Engineering External

1/82

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

83 Terms

plastic gears would most likely be manufactured from?

nylon

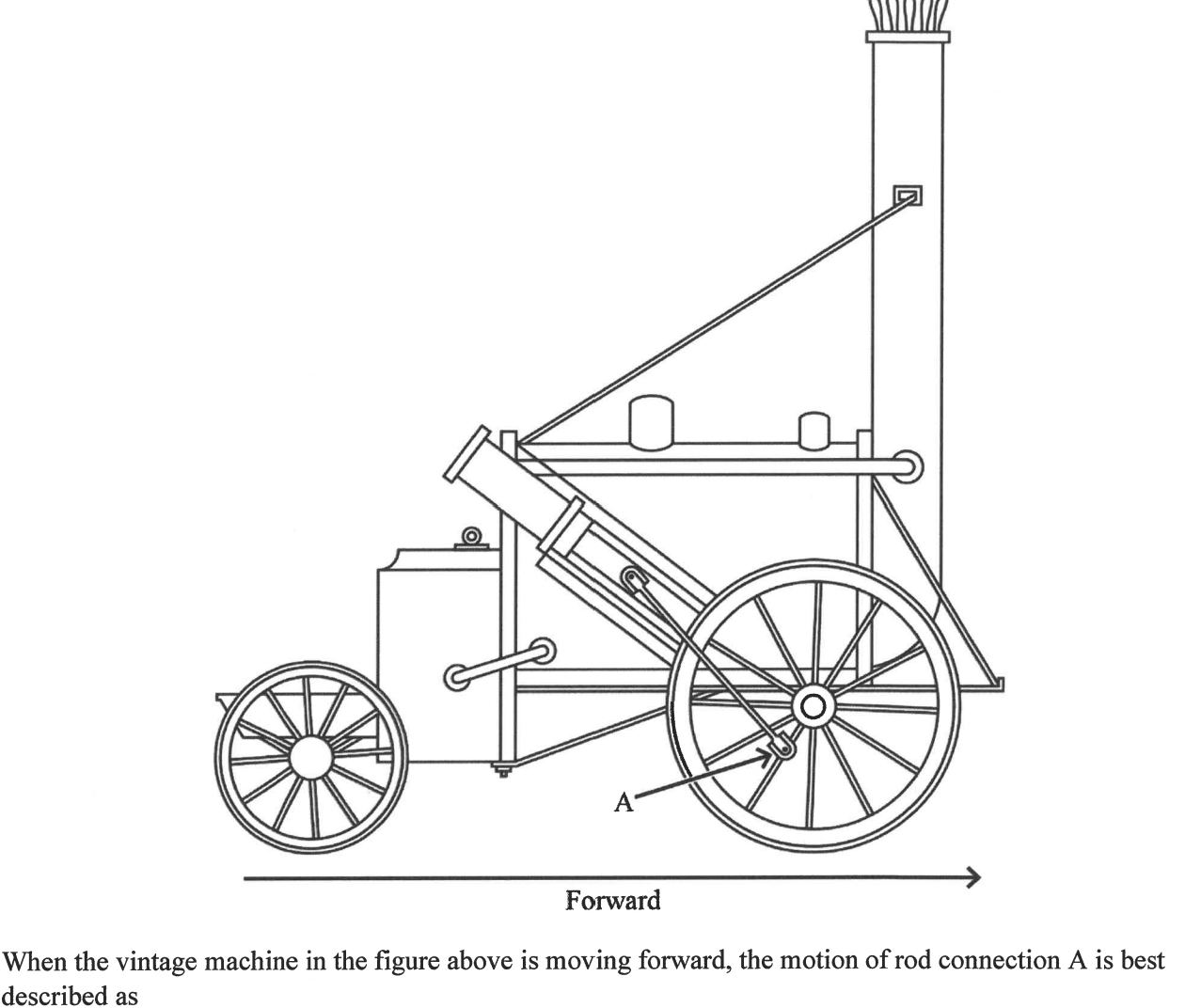

type of motion?

reciprocal and oscillating

describe how one feature of a bicycle provides the rider with a mechanical advantage

Crank - pedals are offset on the crank which produces a crank-lever MA reducing effort because of the distance from the pedals to the rotating shaft

