EGAD Midterm Review

1/103

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

104 Terms

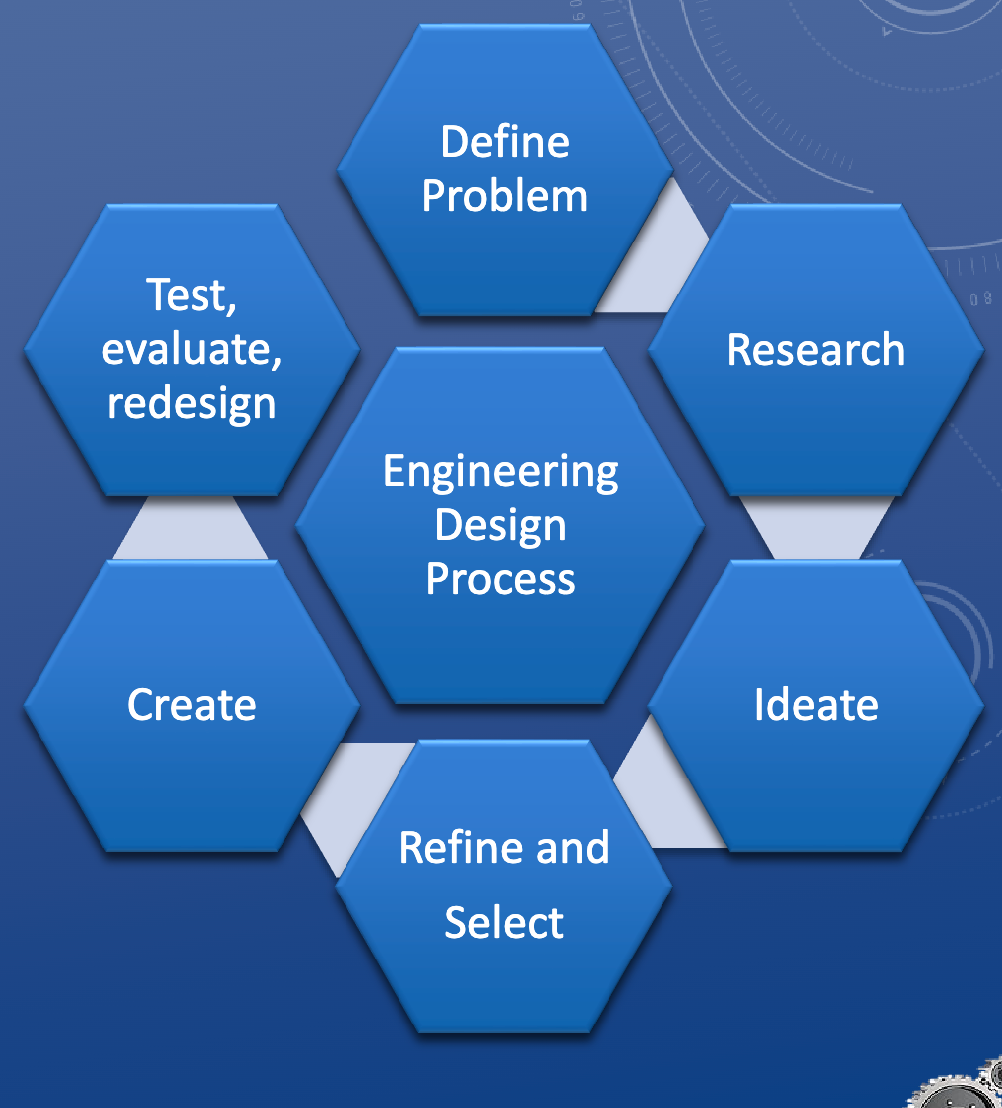

Engineering Design Process

Why is freehand drawing beneficial?

Quick technical drawings, or modifications

• Developing ideas, before & during CAD work

• Presenting conceptual sketches, and debating alternatives

• To aid communication during a technical discussion

Size of engineering lettering

1/8'‘or 3mm

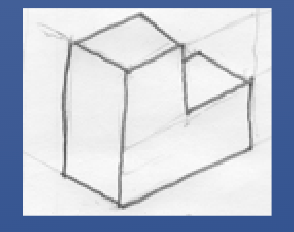

Oblique

One true face

Other faces projected at an angle

Axonometric

Means “to measure along axes”

