CPIM Module 1.1

1/53

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

54 Terms

supply chain

the network of suppliers that deliver products from raw materials to end customers through either an engineered or transactional flow of information, goods, and money.

service industry

narrow definition: an organization that provides intangible goods

broad definition: all organizations except farming, mining and manufacturing

supply chain management

the design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging world-wide logistics, synchronizing supply with demand, and measuring performance globally.

upstream supply chain

moving to the direction of supplier of raw materials

downstream supply chain

moving to the direction of end customer

external influences on supply chains:

customer expectations

government regulations and/or sanctions

economic conditions

political and social environment

global and domestic competitors

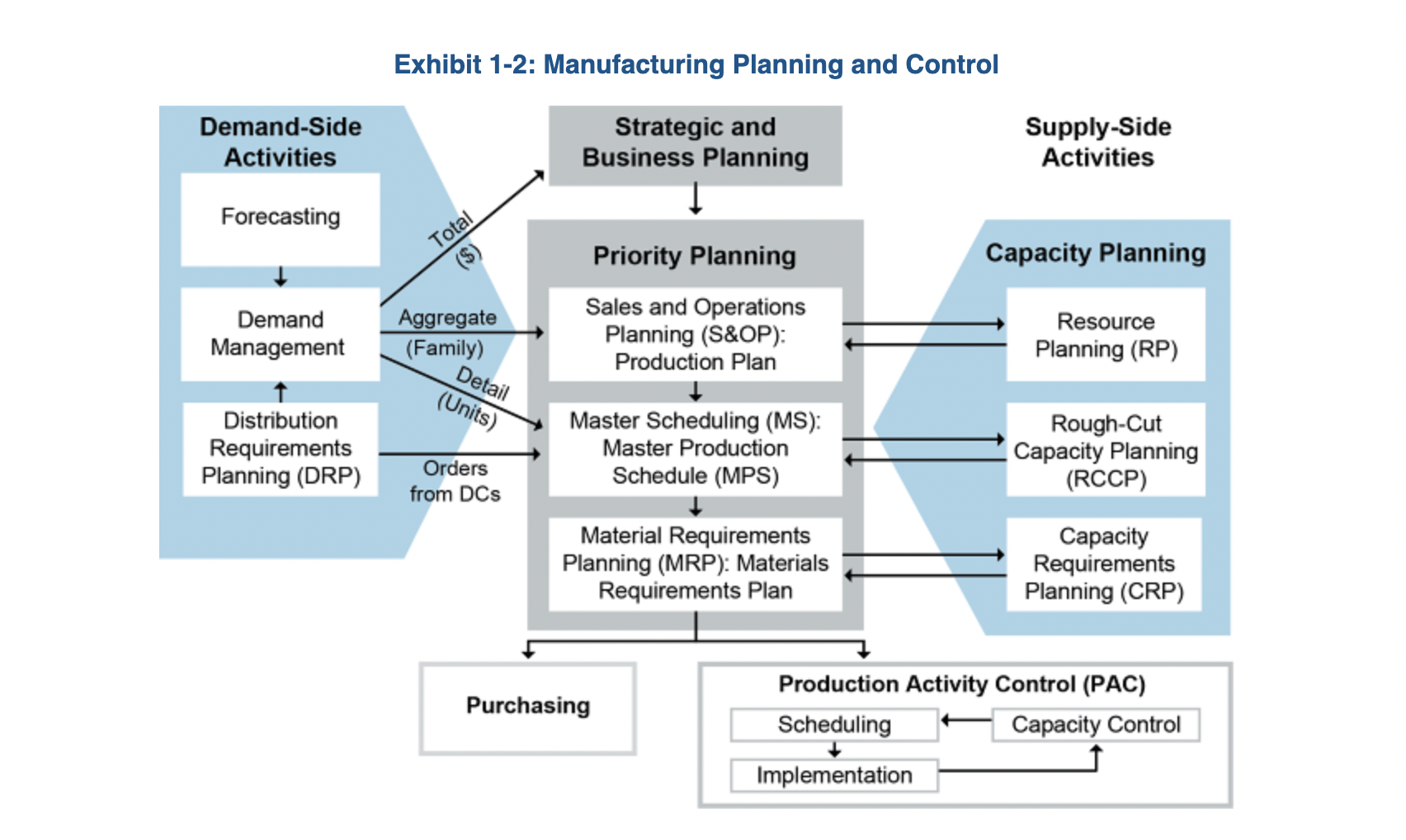

MPC - manufacturing planning and control system

a closed-loop information system that includes the planning functions of production planning (S&OP), master production scheduling, material requirement planning (MRP), and capacity requirement planning - once the plan has been accepted as realistic, execution begins. The execution functions include input-output control, detailed scheduling, dispatching, anticipated delay report (department and supplier), and supplier scheduling