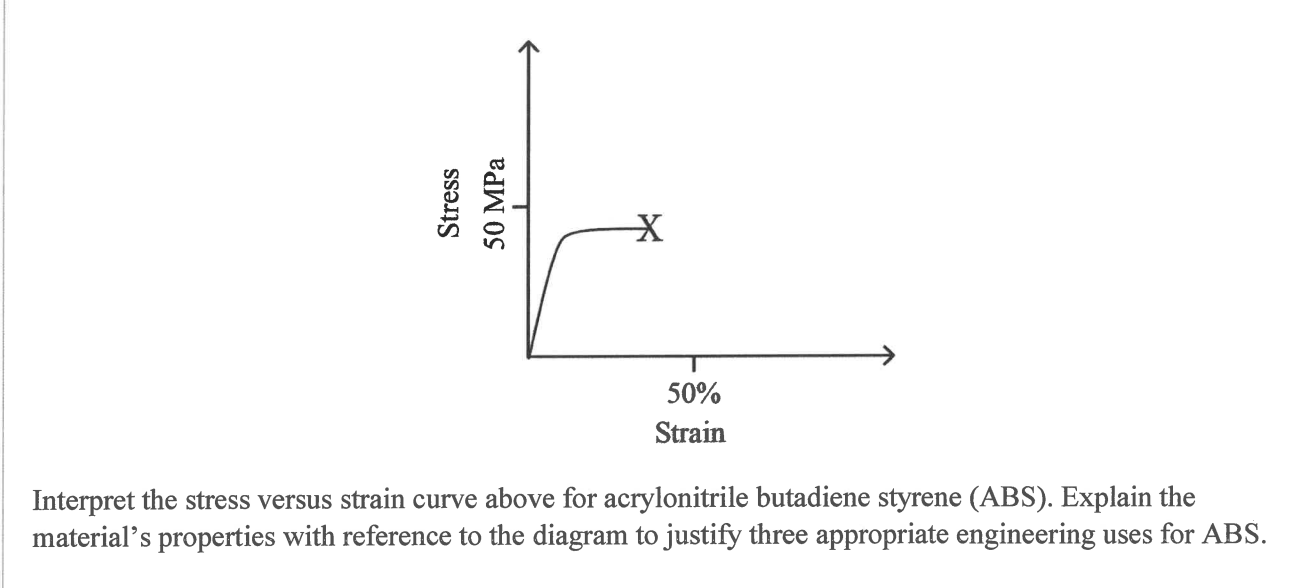

properties and uses?

properties: rigidity, high tensile yield strength (absorbs stress whilst maintaining elasticity), tough

uses: personal protective equipment, computer keyboards and power tool housings

recall an engineering problem that required machines or mechanism as part of the engineered solution. (community benefits, types of engineering knowledge and expertise used. materials, forces, mechanisms and community impacts.)

Animal waste for biogas:

sustainable energy supply for cooking/lighting

solid waste output fertilises crops

system is easily maintained and consists of lightweight, strong and easily transported polymer tanks

few moving parts and minimal forces since biogas is not contained under high pressure

