14 SQ: Fundamentals of Material Processes

1/8

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

9 Terms

What is a “process“?

Series of actions that produce something or that lead to a particular result

Some steps are necessar to fulfill the primary function of the product, while others are necessary to make sure that the process runs smoothly

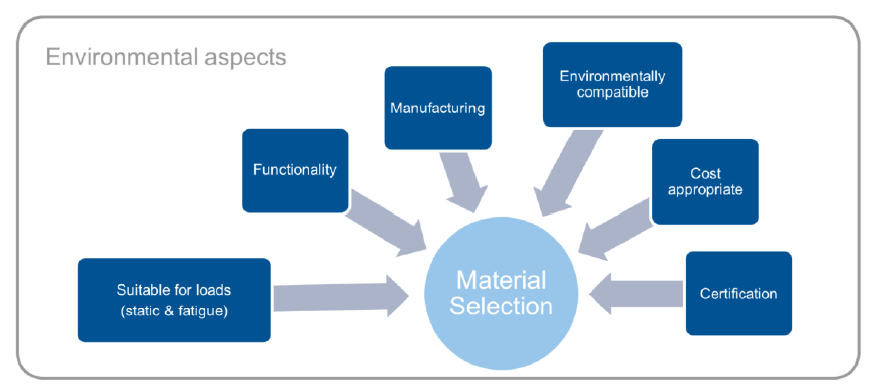

What are two factors not related to material properties that have to be considered when selecting a material for aerospace applications?

Suitable for loads (static and fatigue) (Material related)

Functionality (Material/Case related)

Manufacturing

Environmentally compatible

Cost appropriate

Certification

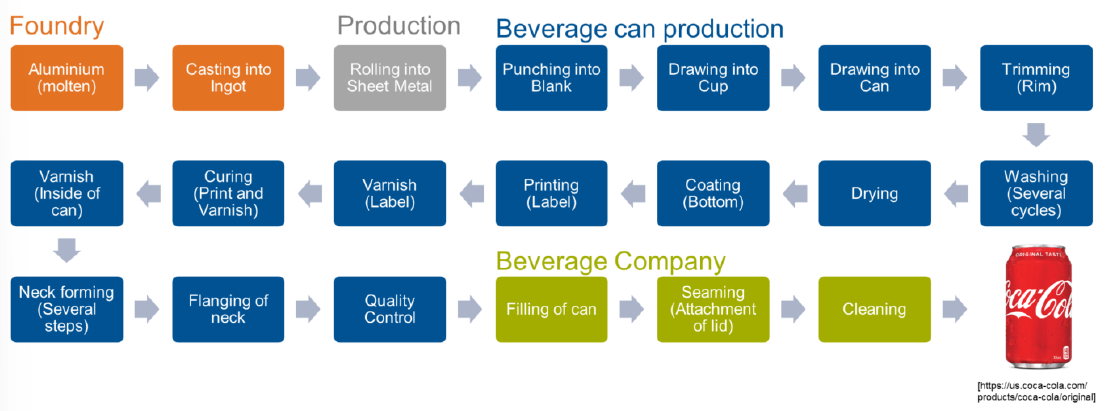

Describe a multi-step production process and how it could be used to produce a part of your choice

Process: beverage can

Melting and casting of Al → Punching → Drawing → Triming → Washing → Drying → Coating → Printing → Varnishing → Curing → Varnishing → Neck forming → Flanging → Quality control → Filling → Seaming → Cleaning

Name different types of material processes and their distinctive attributes in terms of cohesion (acc. DIN 8580)

Primary Shaping: creating cohesion from shapeless material

Forming: maintaining cohesion, plastically deforming a solid body

Separating: reducing cohesion

Joining: local increase of cohesion

Coating: local increase of cohesion

Property Modification:

In which case could a process be assigned to different DIN 8580 groups?

Depending on cohesion (¿?)

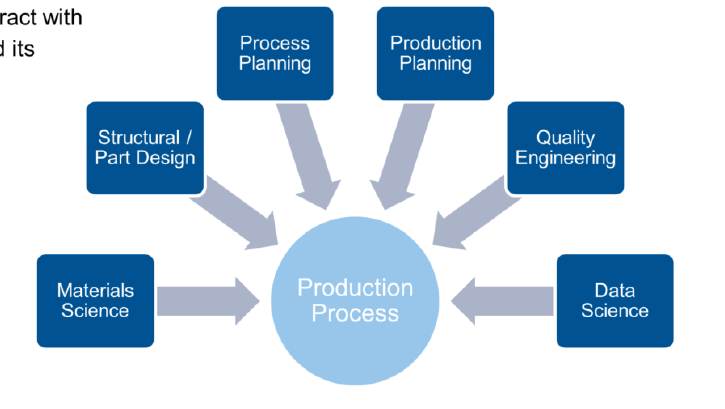

Name disciplines that interact with materials process development and briefly explain points of interaction (6)

Materials Science: at the material properties

Structural / Part Design: design for manufacturability (guidelines); utilization of new materials and processes

Process Planning: material flow and logistics; sequencing of steps; continuous/discontinuous production; cycle times; equipment requirements; material demands

Production Planning: staff; shifts; which machines; material supply; purchased/pre-produced parts; equipping plans

Quality Engineering: certification; qualification; quality assurance; process monitoring; audtis; customer complaints. FMEA (Failure Modes and Effects Analysis) and FAI (First Article Inspection); repeatability; productivity

Data Science: gathering of large amount of real-time data; complex analysis and simulation; optimization of production

What is Industry 4.0 and what tools does it provide that can help optimize production processes? (5)

Industry 4.0: implementation of big-data from sensors to analyze and optimize production

Tools:

Digital Supply Chain: digital reproduction of supple chains with e.g. sensors, trackers, thermometers, etc.

Intelligent Sensor Networks: decentralized, interconnected sensors to caputre and process relevant data from production

Data Mining/Machine learning: statistical analysis of data to find correlations and trends that can be used for Digital Twins

Digital Twin: digital representation of a part of the system to predict its behavior, ideally with AI

Cyber-Physical Systems: interaction of Digital and Physical and components using all avialable data to perform a task

What specific challenges come into play when selecting materials for Advanced Air Mobility (AAM = Air Taxis) applications?

Materials Selection:

Heavy batteries

Process selection and Production Planning:

Comparatively high-rate production

Low airframe cost for competitive market

Qualification:

Ambitious Entry into Service (EIS)

How can these challenges be met (challenges of selecting materials for AAM)?

Materials Selection:

High strength materilas such as composites

Part design

Process selection and Production Planning:

Factory and process planning

Escalable pilot facilities

Automation in all processes → Repeatability

Digital manufacturing (Industry 4.0)

Qualification:

Use pre-qualified materials and processes