dt core content

1/65

Earn XP

Description and Tags

printing, finishing, cutting, mechanical devices

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

66 Terms

what is direct printing?

when the image is directly transferred from the plate cylinder to the surface

what is indirect printing?

when the image is first transferred from the plate cylinder to a blanket cylinder, and then to the surface

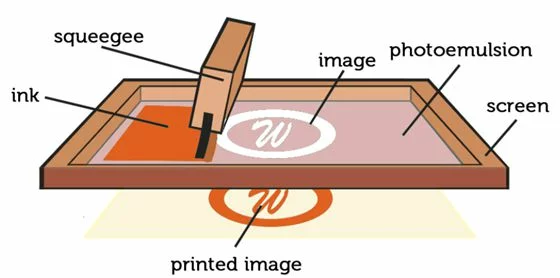

explain the process of screen printing

1) a mesh screen is coated with light-sensitive emulsion to block off areas as a negative of the image, leaving a stencil of the design

2) ink is spread across the screen with a squeegee to cover the open spaces of the stencil/mesh

3) the print is dried using air dryers or heat

what are the advantages of screen printing?

UV resistant, heat resistant, versatile printing surface

what are the disadvantages of screen printing?

long drying time, time-consuming screen preparation, only suitable for batch production

what is screen printing used for?

merchandise, plastic/metal signage, promotional items

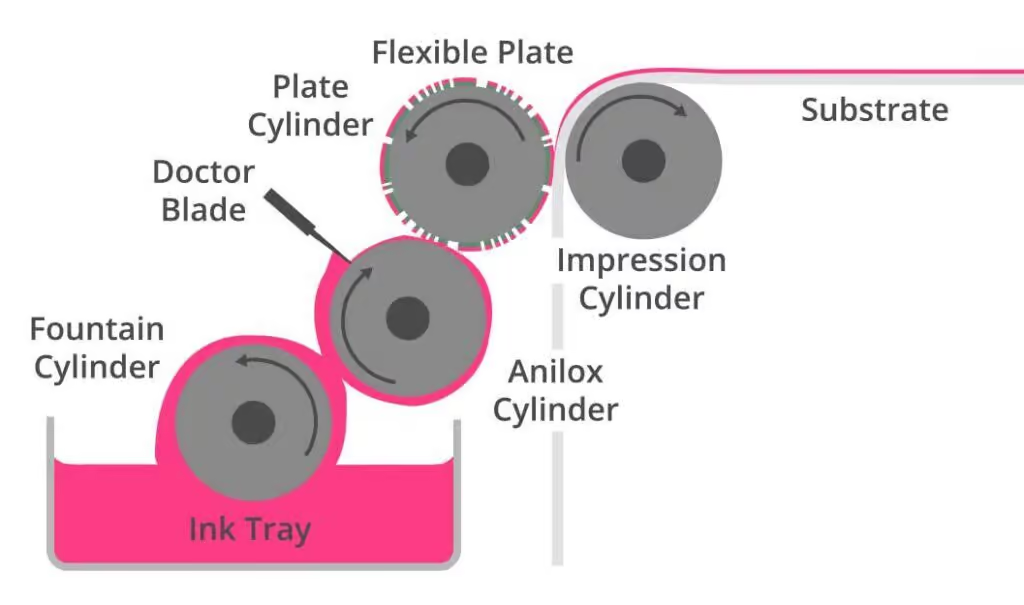

explain the process of flexography

1) a thin layer of ink is applied from the fountain cylinder to the anilox cylinder

2) a spatula (doctor blade) cleans the excess ink from the anilox cylinder, leaving the desired amount in the anilox cells

3) the anilox cylinder offsets the ink onto the plate cylinder, which then prints the image onto the surface

what are the advantages of flexography?

high printing speed, fast drying ink, versatile printing surface

what are the disadvantages of flexography?

high initial costs, difficult to achieve detail

what is flexography used for?