reduced need for firewood so less erosion

drinking water is cleaner

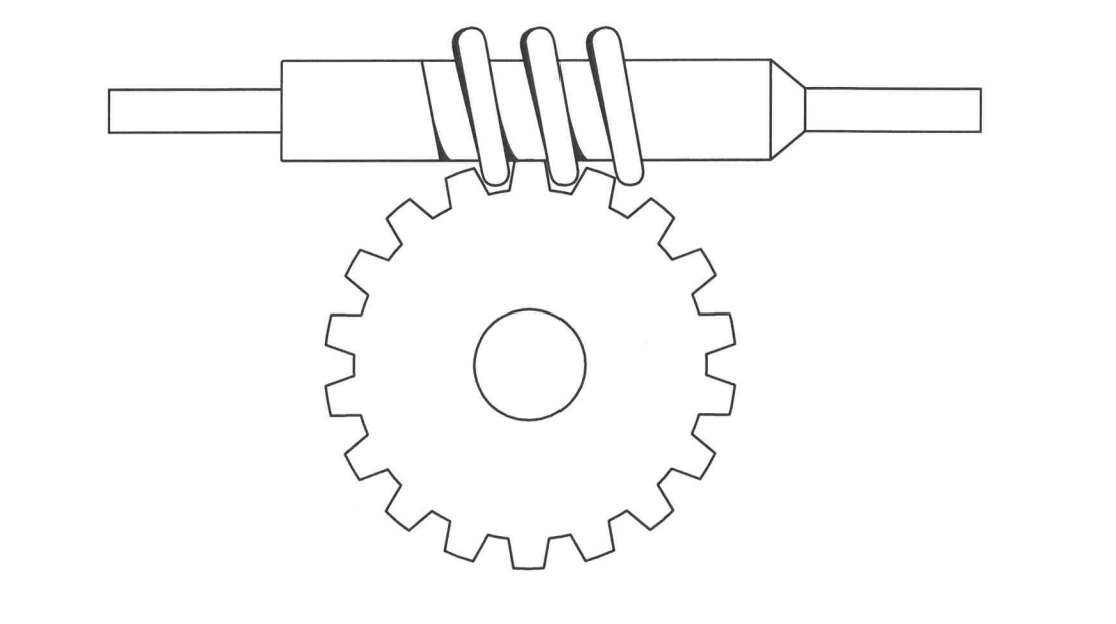

gear ratio?

18:1

high voltage transmission cable insulation would most likely be manufactured from?

polyethylene

what is the proportional limit?

The greatest stress that a material can withstand without losing straight-line proportionality between stress and strain within the material’s elastic limit.

pla properties that make it good for medical implants?

biodegradability, tensile strength, resistance to chemicals, non-toxic in solid form

why would an engineer recommend solar-powered water pumps for crop irrigation?

(3 types of technology knowledge, 2 factors of each)

local environmental conditions:

most days cloud free would allow pumps to operate efficiently

overcast when rain is likely - pumps operate less, water is saved

Economics

high cost of installation but low cost of running

cheap and efficient transport of water

Sustainability

pumps supply large volumes of water

must consider sustainability and irrigation system as breakdowns would need to be repaired

implementation of mechanical system considered in maintenance

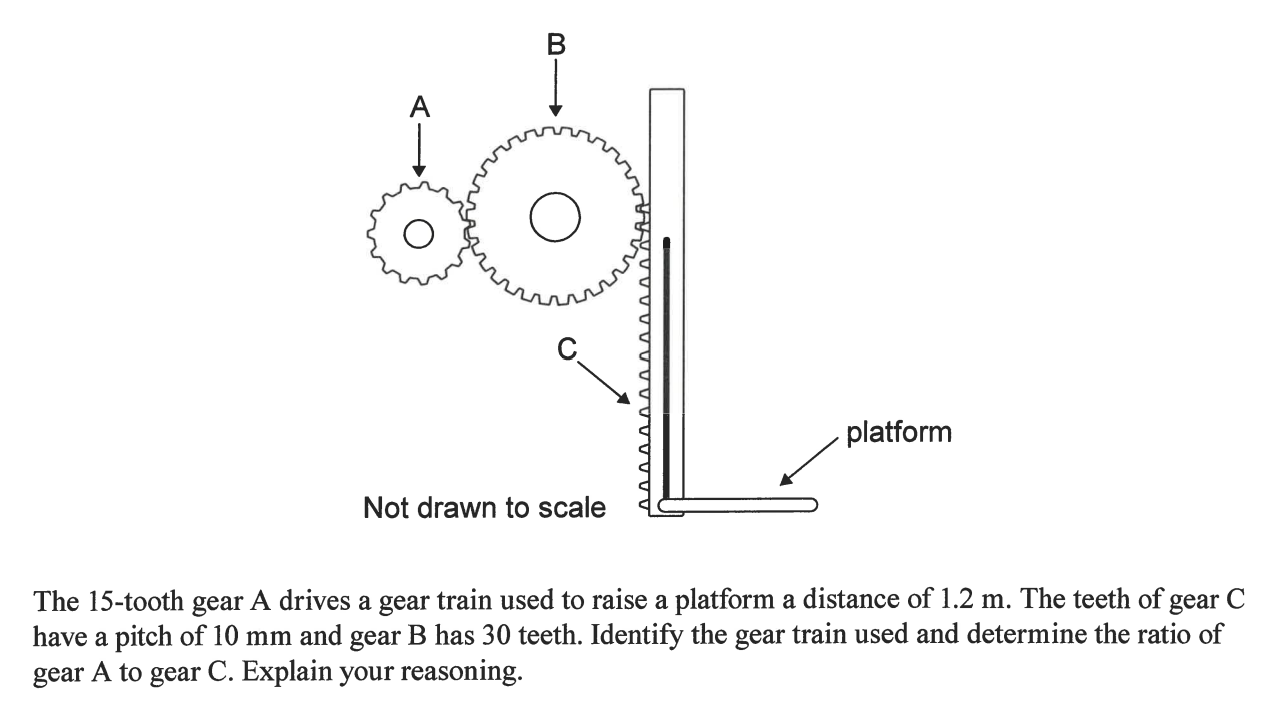

gear ratio?

