can begin, assuming all preceding activities start as early as possible.

Early finish (EF)

The earliest time an activity can finish

Slack

The amount of time that a task can be delayed without delaying the project.

Critical Path

The critical path is indicated by the activities with zero slack.

Activity on Arrow (AOA)

Network diagram convention in which arrows designate activities

Time-cost trade-offs

Activity time estimates are made for some given level of resources

Motivations for project completion

To avoid late penalties, monetary incentives, and free resources for use on other projects

Crashing

Shortening activity durations, typically involving additional funds for personnel or equipment

Crashing decisions

To make decisions concerning crashing requires information about regular and crash time and cost estimates

Critical path activities

Activities that are potential candidates for crashing

Crashing non-critical path activities

Would not have an impact on overall project duration

Crashing procedure

General procedure: Crash the project one period at a time, starting with the least expensive activity on the critical path

Sources of error

Potential sources of error include incomplete project networks and inaccurate time estimates

Project management software advantages

Advantages include imposing methodology, enhancing communication, and generating reports

Process Selection

Refers to deciding on the way production of goods or services will be organized

Process strategy

Key aspects include capital intensity and process flexibility

Capital intensity

The mix of equipment and labor that will be used by the organization

Process flexibility

The degree to which the system can be adjusted to changes in processing requirements

Process choice

Demand driven based on variety and volume

Process selection

Involves substantial investment in equipment and has a very specific influence layout.

Product or service profiling

Linking key product or service requirements to process capabilities.

Key dimensions of profiling

-Range of products or services that will be processed

-expected order sizes

-pricing strategies

-expected frequency of schedule changes

-order-winning requirements

Technology

The application of scientific discoveries to the development and improvement of products and services and/or the processes that produce or provide.

Technological innovation

The discovery and development of new or improved products, services, or processes, for producing or providing them.

Automation

Machinery that has sensing and control devices that enable it to operate automatically.

Programmable automation

Involves the use of high-cost, general-purpose equipment controlled by a computer program that provides both the sequence of operations and specific details about each operation.

Flexible automation

Evolved from programmable automation. It uses equipment that is more customized than that of programmable automation and requires significantly less changeover time.

Facilities layout

The configuration of departments, work centers, and equipment, with particular emphasis on movement of work (customers or materials) through the system.

