Welding (L18, 19, 20)

1/70

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

71 Terms

Joining

welding, brazing, soldering, and adhesive bonding

(processes form a permanent joint between parts)

Assembly

mechanical methods of fastening parts together

Welding

a joining process where material is coalesced at contact surfaces by the application of suitable temperature and/or pressure

weldment

the single entity formed by welded components

Fusion welding

joining process that melt the base metals

a filler material is often added to provide bulk and add strength to the joint

most common

solid state welding

joining processes in which the application of pressure alone or a combination of heat and pressure is used

if heat is used, temp is below melting point of metals being welded

no filler metal added

Arc Welding (AW)

melting of the metals is accomplished by an electric arc (fusion welding) most common

Two types of Arc Welding

consumable and non- consumable

Resistance welding (RW)

melting is accomplished by heat generated from resistance to an electrical current between faying surfaces held together under pressure (fusion)

Oxyfuel gas welding (OFW)

melting is accomplished by an oxyfuel gas such as acetylene (fusion)

Diffusion welding (DFW)

coalescence is by solid state fusion between two surfaces held together under pressure at elevated temperature (solid-state)

friction welding (FRW)

coalescence by heat of friction between two surfaces (solid-state)

Ultrasonic Welding (USW)

coalescence by ultrasonic oscillating motion in a direction parallel to contacting surfaces of two parts held together under pressure (solid-state)

Welding pros

provided permanent joint

can be stronger than base material

economic way to join part

mobile: not restricted to factory environment

Welding cons

done manually

requires skilled labor

dangerous/hazardous

molten metal

gas welding = fire hazard

electrical shock

UV radiation bad for eyes

smoke and fumes

defects

permanent joint

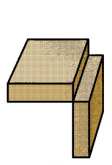

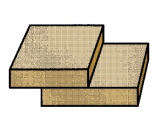

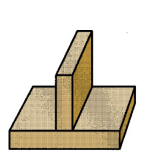

What type of joint is shown?

Butt joint

What type of joint is shown?

corner joint

What type of joint is shown?

lap joint

What type of joint is shown?

Tee Joint

What type of joint is shown?

Edge Joint

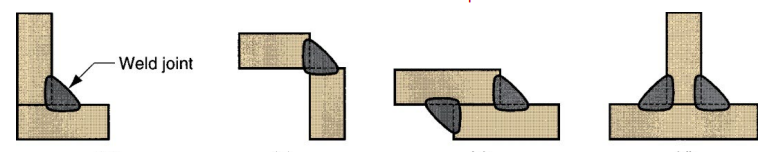

What type of weld is shown?

fillet weld

Fillet Weld

Used to fill in the edges of plates created by corner, lap, and tee joints

What type of weld is shown?

groove weld

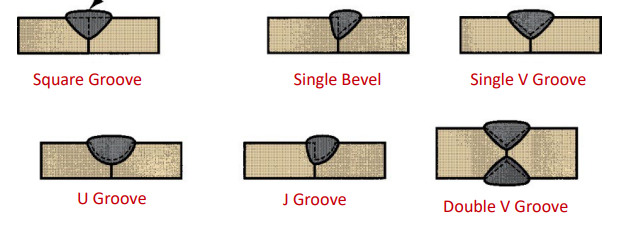

Groove Weld

Usually requires part edges to be shaped into a groove to facilitate weld penetration

What type of weld is shown?

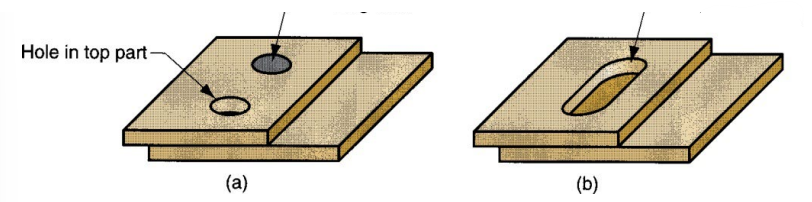

plug/slot wled

Plug/Slot weld

Is used for attaching flat plates using one or more holes or slots in the top part and then filling with filler metal

What type of weld is shown?

