Fuel cells and Batteries

1/35

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

36 Terms

primary cell

non re chargeable - due to the products slowly migrating away from the electrodes or are consumed by side reactions occurring in cell

alkaline cells

they contain no fluids

simple and light

cheap

short lasting

lower self discharge

higher energy density

Properties of secondary cells

Rechargeable- done by reversing reaction through attaching cell to an electrical charge which has a potential difference a little greater than that of the cell. Positive electrode of the charger to positive electrode of cell and negative electrode of the charger to negative electrode.

electrical energy is converted to chemical in cell, in order for it to work products formed must stay in contact with electrodes

These are made up of wet cells (flooded and liquid cells) and molten salt (liquid cells with different composition)

complex and heavy

expensive

long lasting

can withstand higher electrical currents

energy transformation in secondary cells

when cell discharges it acts as a galvanic cell converting chemical energy into electrical

when cell is recharged it acts as an electrolytic cell converting electrical to chemical energy

properties of fuel cells

cells that are constructed with a continuous flow of reactants allowing for a constant production of chemical energy

typically use hydrogen and oxygen gases as fuel and produce water

transform chemical energy into electrical energy

continuous electricity

efficient

a fuel cell using hydrogen produces electricity, water, heat and small amounts of nitrogen dioxide

anode of a leclanche cell

zinc case: Zn → Zn2+ + 2e

cathode of leclanche cell

carbon rod surrounded by paste: 2MnO2 + 2NH4+ + 2e → Mn2O3 + 2NH3 +H2O

lead-acid cell anode and cathode

anode: Made of lead and surrounded by sulfuric acid Pb + SO42- → PbSO4 +2e

Cathode: made of solid lead oxide: PbO2 + 4H+ + SO42- +2e → PbSO4 + 2H2O + 2e

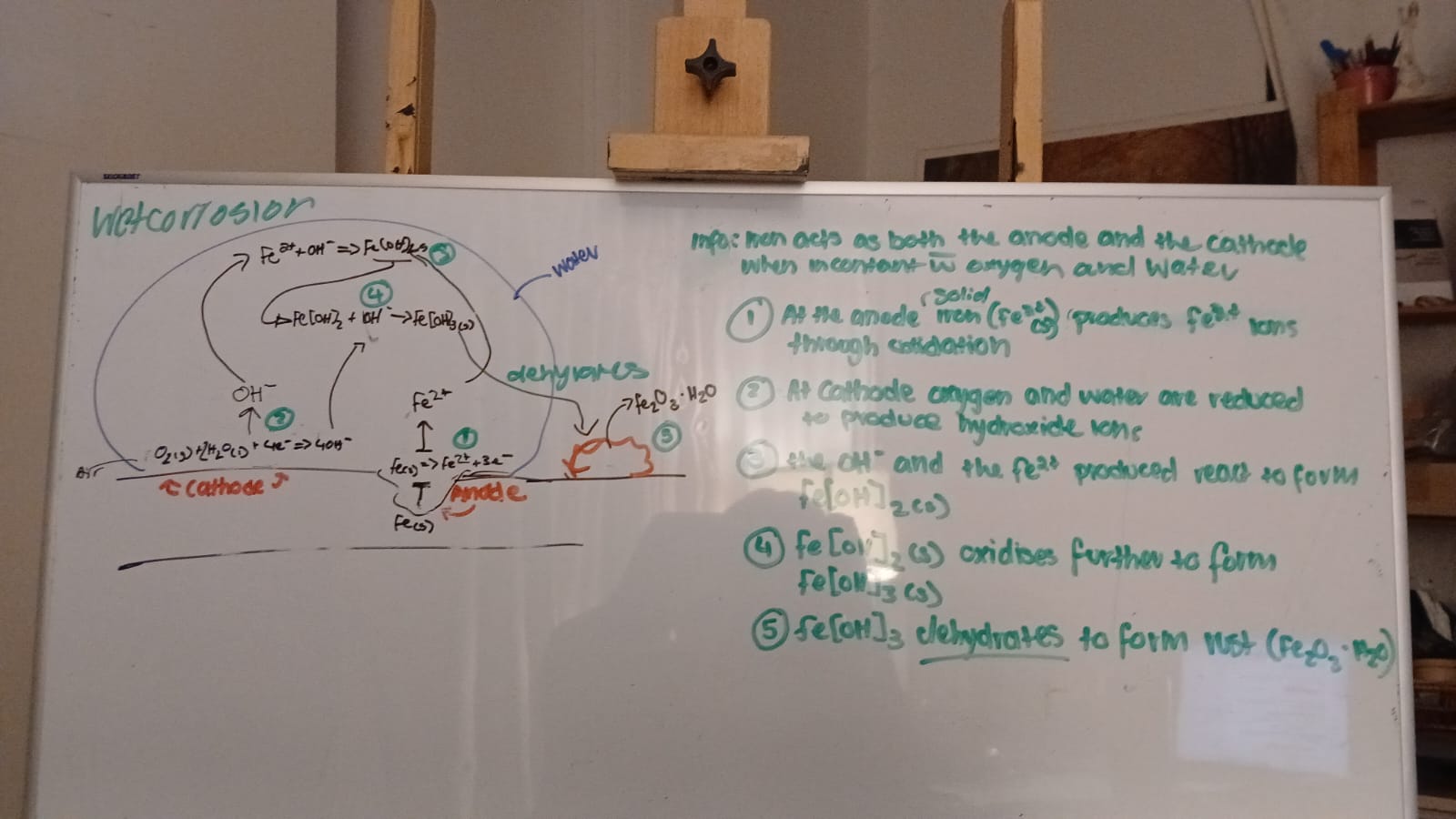

wet corrosion

at anodic site, electrons are released when iron atoms are oxidised to iron (II) ions

at cathodic site the electrons reduce oxygen gas and water to produce hydroxide ions

these combine to form insoluble iron (II) hyrdoxide

iron (II) hydroxide is readily oxidised by more oxygen in the air to form iron (III) hydroxide

Iron (III) hydroxide dehydrates to form rust, Fe2O3*H2O

types of methods to prevent corrosion