Key points about planning system:

top-down approach - every planning proces refers back to the business plan (see figure above)

closed-loop system - continuous improvements made based on the capacity contraints, feedback, unexpected events

supply side priorities: feasibility and availability; demand side priorities: timing and order of work

Time horizon planning of:

Strategic and Business Planning

S&OP

Master Scheduling

Material Requirement Planning

Strategic and Business Planning - STRATEGIC

S&OP - TACTICAL - medium range

Master Scheduling - TACTICAL - medium to short range

Material Requirement Planning - OPERATIONAL - short range

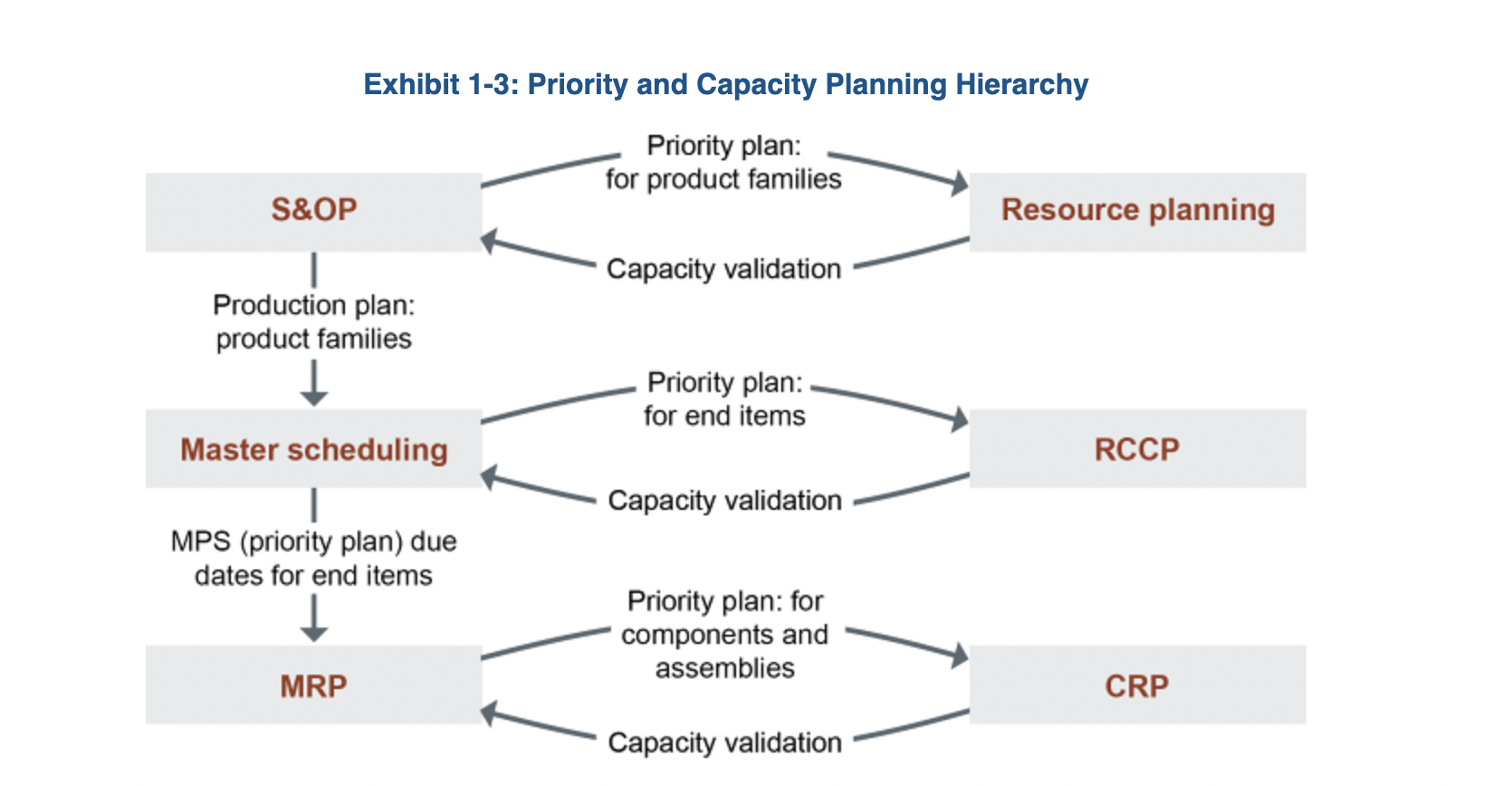

Sales&Operations Planning (S&OP)