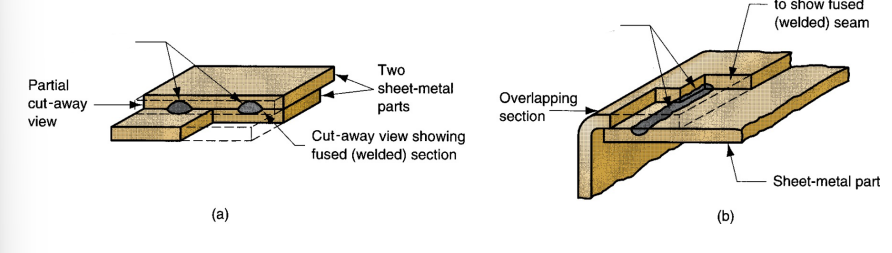

spot/seam weld

Spot/seam weld

Fused section between surfaces of two sheets or plates (typically used on lap joints)

What type of weld is shown?

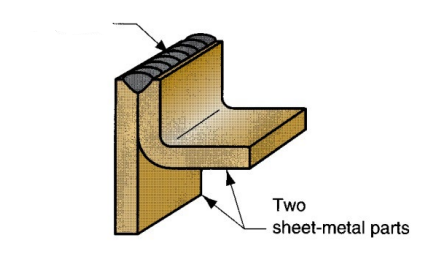

flange weld

Flange Weld

Is made on the edges of two or more parts, at least one of the parts has a flange

What type of weld is shown?

surface weld

Surface weld

Used not to join parts but to deposit filler metal onto surface of a base part

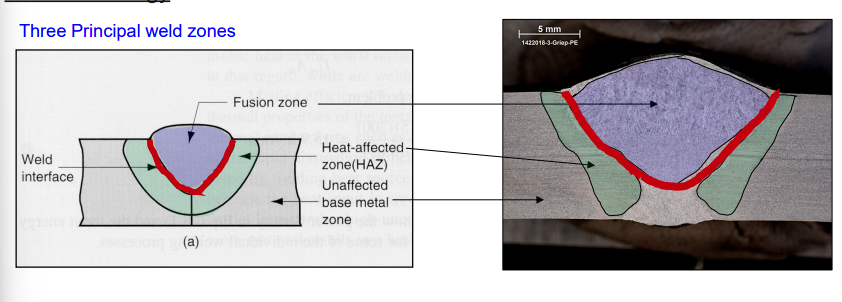

What are the 3 principal weld zones?

Fusion zone (purple)

Weld interface (red)

heat affected zone (green)

Fusion zone

mixture of base & filler metal that fully melted during the welding process

Weld interface

melted or partially melted base metal that immediately re-solidified. Contains

no filler metal

Heat affected zone

base metal that did not melt but was heated above recrystallization temp.

Effects of cold working lost. Region where welding failures often occur

Electric Arc Welding

coalescence of metals achieved by the heat of an electric arc between an electrode and the work

• Energy source is an electric arc

• Very widely used process

• Stick, MIG & TIG welding

Energy Beam Welding

Uses highly focused energy beams

• Good depth of penetration, precise, low heat application

• Laser & E-Beam welding

Resistance Welding

Uses heat generated by resistance to electrical current

• Widely used for sheet metal welding

• Spot, Seam & Projection Welding

OxyFuel Gas Welding

Energy source provided by a flame

• Most common is oxyacetylene welding

Electrode

Source of electric current.