gear ratio determined using distance travelled by rack for each revolution of the pinion gear B

pitch of teeth = 10mm and teeth in gear B is 30 so 1 revolution will raise the rack 300mm

To lift rack 1.2m, gear B must rotate 4 times

gear ratio (A to B) = 30/15 = 2:1

Gear A turns 8 times to turn Gear B 4 times to lift platform 1.2m

gear ratio (A to C) = 1200/8 = 1 to 150mm

Where on stress-strain curve would you use to determine stiffness?

linear section at start within the elastic limit

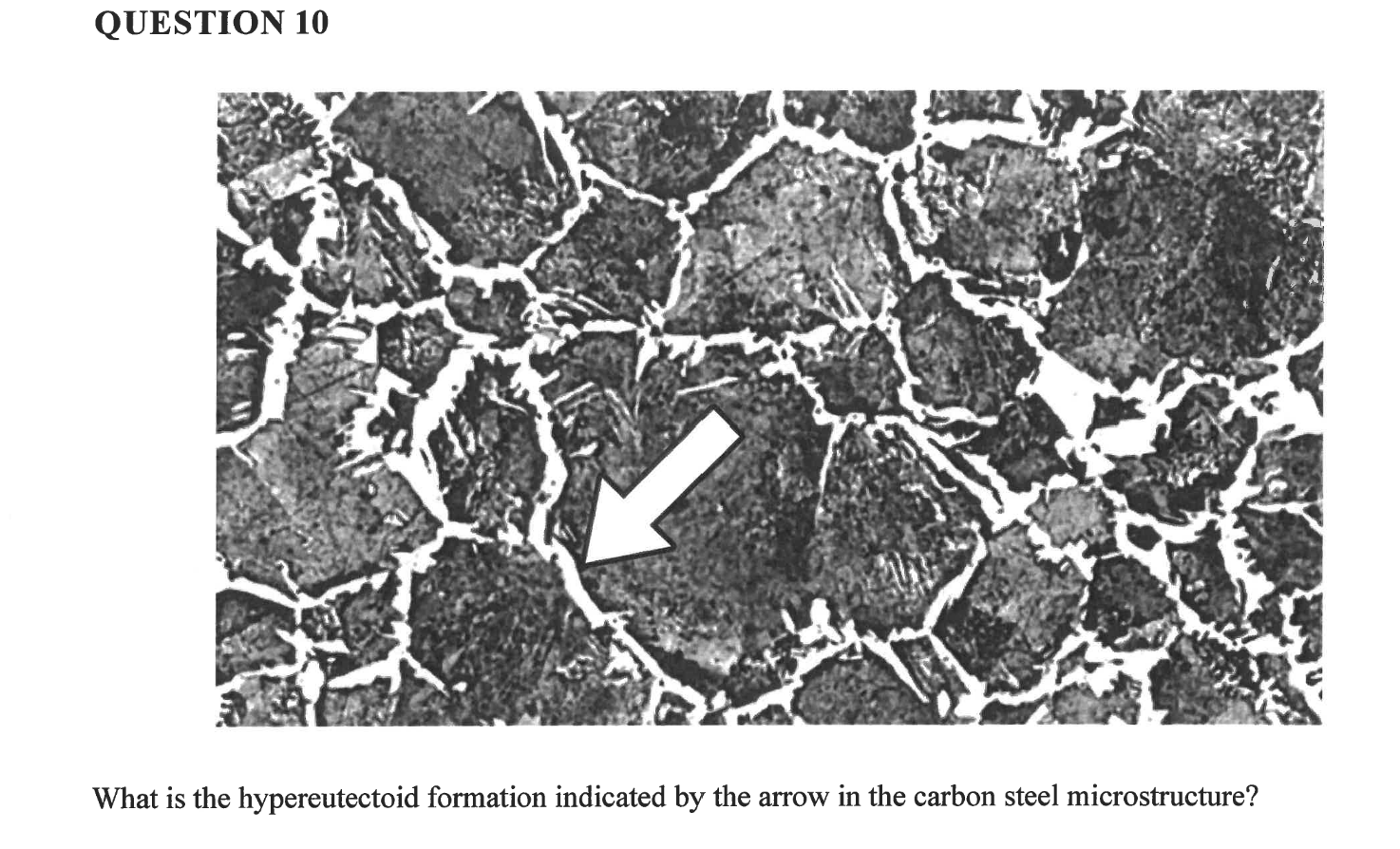

what is the formation?

cementite

fields of knowledge for a biomedical engineer?

electrical, mechanical, materials, electronics

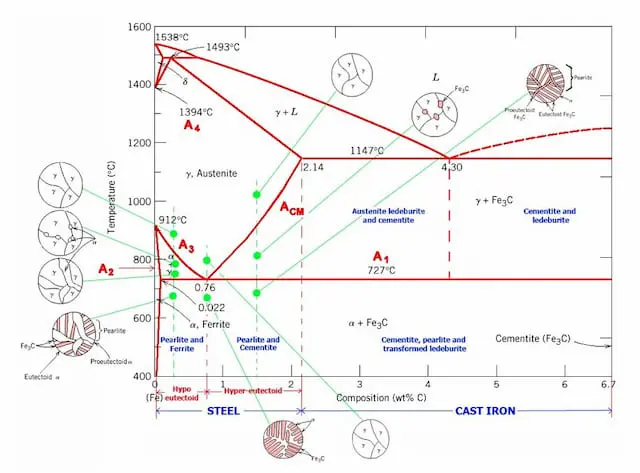

explain how the microstructure of a 3% carbon cast iron changes during the cooling between the eutectic and eutectoid temperatures.

When the eutectic temperature of around 1147 degrees is reached, the residual liquid forms the eutectic mixture of austenite and cementite along with previously formed austenite dendrites. As the temperature drops toward eutectoid temperature, carbon precipitates out of the austenite to be deposited as growing areas of eutectic cementite. When the eutectoid temperature of 723 degrees is reached, the remaining austenite with 0.8% carbon changes to pearlite.

describe a community problem related to a sustainability and an engineered solution.

stoves in developing countries like India that use biomass like timber as fuel

detrimental to environment and poor air quality

knowledge of alloys and ceramics by engineers to develop low cost solution

metal alloys: improve burning efficiency by 50% and reduce size

heat efficient ceramics: reduces smoke by 95%