key output: a consensus set of numbers that the supply side of the organization commits to produce and that the demand side (marketing and sales) agrees to set as their goals

input on the aggregate family level

master scheduling

information on detail level for individual units (MTO - raw materials, ATO - components, MTS - finished goods)

input: S&OP

output: MPS - master production schedule (which units in which period)

MRP - Master Requirement Planning

involves calculating the dependent demand:

input: MPS + BOMs

output: calculations on when and how much of raw materials/components to order

Demand Side Activities:

quantities come from:

forecasts

demand management

distribution requirement planning (DRP)

Supply Side Activities

image

RCCP - Rough-Cut Capacity Planning

comparing required capacity from the MPS (master scheduling level) in key resources (checking on bottleneck work centers, labor, machines…)

CRP - Capacity Requirement Planning

detailed check of capacity based on the MRP - breaks down planned and released orders from MRP into specific workcenters and time-periods: calculates exact workload vs availability capacity

PAC - Purchasing and Production Activity Control

result of MRP; planning —> execution

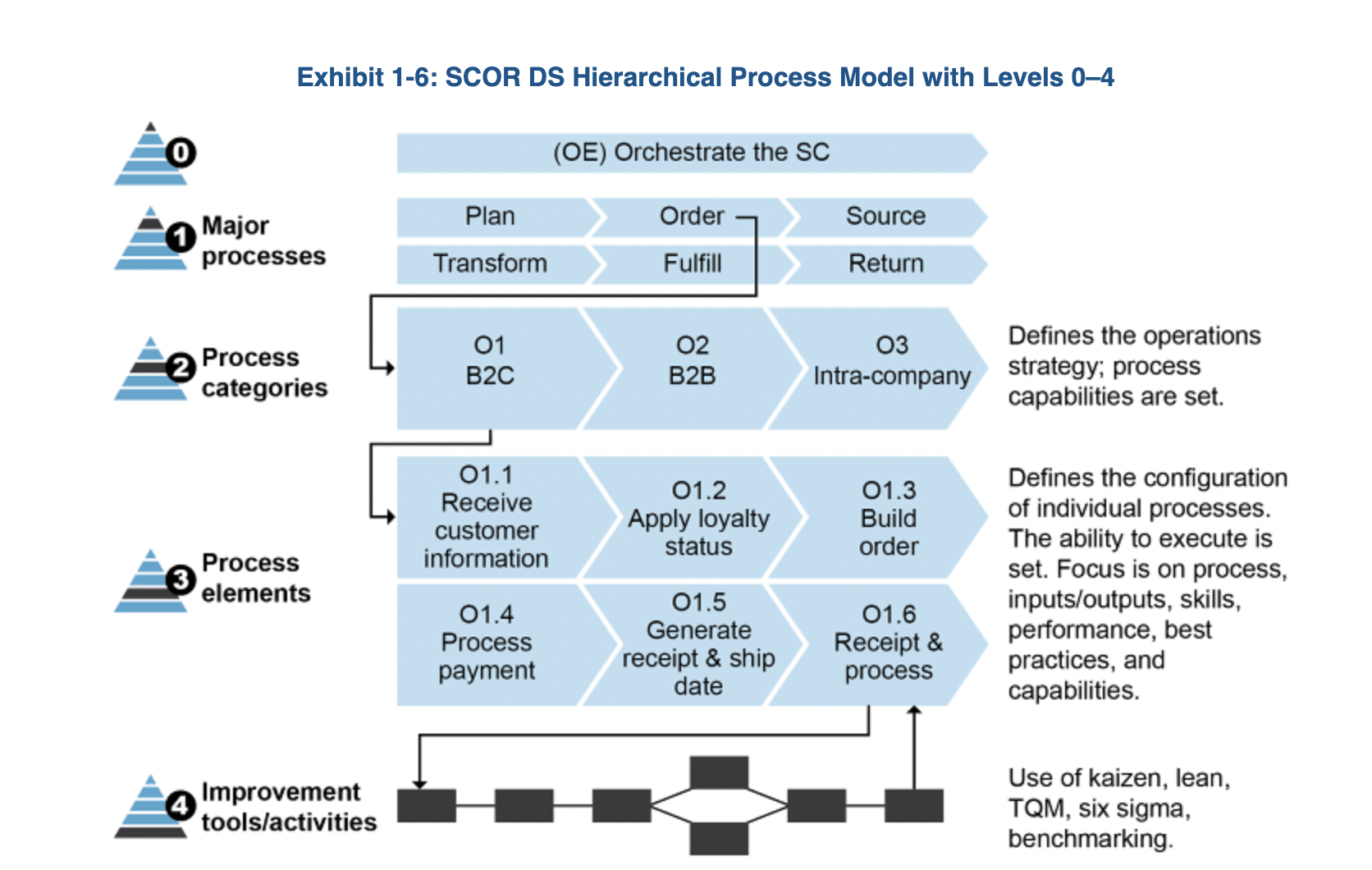

SCOR DS Processes

Orchestrate:

Demand vs Supply

Synchronise vs Regenerate

SCOR DS Model - Demand

Order: managing customer purchase attributes including location, payment methods, fulfilment status, or visibility.

Fulfil: fulfilling customer orders by scheduling order delivery, picking, packing, shipping, installing, commissioning, and invoicing processes

SCOR DS Model - Supply

Source: procuring, ordering, and scheduling the ordering, delivery, receipt, and transfer of products/services in a way that meets market demand and quality expectations.

Transform: creating products (including production, assembly or disassembly, or MRO - Maintenance, Repair, Operations) and services to meet customer demand.

SCOR DS Model - Synchronize

Plan: creating plans for order, source, transform, fulfil, and return to operate the supply chain; balancing requirements and resources; determining capability gaps; and identifying actions to correct gaps

SCOR DS Model - Regenerate

Return: diagnosing, evaluating entitlement of, and determining disposition of approved returned goods from suppliers, distributors or consumers.

SCOR DS - Hierarchical Model

mission

the overall goals set within the parameters of the business scope

mission statement

statement of purpose - why the company exists

vision

the shared perception on the company future - what the organization will achieve and a supporting philosophy