Three-dimensional pictorial image of an object

Can be difficult to draw depending on angle of view

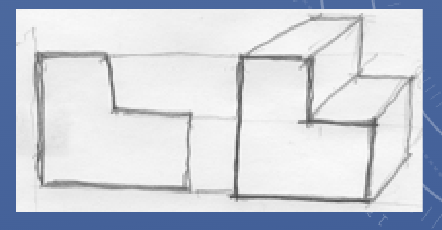

Isometric

Specific axonometric view

Equal proportions for all views

True measurements along three primary axes

Preferred view in technical drawing

Isometric projection

Functions of engineering drawings

Analysis

Production

Maintenance

Assembly

Operation

Types of engineering drawing

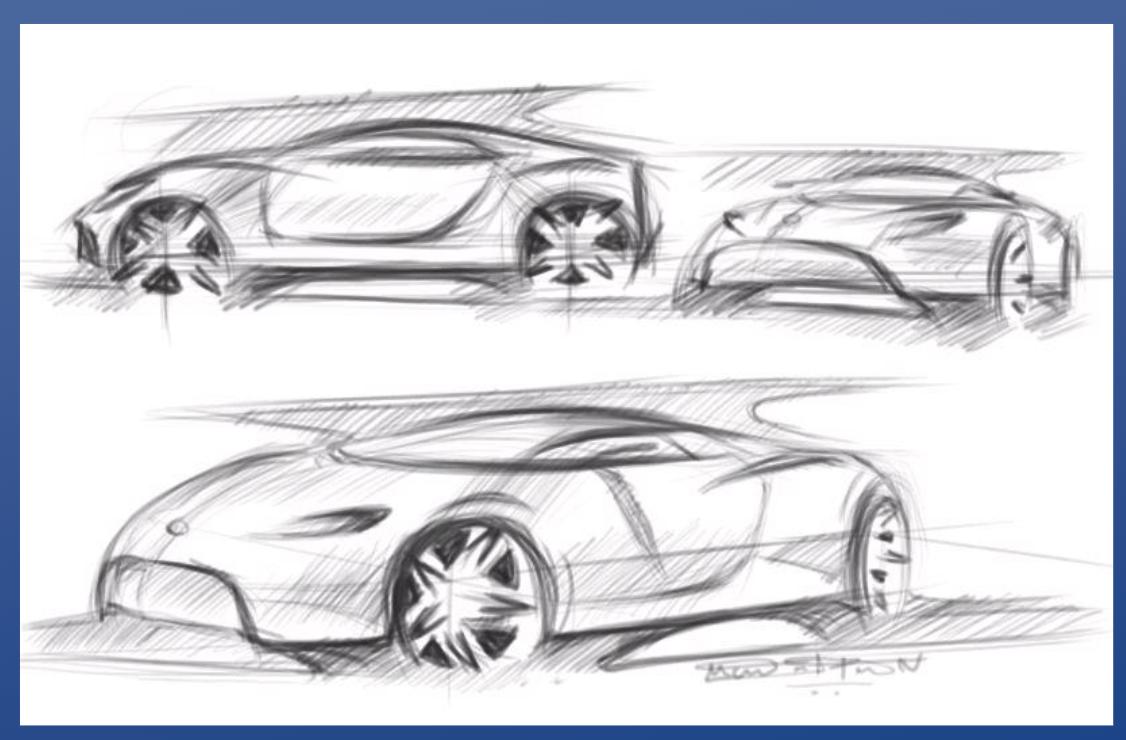

Concept Drawings

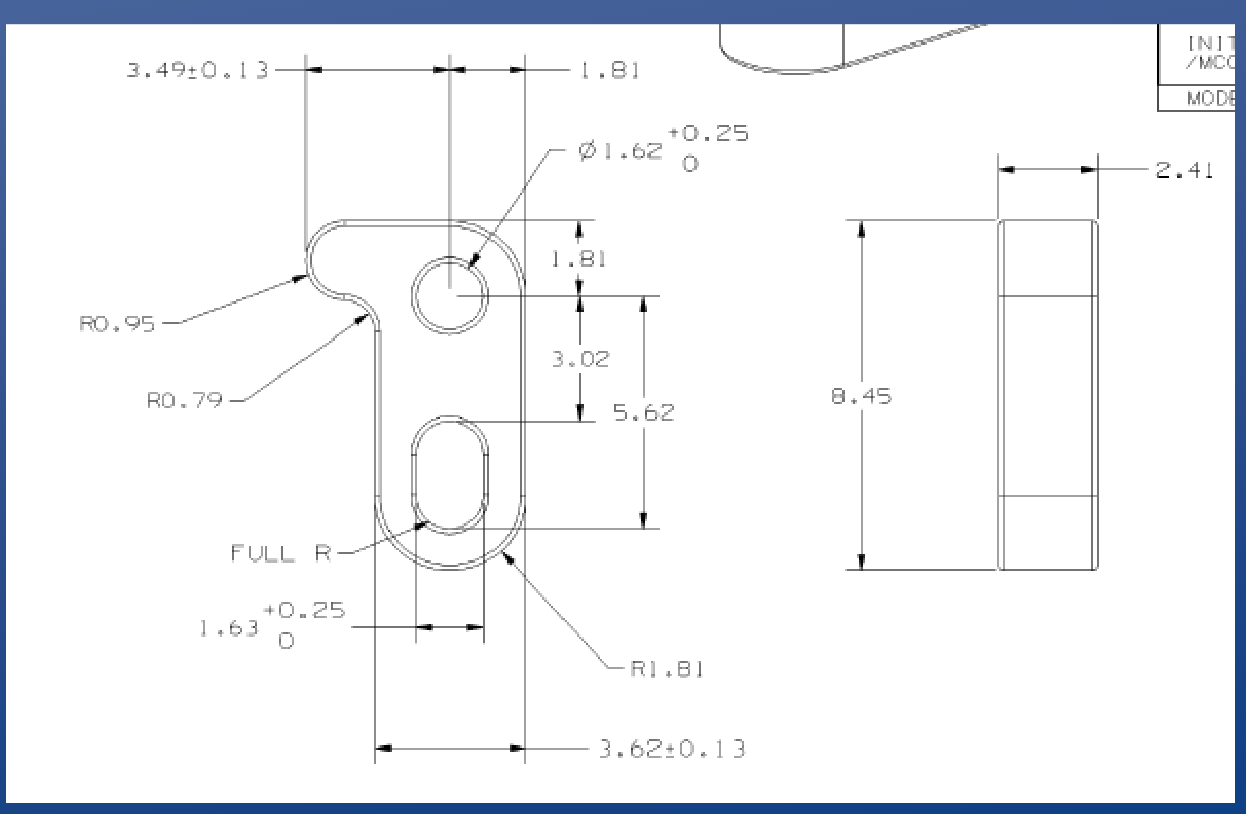

Detail Drawings

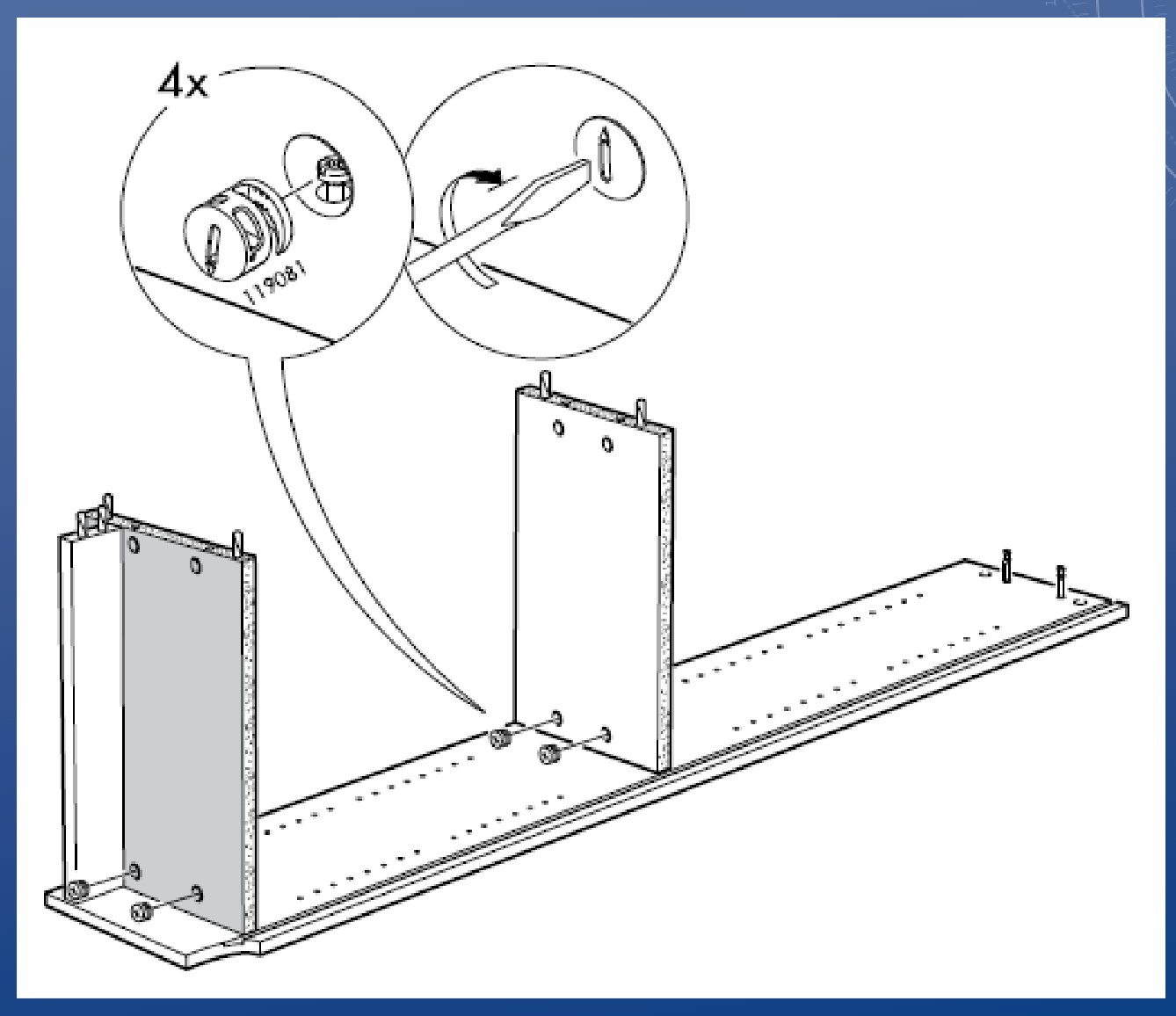

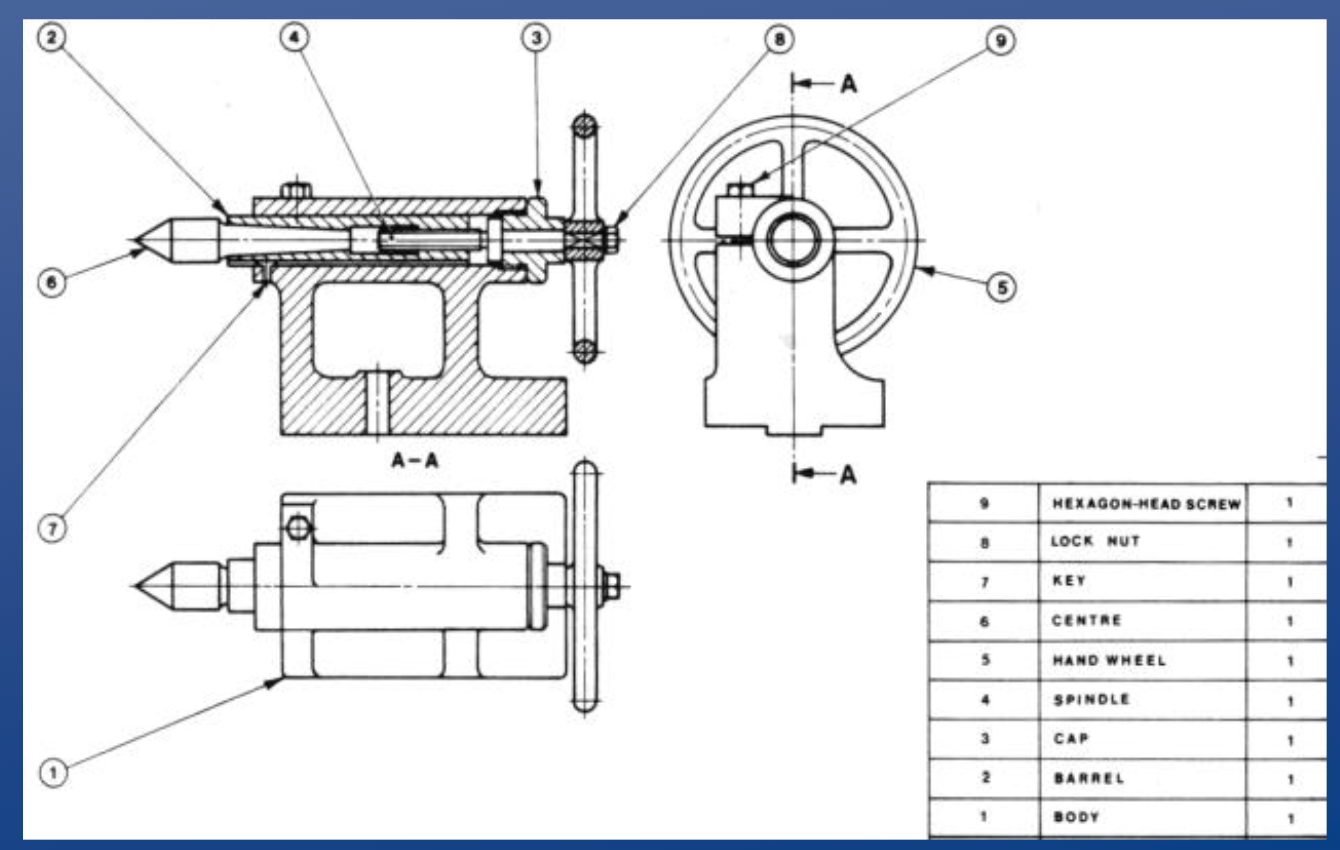

Assembly Drawing

Concept drawing

Detail drawing

Assembly drawing

Border (eng drawings)

Approximately ¼ inch (6 mm) from the outer

perimeter of the drawing sheet; shows a drawing is

complete

Zoning (eng drawings)

A grid system of letters and numbers; allows

reference to various drawing regions (we won’t be focusing on this in EGAD)

Title blocks (eng drawings)

Located in the lower right-hand corner of a drawing and

typically include:

• Company Name

• Main Title and Subtitle

• Scale

• Drawing Date

• Name (possibly also “Checked by” and “Approved by”)

• Drawing Number, Revision Number, Revision Date

Most companies have a pre-formatted title block

Some drawings require an engineer’s stamp

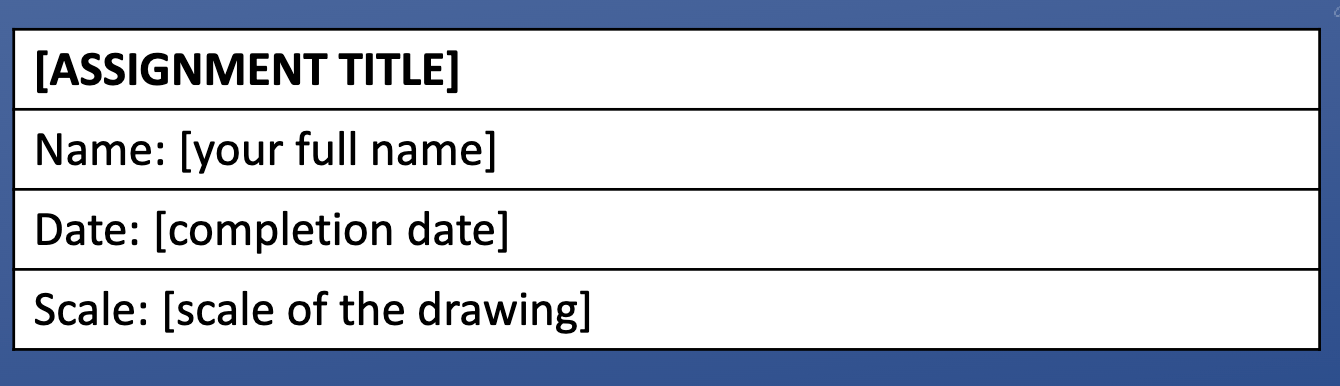

Our title blocks (eng drawings)

Bill of Materials (BOM) (eng drawings)

a parts list containing the following:

• Name

• Component part numbers

• Material

• Basic dimensions

• Required

Revision column (eng drawings)

