Cutting Sections and Electron Microscopy

1/20

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

21 Terms

Once the tissues have been embedded and the wax has solidified, the wax block is removed from the mold, the identification number is noted and the excess wax is cut off from the block to expose the tissue surface in preparation for actual cutting

Only thin slices are taken out at a time to prevent block from cracking

Trimming

useful to uncover the surface of the block to reveal the tissue

Coarse Facing / Coarse Trimming

Coarse facing is done on the microtome at approximately - microns at a time until the entire tissue surface is exposed

30 microns

can be done by setting the thickness adjuster at 15 mm or by advancing the block using the coarse feed mechanism

Fine trimming

Fine trimming

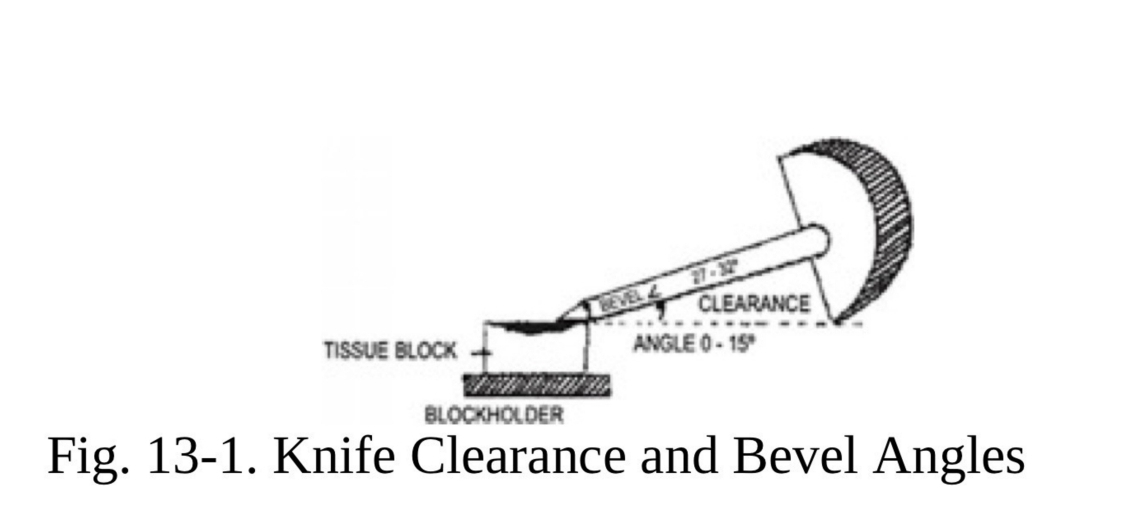

the knife is usually tilted at - to - celcius angulation on a microtome to allow a clearance angle between the cutting facet and the tissue block

- require smaller clearance angles that wedge-shaped knives

0 to 15 degress celcius

Biconcave knives

Knife Clearance and Bevel Angles

Final Test for Sharpness

slight reflection

Perfect straight line

Final test for Sharpness

the angle between two facets that form the cutting edge of the knife

Bevel angle

Bevel angle

- bevel angle results in a sharper knife

smaller

Bevel angle

recommended for general use is around - to -

27 to 32 degrees

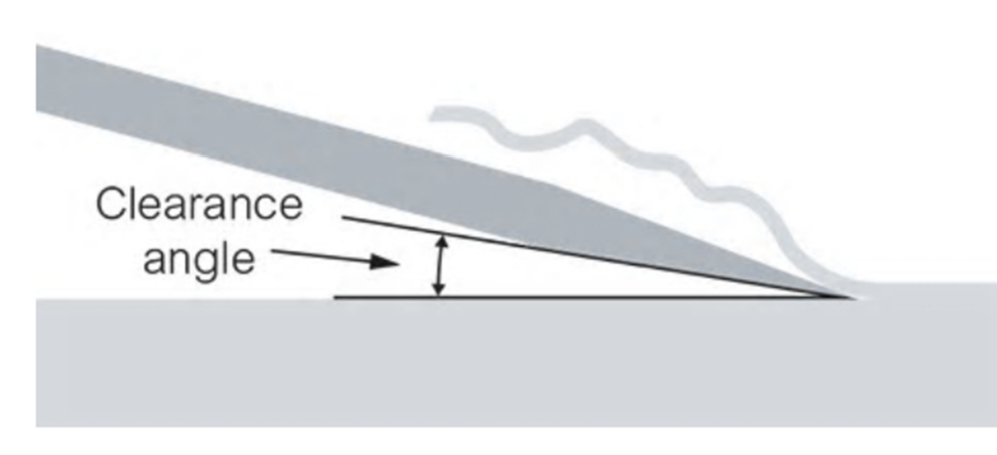

Angle between lower face of the knife and block holder

Clearance angle

Clearance angle

its set to prevent the entire bevel face from sliding over the block, which can cause _

friction damage

Clearance angle

optimal clearance angle is generally between - to - degrees for paraffin section

3 and 8 degrees

angle between block and knife that allows for maximum penetration into the and minimizes distortion during the cut tissues

Perfect/Optimum Cutting angle

Perfect/Optimum Angle

the optimum cutting angle is approx. _

15 degrees

Clearance angles

should expand the section to its original dimensions and ensure that is completely flat

Flotation

Flotation

the temperature will need to be - to - degrees below melting point of wax

5 to 9 degrees celcius

Flotation

Sections should not be left on the water bath for a long time (- seconds will be enough is enough) to avoid undue expansion and distortion of tissue

30 seconds

indicates the edge is still intact and sharp

Slight reflection

along the cutting edge confirms no nicks or dull spots, essential for precise cuts

Perfect straight line