• Brought into close proximity of workpiece

• Consumable or Nonconsumable

• Typically rod or wire

Arc Shielding

protects melt pool from oxygen to prevent oxidation

• Mechanical properties of weld joint degrades significantly without shield

• Argon & Helium gases are most common

• Can be provided by flux coating as well

• Flux hardens as slag and must be removed later by chipping or brushing

Power Source

Provides electrical energy of sufficient voltage and current (the “welding machine”)

Electric Arc

Discharge of electrical energy (current) across a gap

Consumable Electrode

consumed during welding process. Source of filler metal in arc welding

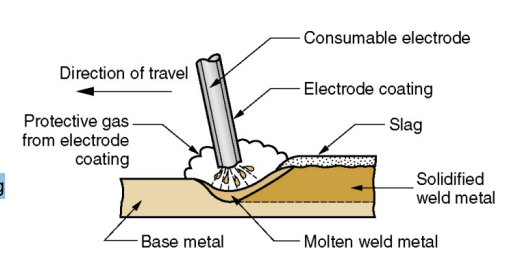

SMAW – Shielded Metal Arc Welding

GMAW – Gas Metal Arc Welding

SAW – Submerged Arc Welding

Non-Consumable Electrode

not consumed during welding process. Filler metal must be added separately

if it is added

GTAW – Gas Tungsten Arc Welding

PAW – Plasma Arc Welding

High Energy Beam (non-arc)

Electron Beam Welding

Laser Beam Welding

Shielded metal arc welding (Stick Welding)

• Consumable electrode

• Flux coated rod (~3/32” diam x 18” long)

• Flux produces protective gas around weld pool

• Slag keeps oxygen off weld bead during cooling

• General purpose welding—widely used

• Thicknesses 1/8” – 3/4”

• Manual process

• Portable Process

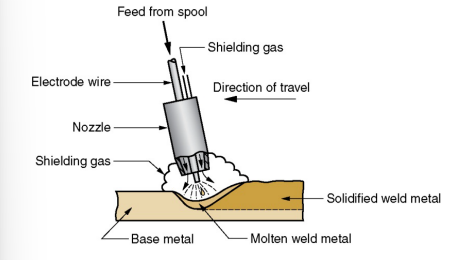

Gas metal arc welding (MIG Welding)

MIG - Metal Inert Gas welding

• Consumable wire electrode

• Shielding provided by gas (argon/helium)

• Double productivity of SMAW

• Continuous process

• Doesn’t generate slag, therefore ideal for multiple welding passes

• Easily automated

(Used in lab)

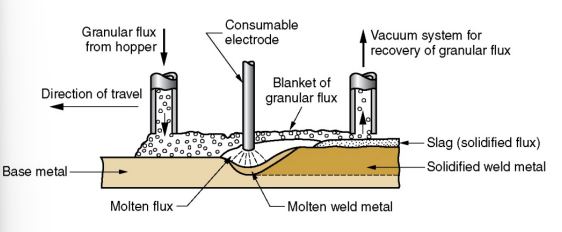

Submerged Arc Welding

• One of the 1st arc welding processes to be automated

• Consumable wire electrode

• Can have multiple wires to increase metal deposition

• Shielding provided by flux granules

• Low UV radiation, fumes, sparks & spatter

• Flux acts as thermal insulator • Automated process

• High speed & quality (4 – 10x SMAW)

• Suitable for thick plates

Gas Tungsten Arc Welding (TIG Welding)

• TIG - Tungsten Inert Gas

• Non-consumable electrode

• With or without filler metal

• Shield gas usually argon

• Used for aluminum and stainless steel

• Most expensive, highest quality

• No weld spatter

• Little to no post weld cleaning because

flux isn’t used

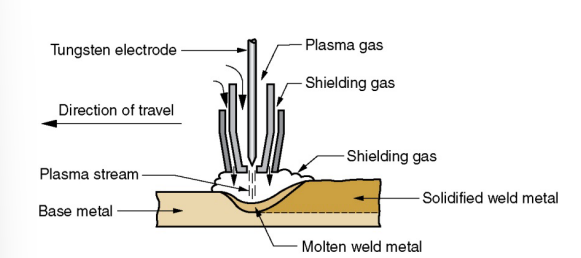

Plasma Arc Welding

Special form of Gas Tungsten Arc Welding (GTAW) in which a constricted plasma arc is directed at weld area

Non-consumable

• Tungsten electrode is contained in a specially designed nozzle that focuses a high velocity stream of inert gas (argon) into arc region

• Forms a high velocity, intensely hot plasma arc stream

• Temperatures in PAW reach 20,000C (36,000F), due to constriction of arc, producing a plasma jet of small diameter and very high-power density

• Hot enough to melt any known metal!