bottle labels, plastic bags, packaging

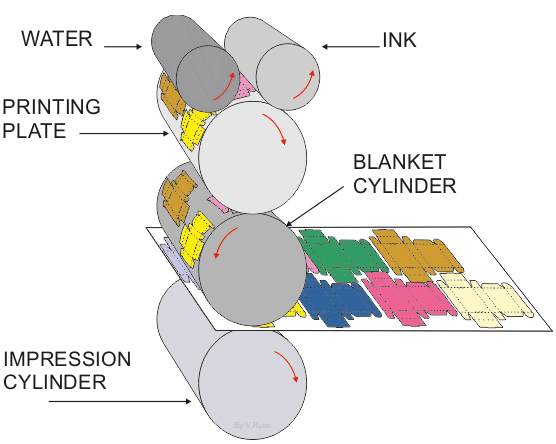

explain the process of offset printing

1) design is laser etched onto a plate and loaded into the plate cylinder

2) the non-image area is dampened with water

3) oil based ink is transferred onto the image area of the plate cylinder

4) the plate cylinder offsets the image onto the blanket cylinder

5) the blanket cylinder then prints the image onto the surface, which is pulled through by the impression cylinder

what are the advantages of offset printing?

high image quality, high printing speed, used for mass production

what are the disadvantages of offset printing?

high initial costs, paper can stretch, plate manufacture is time consuming

what is offset printing used for?

business stationery, brochures, magazines, newspapers

explain the process of digital printing

1) a design is made using a CAD software and the file is prepared for printing (eg resolution, printing size, colour settings)

2) the image is sent directly to the printer through digital files

3) an inkjet printer transfers the image directly onto the surface by spraying ink

a laser printer uses toner and heat to bond the image to the surface

what are the advantages of digital printing?

affordable, quick, easy last-minute changes

what are the disadvantages of digital printing?

low UV resistant ink, graphic problems, slightly lower quality

what is digital printing used for?

posters, brochures, business cards, art prints

what is lamination?

adding a film of PP, PET or LDPE to the surface or both sides of a printed sheet via heated roller

what are the advantages of lamination?

provides barrier protection against spills, smudges and UV, more pronounced than varnish

what are the disadvantages of lamination?

limited recyclability, laminate layer can peel off or bubble

what is lamination used for?

food packaging, consumer goods, school displays

what is varnish?

a liquid finish applied via printing press

what are the advantages of varnish?

seals and protects ink from smudging, distinctive, high quality shine, lightweight

what are the disadvantages of varnish?

difficult to recycle, limited protection

what is varnish used for?

magazines, comic books, brochures

what is spot varnishing?

applying varnish only to specific areas via a custom press plate

what are the advantages of spot varnishing?

highlights detail, distinctive and visually stands out

what are the disadvantages of spot varnishing?

difficult to apply in non-commercial settings, expensive

what is spot varnishing used for?

business cards, invitations, book covers

what is hot foil blocking?

pigment or metal foil being stamped onto a surface using heat and pressure by custom metal dies

what is hot foil blocking used for?

book covers, business cards, invitations

what is embossing/debossing?

using a personalised die to raise or sink images off a surface creating a 3D effect

what are the advantages of embossing?

adds texture, depth and a high-quality finish

what is embossing used for?

business/greeting cards, invitations, book covers

what is linear motion?

movement in a straight line in one direction (eg train tracks)

what is rotary motion?

movement following a circular path around a centre point (eg a bicycle wheel)

what is reciprocating motion?

linear movement back and forth (eg car engine’s piston)

what is oscillating movement?

circular movement back and forth (such as a pendulum)

what is a lever used for?

to lift loads with the least amount of effort

what is a first class lever?

effort, pivot, load (scissors)

what is a second class lever?

effort load pivot (wheelbarrow)

what is a third class lever?

pivot, effort, load (tweezers)

how do you calculate mechanical advantage?