“where are we going?”

corporate culture

set of important assumptions that members of the company shares

STEEPLE analysis

tool to scan organisational external environment on 7 layers:

Sociocultural

Technological

Economic

Environmental

Political

Legal/Regulatory

Ethical

environmental scanning

process used to expose the organization’s potential SWOT. OT primarily external

competitive analysis

analysing the competitor on its strategies, capabilites, prices, and costs

macro environment

the environment external to a business including, technological, economic, natural, and regulatory forces that marketing efforts cannot control. Analyzed through STEEPLE

S - Sociocultural Factors

Demographics, Values and Preferences

T - Technological Factors

Identifying emerging and speculative technology

E - Economical Factors

economic conditions such as gross domestic product, employment level, family or disposable income, interest or currency exchange rates

E - Environmental Factors

natural events, trends, also includes reactions to those trends namely: changes in insurance rates, agricultural practices…

P - Political Factors

political, institutional, governmental practices

L - Legal and regulatory Factors

laws and regulations that are enacted as a result of political attitude.

E - Ethical Factors

business ethics, good governance, ethical sourcing, social responsibility, moral standards, accountability, and sustainability

5 Forces Framework

Competitive Rivalry

Bargaining Power of Suppliers

Bargaining Power of Buyers

Risk of Substitutes

Possibility of New Entrants

Internal Capabilities

resource

anything that adds value to a good or service in its creation, production or delivery.

tangible resources

physical

financial

technological

organizational

intangible resources

human assets and intellectual capital

brands and reputation

relationships

culture and the compensation system

VRIN

valuable resource or capability is directly related

VRIN stands for Valuable, Rare, Inimitable, Nonsubstitutable

VRIN - Valuable

directly related to the strategy being considered - relevant, will help to create a competitive advantage over competitors

VRIN - Rare

something that the competitors lack

VRIN - Inimitable

Something that is hard to copy for the competitors

VRIN - Nonsubstitable

an asset/resource that cannot be easily altered by the competitor

Value Chain

the functions within a company that add value to the goods or services that the organization sells to consumers and for which it receives payments

It is divided between primary and support activities.