surface protection, galvanising, sacrificial anode and cathodic protection

Surface protection

prevents iron from coming into contact with oxygen and water

oil, grease, paint, plastic, other metals

advantages: cheap and easy, can be flexible, effective for as long as coat remains in tact

Disadvantages: coating must be reaplied when it deteriorates any scratch will leave metal susceptible

For less reactive metal coating: any scratch will mean the more reactive iron will act as the anode and will corrode faster

Galvanising

more reactive metal e.g. zinc is used as a coating

more reactive metal will corrode quickly and form a thin layer of zinc oxide which protects the iron

will protect the iron even if scratched since zinc is more reactive

Sacrificial anode

force iron to become the cathode by electrically connecting it to a more reactive metal which will act as the anode

Sacrificial anode will need to be replaced

Cathodic protection

Use of sacrificial anode may be improved by use of a DC electrical current

The (-) terminal of the DC power supply is electrically connected to iron making it the cathode of a galvanic cell

the (+) terminal is connected to the sacrificial anode, which could be made of iron in this scenario but typically a more reactive metal

Electrolysis

Forcing a non-spontaneous to occur reaction by using electricity

Rechargeable batteries act as a voltaic cell when discharging and a electrolytic cell when recharging

under what conditions are standard reduction potentials measured

solution concentration of 1.00 mol/L

temp of 298 K (25C)

pressure of 100 kPa

Why is the salt bridge needed?

it completes the circuit by allowing ions to move between the half cells

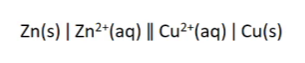

cell notation

anode on the left, cathode on the right

rules of standard reduction potentials

reduction half equation must be above oxidation half on the table

reduction is in the forward and oxidation in the reverse for reaction to occur

voltage (E^0) must be positive for it to be spontaneous

Hydrogen half cell

How are the standard equation found

by constructing a hydrogen half cell with that element

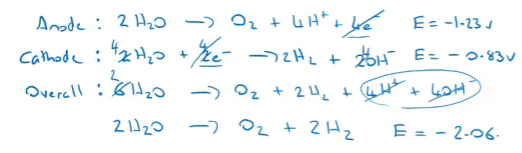

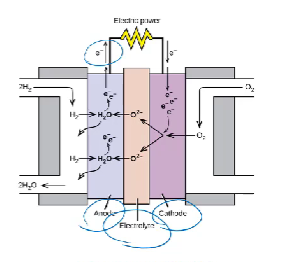

electrolysis of water

water can be split into hydrogen and oxygen gas

small amount of sulphuric acid is added to increase the number of ions in the solution, since pure water is a poor conductor