Reducing mass of timber burned (long and short term benefits): improving air quality, improving respiratory health and reducing effects on global warming

applications of carbon steel with 0.15% to 0.30% carbon content?

structural plates, seamless tubes, forgings, stampings

a plastic beaker used to hold liquids in a lab is commonly manufactured using?

polypropylene

steeling containing 0.11% carbon is?

low carbon steel

applications of abs?

bumper bar of car, electrical wall socket, hard hat, face shield

explain how a mechanical engineer might use the problem-solving process to develop a solution for automotive components on a production line to be automatically pressed and moved. (2 areas of engineering expertise?)

in the automotive manufacturing industry, explore similar problems involving these machines that automatically press and move components

SSC to develop, test, evaluate ideas and prototype

knowledge of how metals plastically deform into components

knowledge of how sensors control the function of automated stamping machines

solution manufactured and refined after evaluation of its function using SSC

using examples explain why gears are used in the design of vehicles

gears are sued to change speed, torque and rotation direction

engineers use a combination of gear rations to change speed/torque

e.g. sports cars are fast but cannot hold heavy loads, trucks are not fast but can hold heavy loads

justify why pvc based polymer is a suitable material for student travel cards

durable and waterproof

lower cost so mass production

appropriate rigidity whilst maintaining some flexibility, reducing potential for accidental breakages

lightweight

ease of manufacture

how can engineers use an understanding of the effects of drag to improve the design of racing yacht hulls

