particle-size-reduction

1/19

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

20 Terms

Why is particle size important in pharmaceutical manufacturing?

It affects material handling (e.g. flowability) and biopharmaceutical properties such as dissolution and bioavailability.

How does comminution (particle size reduction) affect drug dissolution and bioavailability?

It increases surface area, leading to a higher dissolution rate and potentially increased bioavailability if absorption is dissolution-limited.

Why is particle size critical for inhaled and transported pharmaceuticals?

It determines lung deposition site for inhaled drugs and increases bulk density, improving transport efficiency.

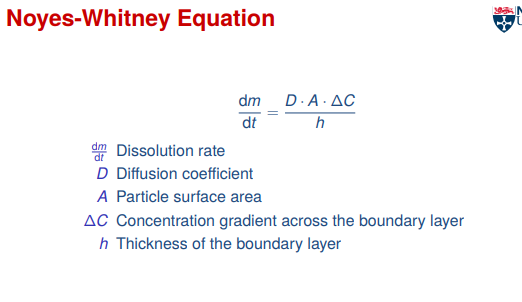

noyes whitney requation

Dissolution rate ∝ surface area of the drug

Increased by smaller particle size

Increased by higher diffusion coefficient

Increased by greater concentration gradient

what is milling?

A mechanical process used to reduce particle size of solid materials

Achieved by impact, compression, attrition, or shear forces

Increases surface area, improving dissolution rate

Improves flowability and uniform mixing in manufacturing

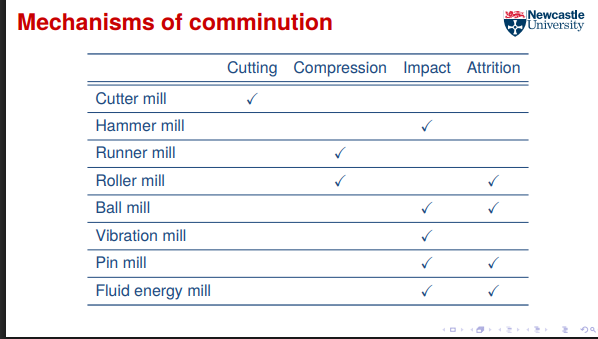

What is a cutter mill and how does it work?

Uses rotating and stationary knives to cut particles

Produces coarse particle size reduction

Screen retains particles until the desired size is achieved

What is a hammer mill and how does it work?

Hammers radiate from a central rotating shaft

Particles are struck at high velocity

Causes brittle fracture of most materials

What is a runner mill and how does it operate? edg and end

Based on pestle and mortar (manual or mechanised)

Edge runner mill: grinding occurs at the edge of a rotating wheel

End runner mill: grinding occurs under the flat base of the rotating wheel

What is a roller mill and how does it work?

Uses two rotating rollers (or one rotating, one stationary)

Particles are crushed as they pass through the roller gap

Speed difference between rollers introduces shearing action

What is a ball mill and how does it reduce particle size?

A:

Hollow rotating drum partially filled (≈30–50%) with mill balls

Rotation speed and feed volume are critical

Balls are lifted by centrifugal force

Avalanche (cascading) effect causes impact and attrition, reducing particle size

What is a vibration mill and how does it work?

Mill chamber is ~80% filled with milling balls

Vibration causes frequent impacts between balls and particles

Produces fine particle size reduction

What is a pin mill and how does it reduce particle size?

Consists of two discs with closely positioned pins

Size reduction occurs by impact when particles collide with pins

Also by attrition/shear between opposing pins

What is a fluid energy mill and how does it reduce particle size?

Uses high-velocity air injected into a toroidal milling chamber

Particles are suspended in turbulent airflow

Size reduction occurs by particle–particle and particle–wall collisions

What is Griffith’s theory of brittle fracture?

Materials contain microscopic cracks (flaws)

During comminution, applied energy concentrates at crack tips

When energy exceeds bond strength, the crack ruptures and propagates

How do cracks propagate according to Griffith’s theory, and how do tough materials differ?

Cracks spread through weak regions with many flaws

Elastic energy redistributes, concentrating at other cracks

Causes a cascade effect → rapid brittle fracture

Tough materials show ductile fracture with slower crack growth

What is deformation and how does it affect fracture?

Deformation dissipates applied energy that might otherwise cause fracture

Energy used in deformation is not available for crack propagation

Therefore, deformation can reduce brittle fracture

What is the difference between elastic and plastic deformation?

Elastic deformation: reversible; material returns to original shape when stress is removed

All materials show some elastic deformation

Plastic deformation: irreversible; permanent shape change

What is hardness and how is it measured?

Hardness is the ability of a material to resist plastic deformation

Measured in N m⁻² or using the Mohs’ scale (ordinal)

On the Mohs’ scale: Diamond = 10, stainless steel ≈ 5

Measured using hardness testers (e.g. Brinell, Vickers)

ow does hardness affect comminution?

Hard materials are more difficult to comminute

Require more energy for size reduction

Can cause wear of milling equipment parts