Advantages of PAW

• Good arc stability

• Better penetration control

• High travel speeds

• Excellent weld quality

Electron Beam Welding (EBW)

Fusion welding process in which heat for welding is provided by a highly-focused, high-intensity stream of electrons striking the work surface

Electron beam gun operates at:

High voltage (e.g., 10 to 150 kV typical) to accelerate electrons

Beam currents are low (milliamps)

Power in EBW not exceptional, but power density is very high

Laser Beam Welding (LBW)

Fusion welding process in which coalescence is achieved by energy of a highly concentrated, coherent light beam focused on joint

LBW normally performed with shielding gases to prevent oxidation

Filler metal not usually added

High power density in small area

So LBW often used for small parts

LBW vs EBW

No vacuum chamber required for LBW

No X-rays emitted in LBW

LBW not capable of the deep welds and high depth-to-width ratios of EBW

Maximum LBW depth = ~ 19 mm (3/4 in), whereas EBW depths = 50 mm (2 in)

Solid State Welding vs Fusion Welding

If no melting, then no heat affected zone, so metal around joint retains original properties

Many SSW processes produce welded joints that bond the entire contact interface between two parts rather than at distinct spots or seams

Some SSW processes can be used to bond dissimilar metals, without concerns about relative melting points, thermal expansions, and other problems that arise in FW

Types of Solid State Welding

Forge welding

Cold welding

Roll welding

Hot pressure welding

Diffusion welding

Explosion welding

Friction welding

Ultrasonic welding

Friction Welding

• One part rotated, one stationary

• Stationary part forced against rotating part

• Friction converts kinetic energy to thermal energy

• Metal at interface melts and is joined

• When sufficiently hot, rotation is stopped & axial force increased

Diffusion Welding

• Parts forced together at high temperature (< 0.5Tm absolute) and pressure

• Heated in furnace or by resistance heating

• Atoms diffuse across interface

• After sufficient time the interface disappears

• Good for dissimilar metals

• Bond can be weakened by surface impurities

Soldering and Brazing

Processes in which filler metal is melted & distributed within faying surfaces of a joint by capillary action.

• Only filler metal is melted, not base metal

• Lower temperatures than welding

• Metallurgical bond formed between filler & base metals

Strength of joint typically

stronger than filler metal itself

weaker than base metal

• Gap at joint important (0.001 – 0.010”)

• Surface cleanliness is important

• Flux used to enhance flowability of filler metal

Pros and Cons of Soldering and Brazing

Can join dissimilar metals

Less heat - can join thinner sections (relative to welding)

Excessive heat during service can weaken joint

Brazing

• Filler metal (Al, Mg & Cu alloys) melt Temp Tm > 840 F

• Many types of joint geometries possible

• Joint gap affects material flow & joint strength (see graph )

• Heat application can be via flame or in a furnace

• Multiple methods of applying filler metal

Solder

Filler metal

Flux

used to clean joint and prevent oxidation

Tinning

pre-coating with thin layer of solder

Solder Paste Functions

– supply solder material to the soldering spot,

– hold the components in place prior to soldering,

– clean the solder lands and component leads

– prevent further oxidation of the solder lands.

PTH

Pin-Through-Hole Connectors

SMT

Surface Mount Technology

Automates Reflow Soldering

• Solder/Flux paste mixture applied to PCB using screen print or similar transfer method

• PCB assembly then heated in “Reflow” oven to melt solder and secure connection

slag

hardened flux