minimising drags means maximum forward thrust hence increased speed

polished surfaces mean less drag

streamlined shape of hull minimises vortices

minimise weight with appropriate materials

benefits of using electric motors to power self-driving cars

increased use of renewable energy

reduced atmospheric particulate matter

improved power to weight ratio

decreased noise pollution

easier to integrate into an automated vehicle control system

why is PP an appropriate material for sleds

lightweight

easy to mould in an injection moulding machine

provides high flexural strength and durability

smooth with a low coefficient of friction

controls technologies that make modern cars safer

reverse cameras and sensors

ABS brakes prevent lock up of brakes and skidding

cruise control allows driver to maintain a constant speed to suit the speed limit and road conditions

airbags

electronics stability program (ESP)

describe the development of a specific material that has changed bicycle frames

carbon fibre composite frames are super lightweight with high rigidity and strength

strength to weight ratio permits the use of thinner walled tubular frames

compare ramp with block and tackle

Block and tackle:

uses mechanical advantage

operates in a small space

varied angle of effort

Ramp:

operates in most environments

simple to operate

parts easy to assemble

explain the in-service and manufacturing properties of ABS that make it suitable for an exterior shell of a helmet

In-service:

lightweight

relatively strong

relatively tough

relatively flexible

Manufacturing:

thermo-softening polymer

readily coloured

easily moulded to complex shape

lends itself to mass production

compare the use of polycarbonate and aluminium alloy for traffic light housing

polycarbonate is an electrical insulator, lighter weight for strength, chemically inert/non-corrosive, more complex moulded shapes

compare the use of composites like reinforced carbon and aramid fibre over the use of traditional materials such as aluminium alloys for applications like modern aircraft production

better strength to weight ratio

low corrosion characteristics

low drag surface

readily formed into complex shapes

good with adhesives as joining mechanisms

how has a certain field of engineering contributed to the manufacture of the modern bicycle

Production engineers:

mass production

interchangeability of parts

assembly lines

robotics

quality control

properties of polymers that make them suitable for cable insulation

high ductility and flexibility

what are iron-carbon alloys containing over 2% carbon known as

cast irons

what is the maximum percentage of carbon on ferrite

0.022%

The temperature and carbon content at which the eutectic reaction occurs in Fe-C equilibrium diagram

1147°C and 4.3%

approximately 0.8% C steel is called

eutectoid steel

toughness

the ability of a material to absorb energy up to fracture. it is equal to the area under the elastic and plastic region on a stress strain curve.

what principle do all simple machines ideally work on

work input equals work output

what are the different simple machines

screw (car jack), lever (seesaw, crowbar), incline plane, pulley (box and tackle), wedge, wheel and axel (gears, pinion and rack)

how can the mechanical advantage of a wedge be increased

make it longer

What is the purpose/role of a mechanical engineer? What are some examples of mechanical engineering projects?

Designs/analyses/creates/maintains physical machines that involve force and movement.

Anything that has mechanical aspects, e.g., electric generators, combustion engines, steam/gas turbines, fridges, AC systems, etc.

What is the purpose/role of a mechatronic engineer? What are some examples of mechatronic engineering projects?

Focuses on the integration of mechanical, electrical and software engineering to create computer-controlled machines/systems.

Anything that has mechanical, electrical and software aspects, e.g., robotic arms, aircraft control systems, elevators, etc.

What is the purpose/role of a biomechanical engineer? What are some examples of biomechanical engineering projects?

Designs/analyses/creates/maintains equipment and devices that relate to the human body.

Anything that has mechanical and biomedical aspects, e.g., artificial organs, limbs, as well as various sensors for diagnosis of conditions.

explain how a bicycle works

Basic machines: lever (pedals), pulley (chain), and wheel & axle

Used to allow people to travel faster while expending less energy (more efficiency)

coverts reciprocal motion into linear motion through the wheels, and provides a mechanical advantage at the crank

explain how a car jack works

Basic machines: screw (thread rod)

Used to allow people to lift a car while expending less energy (more efficiency)

Rotary input provides mechanical advantage at the fulcrum. This rotary input is converted into linear motion directed upwards.

explain how a crowbar works

Basic machines: first order lever

Used to allow people to pry things apart while using less energy (efficiency)

Iron or steel bar that is usually wedge-shaped at the working end

what are the four types of motion?

Linear -in a straight line

Rotary - circular motion (eg. a tyre)

Oscillatory - Circular motion except changing direction (so back and forth, like a pendulum)

Reciprocal - Linear motion back and forth, returning to original position each time

Mechanical Advantage

A measure of the force amplification achieved by using a tool, mechanical device or machine system; ideally, the device preserves the input power and simply trades off forces against movement to obtain a desired amplification in the output force; the model for this is the law of the lever

Velocity Ratio

The ratio of the distance moved by the point of application of the effort to the distance moved by the load in a simple machine.