• Records changes and approvals

• Numbered, date, brief description of the change, signatures

Notes (eng drawing)

information necessary for the drawing that don’t fit anywhere else

Legend (eng drawings)

explains uncommon drawing symbols

Object line weight

0.6 mm

Hidden line line weight

0.3

Centreline line weight

0.05

Dimension/extension line weight

0.05

Baseline dimensioning

• In baseline dimensioning, all dimensions in your drawing are measured relative to a specified reference point

• This reference point is called a Datum

*datums can also be object lines

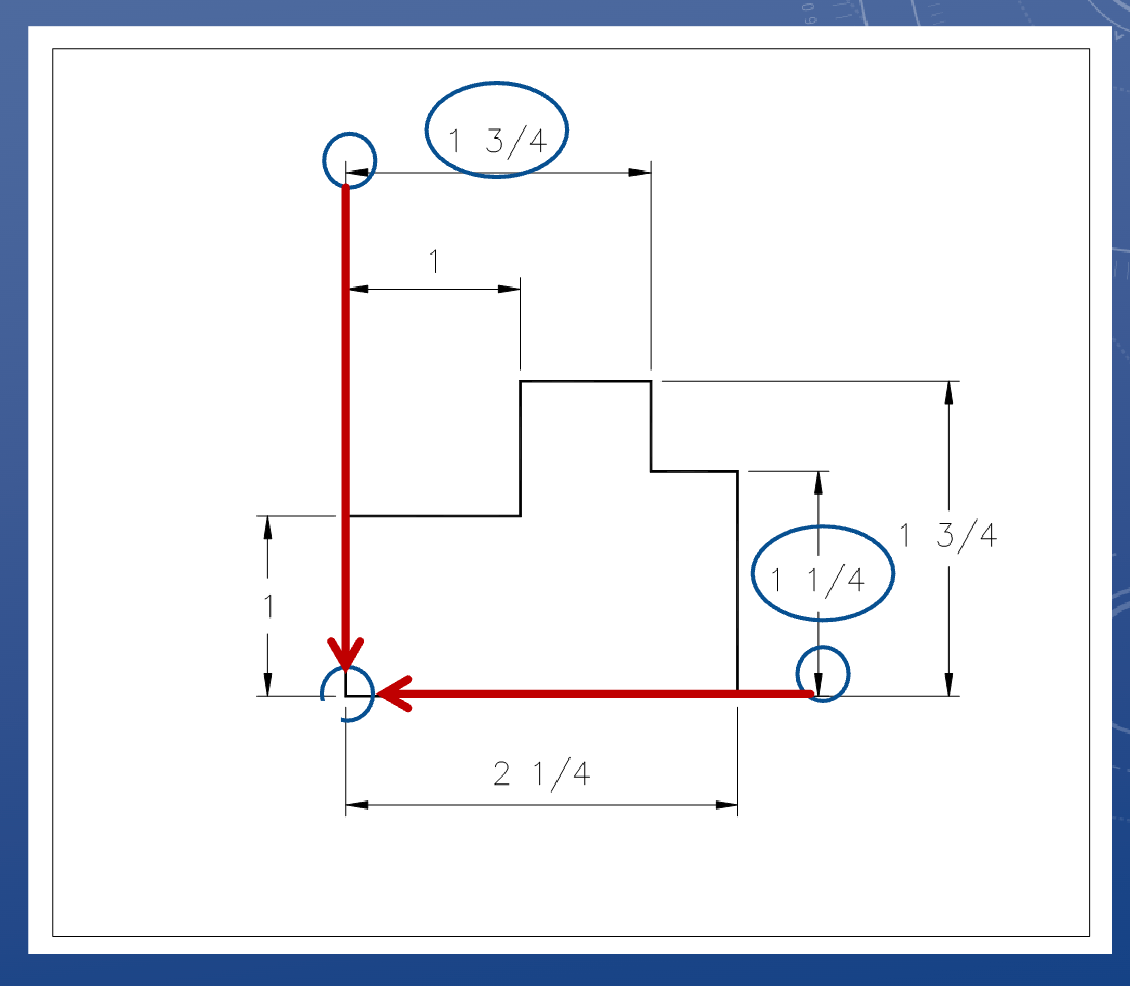

Vertically dimensioning a circle

Always weasure to the centre

VERTICAL 3-AXIS MILLING MACHINE

• Also known as a:

• Mill

• Milling machine

• Bridgeport mill

• Manual milling machine

• Used for high precision cutting operations

• Cranks are used to move the table in xyz

• Workpiece is fixed to table and moved against rotating tool

Tooling is mounted to the spindle. Measurements can be taken from the crank or digital readout. Machinists establish a datum by zeroing out the digital readout.

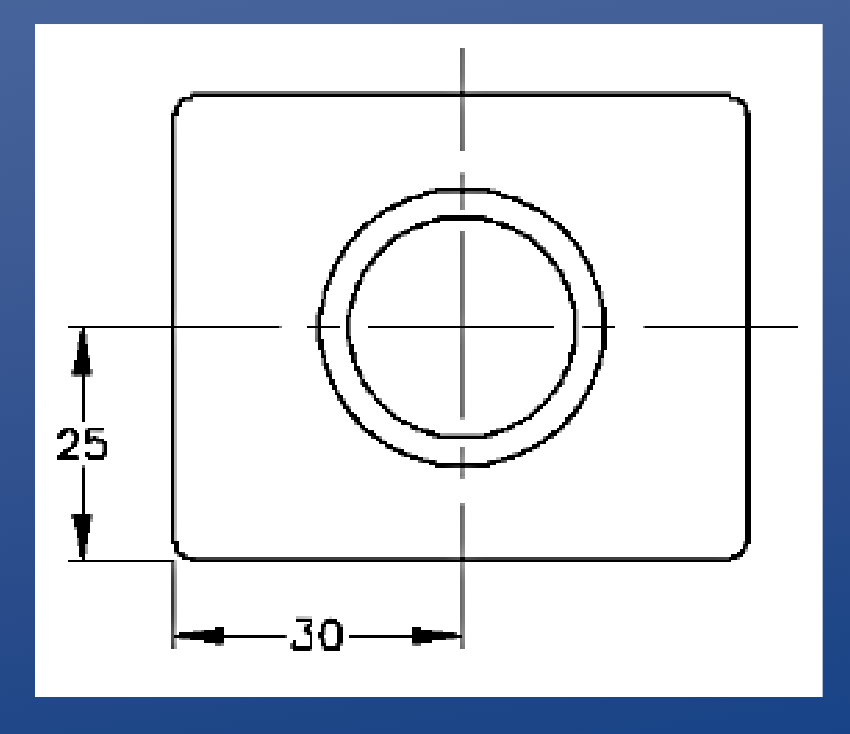

Orthographic view

An object can be viewed from

6 orthogonal (i.e. 90° apart)

directions, also known as the

principal views:

1. Top

2. Front

3. Right Side

4. Left Side

5. Rear

6. Bottom

When creating your orthographic views, they must be placed in the correct orthographic position/orientation

• Everything is projected off the Front view

• i.e. Top view is always above the Front view, Right-side is always to the right of the Front view, etc.

*only include hard edges (no curvature)

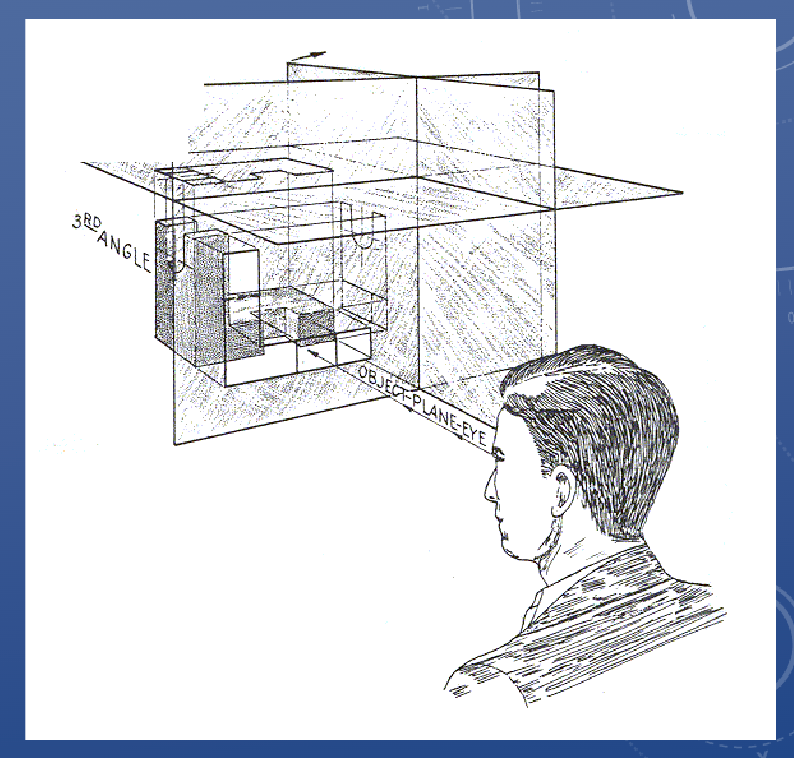

Third angle projection

Views oriented from the perspective of an outside

observer

• The plane of projection

(drawing surface) is between

the object and the observer

• North America typically uses

third angle projection

• Europe and Asia typically use

first angle projection

Picking orthographic views

Maximize clarity by:

• Matching intuitive orientation (T/F/RS)