Needs for layout planning

- Inefficient operations

- Accidents or safety hazards

- Changes in product or service design

- Introduction of new products or services

- Changes in output volume or product mix

- Changes in methods or equipment

- Changes in environmental or other legal requirements

- Morale problems

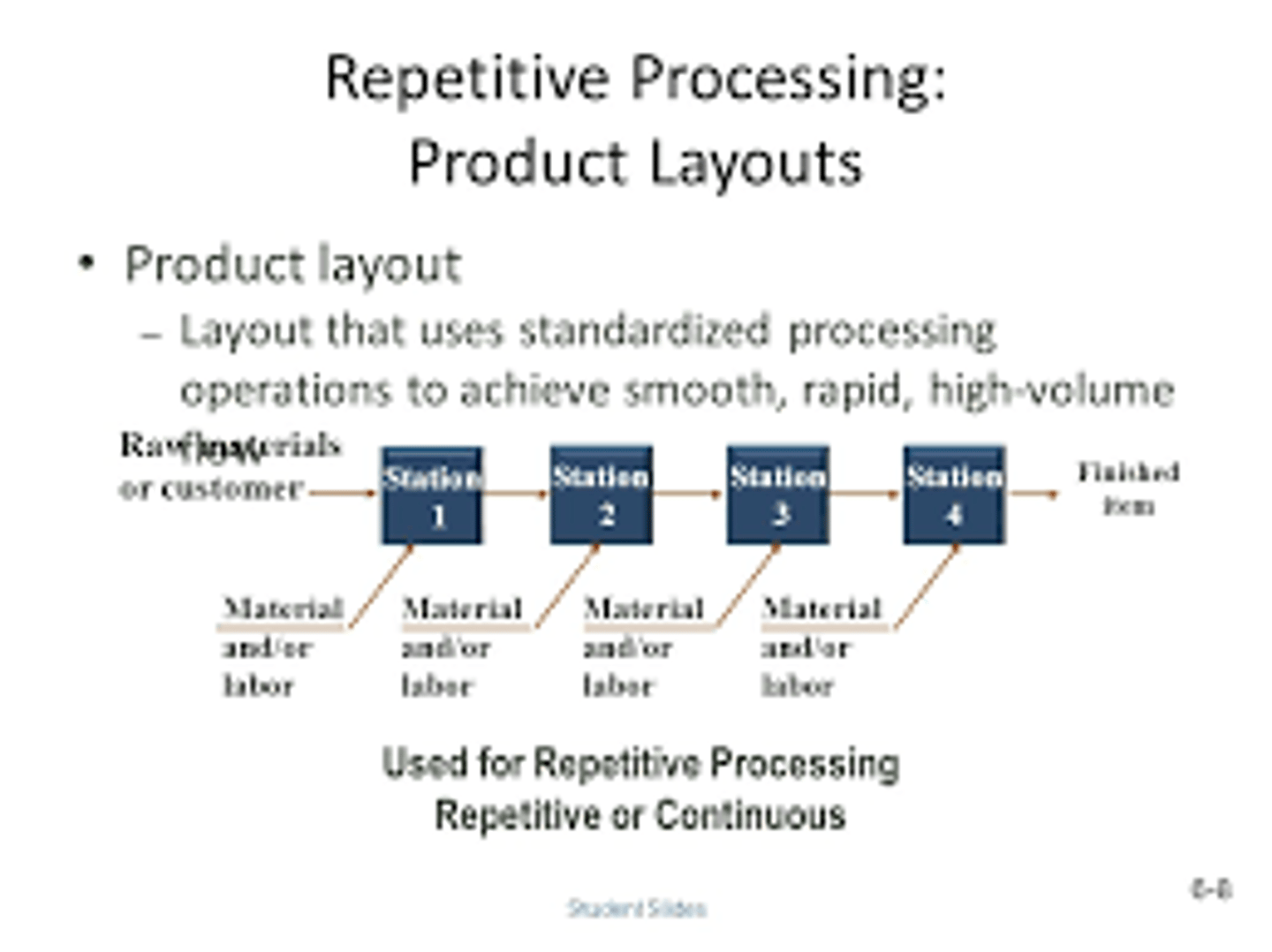

product layouts

layout that uses standardized processing operations to achieve smooth, rapid, high-volume flow

Advantages of product layouts

-High rate of output

-low unit cost

-labor specialization

-low material handling cost per unit

-high utilization of labor and equipment

-established routing and scheduling

-routine accounting, purchasing and inventory control

Disadvantages of product layouts

-Creates dull, repetitive jobs

-poorly skilled workers may not maintain equipment or quality of output

-fairly inflexible to changes in volume or product or process design

-highly susceptible to shutdowns

-preventive maintenance

-capacity for quick repair and spare-parts inventories are necessary expenses

-individual incentive plans are impractical

Process layouts

Layouts that can handle varied processing requirements.

Advantages of process layouts

-Can handle a variety of processing requirements

-not particularly vulnerable to equipment failures

-general-purpose equipment is often less costly and easier to maintain

-it is possible to use individual incentive systems.

Disadvantages of process layouts

-In-process inventories can be high

-routing and scheduling pose continual challenges

-equipment utilization rates are low

-material handling is slow and inefficient

-reduced spans of supervision

-special attention necessary for each product or customer

accounting

-inventory control

-purchasing are more involved

Fixed-position layout

Layout in which the product or project remains stationary, and workers, materials, and equipment are moved as needed.

Combination layouts

Some operational environments use a combination of the three basic layout types.

Cellular layouts

Layout in which workstations are grouped into a cell that can process items that have similar processing requirements.

Cellular Production

layout in which workstations are grouped into a cell that can process items that have similar processing requirements

Group technology

The grouping into part families of items with similar design or manufacturing characteristics.

Line balancing

The process of assigning tasks to workstations in such a way that the workstations have approximately equal time requirements.

Cycle time

The maximum time allowed at each workstation to complete its set of tasks on a unit; also establishes the output rate of a line.

Precedence diagram

A diagram that shows elemental tasks and their precedence requirements.