amount of Hydrogen gas produced is 2x the amount of Oxygen gas produced

H2 is produced at the cathode and O2 is produced at the anode

what makes electrolysis of Aqueous solutions more complicated than molten

water can be oxidised or reduced instead of the ions of the salt

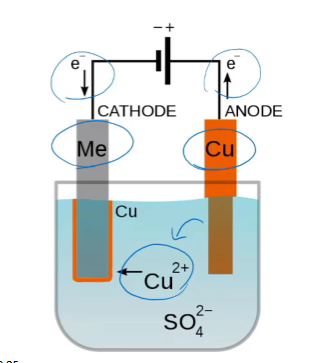

electroplating

electrolysis can be used to coat a thin layer of a metal over another metal

electrorefining of copper

electrolysis of aqueous solutions rules

the oxidation reaction is above the reduction

the oxidation reaction goes in reverse

reduction reaction goes forward

types of voltaic cells

primary and secondary cells

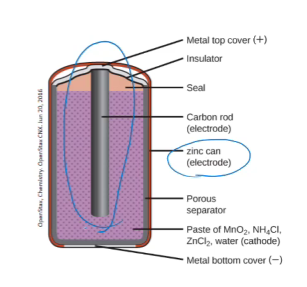

dry cell (zinc-carbon cell or leclanche cell)

primary cell

the zinc case acts as the anode

the cathode is a rod made from carbon surrounded by a paste of MnO2, ZnCl2, NH4Cl and powdered carbon

initial overall voltage is 1.5 volts

Disadvantage of the dry cell

since the zinc case takes part in the reaction, it will deteriorate and eventually leak

also ammonium ions are weakly acidic which causes further deterioration of the zinc

can’t be reversed because running the current through it in reverse will cause potentially dangerous side reactions which can produce gases (producing gases in a confined space will cause an explosion

alkaline battery

primary cell

Anode is a zinc rod: Zn + 2OH- → ZnO +H2O + 2e

Cathode is the steel casing: 2MnO2 + H2O + 2e → Mn2O3 + 2OH

similar voltage to dry cells but can sustain higher currents

small and inexpensive

cannot be recharged as products of the discharge reaction can move away from the electrodes and attempts to recharge can produce gases or cause the case to rupture

Lead - acid battery (car battery)

secondary cell (can be recharged)

made up of 6 cells, able to produce 2 volts each therefor the total volatge of the battery = 12 volts

Anode is made up of lead surrounded by sulphuric acid: Pb + SO4²→ PbSO4 + 2 e

Cathode is made of solid lead oxide: PbO2 + 4H+ + SO4² + 2 d → PbSO4 + 2 H2O

because both reactions produce solid PbSO4 which remains on the electrodes, the battery can be effectively recharged by applying a voltage of at least 12v

impractical due to their size and weight

contains large amounts of lead and sulphuric acid, both of which are quite toxic, so they must be handled with care and disposed of properly

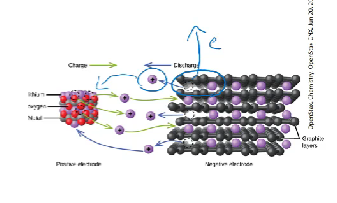

Lithium Ion Battery

secondary cell (can be recharged)

Anode is made from lithium ions attached to a thin layer of graphite. this is called intercalation

lithium ions (having a positive charge) are attached to the delocalised electrons in the graphite

combination of lithium ions with atoms of carbon makes them behave like a lithium metal (a strong reducing agent) with a high tendency to donate electrons and become cations

takes at least 6 carbon atoms per lithium ion for this to work perfectly

electrolyte is an organic solvent containing dissolved lithium ions

function: as battery discharges the lithium ions from the graphite anode move through the electrolyte to the cathode, releasing electrons through the external circuit and producing a voltage of about 3.7 v

Anode: LixC6 → X li+ + X e- + C6

Cathode: Li1-xCoO2 + XLi+ Xe- → LiCoO2

Recharge: exact opposite process occurs with electrons moving to graphite from the external circuit which attracts lithium ions back to graphite

Disadvantage:

expensive due to complexity and need for purity

solid oxide fuel cell

Anode: 2 H2 + 2 O2- → 2 H2O + 4 e

Cathode: O2 + 4e- → 2O²

disadvantage of fuel cells

poor reliability over long periods of time

expensive

producing hydrogen gas requires a lot of electricity

about 30% efficient

IPHE

Battery definition

two or more cells together is the traditional definition

dry corrosion

example: the patina that forms on copper, copper reacts with the air to form copper oxide

2Cu(s) + O2(g) → 2CuO(s)