dt mock poooooooooo

1/56

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

57 Terms

the 6 rs

are the principles of reducing, reusing, recycling, recovering, remanufacturing, and redesigning waste materials to promote sustainability and minimize environmental impact.

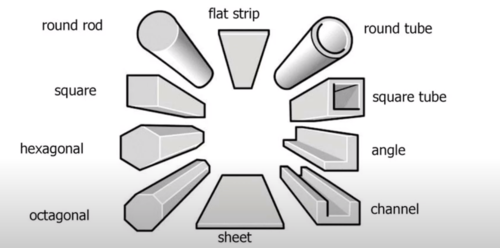

what is a stock form?

Stock forms refer to raw materials that have been processed into standard sizes and shapes

why are stock forms so important?

Stock forms are essential as they standardize raw materials, streamline production processes, reduce waste, and facilitate easier storage and transportation, ultimately contributing to efficiency and sustainability in manufacturing.

examples of stock forms (metals)

-round rod

-round tube

-square

-hexagonal

-octagonal

-sheet

-channel

-square tube

-angle

advantages of stock forms

-uniformity of material sizes across countries

-transported more easily compared to raw materials

-standard sizes are less expensive as theyre processed in large quantities

-less waiting time for a specialist size

-reduction in scrap material productions

mechanical properties of materials + examples

how a material reacts to an external force

-malleability

-ductility

-elasticity

-strength

-hardness

toughness

-durability

physical properties of a material + examples

actual structure of the material

-electrical properties

-thermal properties

-optical properties-density

malleability

withstand deformation by compression

ductility

deform under tensile strength

elasticity

bend and flex when force is applied (returning to its normal shape)

tensile strength

resist stretching/pulling forces

compressive strength

withstand pushing forces to resist deformation under compression

bending strength

withstand forces to bend material

shear strength

withstand forces acting against another

torsional strength

withstand twisting forces

hardness

how resistant a material is to indents/deformation

toughness

ability to absorb sudden impact before breaking

durability

resistance to wear and tear/corrosion

opaque

prevents light from passing through

translucent

allows light through but diffuses so objects look blurred

transparent

allows light to pass through easily so its clear

ferrous

contains iron, rusts, easily magnetic

non-ferrous

opposite of ferrous (copper/aluminium)

alloy

combination of a ferrous and non-ferrous material (bronze/brass)

hardwood

broad leaves

-ash

-maple

softwood

evergreen leaves, easier to cut

-pine

-cedar

manufactured board

sheet materials made through pressing/bonding

-mdf

-plywood

-flexiply

thermoplastics

becomes mouldable through heat and goes hard

-acrylic

-polyester

-tefilon

thermosetting polymers

resins with are set with heat

-epoxy

-silicone

elastomer

polymer with elasticity (weak)

-natural rubber

paper and boards

paper = recycled wood which has been rolled out

-wood

-pulp

composites

materials mixed with others to create better qualities

-reinforced concrete

smart materials

physical properties which can change in response to input

-titanium

-graphene

modern materials

materials engineered to increase the properties

-graphene

tensile strength test

-clamp materials in a vice

-add weights till material snaps

toughness test

-clamp in vice

-hit with a hammer

-if it withstands its tough, if not its brittle

hardness test

-centre punch on a material

-hit with a hammer

-the amount it dents shows how hard t is

malleability/ductility test

-clamp in vice

-if bends without creating a crack = ductile

corrosion test

-dropping material into salt water/acid

test for electrical conductivity

-use a volt meter

-amount of volts = conductivity

thermal conductivity

-use a thermometer when placing material above a bunsen burner

tensile test

-material placed in between grips

-weight applied to end

-materials tensile strength changes (measure till breaks)

die cutting

-cutting shape using a die

-die = sharp metal blades fixed to a block in the shape of the cut-

-rounded metal edges can also be in the block to create crease

-Can be used on paper, thin wood and polymer sheets

lathe

-turn a long length of material with specialist shaped tools

-Turning spins the material round whilst layers are shaved off

-is used for items like furniture and stair spindles

milling

-used for metal work

-a thin layer of metal is removed each turn at a carefully measured depth and speed

-can produce a really accurate finish

brazing, soldering and welding

-all use molten metal to join metal together

-Soldering uses solder melted at a relatively low temperature to join metal. It’s particularly used for electrical circuits and plumbing joints.

-Brazing heats joints to a higher temperature and uses brass to flood the joints.

-The strongest of all of the addition joints is welding which uses an electrical current to melt welding rod to flow together and cool between joints. Polymer can also be welded with plastic rod.

lamination

-sandwiches layers together to strengthen or protect

-plastic laminated paper, foam board, and plywood

Deforming and reforming

Vacuum forming heats sheet polymer until it is flexible and then sucks out the air between it and the mould to create a vacuum and an accurate copy.

blow moulding

-takes softened polymer and blows it into a mould with air like a balloon

-used to mould bottles and containers

casting

-pours molten material (pewter) into a mould (the die)

-used with metal, plastic, toilets and plastic soldier toys.

injection moulding

-injects liquid plastic into a mould under high pressure

-it creates accurate and quick products such as buckets and washing up bowls.

what is a nyloc nut?

-a kind of locknut with a nylon collar that increases friction on the screw thread so it is less likely to loosen

advantages and disadvantages of softwoods

Advantages of Softwoods:

Fast-growing and readily available

Generally less expensive than hardwoods

Easy to work with due to their softer nature

Good for general construction, framing, and paper production

Disadvantages of Softwoods:

Less dense and not as strong as hardwoods

Not as resistant to wear and decay

Limited aesthetic appeal compared to hardwoods

Not suitable for high-end furniture or flooring

advantages and disadvantages of hardwoods

Advantages of Hardwoods:

Higher density and more durable than softwoods

Greater strength, making them suitable for structural applications

More resistant to dents and scratches

Offer a wider range of aesthetic qualities with varied grains and colours

Disadvantages of Hardwoods:

Slower growth rates result in higher costs

Can be more challenging to work with due to their density

Some species are becoming less readily available due to deforestation

Generally heavier, which can complicate handling and installation

What is small scale production and what are its pros and cons?

-Small-scale production involves producing a limited quantity of items, often customized for niche markets, using less automation and more craftsmanship.

-This approach allows for greater customization, higher quality control, and stronger customer relationships.

-However, it generally results in higher per-unit costs and may not be suitable for mass markets.

What is medium scale production and what are its pros and cons?

-Medium-scale production involves producing goods in moderate quantities, balancing cost-effectiveness and customization.

Advantages include moderate per-unit costs, the ability to cater to a broader market than small-scale production, and some level of customization.

-However, it may lack the high level of customization seen in small-scale production and may not achieve the cost efficiencies of mass production.

What is large scale production and what are its pros and cons?

-Large-scale production refers to the manufacturing of goods in substantial quantities, utilizing highly automated processes and standardized procedures to achieve maximum efficiency.

-This approach is characterized by low per-unit costs, making products affordable and accessible to mass markets.

-However, large-scale production offers limited customization options and can be less adaptable to changing consumer preferences.

-It is well-suited for products with stable demand and uniform specifications.