• Reducing hidden lines

• Showing the most relevant features

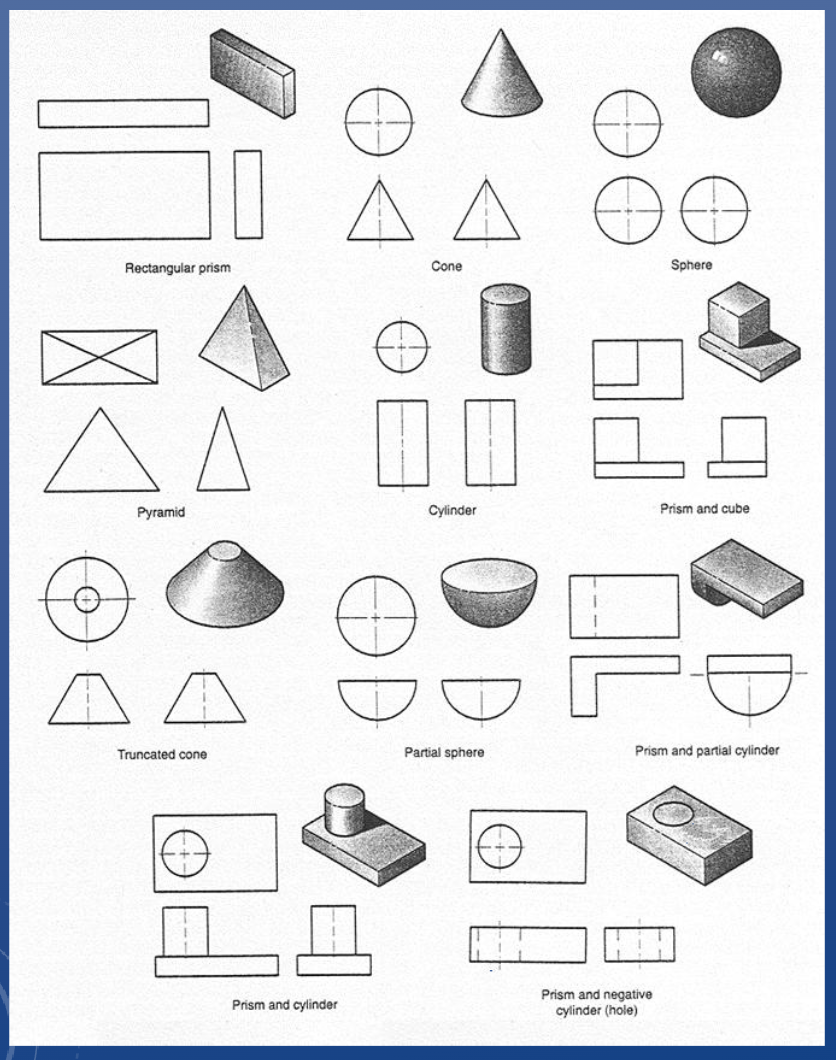

Orthographic views of common shapes

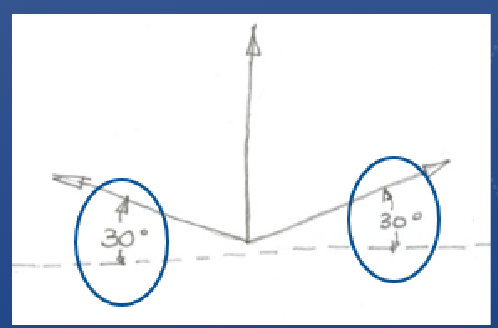

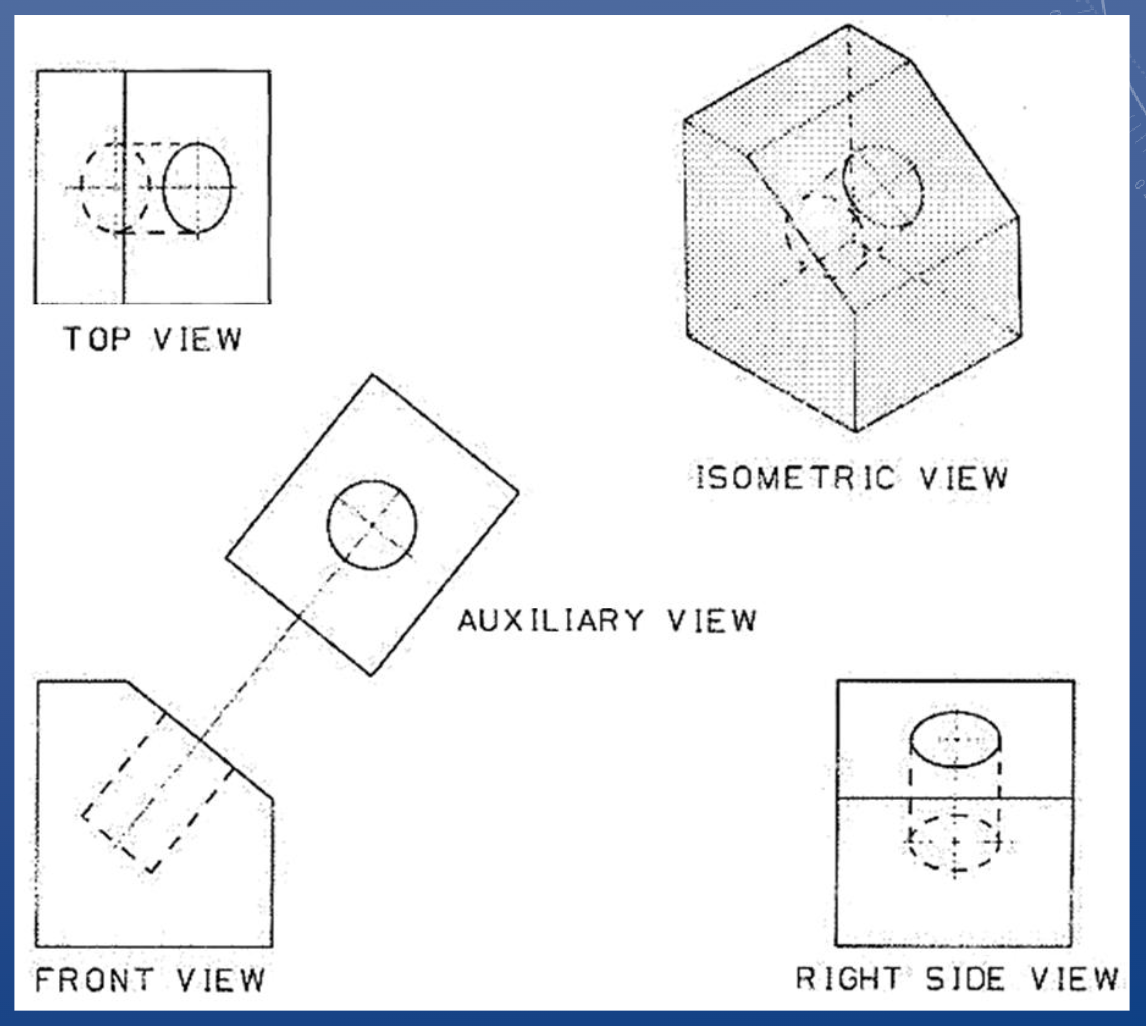

Auxiliary views

Used when the standard views will

not provide a desired detail

• It is an orthogonal projection – at an

angle to the primary views

• You are not expected to be an expert

on auxiliary views, but a general

understanding is required

Tap and Die

TAPS

• Used for cutting internal threads into a hole

• Note the tapered tip

• Cannot tap to the bottom of a “blind” hole (i.e. a hole that doesn’t go all the way through)

DIES

• Used for cutting external threads (i.e. threaded rods and bolts)