MA=load/effort

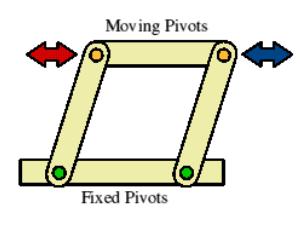

what is a linkage?

a mechanism which creates movement around a pivot - they can change the direction of motion, type of motion or the size of a force

function of parallel motion linkages

uses two fixed pivots to make the input and output travel the same direction

examples of parallel motion linkages

tool box drawers

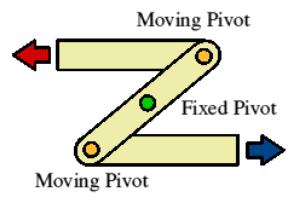

function of reverse motion linkages

changes the direction of the input so the output travels the opposite direction

examples of reverse motion linkages

foldable clothing racks

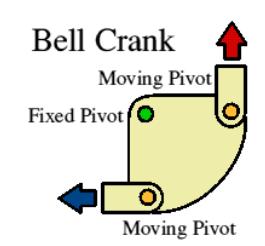

function of bell crank motion linkages

transmits the direction of motion through 90 degrees

examples of bell crank linkages

bicycle brakes

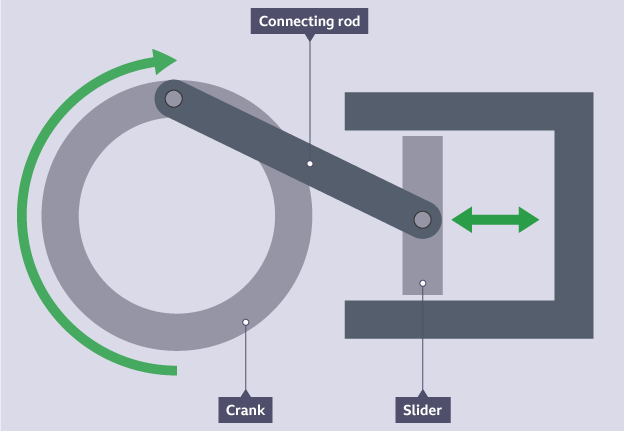

function of crank & slider linkages

transmits rotary motion to reciprocating motion using a fixed pivot attached to a crank which pulls/pushes a slider

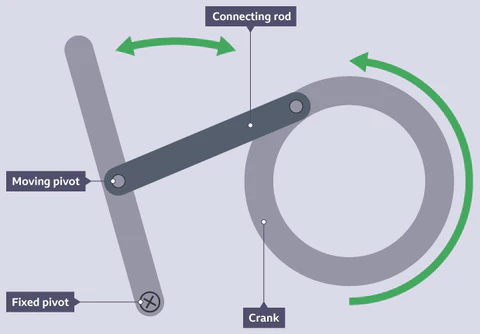

function of treadle linkages

uses a rotary input to turn a crank on a fixed pivot

converts rotary motion into an oscillating motion

movement of circular cams

uses an off-centre pivot to move the follower up and down

movement of pear cams

causes the follower to remain stationary for half a turn and then gently rises and falls

movement of snail cams

causes the follower to remain stationary for half a turn before rising and suddenly falling

movement of heart cams

causes the follower to rise and fall steadily with uniform velocity without a stationary period

pros and cons of flat followers

copes well under load, lacks accuracy, high friction

pros and cons of point/knife followers

very accurate, low friction, quick to wear away pointed edge

pros and cons of roller followers

accurate, low friction, can withstand load, costly to produce

what is a driver gear?

a gear which is attached to a motor or crank

what is a driven gear?

a gear turned by the driver gear

what is a compound gear?

a gear mounted on another gear’s shaft to change speed or direction of rotation

what is an idler gear?

a gear which rotates in the opposite direction of two gears allowing them to rotate the same way

what is a bevel gear?

a gear which transmits rotary motion through 90 degrees (eg hand drills)

what is a rack & pinion gear?

a gear that transmits rotary motion into linear motion (such as steering systems or pillar drills)