Angle of repose

The maximum angle at which an object can be placed on an inclined plane without it starting to slide down the slope due to the force of gravity.

It represents the steepest angle the incline can have while still maintaining static equilibrium (i.e. the object is at rest and not accelerating)

low carbon steel

0.07% to 0.15%

Automobile body parts, Wire products

mild carbon steel

0.15% to 0.30%

2. Structural plates and sections, Stampings, Forgings, Seamless tubes, Boiler plates

medium carbon steel

30% to 0.60%

Forgings, Automotive components, including shafts, axles, gears, crankshafts and also Train rails, wheels & axles (only 0.40% to 0.60%)

high carbon steel

60% to 1.25%

High-strength spring materials, Wires, Cutting tools, Punches, Dies, Industrial knives

ultra high carbon steel

25% to 2.00%

Highly tempered non-industrial-purpose knives, Punches, Axles

stampings

Stampings are components/parts made from thin sheets/coils of carbon steel, that go through a stamping press or a die. The process involves applying pressure to the steel material, allowing it to take a specific shape

forgings

Forgings are components/products made by heating carbon steel to a high temperature and then shaping it using mechanical force, typically through hammering, pressing or rolling. Forging improves the strength and durability of steel by aligning its grain structure

boiler plates

Boiler plates are flat carbon steel plates that are specifically designed for use in the construction of boilers and pressure vessels. They are engineered to withstand high temperatures and pressures without deformation or failure.

punches

Punches are tools/devices that are used to create holes/indentations in materials. They have a pointed/sharp end for cutting/piercing through materials

dies

Dies are tools/moulds used for shaping or forming other materials. They are typically used in conjunction with a press or stamping machine to create specific shapes.

Polyethylene (PE)

Polyethylene is a widely used plastic with variations like HDPE and LDPE. It is known for its flexibility, chemical resistance, and good electrical insulating properties.

plastic containers, water pipes, cable insulation

polypropylene (PP)

Polypropylene is a common thermoplastic polymer known for its strength, toughness, and resistance to heat. It is also chemically resistant and has a low density.

laboratory equipment, electronics. automobile products

ABS

ABS is a tough, impact-resistant thermoplastic known for its strength and durability. It has good temperature resistance and can be easily moulded.

automotive body parts, household electronics & electrical appliances, business equipment

PLA

PLA is a biodegradable thermoplastic made from renewable resources like cornstarch or sugarcane. It is known for its environmental friendliness and ease of 3D printing.

automobile interiors, medical implants, screws, plates, pins, rods, mesh

PVC

PVC is a versatile thermoplastic known for its chemical resistance and durability. It can be rigid or flexible, depending on its formulation.

automobile parts, electronic and electrical equipment, water/waste drainage pipes, furniture

Nylon

Nylon is a synthetic thermoplastic known for its strength, toughness, and wear resistance. It can be used in various forms, including fibres and engineering plastics.

Gears, Rollers, Guides, Bearings, Wear Pads

What are the following terms: logical true, logical false, logical identity and logical negation

Logical true: 1

Logical false: 0

Logical Identity: A = A

Logical Negation: A --> ~A ("not A")

What % carbon is the eutectoid point and what Temperature is it at?

76% carbon 723 °C

What % composition is the eutectic point on a Lead Tin diagram and what Temperature is it at?

61.9% Tin and 183 °C

velocity ratio of an inclined plan

VR = 1/(sin(θ))

velocity ratio of a car jack

VR = (πD ) / (pitch)

velocity ratio of a spur gear

VR = (Number of teeth on driven gear)/(Number of teeth on driving gear)

or

(Angular vel of driver) / (Angular vel of driven)

or

(Diameter of driven) / (Diameter of driving)

velocity ration of worm gear

VR = (Number of teeth on worm gear) / (Number of threads (starts) on worm)

velocity ration of rack and pinion

VR = (Number of teeth on rack) / (Number of teeth on pinion)

velocity ratio of a belt

VR = (Diameter of driven sheave) / (Diameter of driving sheave)

microstructures of carbon steel

explain the concepts of mechanical advantage and work done in the context of a crowbar