Primary activities are those that create value, while support activities make the primary activities possible.

trading partner

any organization external to the company that play an integral role within the supply chain community and whose business fortune depends on the supply chain community

Value Chain Analysis

an examination of all links a company uses to produce and deliver its products and services, starting from the origination point and continuing through the delivery to the final consumer.

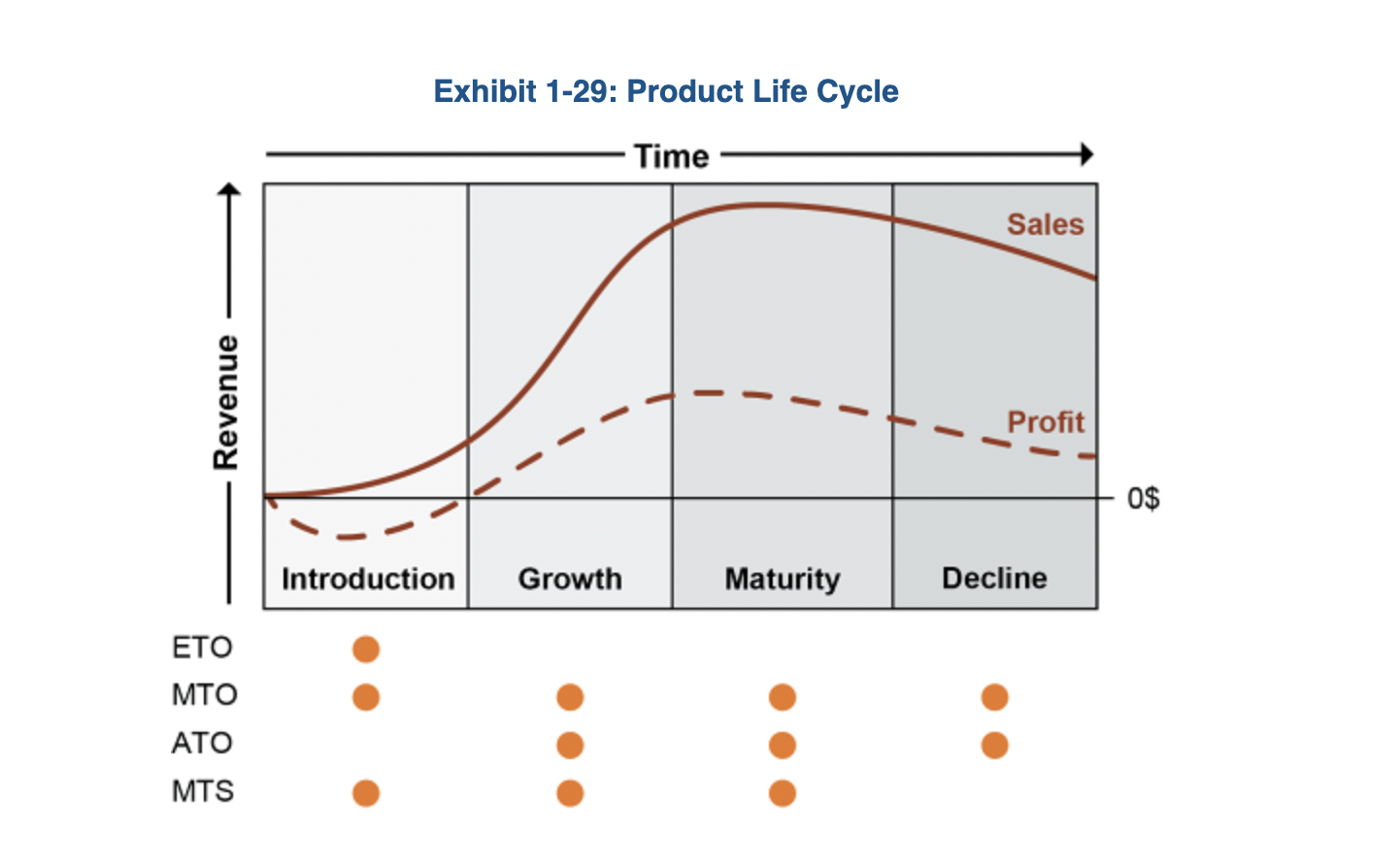

Product Life Cycle

1) The stages a new product goes through from beginning to end 2) the time from initial R&D to the time at which sales and support of the product to the customers are withdrawn 3) the period of time during which a product can be produced and marketed profitably.

Phases of Product Life Cycle (PLC)

Introduction

Growth

Maturity

Decline

functional product

mature products that tend to have a low profit margin and a predictable demand