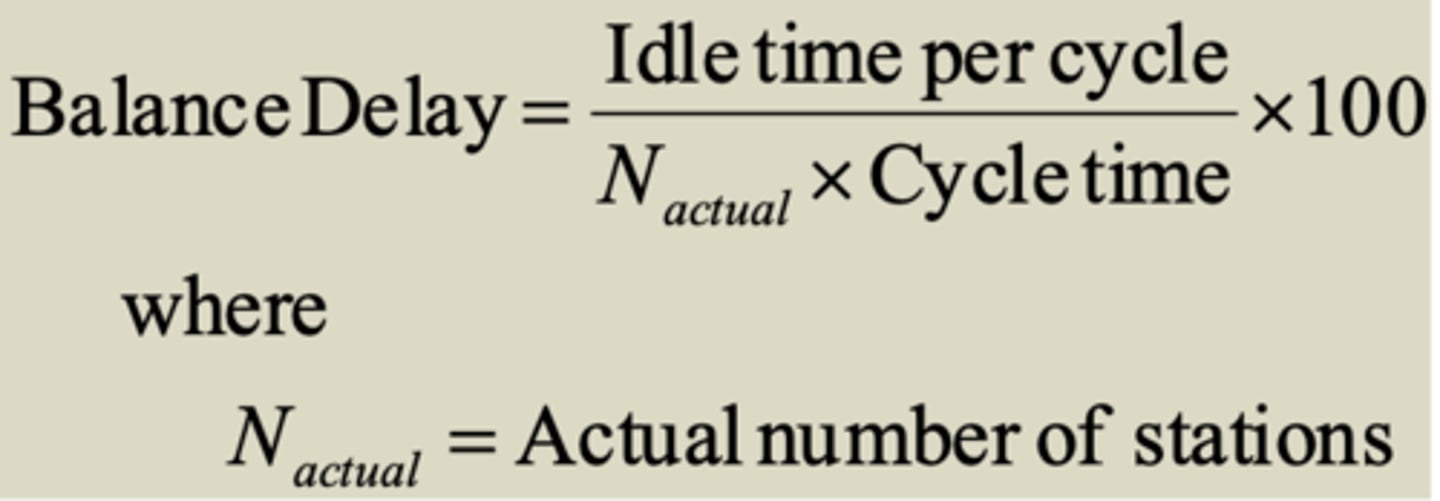

Balance delay

Percentage of idle time.

Efficiency

Percentage of busy time of a line.

Cost Volume Analysis Assumptions

One product is involved

Everything produced can be sold

The variable cost per unit is the same regardless of volume

Fixed costs do not change with volume changes, or they are step changes

The revenue per unit is the same regardless of volume

Revenue per unit exceeds variable cost per unit

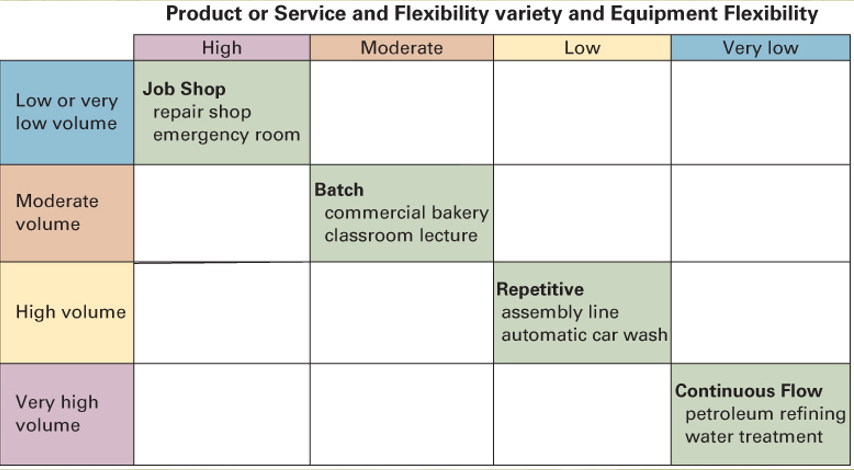

Product Process Matrix

Process Types

Job Shops, Batches, Repetitive/Assembly, Continuous