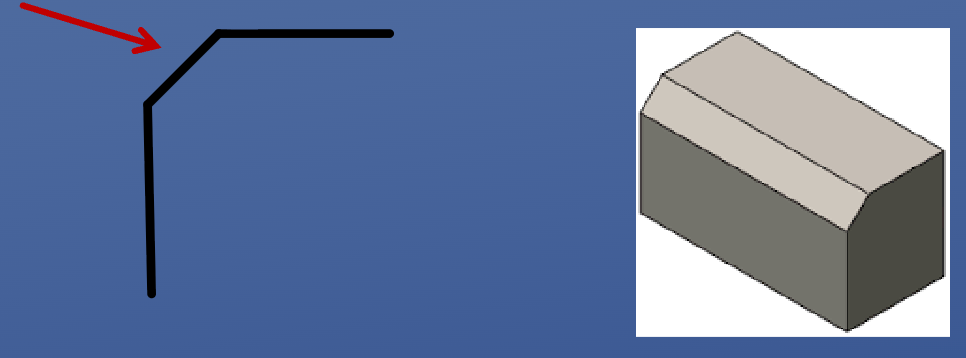

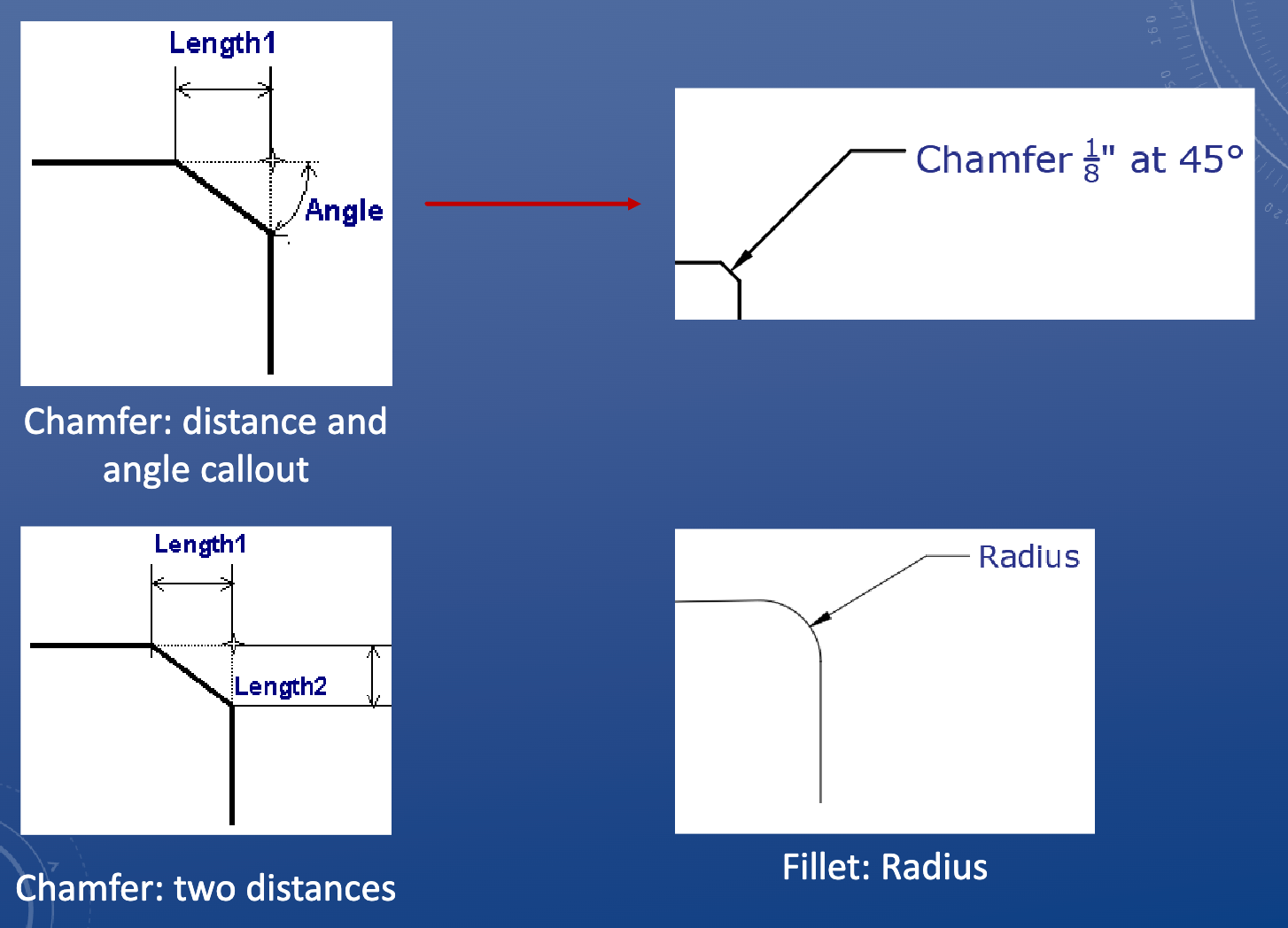

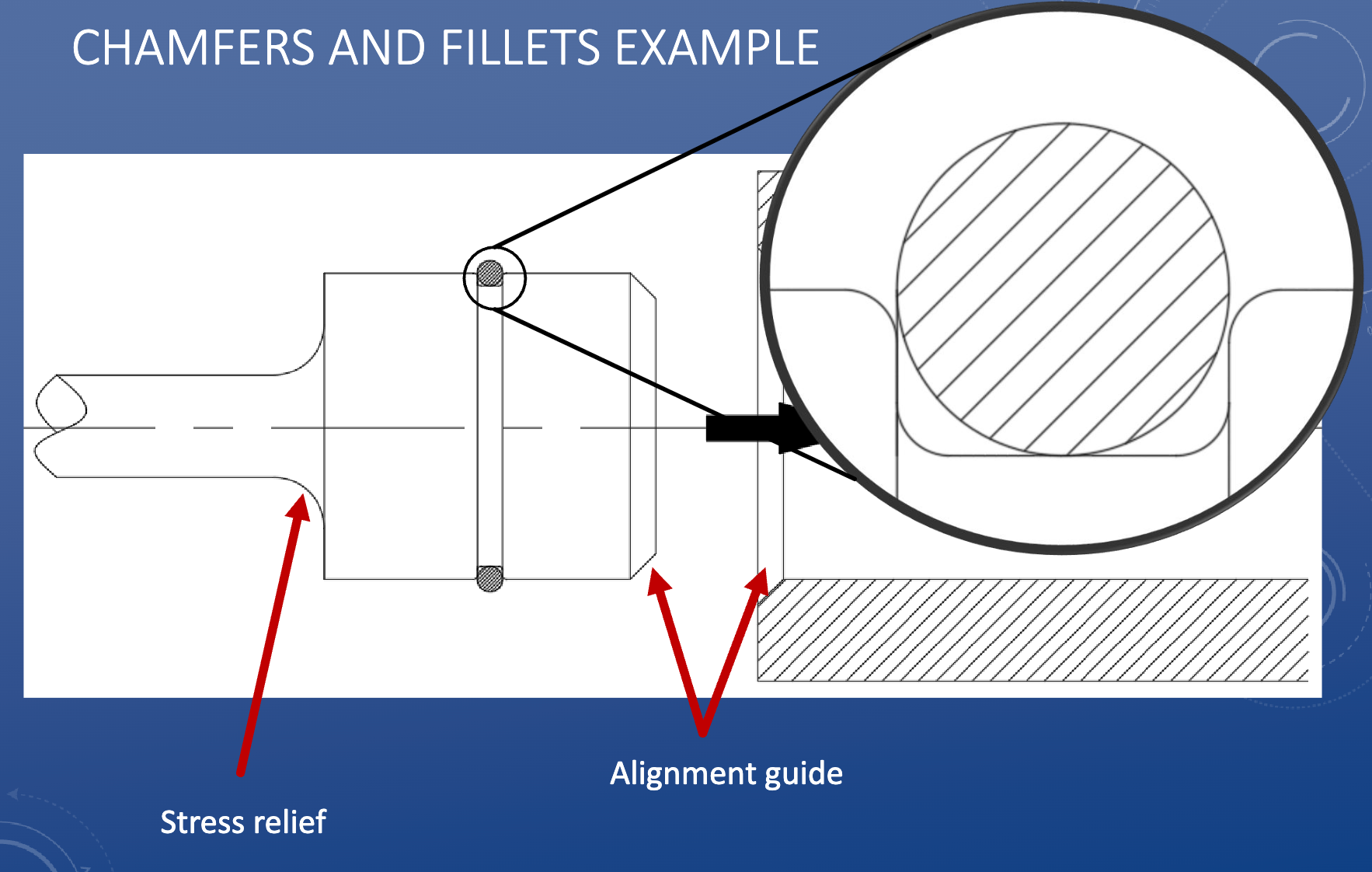

Chamfer

A bevelled edge, consistent angle

• Chamfers are relatively small (<1”)

• Usually on outer edges

• Typically produced by “knocking off” a corner

• Not a mating surface

Functions:

• Appearance

• Safety: removes sharp edges

• Part interactions/fit: easier lead-in

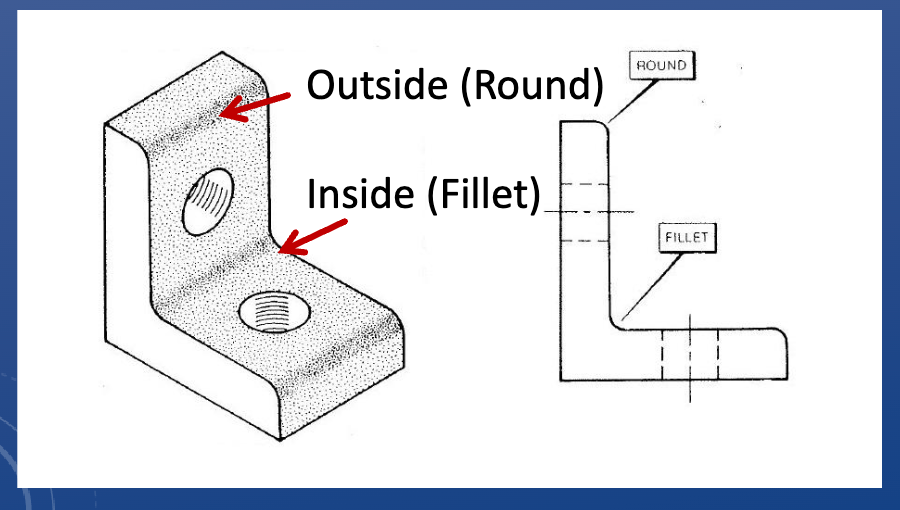

Fillets

A curved edge, consistent radius

• Fillets typically have a small radius (<1”)

