MICROMETRICS SAQ 2

1/8

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

9 Terms

What is the difference between the bulk, tapped and true density?

Bulk: density of powder after loose pouring

Tapped: density after tapping and consolidation

True: density of the solid material excluding voids and pores

What are liquid bridges and how can they arise?

Liquid films between particles often arising from moisture adsorption increasing cohesion and reducing flow

What are solid bridges and how can they arise?

Solid bridges form when particles bond together for example dur to storage at fluctuating relative humidity or recrystallisation

How can particle size affect powder flow characteristics?

Very fine particles (<10um) have poor flow due to increased cohesive forces – e.g. Van der Waals forces dominating gravity

How can particle shape affect powder flow characteristics?

Rounded isometric particles flow better

Anisometric particles may interlock mechanically reducing flow

Describe two methods by which the angle of repose can be determined. method 1

Fixed funnel method

1. A funnel is fixed at a known hight above a flat horizontal surface

2. Powder is allowed to flow freely through funnel onto surface

3. Powder forms a conical heap

4. Measure height of cone (h) and diameter of the base of the cone (D)

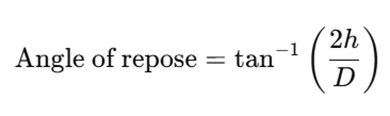

5. Calculate angle of repose

method 2

Tilting Table Method

1. A quantity of powder is placed on a flat table to form a heap

2. The table is slowly tilted

3. The powder remains stationary until a point is reached where it just beings to slide/ move

4. At the moment movement starts, the angle between the table and the horizontal is measured

5. The angle is taken as the angle of repose

What is Carr’s Compressibility Index and how does it relate to powder flow?

It quantifies the difference between bulk and tapped density

Lower values indicate better flow, higher values indicate poor flow

What are the phenomena of “bridging” and “rat-holing”?

Bridging – formation of stable arches blocking hopper flow

Rat holing – central flow channel empties while surrounding material remains stagnant