A crowbar is a simple machine that increases mechanical advantage as a first class lever by increasing the velocity ratio. By having the pivot point closer to the load, the output force is increased due to the large distance to the input force. The user must push the crowbar handle a further distance than the distance moved by the load but this allows for a greater output force. Therefore a higher velocity ratio makes the mechanical advantage higher by amplifying the effort force.

engineers without borders

Engineers Without Borders focuses on providing sustainable engineering solutions to underserved communities, often in developing countries. Common community problems they address include:

Clean Water Access: Engineers design water filtration systems, solar-powered water pumps, and irrigation systems that are reliable and low-cost. Mechanical and mechatronic engineers often develop these systems to operate in off-grid areas.

Energy Poverty: Engineers create solar power systems, wind turbines, and biomass generators for remote communities. These machines provide renewable energy, improving living standards and enabling sustainable growth.

Sanitation: Inadequate sanitation leads to the spread of disease. Engineers design mechanized composting toilets or wastewater treatment systems that are affordable, eco-friendly, and tailored to community needs

human interface technologies

Human interface technologies are vital for creating devices that communities can use easily and intuitively. These technologies address problems like:

Accessibility for Disabled/Elderly: Human interface engineers design automated doors, grabbers, and smart home systems with intuitive interfaces that assist people with limited mobility. For example, a door that uses sensors and motors to automatically open without requiring physical strength can dramatically improve independence for the elderly.

Education and Healthcare: In underserved areas, telemedicine devices and digital education platforms are being implemented with easy-to-use interfaces. These systems bridge gaps in access to healthcare and education, providing remote medical consultations or educational resources with simple touch-screen interfaces or voice commands

Disaster Response

Natural disasters—such as earthquakes, floods, and hurricanes—create urgent community needs for rescue, recovery, and rebuilding. Engineers work on designing machines and systems that provide fast and effective solutions during disasters like:

Search and Rescue: In disaster zones, rapid response is critical. Rescue robots and drones can be deployed to search for survivors in dangerous environments. Drones equipped with cameras or thermal imaging sensors can identify people trapped under rubble or in remote areas.

Temporary Shelter: After a disaster, displaced populations require shelter. Engineers design modular, rapidly deployable housing units with mechanical systems for easy setup. These units often include energy-efÏcient features like solar panels or built-in water filtration to sustain displaced communities.

Disaster Communication Systems: Power and communication lines are often knocked out during disasters. Engineers develop portable communication towers, solar-powered radios, and satellite-based networks to restore communication in affected areas quickly, allowing communities to coordinate relief efforts and receive timely updates

areas of engineering expertise to benefit communities

1. Infrastructure Development

Roads and Bridges: Design and construct transportation networks to improve connectivity.

Water Supply Systems: Develop systems to provide clean drinking water.

Waste Management: Create efÏcient waste disposal and recycling systems.

2. Public Health and Safety

Medical Devices: Develop life-saving equipment like ventilators, MRI machines, and prosthetics.

Sanitation: Design sewage systems to prevent disease.

Safety Engineering: Implement safety protocols in buildings and public spaces

3. Environmental Protection

Renewable Energy: Develop solar, wind, and other renewable energy sources to reduce pollution.

Pollution Control: Design systems to reduce industrial emissions and manage waste.

Sustainable Design: Create eco-friendly buildings and products.

4. Technology and Innovation

Smart Cities: Integrate technology to improve urban living (e.g., smart traffic management, energy-efficient buildings).

Communication Systems: Develop reliable communication networks (e.g., 5G).

Automation and Robotics: Enhance productivity and efÏciency in various sectors.

5. Disaster Management

Early Warning Systems: Develop systems to predict and warn about natural disasters (e.g., tsunamis, earthquakes).

Resilient Structures: Design buildings and infrastructure that can withstand disasters.

Emergency Response: Create technologies for efÏcient emergency response and recovery.

6. Education and Empowerment

STEM Education: Promote science, technology, engineering, and math education to inspire future engineers.

Community Training: Provide technical training to communities for better employment opportunities.

Open-source Innovations: Develop and share open-source projects that communities can use and improve.

7. Economic Development

Industrial Engineering: Improve manufacturing processes to boost local economies.

Transportation: Design efÏcient logistics and transportation systems to enhance trade and commerce.

Agricultural Engineering: Develop technologies for better farming practices and increased food production.