• Always tangent to both faces

• Rounds off existing corners

• Allows material to be left after a machining process

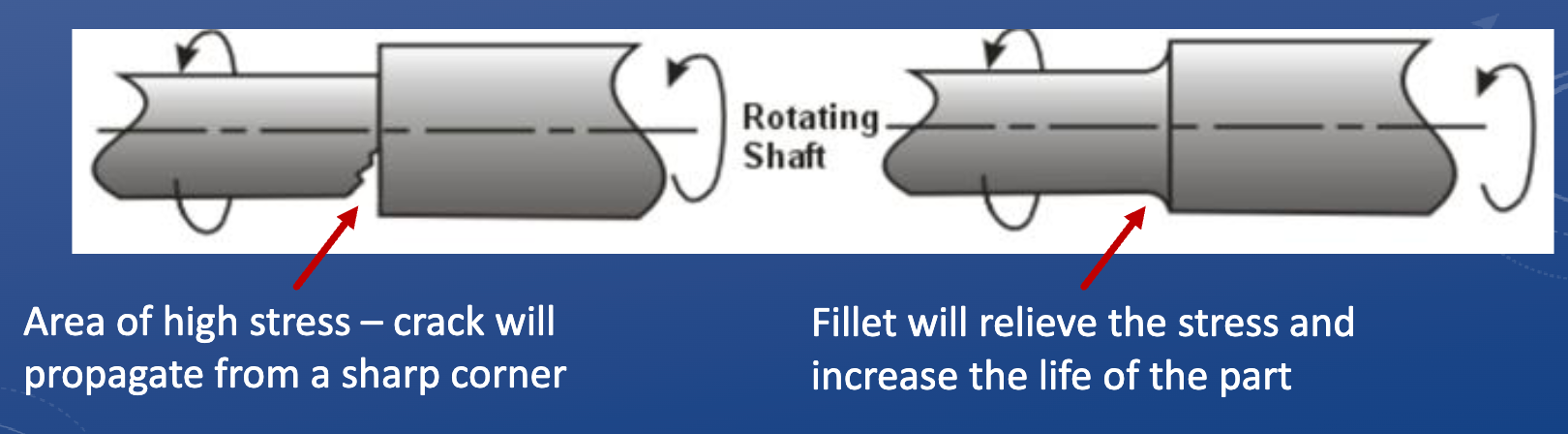

Function of fillets

• Appearance

• Safety: removes sharp edges

• Cost reduction: ease of machining = less time spent

• Strength: reduces stress concentrations

Dimensioning chamfers and fillets

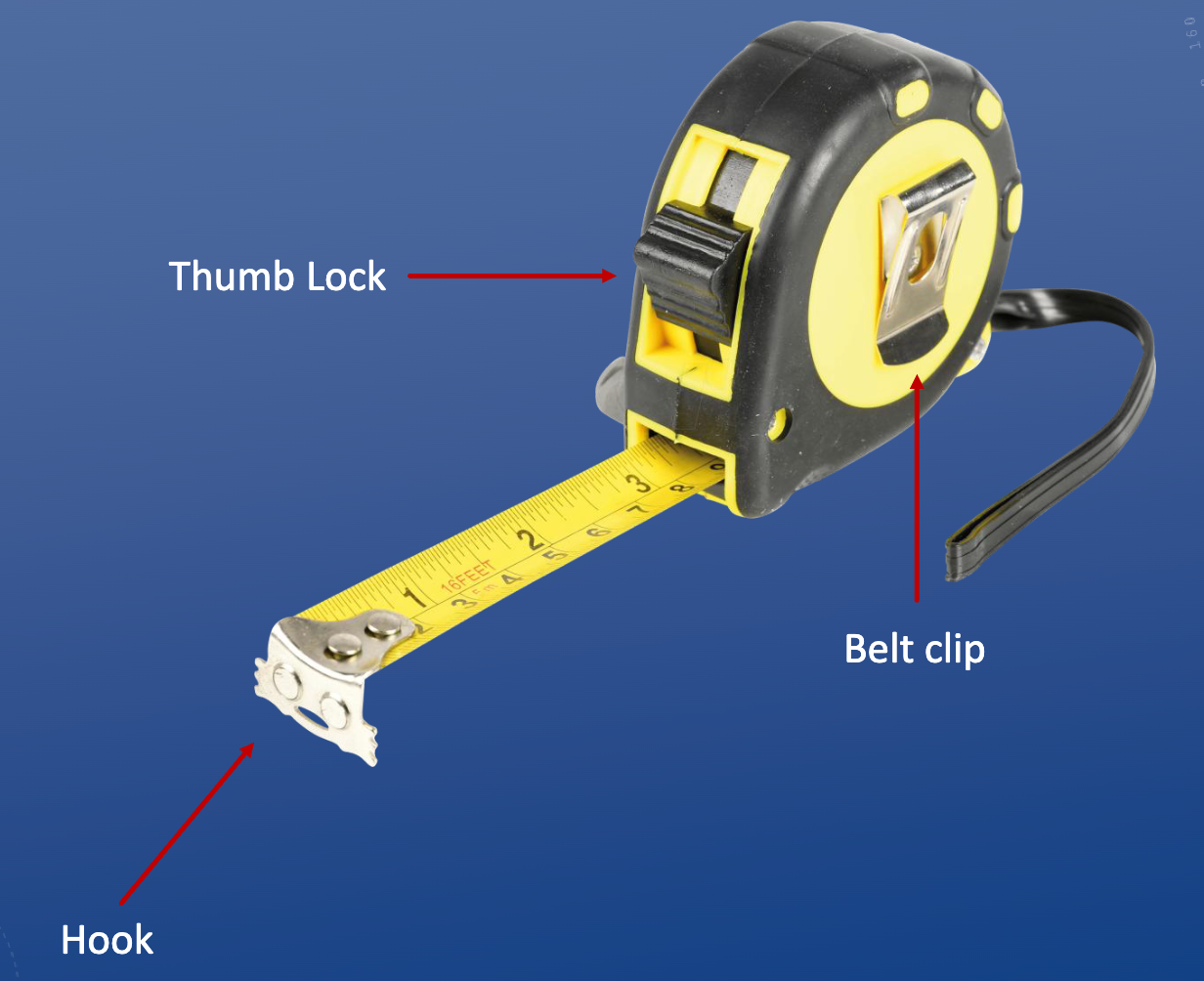

Tape Measure

End wiggles around so you can hook it onto things/push it up against things.

Slot on the end for hooking onto screws.

Max tape measure resolution: 1/16”

*Woodworking has tolerances between 1/64” and 1/8”

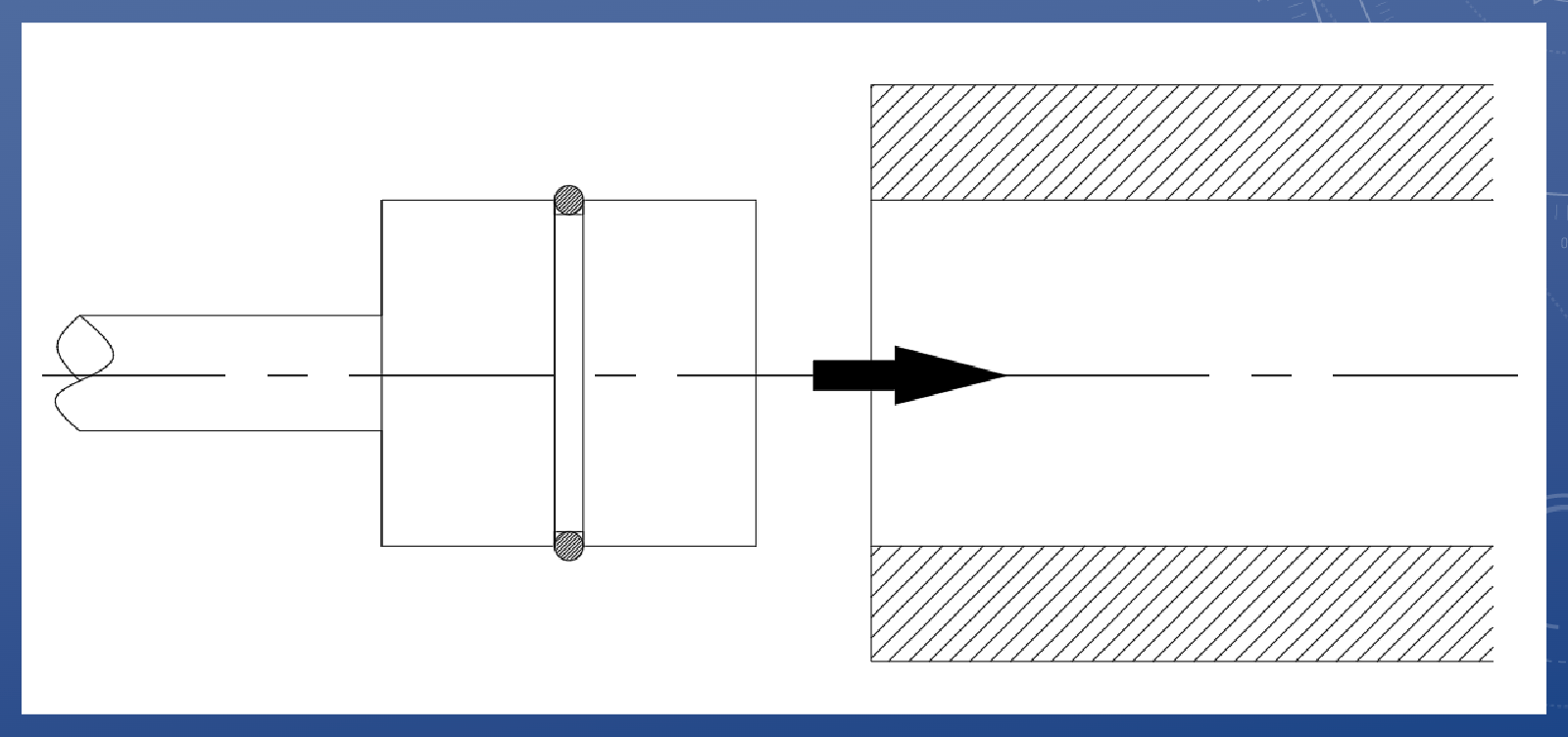

Curves and design considerations

Cutting plane line weight

0.8mm

Hatching line weight

0.15mm

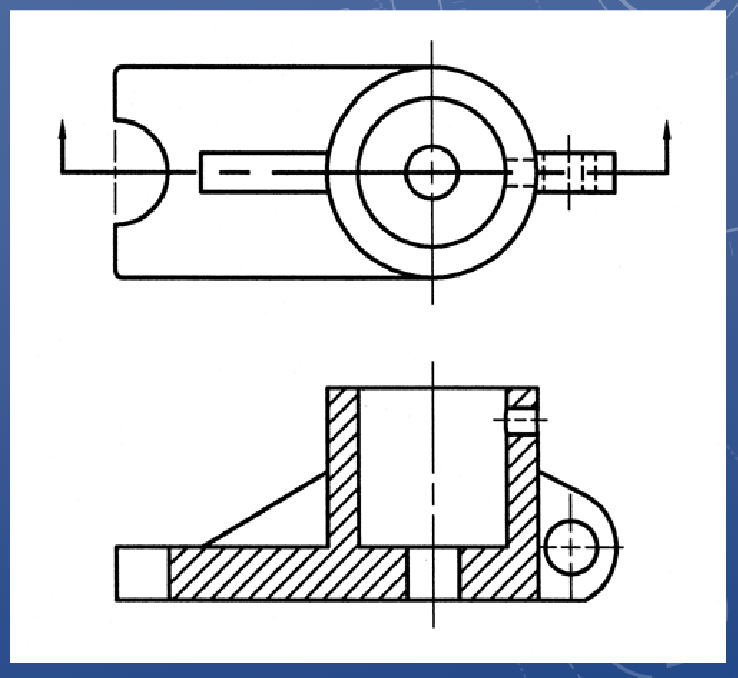

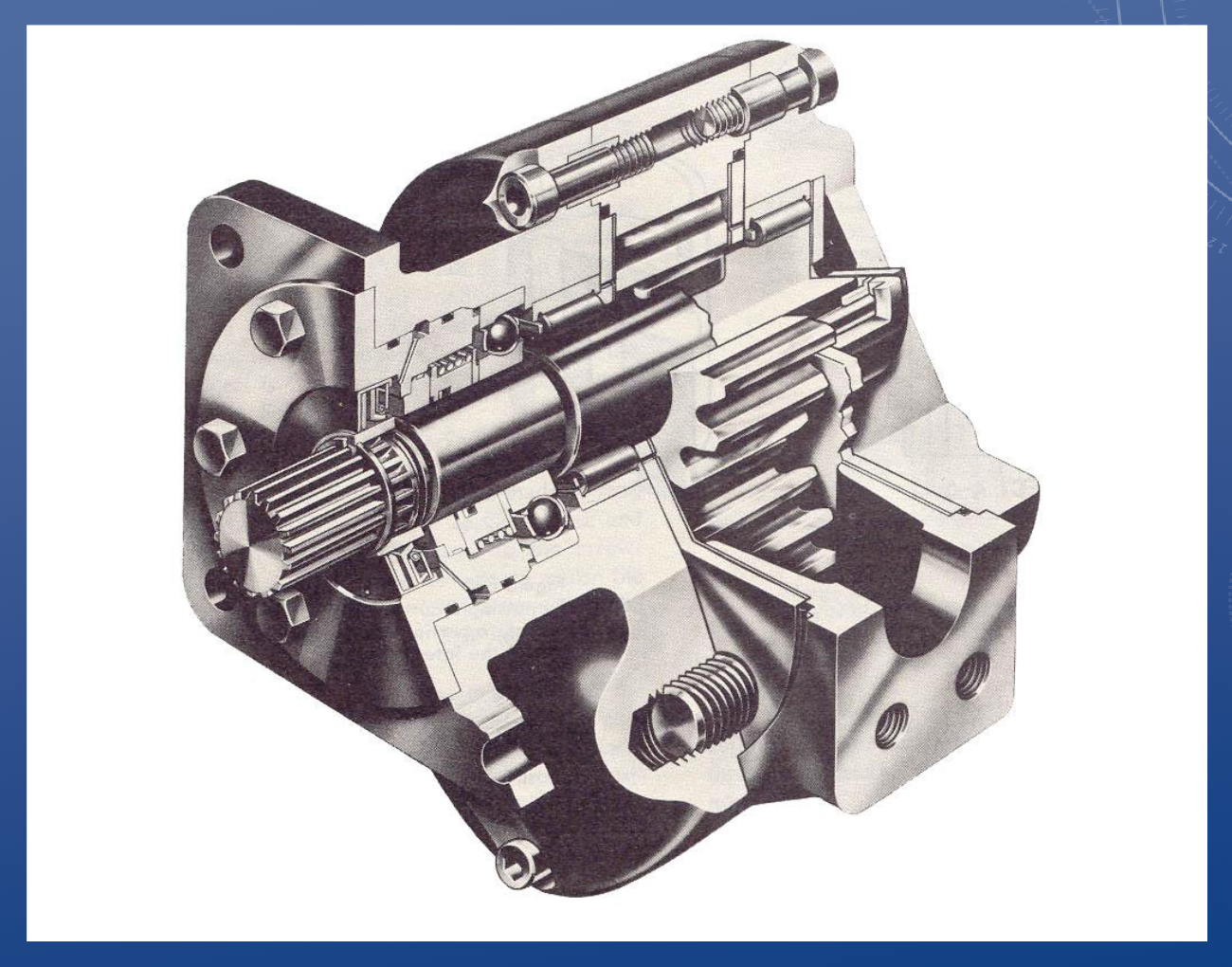

Section views

Why?

1. To reveal internal geometric properties

2. To communicate graphical details clearly

3. To avoid a mess of hidden lines

4. To show material composition

• Whenever possible, section views are aligned in proper orthographic position with the view that contains the section line (and can go in place of an existing view)

• Note: Do not include hidden lines in section views

Uses:

1. Round objects such as wheels and pulleys

2. Parts with webs and fillets

3. Parts that have complex holes in them

4. Enclosed spaces where material has been removed

5. Equipment layouts

6. Assembly views

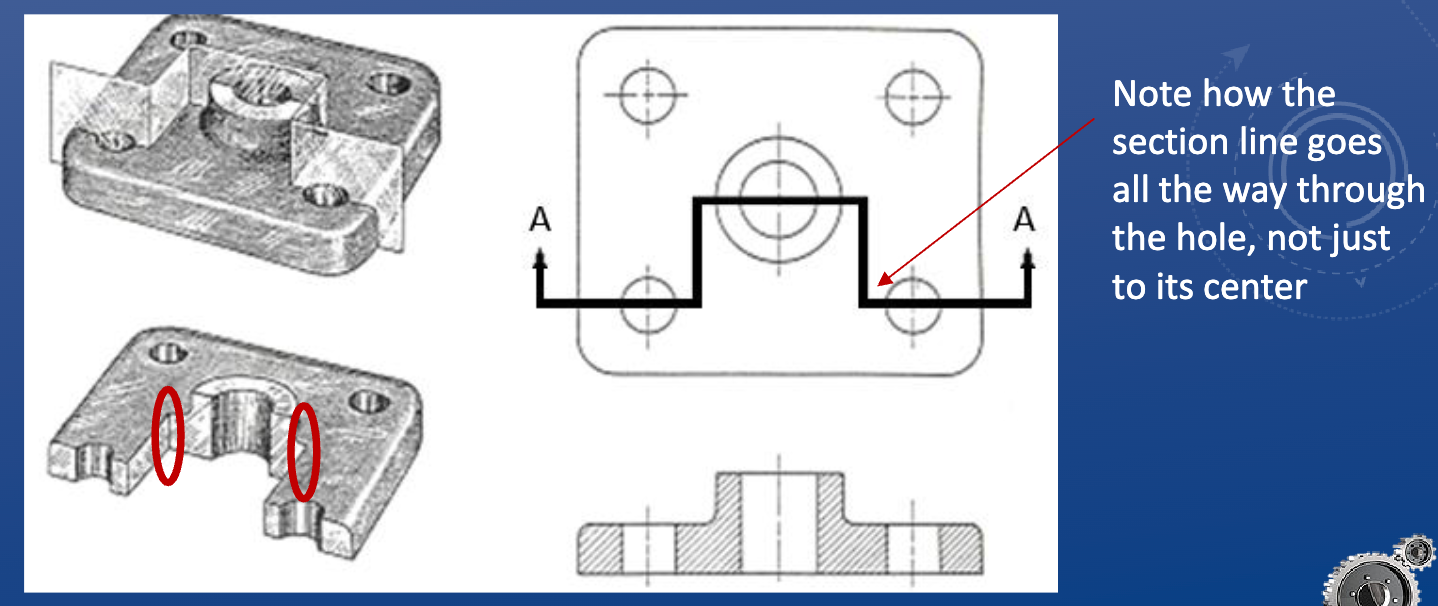

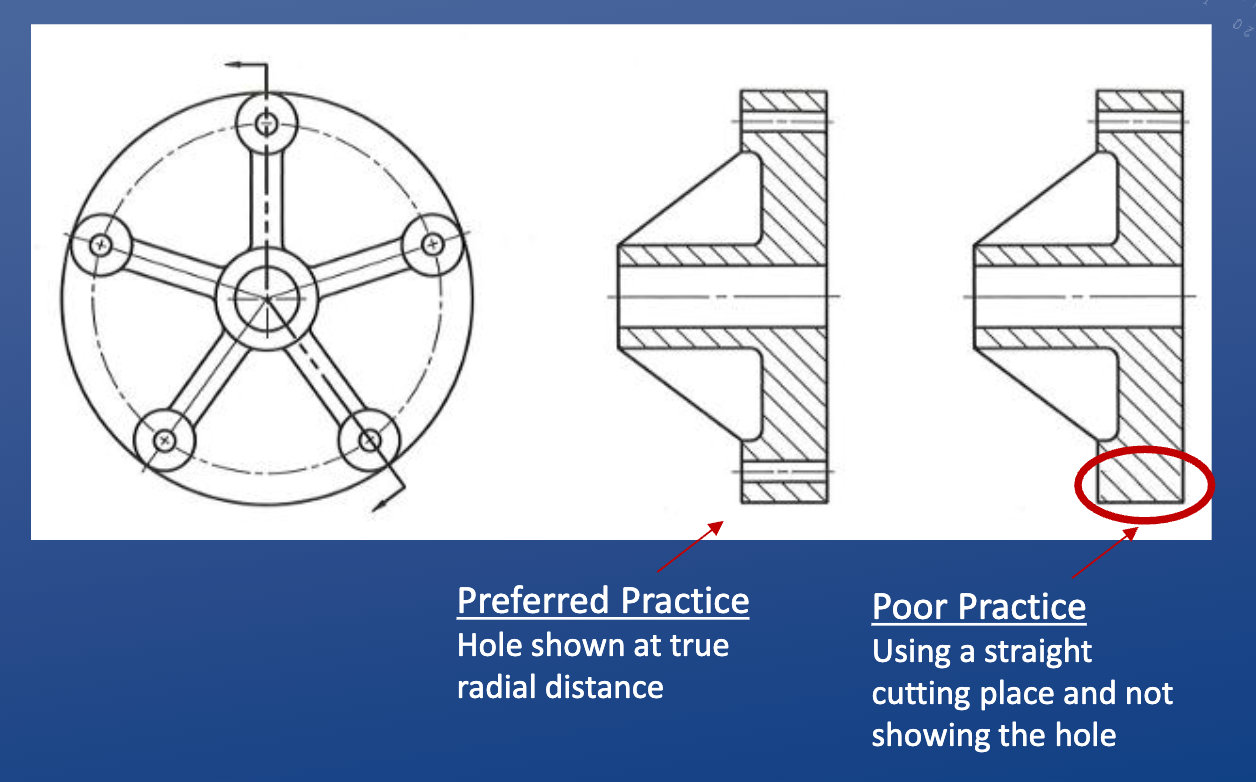

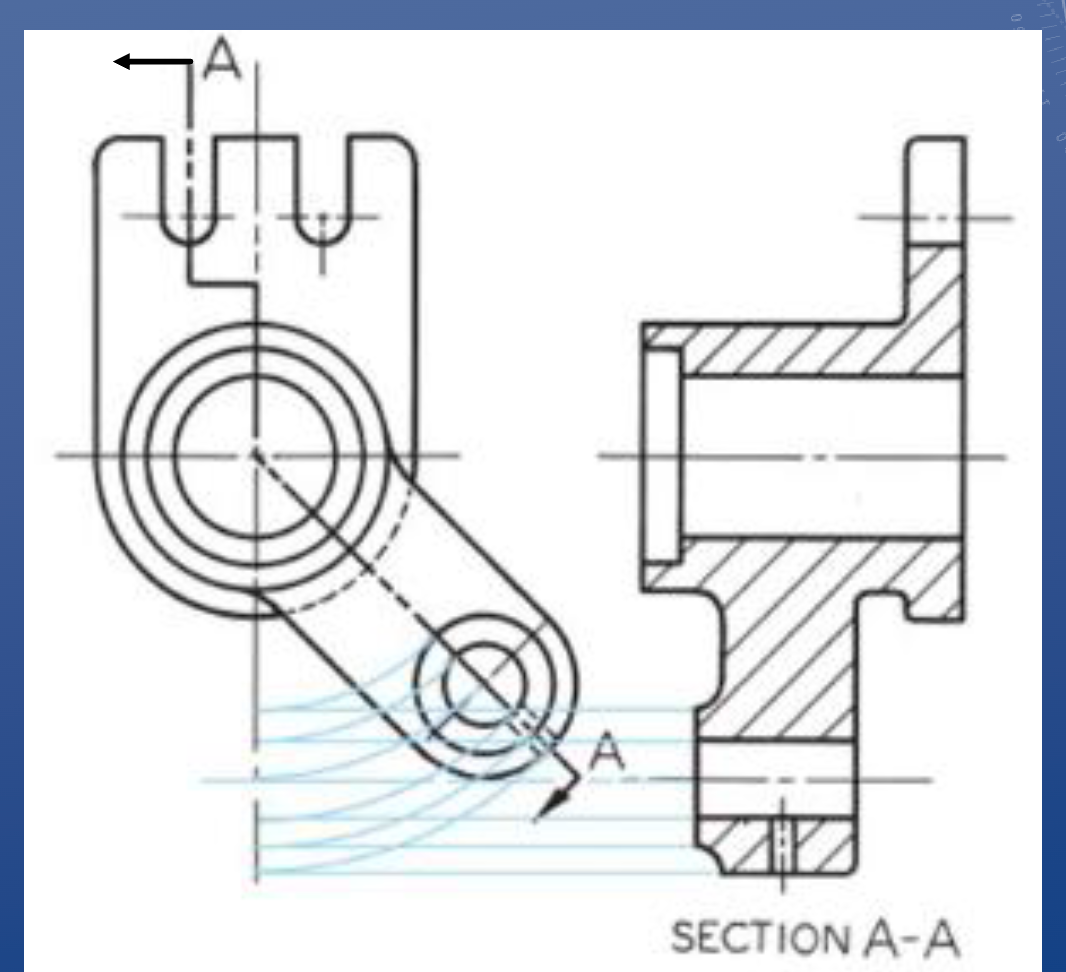

Offset cutting planes

• Two important notes about offset cutting planes:

• Any jogs in your cutting plane must be perpendicular to your view

• Any hard edges created by the cutting place do not appear in the sectional

view, as those hard edges don’t actually exist in the part

Aligned cutting plane

*If cutting through thin material (i.e. < 1 cm thick), you do not hatch that section even if you’re cutting through it

Combined aligned and offset section

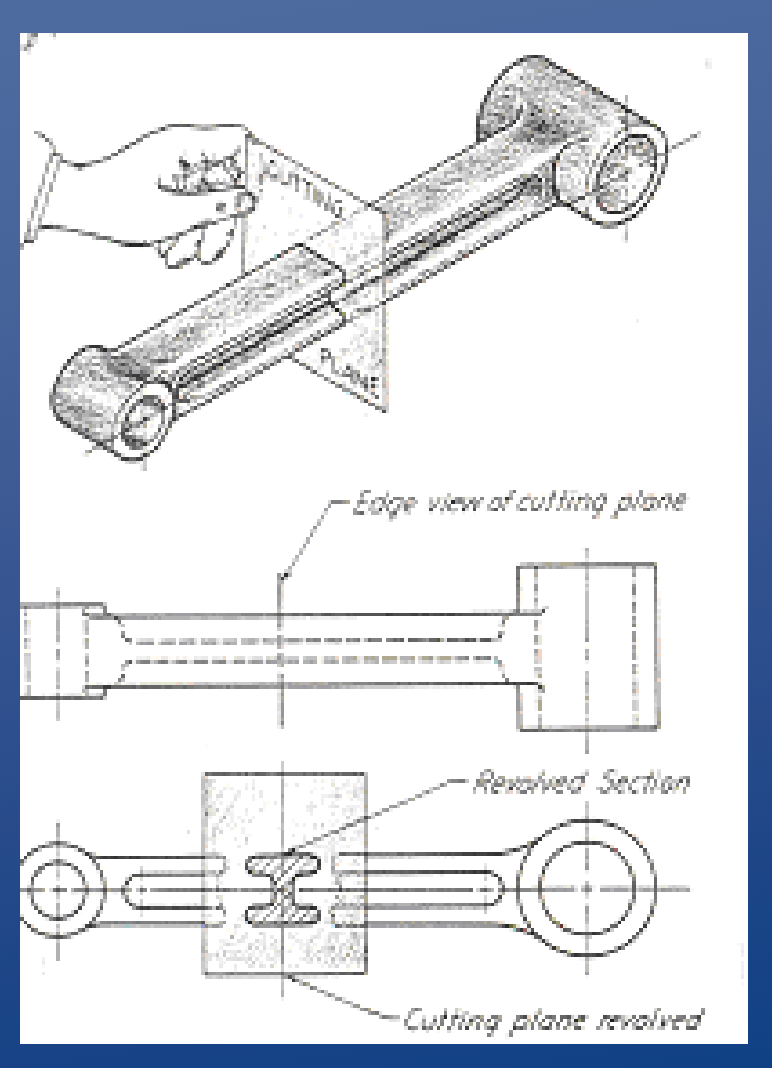

Revolved section

Assembly section view

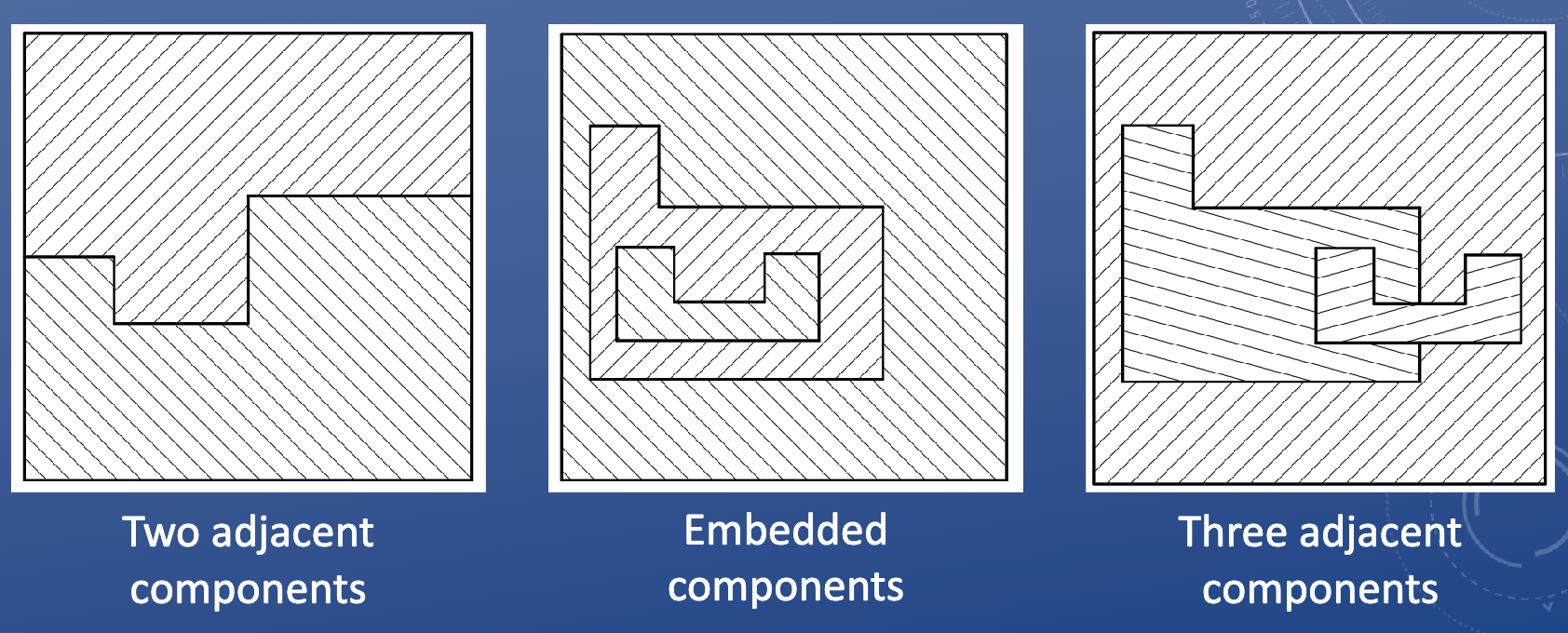

Hatching adjacent components

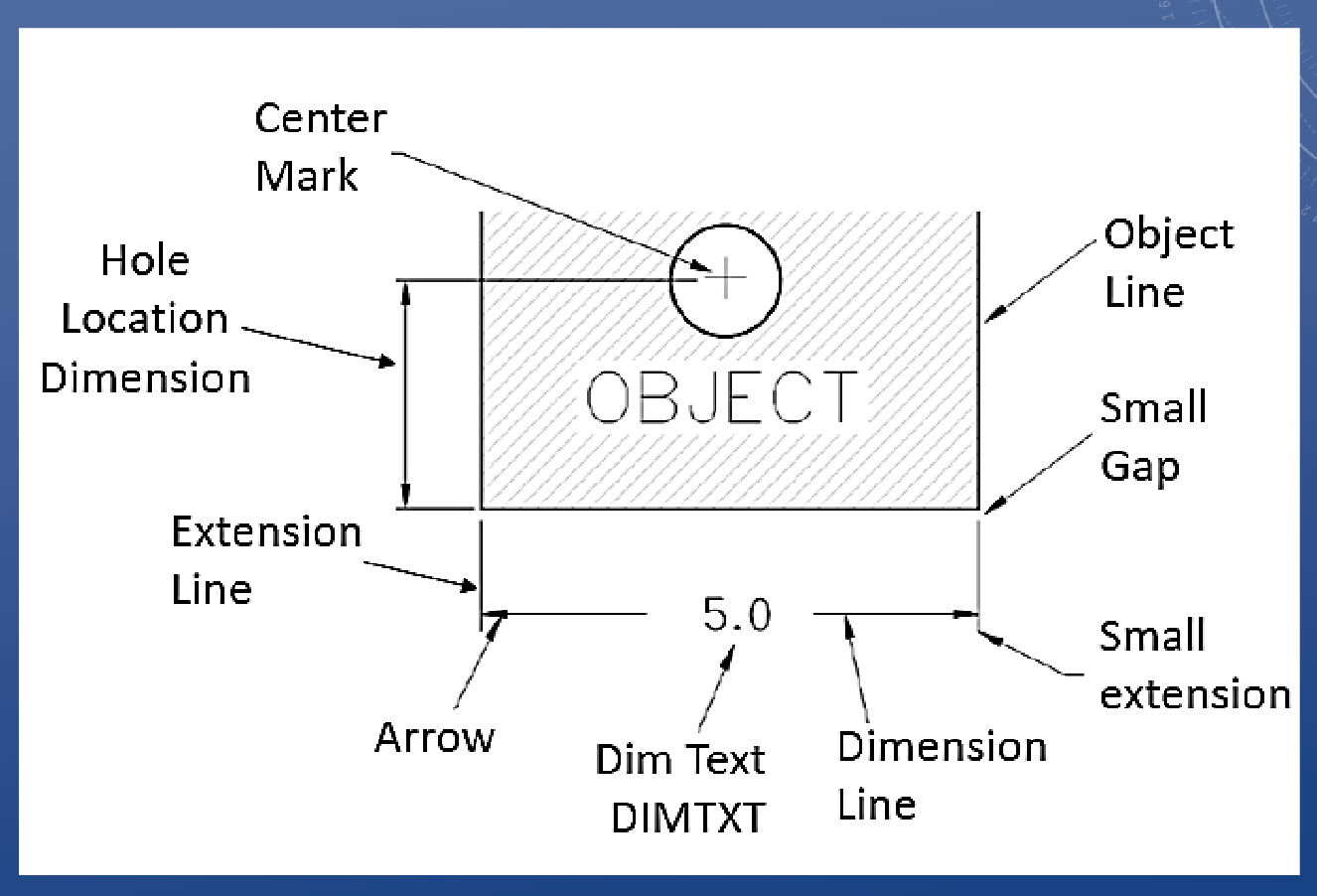

Dimensioning terminology

Every dimension should…

a. Be clear so that it can be interpreted in only one way

b. Be kept off the part wherever possible

c. Denoted features in one view only (if possible); e.g. diameter and depth of drilled hole

2. A dimension line should never…

be joined end to end with any line of the drawing

3. Dimension lines should be spaced uniformly;

they should be ~10mm (3/8”) from the object outline and 6mm (1/4”) apart

4. Longer dimensions should be placed

outside all smaller dimensions, so that dimension lines do not cross extension lines

*It is okay to cross extension lines, but dimension lines should never be crossed